5.MAKE HEATER PLUMBING CONNECTIONS

Connect ALL the plumbing valves in the sequence shown in diagram 1.

The cold water inlet to the heater is marked BLUE and the hot water outlet is marked RED.

OBSERVE FLOW DIRECTIONARROWS ON SUPPLIEDVALVES.

The drain valve must be fitted close to the COLD inlet to allow drain down if necessary.

An isolating valve should be fitted UPSTREAM of all of the valves to allow the heater to be maintained without impacting on

other facilities.

Do NOT fit a service or other valves between the heater and the pressure relief (safety) valve as this could impede its

correct operation.

The pressure reducing valve is factory set at 3 bar.If a balanced cold water draw off is required this should be tee-ed off

down stream of this valve.

A balanced cold water feed is recommended as it ensures hot and cold water is supplied at the same pressure. Some mixer

taps and thermostatic showers require hot and cold water to be to be at the same pressure for correct operation.

The expansion vessel supplied must be supported using a bracket or similar fixing.Do not rely on the pipework alone – it will

not be strong enough.The orientation of the vessel is not important.

When all valves are correctly fitted, open a hot tap and wait until the water flow is steady and without traces of air. Close the

tap to allow the system to reach full pressure and carefully check system for leaks.

CONTROLVALVES MAY BE SUPPLIED LOOSELY CONNECTED FOR IDENTIFICATION PURPOSES,BUTTHESE

JOINS HAVE NOT BEEN LEAKTESTED.THIS MUST BE DONEAT INSTALLATION.

IT IS ESSENTIALTOALSO CHECKTHETEMPERATURE PRESSURE RELIEFVALVE CONNECTIONTOTHE

HEATER FOR LEAKS. NOTETHATA LEAK FROMTHETEMPERATURE AND PRESSURE RELIEFVALVE MAY NOT

BE IMMEDIATELY OBVIOUS,ASTHE CONNECTION ISATTHETOP OFTHE HEATERAND LEAKINGWATER

MAY INTHE FIRST INSTANCE RUN DOWNTHE PIPEWORKAND COLLECT INTHE HEATER INSULATION.

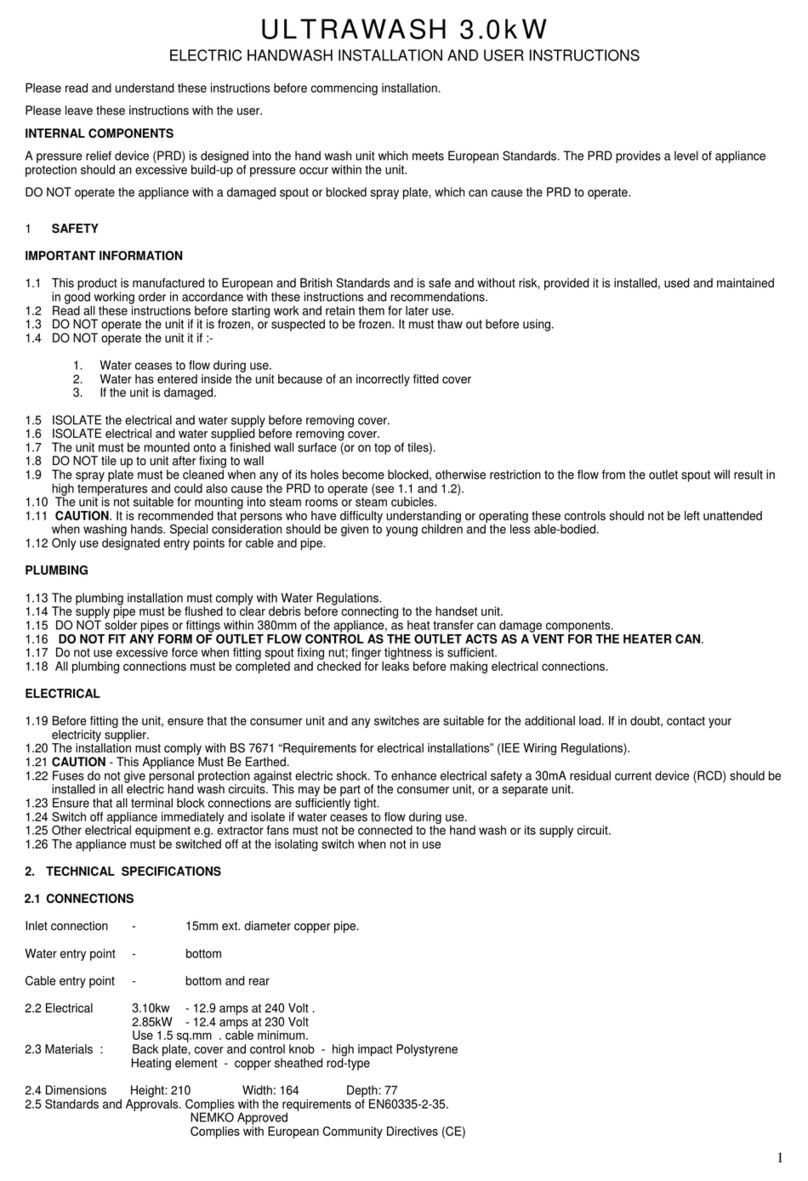

6.DISCHARGE PIPE CONNECTIONS (SEE DIAGRAM 3,PAGE 4)

This product falls within the scope of Building Regulation G3 which stipulates certain conditions relating to the way any water

discharge from relief valves is transported away.

These conditions are designed to ensure that any discharge will not present a hazard to people or to property,and that any

discharge is clearly visible so that the underlying cause is likely to be rectified promptly.

The essential requirement of G3 in relation to water discharge is that the discharge pipe MUST terminate in a safe,visible

position.

In achieving this aim the G3 regulations strongly recommended that:

1. The tundish is located within 500mm of theTemperature and Pressure Relief valve and it is wherever possible oriented

vertically. It must be visible to occupants and positioned away from electrical devices.

2. The discharge pipe has a vertical fall of at least 300mm immediately below the tundish.

3. The discharge pipe below the tundish is at least 22mm diameter (i.e.one size larger than theTemperature and Pressure

Relief valve outlet).

4. The discharge pipe should be as straight and as short as is possible and positioned away from electrical components.

Diagram 3 illustrates an acceptable discharge pipe arrangement.The table below the diagram specifies how the maximum

acceptable pipe length from the tundish to the final outlet depends on the pipe diameter and the number of bends (reference

the chart on page 4 for pipe sizing).

For example in 22mm copper with no bends the pipe could be up to 9m long.With two bends present the maximum length

drops to 9.0m - (2 x 0.80m) = 7.4m.

7.ELECTRICAL CONNECTIONS

The heater is supplied pre-wired with appropriate cable.

Electrical installation should conform to the latest edition of the IEEWiring Regulations.

Electrical supply should be capable of isolation via a user-accessible double pole isolation switch rated for a 13A supply.

3

8.COMMISSIONING

Visually re-confirm all plumbing and electrical connections are sound.

• Open a hot water tap and turn on mains water supply to the Powerflow heater

• Allow unit to fill and leave tap running for a short time to flush out the pipework and purge any air from the system

before closing the hot tap and checking the system for any leaks.

Check the operation of theTemperature and Pressure relief valve located at the top of the heater twisting the knob at the

top of the valve.This lifts the valve seat and water will flow rapidly and be visible at the tundish.Ensure the discharge pipe can

cope with this flow rate continuously.Release theTemperature and Pressure relief valve.The flow should stop completely.

Open the expansion relief valve and likewise check that water flows freely through the discharge pipe,that the discharge pipe

can cope with the flow rate and that the water flow ceases when the valve is released.

Switch on the electrical supply and select an appropriate heater setting on the thermostat knob (the thermostat is adjustable

in the approximate range 20°C to 65°C.

The neon indicator light comes on when the element is heating.

9.DRAININGTHE UNIT

To drain the unit disconnect electrical supply and close service valve on cold inlet.

Open the drain cock on cold inlet and open a hot water outlet to enable air to replace draining water.

NOTETHATA SMALL QUANTITY OFWATERWILL REMAIN IN THETANK.THIS RESIDUALWATER CAN

ONLY BE DRAINED BY REMOVINGTHE HEATING ELEMENT.

4

Diagram 3

Safety Device

Tundish

500mm MAXIMUM

Metal Discharge Pipe (D1) from

Temperature Relief toTundish

Discharge Below

Fixed Grating

300mm MINIMUM

Metal Discharge Pipe (D2) from

Tundish with Continuous Fall

Fixed Grating

Trapped Gully

Sizing of D2 Copper Discharge pipe for common temperature relief valve outlet size

Valve

outlet

size

Minimum size of

discharge pipe (D1) Minimum size of

discharge pipe (D2)

fromTundish

Maximum resistance allowed,

expressed as a length of straight

pipe (I.E.no elbows or bends)

Resistance

created by each

elbow or bend

G1/2 15mm 22mm up to 9m 0.8m

28mm up to 18m 1.0m

25mm * to 27m 1.4m