Contents

1. GETTING STARTED........................................................................................1

1.1 Introduction.................................................................................................................1

1.2 For Your Safety ...........................................................................................................1

Hazard Definitions.................................................................................................. 1

IMPORTANT SAFETY INSTRUCTIONS............................................................... 1

1.3 Control Pedals............................................................................................................. 3

1.4 Wheel Rotation Pedal .................................................................................................4

1.5 Tire Bead Breaker Shovel Pedal (Non-PowerOut versions)................................... 4

1.6 Tire Bead Breaker Shovel - PowerOut Versions......................................................4

1.7 Wheel Clamping Pedal ............................................................................................... 5

1.8 Column Rotation Pedal ..............................................................................................5

1.9 Air Inflation Pedal .......................................................................................................5

1.10 Inflator and Pressure Limiter...................................................................................6

1.11 Mount / Demount Head.............................................................................................6

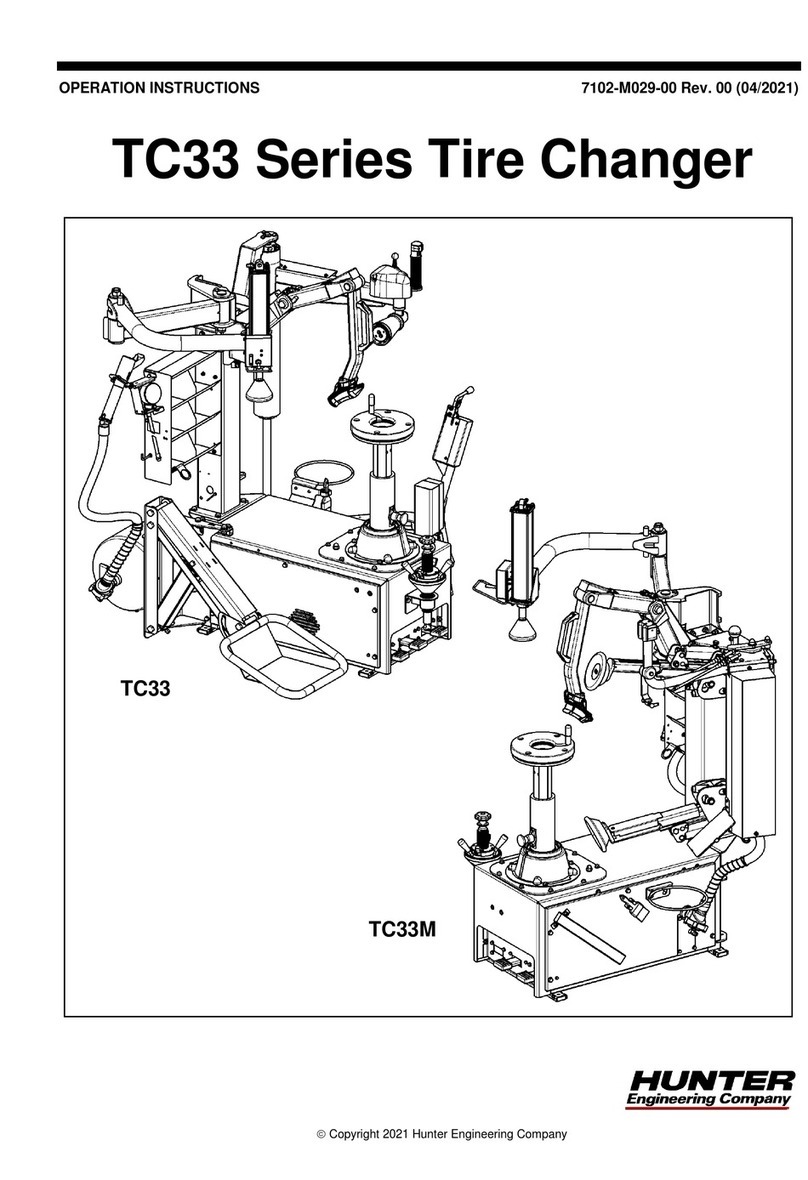

1.12 Equipment Components ..........................................................................................7

TCX575 Tire Changer Components ...................................................................... 7

Bead Press System (BPS) Components ............................................................... 8

TCX575 Tire Changer Decal Locations ................................................................. 9

2. BASIC PROCEDURES ..................................................................................11

2.1 Bead Breaking...........................................................................................................11

PowerOut Versions .............................................................................................. 11

Non-PowerOut Versions ...................................................................................... 12

2.2 Placing Wheel on Tire Changer...............................................................................13

Clamping the Wheel from Inside of Rim - Steel Rims ......................................... 13

Clamping the Wheel from Outside of Rim - Alloy Rims ....................................... 13

2.3 Demounting Standard Tire from Rim...................................................................... 13

Top Bead Demounting ......................................................................................... 13

Difficult Tires ........................................................................................................ 15

Precautionary Notes ............................................................................................ 17

Bottom Bead Demounting with Tool Head........................................................... 17

Bottom Bead Demounting with Disc .................................................................... 18

Difficult Tires.................................................................................................. 20

Alternate Procedure ............................................................................................. 20

Using the Bead Lever .................................................................................... 20

2.4 Mounting Standard Tire to Rim ...............................................................................22

Mount a standard tire to rim as follows: ............................................................... 22

2.5 Match Mounting ........................................................................................................ 25

2.6 Tire Inflation...............................................................................................................26

2.7 Removal of Wheel from Tire Changer.....................................................................27

3. ADVANCED PROCEDURES .........................................................................28

3.1 Advanced Bead Breaking Procedures....................................................................28

Bead Breaking “AH” Wheels (e.g. BMW M3, M5, Some Porsches, Range Rover,

Lancia, etc.).......................................................................................................... 28

Bead Loosen “AH” Wheels as follows: .......................................................... 28

4. MAINTENANCE, CALIBRATION AND REPLACEMENT PARTS.................31

4.1 Maintenance Schedule.............................................................................................31

4.2 Mount/Demount Head Assembly.............................................................................32

Mount/Demount Head Calibration ....................................................................... 32

Horizontal Adjustment of the Tool Head........................................................ 33

Radial Adjustment of the Tool Head.............................................................. 33

Adjusting the Vertical Gap............................................................................. 34

Adjusting the Horizontal Gap......................................................................... 34

4.3 Replacement Parts....................................................................................................36

5. GLOSSARY....................................................................................................37