Protocol Description HLB 1400 CANopen Page 3

Status 2021-05-27 HYDAC ELECTRONIC GMBH Part no.: 670065

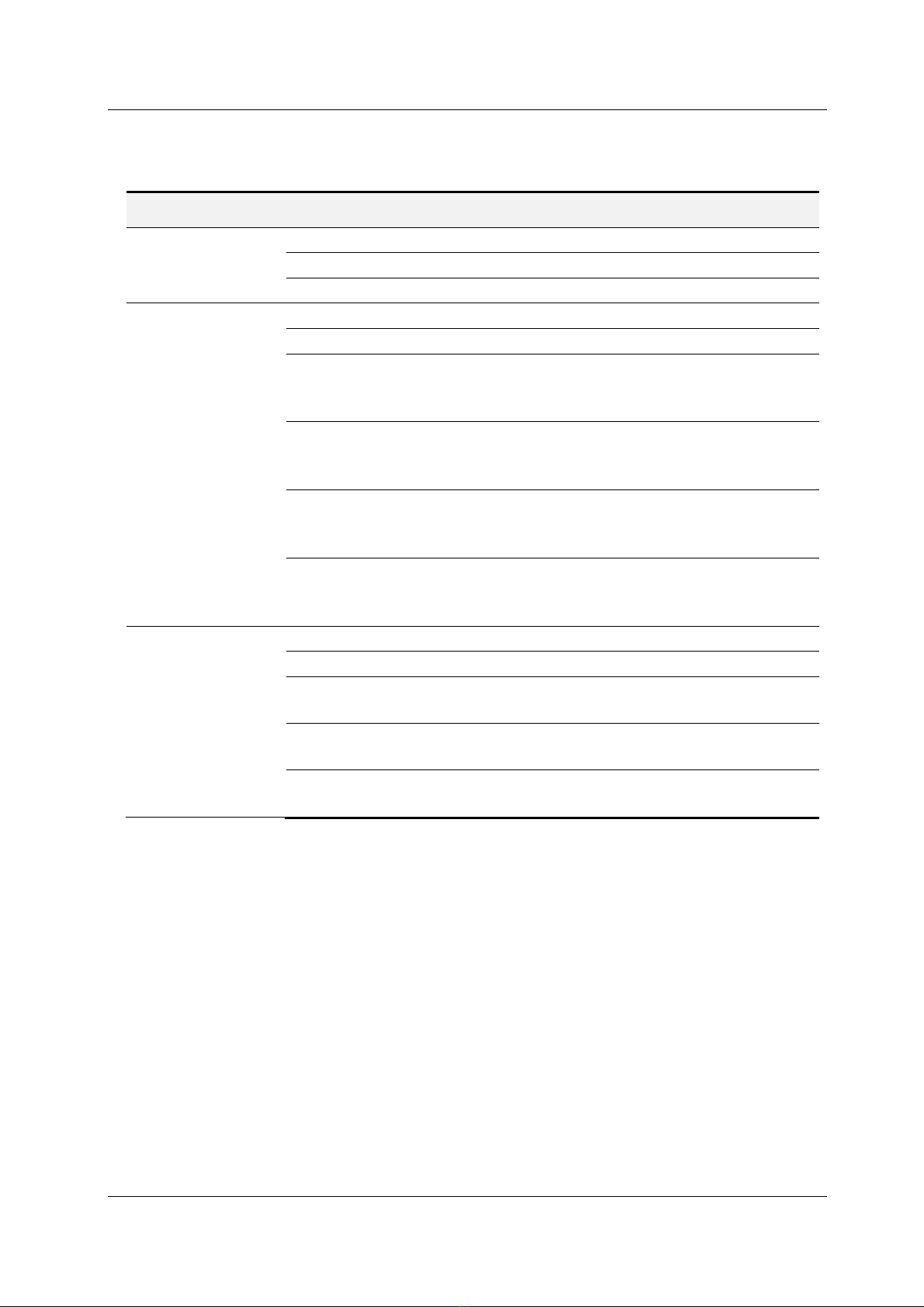

8.2.4Index 6131h: PhysicalUnitProcessValue..............................................................21

8.2.5Index 6132h: ProcessValueDecimalDigits ........................................................... 21

8.2.6Index 61B0h:ProcessValueSignalNames.............................................................22

8.2.7Index 6150h: AnalogInputStatus (mappable) .......................................................22

8.3Manufacturer Specific Entries......................................................................................22

8.3.1Index 2001h: NodeID (read write) ........................................................................ 22

8.3.2Index 2002h: Baudrate (read write)...................................................................... 23

8.3.3Index 2100h: Temperature Settings ..................................................................... 23

8.3.4Index 2101h: Oil condition warning thresholds.....................................................24

8.3.5Index 2102h: Oil condition alarm thresholds ........................................................ 24

8.3.6Index 2103h: Reset reference cycle (write only) .................................................. 24

8.3.7Index 2104h: Conductivity measurement method (write only) .............................24

9Layer setting services (LSS) and protocols ...............................................................25

9.1Finite state automaton, FSA ........................................................................................26

9.2Transmission of LSS services .....................................................................................27

9.2.1LSS message format............................................................................................ 27

9.3Switch mode protocols ................................................................................................28

9.3.1Switch mode global protocol ................................................................................28

9.3.2Switch mode selective Protokoll........................................................................... 28

9.4Configuration protocols................................................................................................29

9.4.1Configure Node ID protocol.................................................................................. 29

9.4.2Configure bit timing parameters protocol ............................................................. 30

9.4.3Activate bit timing parameters Protokoll ............................................................... 31

9.4.4Store configuration Protokoll ................................................................................31

9.5Inquire LSS-Address Protokolle ..................................................................................32

9.5.1Inquire Identity Vendor-ID Protokoll .....................................................................32

9.5.2Inquire Identity Product-Code Protokoll................................................................32

9.5.3Inquire Identity Revision-Number Protokoll .......................................................... 33

9.5.4Inquire Identity Serial-Number Protokoll...............................................................33

9.6Inquire Node-ID Protokoll ............................................................................................34

9.7Identification Protocols ................................................................................................35

9.7.1LSS identify remote slave protocol.......................................................................35

9.7.2LSS identify slave protocol ...................................................................................35

9.7.3LSS identify non-configured remote slave protocol..............................................36

9.7.4LSS identify non-configured slave protocol ..........................................................36

9.7.5Fastscan protocol ................................................................................................. 36

10Connection ....................................................................................................................37

10.1Switching on the supply voltage ..................................................................................37

10.2Setting the Node ID and Baud rate by means of LSS services ...................................37

10.2.1Configuration of the Node ID, sequence ..............................................................37

10.2.2Configuration of the Baud rate, sequence............................................................ 38

11Commissioning .............................................................................................................39

11.1CAN interface ..............................................................................................................39

11.2EDS file........................................................................................................................39