OPERATING PROCEDURES

MP34.3303

18DEC09

MANUAL JACK RETRACTION

been opened far enough to allow the jacks to retract.

the T-Handle will turn harder. Make sure the valves have

will turn several turns easily. As the valve starts to open,

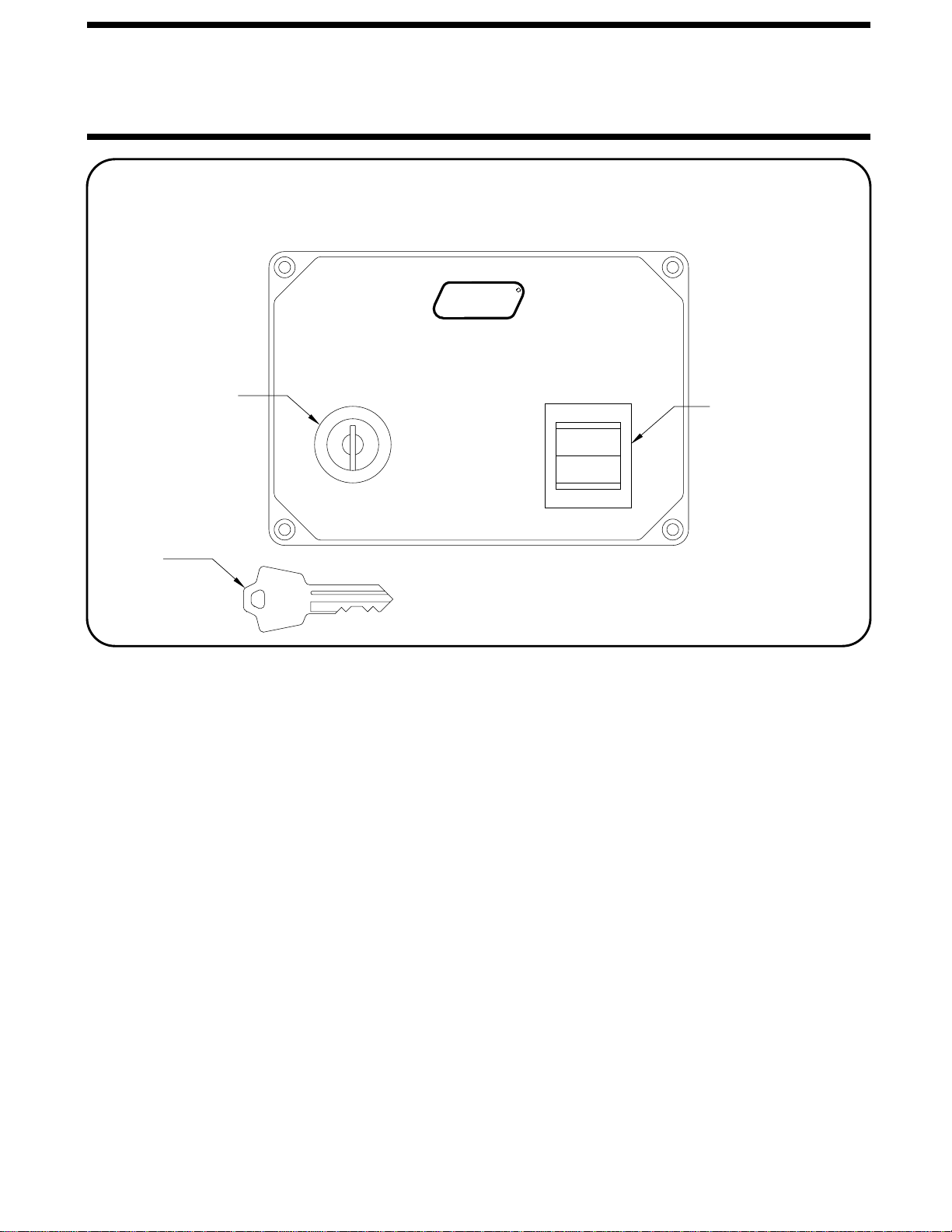

Large style with T-Handle valve release:

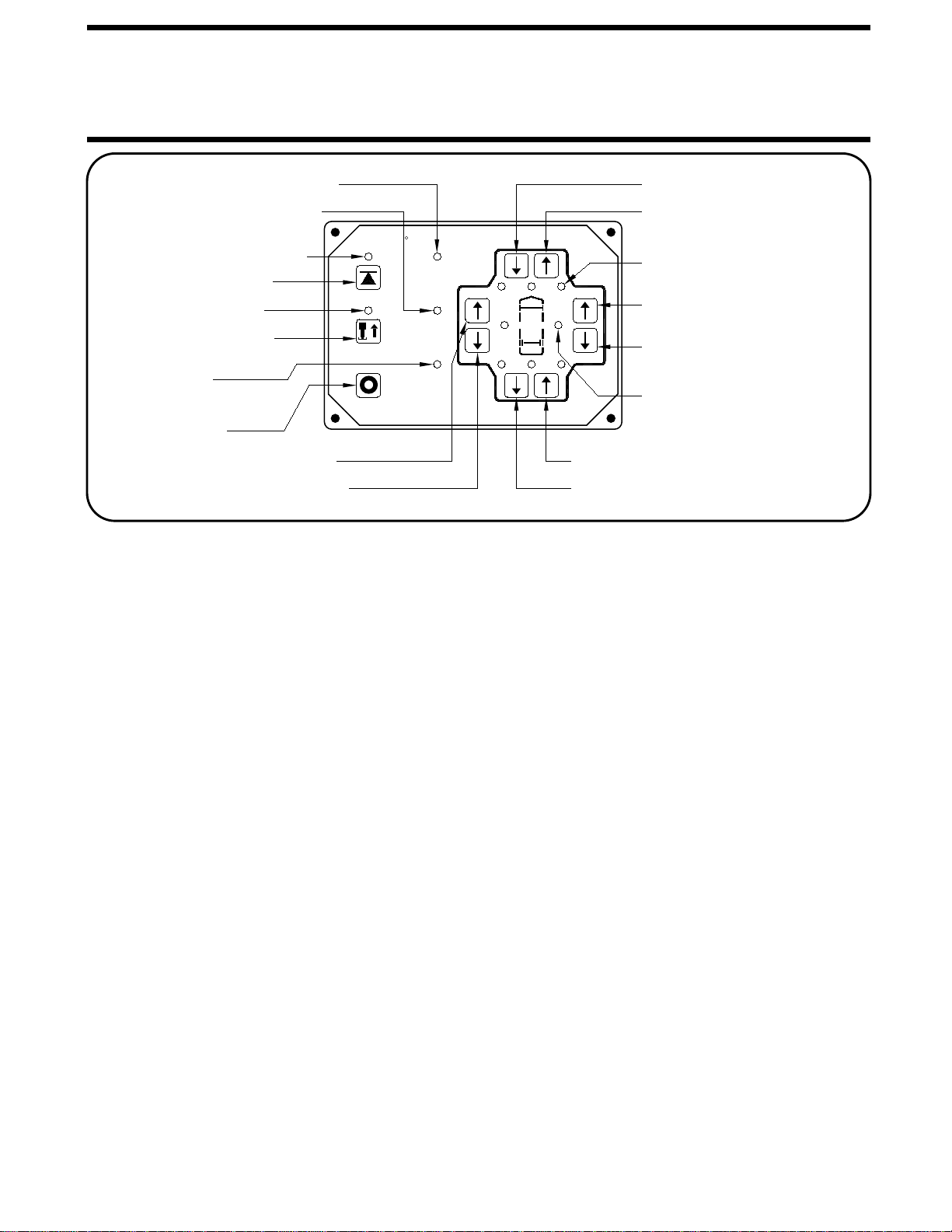

power unit. The upper most manifold should control

NOTE: Multiple manifolds may be present on the

retract the jacks.

if the STORE feature on the HWH control panel will not

Use the manual valve release for retracting the jacks only

DO NOT CRAWL UNDER THE VEHICLE, KEEP A SAFE

DISTANCE IN FRONT AND REAR OF THE VEHICLE.

THE VEHICLE MAY DROP AND/OR MOVE FORWARD

OR BACKWARD WITHOUT WARNING AS THE VALVE

RELEASE IS OPERATED.

1. Locate your power unit-manifold assembly.

2. Allow clearance for the vehicle to lower. If equipped with

CAUTION:KEEP AWAY FROM THE WHEELS,

point as internal damage may occur to the solenoid.

incorporated into the Breather Cap. Before using read

NOTE: As of APRIL 2002 a 1/4" Nut Driver has been

and understand the last page of this manual.

6. Check that all jacks are now retracted. If yes, continue.

7. Close the valves by turning each valve release clockwise.

DO NOT tighten the manual valve release past this

IMPORTANT: Once the manual valve release is snug,

9. The system should now be repaired before using again.

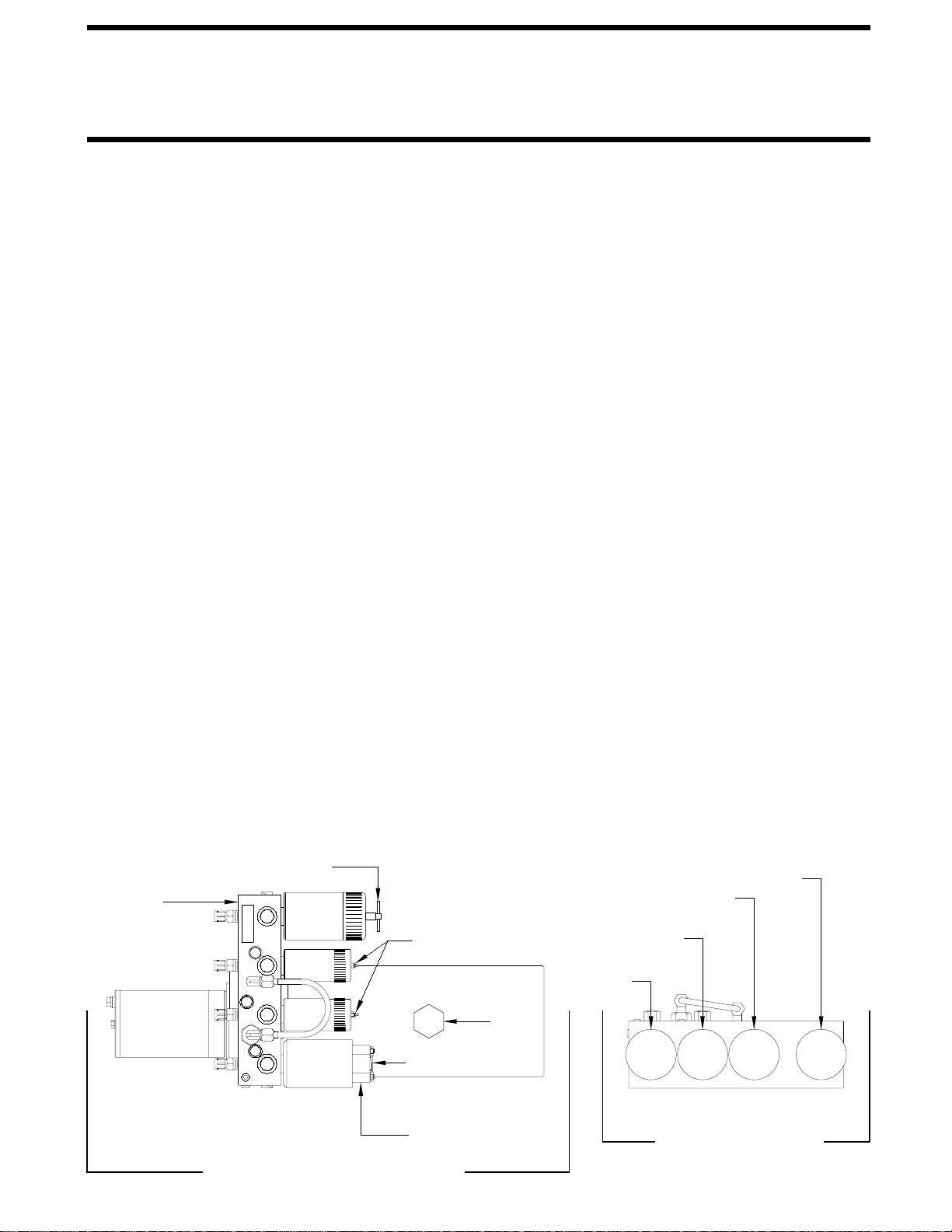

3. Using the diagrams below identify the style and location

5. Repeat the process by identifying then opening the two

rear control valves.

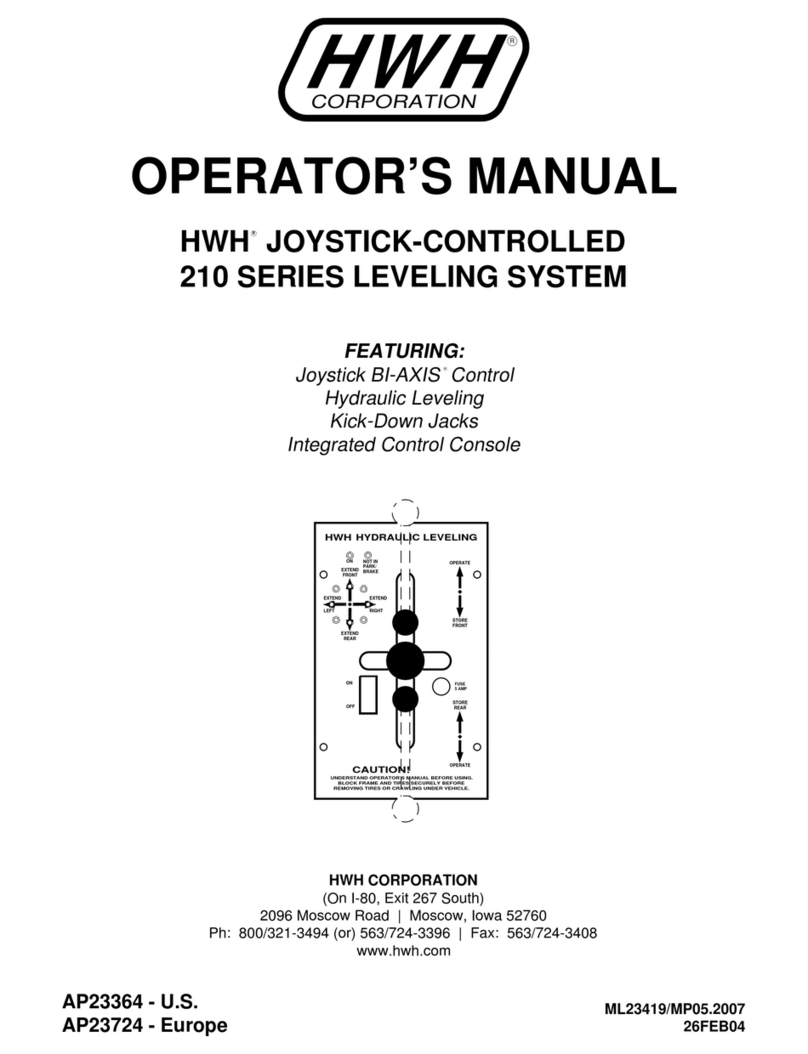

LARGE STYLE WITH T-HANDLE

VALVE RELEASE

SMALL STYLE

WITH VALVE

RELEASE NUT

LARGE STYLE

RELEASE NUT

WITH VALVE

PLASTIC PLUG

BREATHER

CAP

Small style with Valve Release Nut: DO NOT

1/4" valve release nut more than . Turning

the nut more could damage the valve.

The T-Handle

turn the

jack functions. (Valve styles and arrangements will vary)

POWER UNIT-MANIFOLD ASSEMBLY

MANIFOLD

of your two front jack control valves.

If no, notify the dealership where you purchased the vehicle

or had the leveling system installed or contact

(The diagram below represents a typical Power Unit-

MANUAL JACK RETRACTION

extensions are fully retracted prior to performing

IMPORTANT: HWH recommends that all HWH room

manual jack retraction procedures.

Manifold Assembly it may not be an exact match to yours).

4. Retract the front jacks by opening the correct valves.

Slowly turn the manual valve releases counter clockwise

until the jacks start to retract. Hitch the trailer to the tow

4 and 1/2 turns

HWH Corporation customer service.

FOR TRAILERS WITHOUT LOCK VALVE

RR RF LR

LF

VALVE ARRANGEMENT

TRAILER

RIGHT

REAR

FRONT

RIGHT

LEFT

FRONT REAR

LEFT

landing gear, lower the landing gear to support the trailer

while manually retracting the jacks.

vehicle during this operation if the vehicle is not equipped

8. Retract all landing gear before traveling.

with an alternate landing gear.

valve. Replace the protective plastic plug.

Turning the nut more could damage the

release nut more than

The 1/4" Valve

removed to gain access. Open valve 1-1/2 to 2 full turns.

release nut is located under a plastic plug that must be

turn the 1/4" valve

Large style with Valve Release Nut:

2 full turns.

DO NOT