Page 9 of 20 pages

HWAM® SMArtControl™

Congratulations on your new wood-burning stove complete with a HWAM®SmartControlTM

We are pleased that you have chosen a HWAM woodburning stove and confident that it will give you

much pleasure.

The HWAM®SmartControlTM is a digital control of the combustion in your new wood-burning stove.The

purpose of the HWAM®SmartControlTM is to control the combustion in an environmentally optimal and

economically efficient way, with a view to generating greater user comfort.

The HWAM®SmartControlTM is a new patented technology, which electronically adjusts the air supply to

the combustion chamber.Your new wood-burning stove continually measures the temperature and the

oxygen levels of the combustion. Moreover, it is programmed to supply oxygen to the fire through three

important air inlets in the right amount, and at the right time and place in the combustion chamber. By

downloading a free app for your smartphone or tablet, you can use the app among other things: to set

the thermostat to the desired room temperature level, choose time for night-time reduction and keep

your stove updated.The app also gives you current information on burning in the stove. See details in

separate manuals for the app IHS Smart ControlTM or in the Quickguide.

.

Your new wood-burning stove and the HWAM®SmartControlTM will ensure the cleanest possible com-

bustion as well as a good fuel economy, regardless of external conditions such as the type of firewood

used, the chimney, the user’s experience, and other external circumstances.

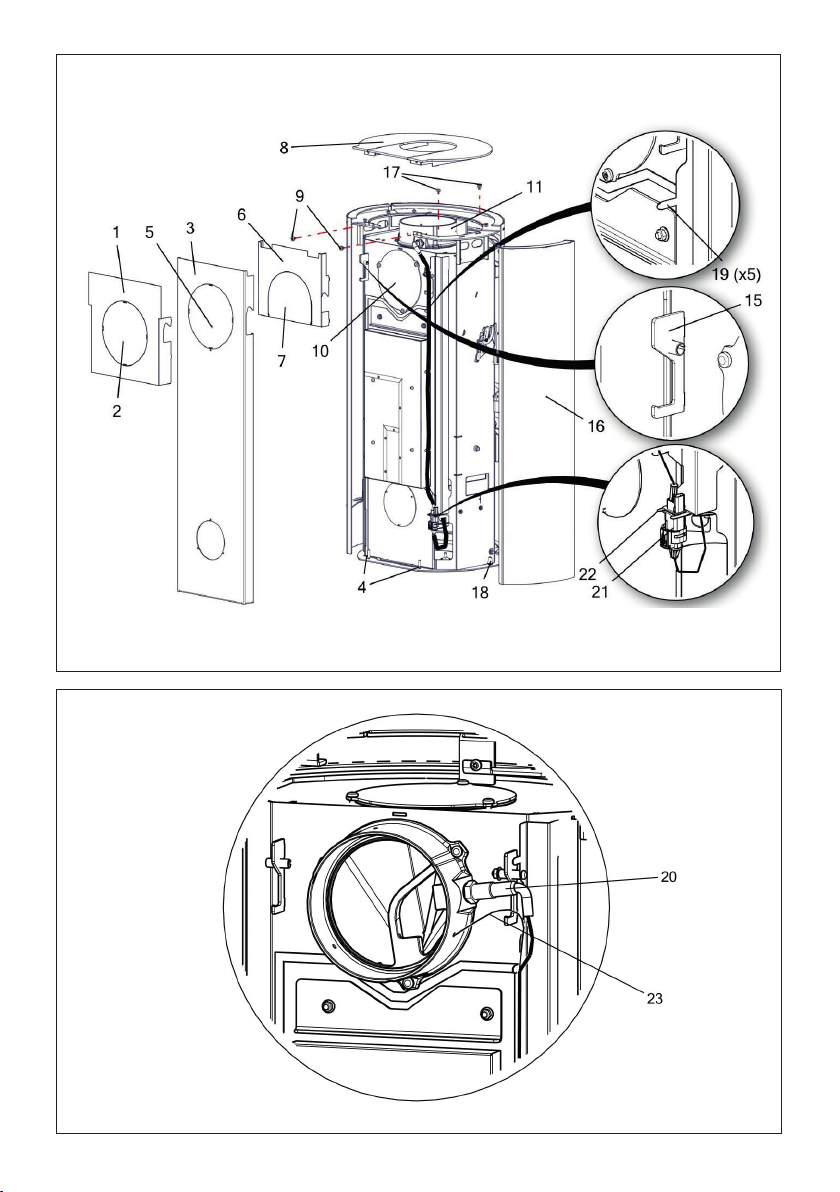

The HWAM®SmartControlTM consists of the following components:

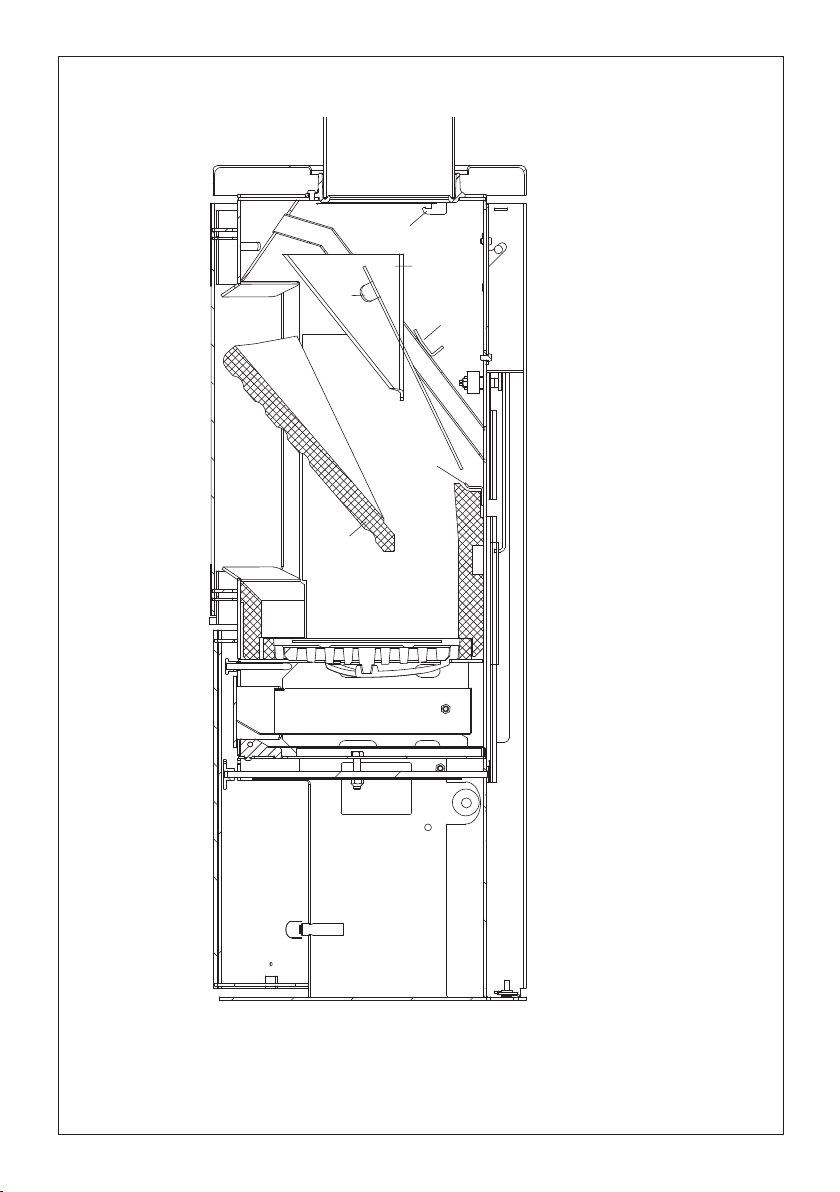

• Air box: the Air box contains a printed circuit board/software, as well as three motors and dampers

that control primary, secondary, and tertiary combustion air.The fresh air system can be mounted

on the Air box to the back or in the bottom.

• Two sensors: a temperature sensor and an oxygen sensor transmit information from the wood-

burning stove to the Air box.

• Room temperature sensor: The room temperature sensor with batteries communicates with the

HWAM®SmartControlTM via a wireless connection. It should be placed so it does not have direct

radiant heat from the stove. Note that the maximum distance between stove and room temperature

indicator is about 4-5 metres.The range is reduced if there are walls or other obstructions between

the stove and the room temperature indicator.

• Electricity supply: from the Air box to the nearest wall socket.

• App "IHS Smart ControlTM:The app can be downloaded free from the App Store or Google Play

Store. See details in separate manuals for the app IHS Smart ControlTM or in the Quickguide.