Page 1

Contents

Safety and Warning Advice + General Advice .... 2

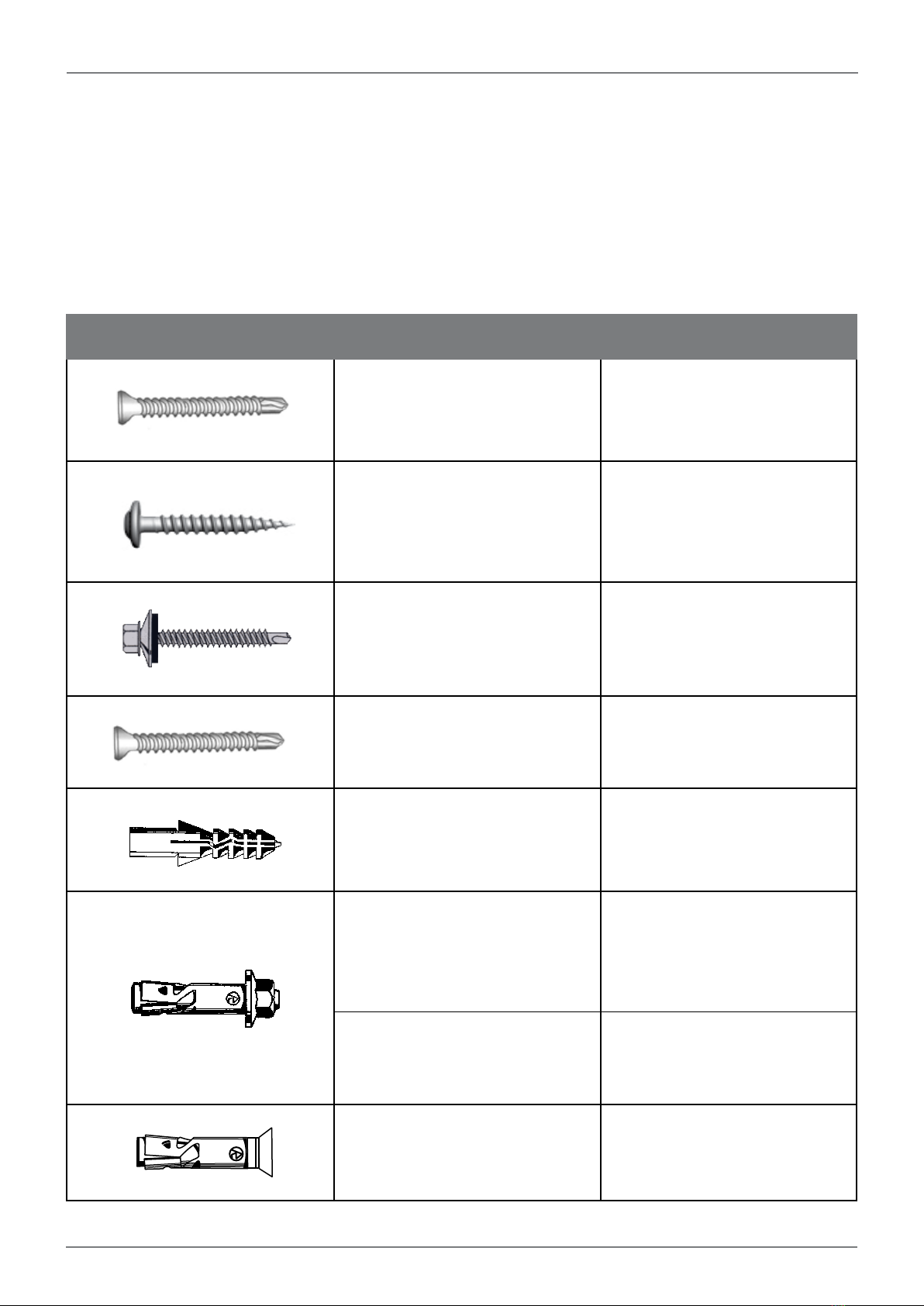

Fixings .......................................................... 3

Characteristics of Awning Fabrics................... 4

Options and Limitations .................................. 5

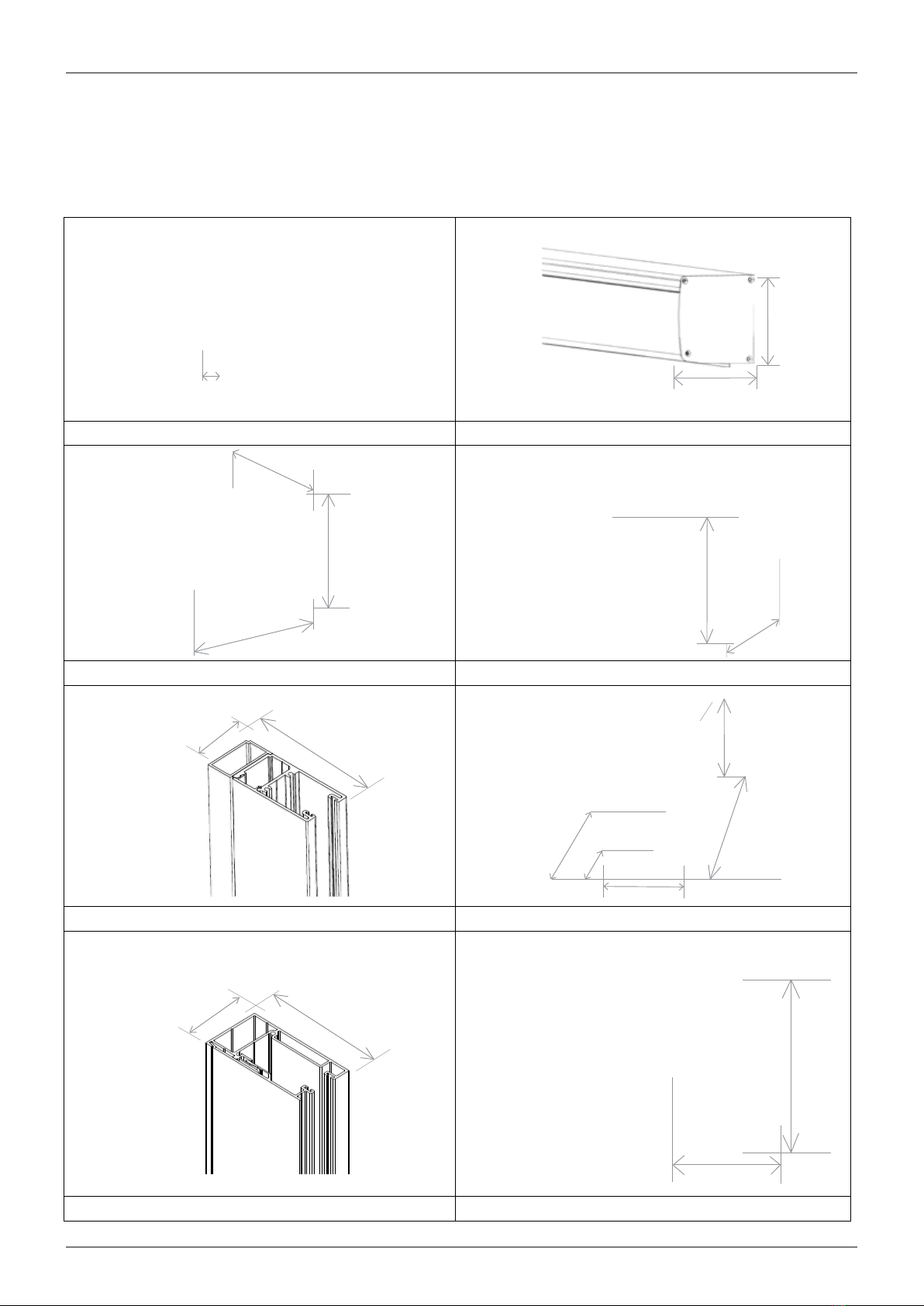

Component Dimensions ................................. 6

INSTALLATION

Open Roller Installation................................ 7

• Flow Chart..........................................................7

• Installation Instructions........................................8

Headbox Installation ................................... 9

• Flow Chart .........................................................9

• Installation Instructions.....................................10

Installing the Roller Tube........................... 12

• Flow Chart .......................................................12

• Installation Instructions.....................................13

ALPHA Straight Drop Awning ................... 15

• Exploded view diagram....................................15

• Flow Chart .......................................................16

• Installation Instructions.....................................17

ALPHA Cable Guide Awning .................... 18

• Exploded view diagram....................................18

• Flow Chart .......................................................19

• Installation Instructions.....................................20

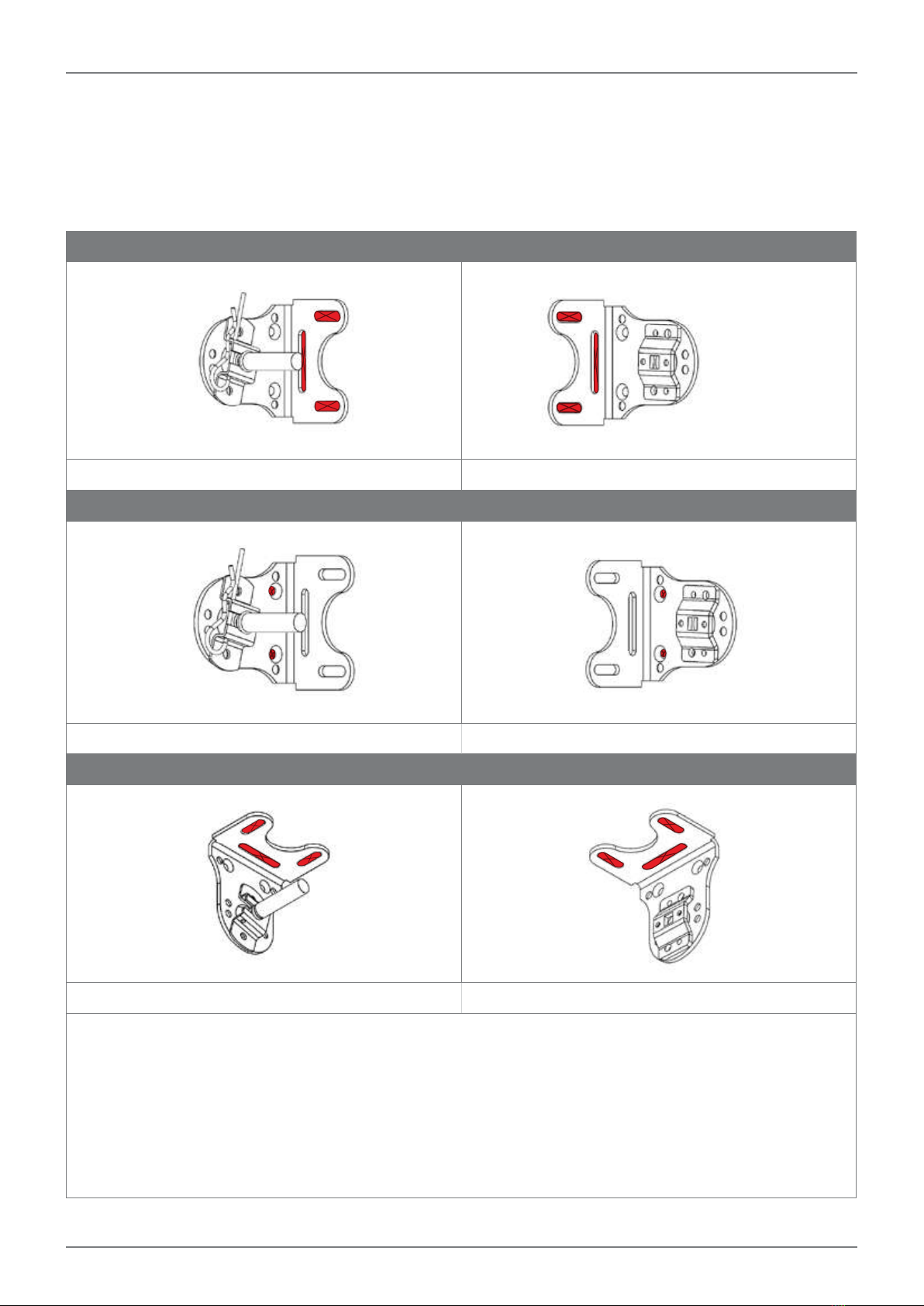

ALPHA SRS V2 (Side Retention System)

Awning ....................................................... 22

• Exploded view diagram....................................22

• Flow Chart .......................................................23

• Installation Instructions.....................................24

ALPHA Deep Channel Awning ................. 30

• Exploded view diagram....................................30

• Flow Chart .......................................................31

• Installation Instructions.....................................32

ALPHA Pivot Arm Awning ......................... 34

• Exploded view diagram....................................34

• Flow Chart .......................................................35

• Installation Instructions.....................................36

Pretensioning the Spring for Literise/Light Lift

Pretensioning the Spring for Literise/Light Lift.....38

Pretension Chart.......................................... 39

ALPHA Linking Option .............................. 40

• Exploded view diagram....................................40

• Flow Chart .......................................................41

• Installation Instructions.....................................42

USER INFORMATION

Operating Instructions .................................. 46

MEASURING INSTRUCTIONS

On Face Architrave....................................... 46

Reveal and Top Fix (Side Fix) ........................ 48

ALPHA AWNING SERIES INSTALLATION MANUAL