Contents

1. Getting Started ......................................................................................... 8

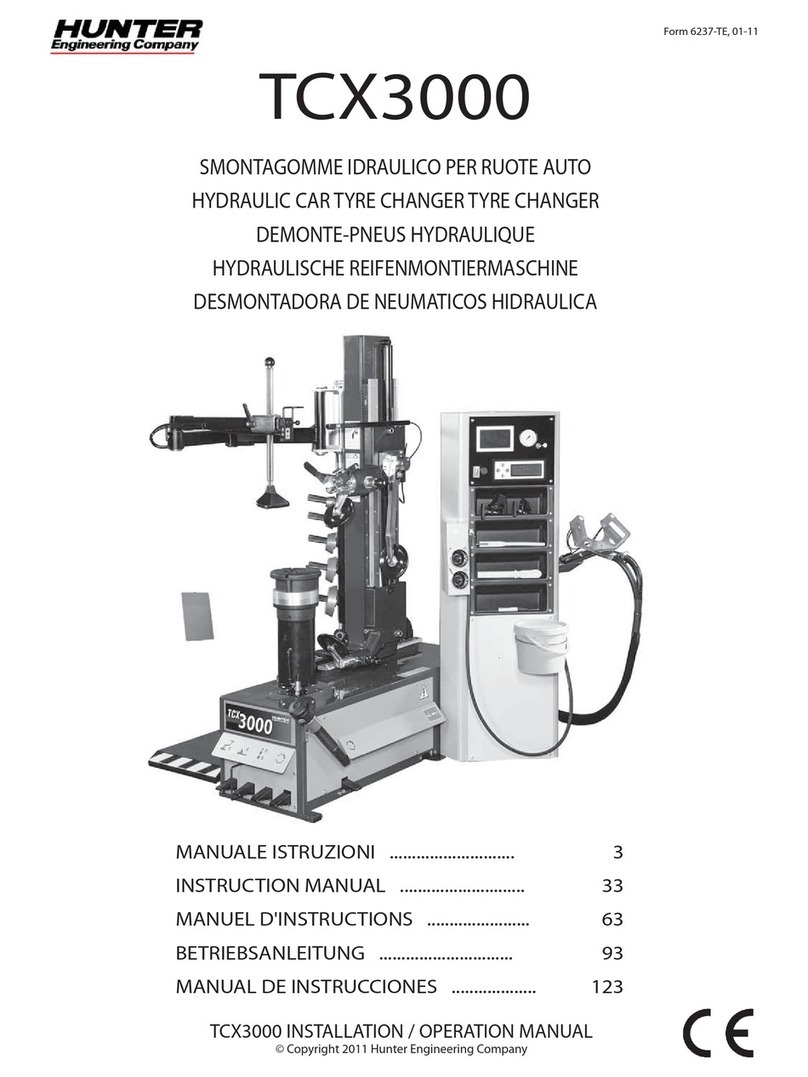

1.1 Introduction........................................................................................................ 8

1.1.a – PURPOSE OF THE MANUAL...................................................... 8

1.2 For Your Safety ................................................................................................. 9

Hazard Denitions ................................................................................... 9

1.3 General Warnings and Instructions .................................................................. 9

Electrical Indications .............................................................................. 13

Specic Precautions/Power Source....................................................... 14

Equipment installation and service......................................................... 14

Equipment specication ......................................................................... 14

Explanations of symbols ........................................................................ 14

1.3.b. Air Pressures................................................................................ 15

1.4 Special Rim/Tire Considerations ..................................................................... 15

1.5 Intended Use of The Machine ......................................................................... 15

1.6 Employee Training........................................................................................... 16

1.7 Pre-Use Checks .............................................................................................. 16

1.8 During Use ...................................................................................................... 16

1.9 Control Pedal Congurations ......................................................................... 17

1.10 Wheel Rotation Pedal ................................................................................... 17

1.11 Tire Bead Breaker Shovel control.................................................................. 17

1.12 Wheel Clamping Pedal.................................................................................. 18

1.13 Air Ination Pedal .......................................................................................... 18

1.14 Moving Parts ................................................................................................. 19

1.15 Inator and Pressure Limiter ........................................................................ 19

1.16 Mount / Demount Head ................................................................................. 20

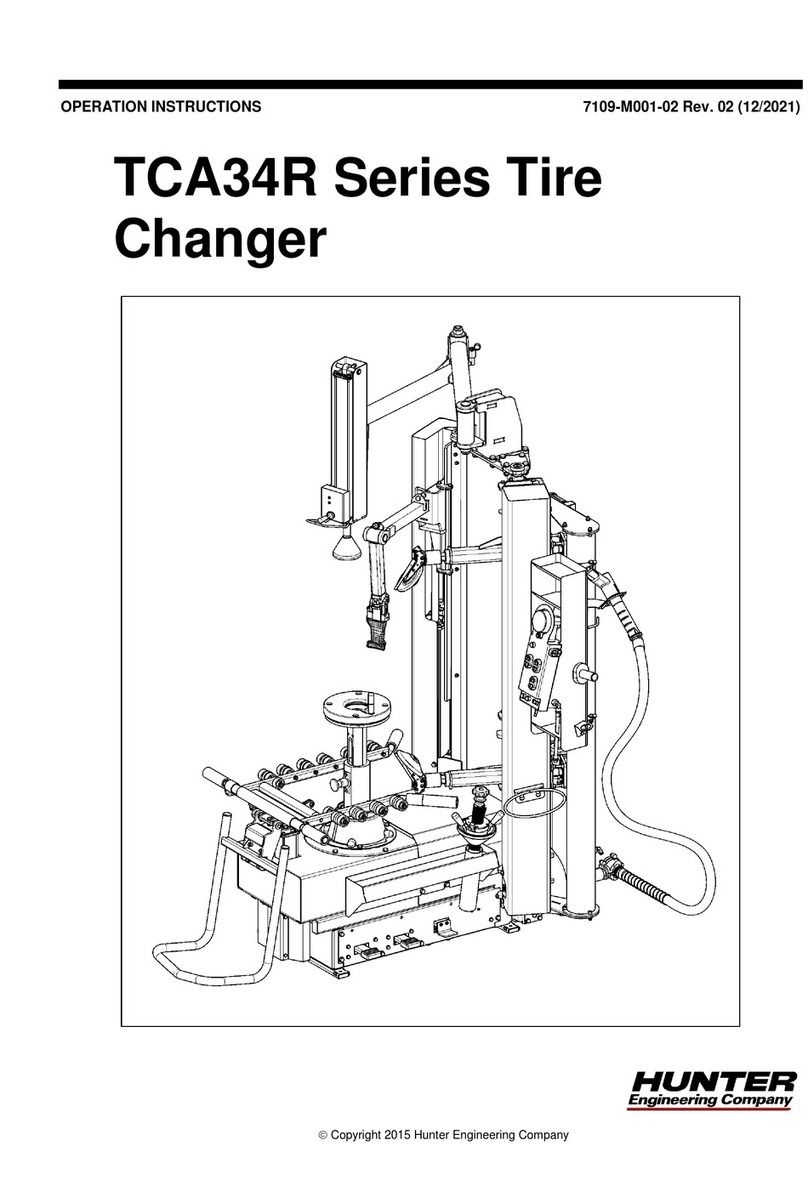

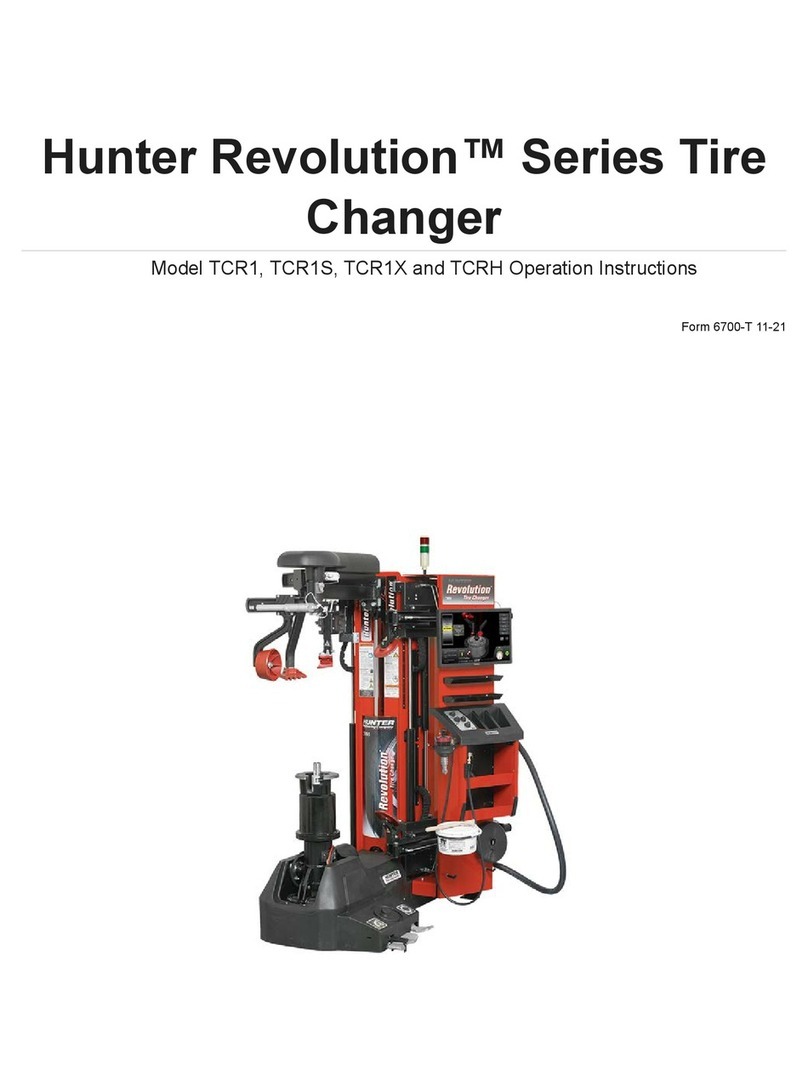

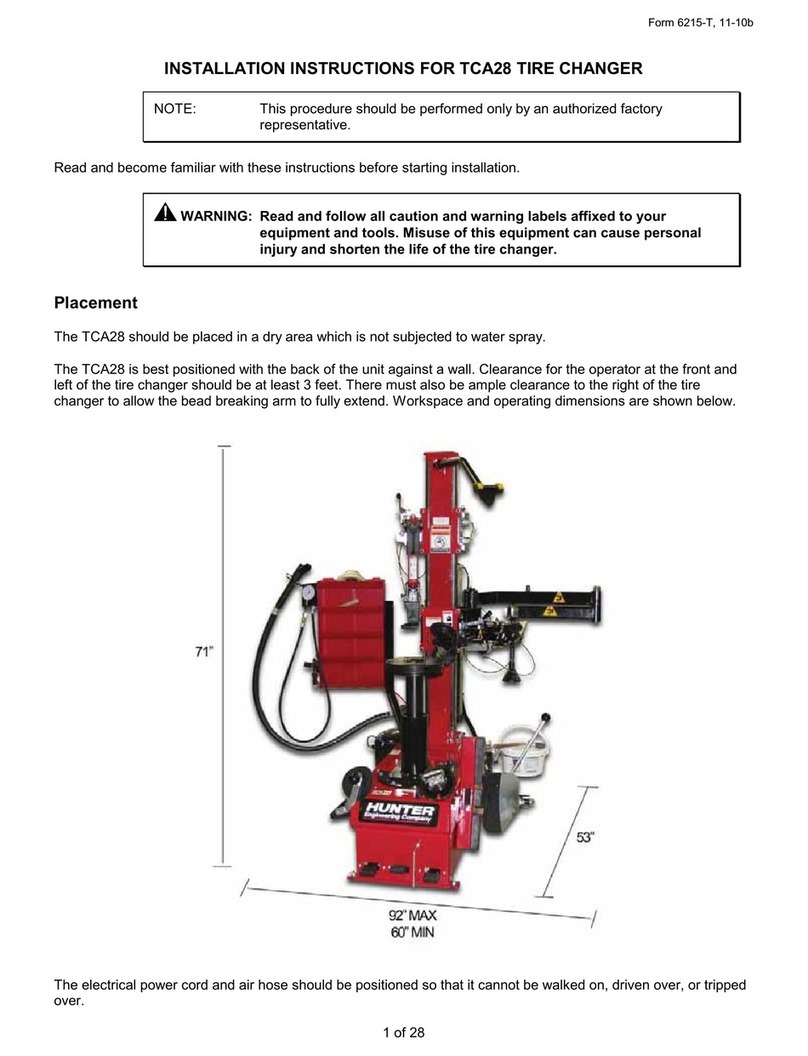

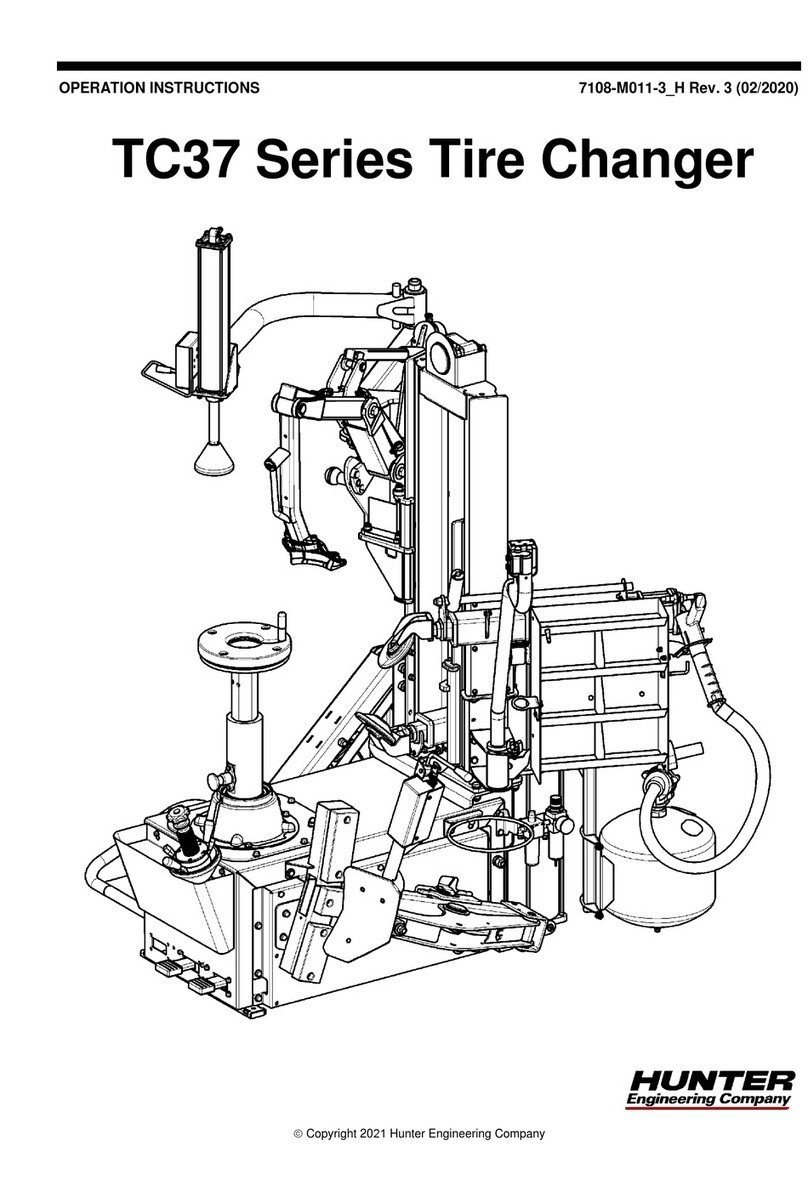

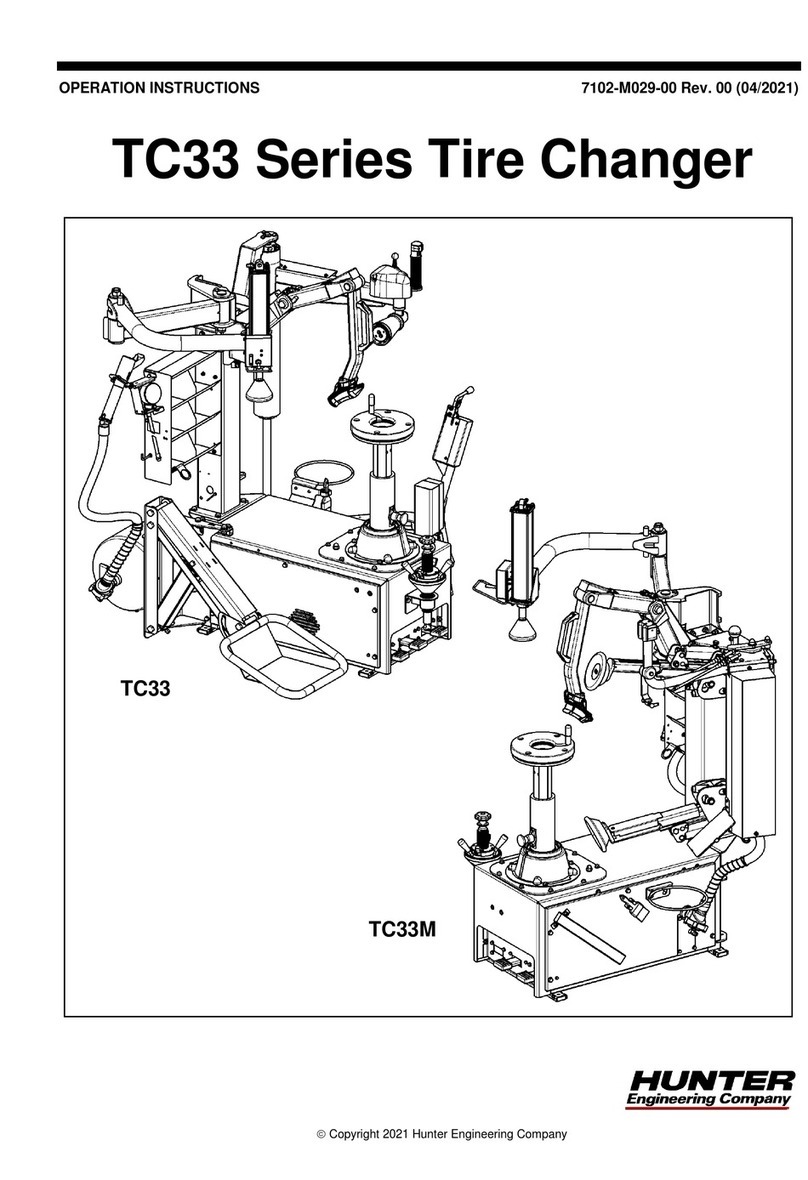

1.17 Equipment Components................................................................................ 21

2. Basic Procedures .................................................................................. 22

2.1 Bead Breaking................................................................................................. 22

2.2 Placing Wheel on Tire Changer ...................................................................... 23

Clamping the Wheel from Inside of Rim - Steel Rims ........................... 23

Clamping the Wheel from Outside of Rim - Alloy Rims ......................... 23

2.3 Demounting Standard Tire from Rim .............................................................. 25

Standard Mount / Demount Head ......................................................... 25

PLASTIC PROTECTORS BEAD LEVER .............................................. 25

Leverless version ................................................................................... 26

Lockable arm.......................................................................................... 26

Demount the Outer Bead ....................................................................... 27

Difcult Tires .......................................................................................... 29

Leverless / Demount Head - Bottom Bead............................................. 31

2.4 Mounting Standard Tire to Rim ....................................................................... 32

Mount a standard tire to rim ................................................................... 33

Difcult tires............................................................................................ 34

2.5 Tire Ination .................................................................................................... 35

Special procedure .................................................................................. 36

2.6 Removal of Wheel from Tire Changer ............................................................ 38

2.7 Optional Clamping Jaw Extensions................................................................. 39

3. Advanced Procedures ........................................................................... 40

3.1 Advanced Bead Breaking Procedures ............................................................ 40

Bead Breaking “AH” Wheels (e.g. BMW M3, M5, Some Porsches, Range

Rover, Lancia, etc.) ............................................................................... 40

Bead Breaking “AH” Wheels as follows: ............................................... 40