English – 4

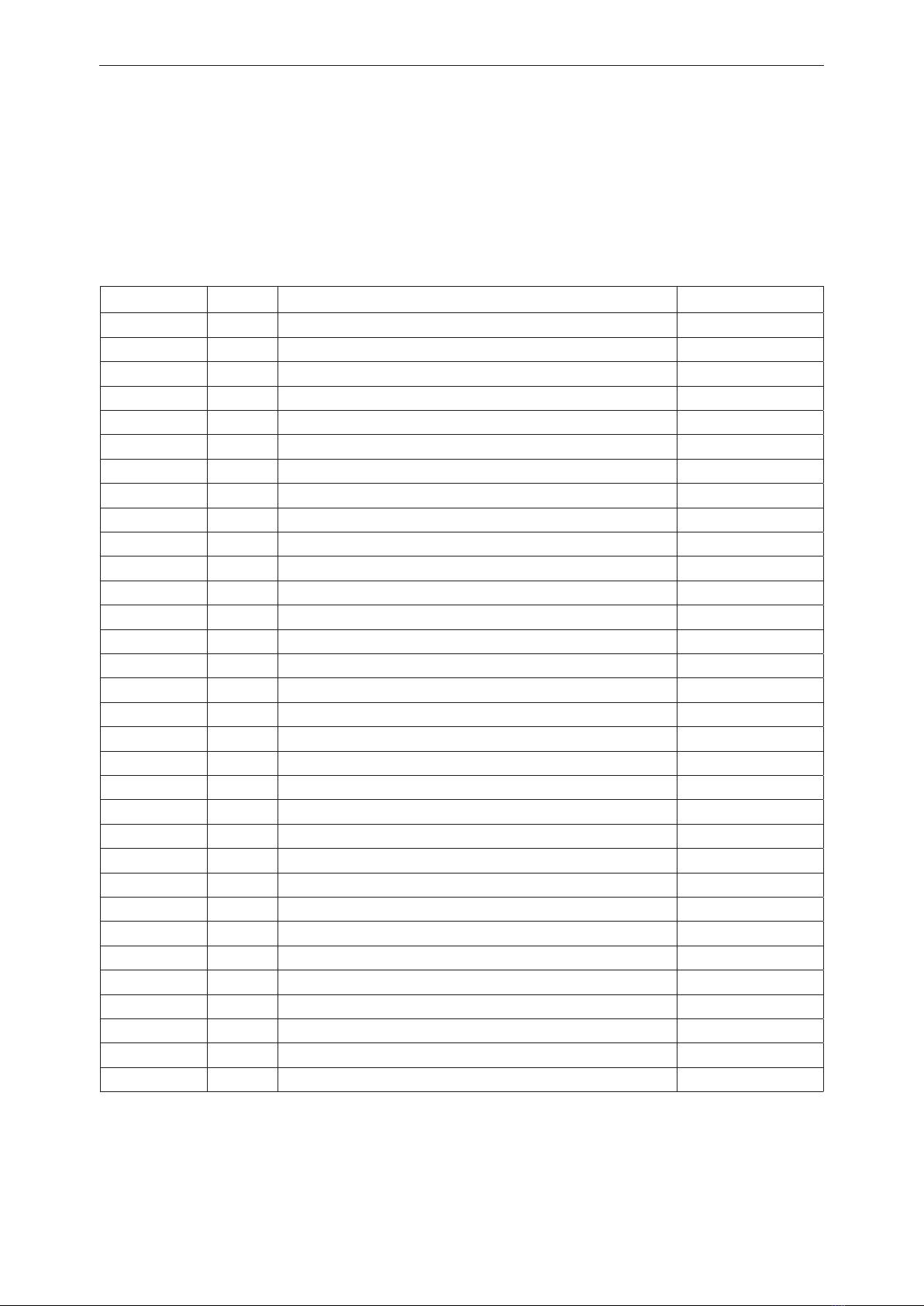

Index

1 Index

1 Index .............................................................................. 4

2 Introduction and Safety Regulations .......................... 7

2.1 General ................................................................. 7

2.2 Safety ................................................................... 7

2.3 Target Group ......................................................... 7

2.4 Changes ............................................................... 7

2.5 Tools ..................................................................... 7

2.6 Parts and Accessories .......................................... 7

2.7 Structure ............................................................... 7

2.8 Numbering ............................................................ 7

2.9 Symbols on Rider ................................................. 8

2.10 Special Safety Instructions ................................. 9

2.11 Risk of Sparks ..................................................... 9

2.12 Cutting Power ................................................... 10

3 Special Tools ............................................................... 11

4 Technical Data ............................................................ 14

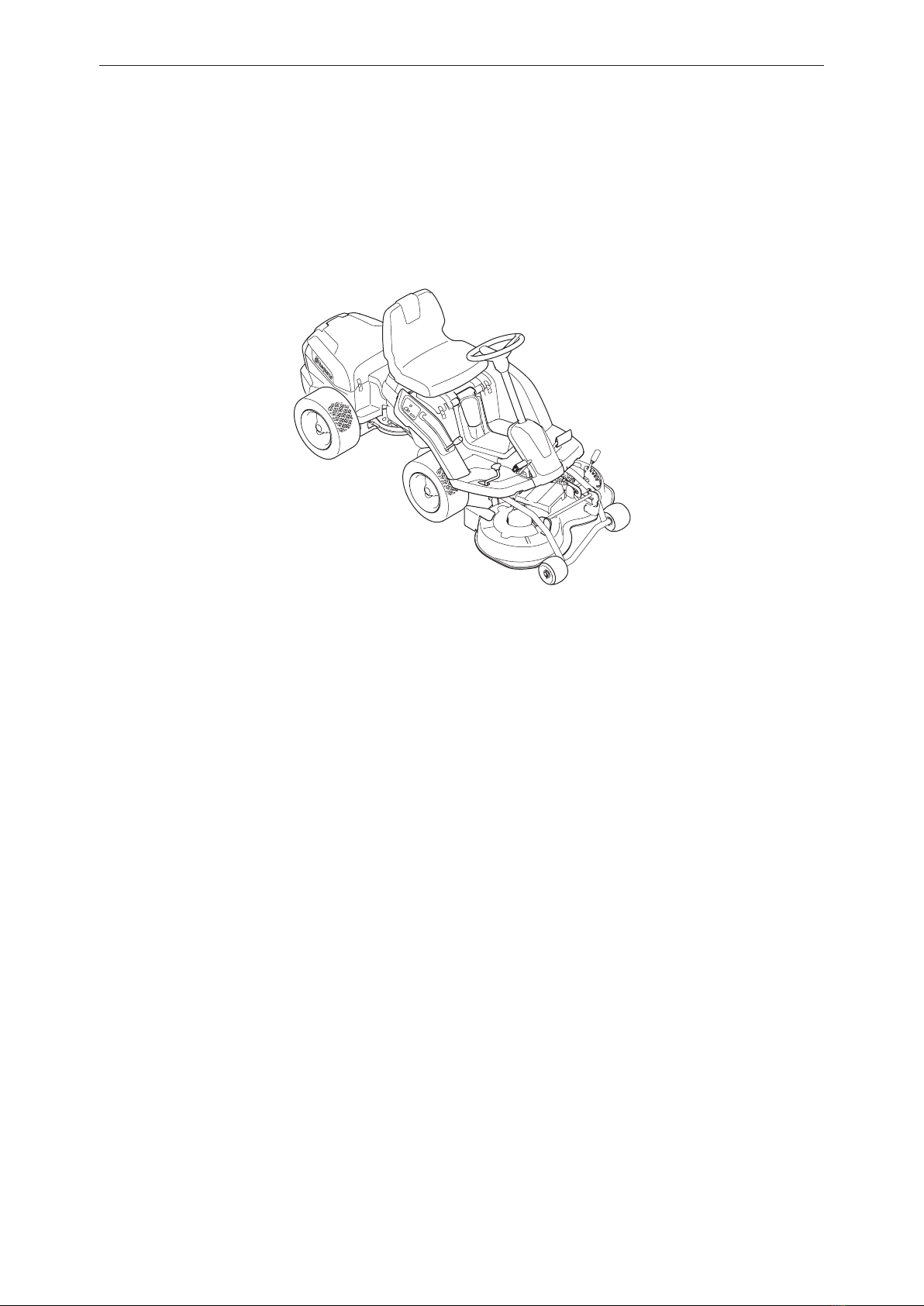

5 Design and Function .................................................. 15

5.1 Administration ..................................................... 15

5.2 Wheels ................................................................ 15

5.3 Serial Number ..................................................... 16

5.4 Steering .............................................................. 17

5.5 Cutting Deck ....................................................... 18

5.6 Service Position for Cutting Deck ....................... 18

5.7 Removing the BioClip Plug ................................. 18

6 Basic Dismantle/Assembly ........................................ 19

6.1 Wheels ................................................................ 20

6.2 Covers ................................................................ 21

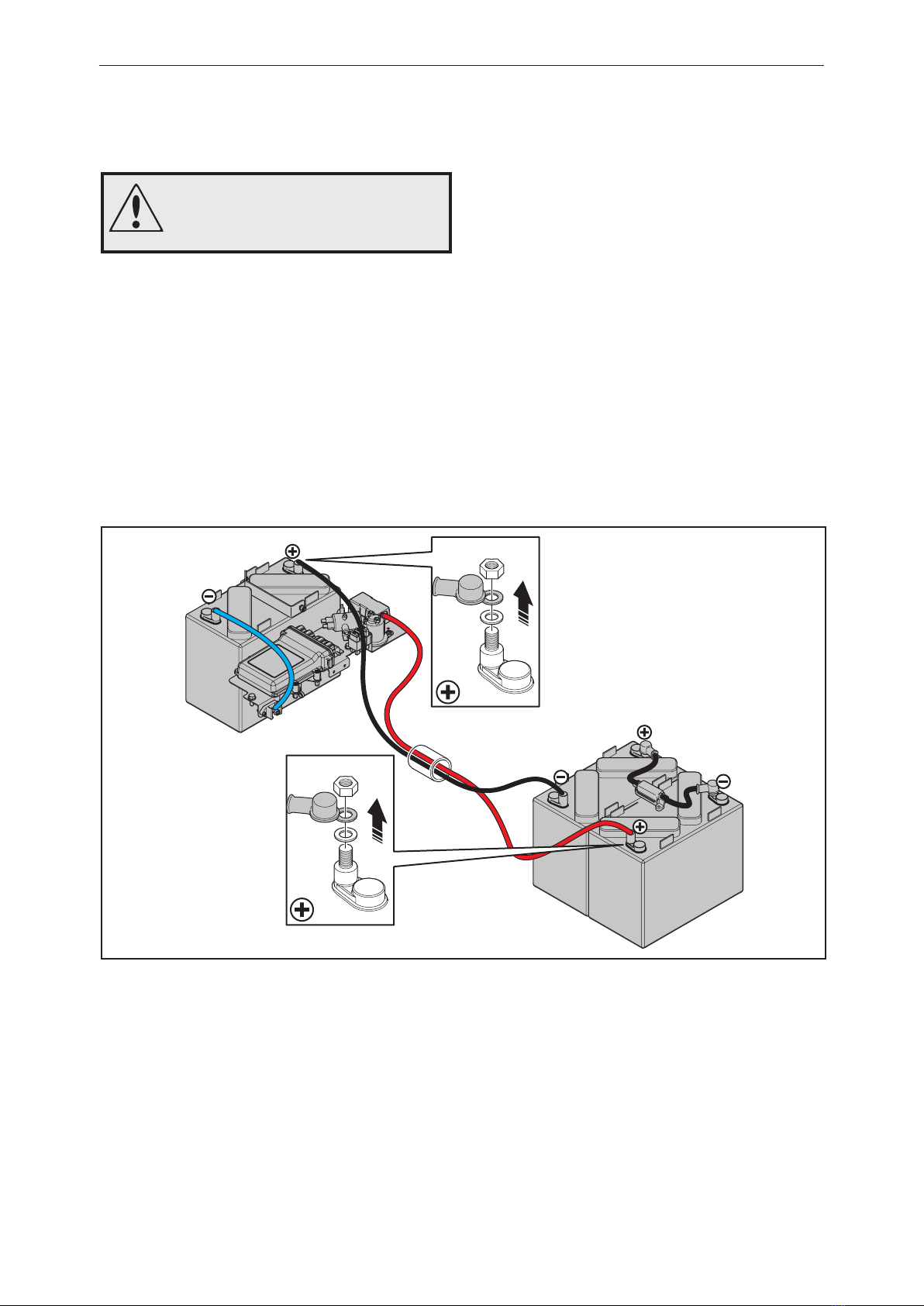

6.3 Front Batteries .................................................... 25

6.4 Rear Battery ....................................................... 27

6.5 Exploded View Drawing Cutting Deck ................ 28

6.6 Removing the Cutting Deck ................................ 29

6.7 Assembling the Cutting Unit ............................... 31

7 Repair Work ................................................................ 33

7.1 Replacing the Steering Cables ........................... 34

7.2 Removing/Fitting the Steering Shaft ................... 35

7.3 Removing/Assembling the Cable Pulley ............. 36

7.4 Replacing Brake Cable ....................................... 37

7.5 Checking and Adjusting the Brake Cable ........... 37

7.6 Changing Articulated Steering Bearing ............... 37

7.7 Removing the Pendulum Shaft ........................... 40

7.8 Replacing the Pendulum Shaft Bushings ........... 41

7.9 Assembling the Pendulum Shaft ......................... 41

7.10 Removal of Blades and Blade Adapter ............. 43

7.11 Grinding and Balancing Blades ........................ 44

7.12 Removing the Blade Motor ............................... 45

7.13 Loosen the Pedal Plate .................................... 48

7.14 Changing Microswitch, P-brake ........................ 52

7.15 Changing Microswitch, Reverse Drive .............. 53

7.16 Changing Microswitch, Forward Drive .............. 54

7.17 Changing Speed Potentiometer ....................... 56

7.18 Changing Recoil Spring in Pedal Plate ............. 57

7.19 Calibrating Speed Potentiometer ...................... 59

7.20 Calibrating Speed ............................................. 60

7.21 Assemble New Bafe Plate .............................. 61

7.22 Changing Microswitch, Bafe Plate .................. 63

8 Repair Work Electrical Components ........................ 64

8.1 Changing Seat Switch ........................................ 65

8.2 Changing Control Panel ..................................... 67

8.3 Changing Key Switch ........................................ 68

8.4 Changing Drive Motor ......................................... 69

8.5 Changing Control Unit (CCU) ............................. 74

8.6 Changing Fuses ................................................. 76

9 Troubleshooting with Common Service Tool .......... 77

9.1 Common Service Tool (CST) .............................. 78

9.2 Connecting CST ................................................. 78

9.3 Component Locations, Electrical System ........... 79

9.4 Electrical Components ........................................ 80

10 Description of Electrical System............................. 81

10.1 Cable Drawing .................................................. 82

10.2 Wiring Diagram (cutting motor control ver. 1) ... 84

10.3 Wiring Diagram (cutting motor control ver. 2) ... 86

10.4 Description of CCU ........................................... 88

10.5 Contacts ........................................................... 92

10.6 Description of Cables ....................................... 93

11 CST Autotest ............................................................. 97

11.1 Power Supply .................................... 98

11.1.1 Test of +36 V ..........................................98

11.1.2 Test of +5 V ............................................99

11.2 Switches ..........................................107

11.2.1 Test of Cutting Deck ...............................107

11.2.2 Test of Seat Switch ................................108

11.3 Pedals ..............................................109

11.3.1 Test of Switch for Forward Pedal ...........109

11.3.2 Test of Switch for Reverse Pedal ...........110

11.3.3 Test of Switch for P-Brake .....................110

11.4 Keypad ............................................. 111

11.4.1 Test of LED ............................................111

11.4.2 Test of Buttons .......................................111

11.5 Miscellaneous ................................. 113

11.5.1 Test of Charger ......................................113