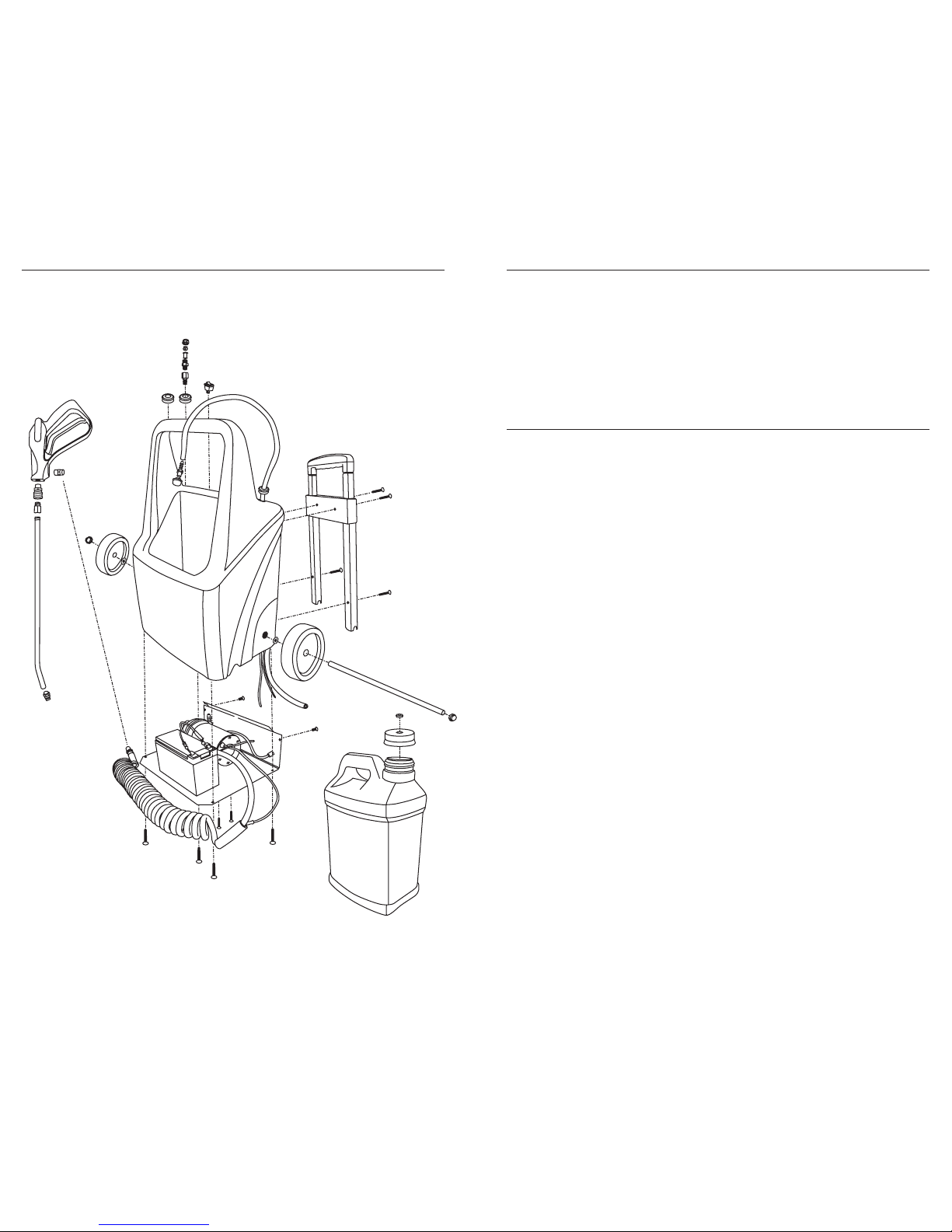

PART # DESCRIPTION QUANTITY

AP21 Water Pump 1

NM4100 Battery 1

NM5082 Coil Hose 15 feet

NA030 Spray Gun Valve 1

NA0833 Extension 1

B281 Veejet 8005 ¼”FPT 1

NM4102 Bottle 1

NM4103 Cap 1

NA0840 Strainer 1

NA0839 Barb Nylon 1

XAF1 Tubing ¼” ID 48”

BR013 Barb 1/4Fx1/4 1

NM4104 Axle Cap 2

NM4105 Wheel 1

NM4107 Handle Extendable 1

NM4106 Base Plate 1

NS123 Hose Clamps 2

NS162 Elbow Barbs 2

NS126 Power Recepticle 1

NM4111 Switch Rocker 1

NM4017 Connectors 4

NM4020 Wire Black 2 feet

NM5020 Wire Red 2 feet

NM4110 Axle 1

NM4113 Molded Plastic 1

BR335 Quick Male 2

BR337 Quick Female 1

B006 Upholstery TeeJet 6501 1

NM4116 Rubber Bushing 3/8” 3

NM4061 Base Plate Screws 10

NM4080 Handle Screws 2

BR112 Coupling ¼”FXF 1

NM5034 Pump Base Bolts 2

NM4003 Pump Base Nuts 2

NM5066 Pump Base Washers 2

NA0802 Strainer Body 1

NA0803 Strainer 1

NA0826 Teejet Cap 1

NM4074 Double Stick Tape 4 inches

NM4109A Car Charger (included) 1

NM4108A Wall Charger (not included) optional

NM4117 Rubber Bushing 3/4” 2

NM4064 Washer Spacer 2

PLF-AGC10 Fuse 1

NS177 Fuse Casing 1

NM4118 Car Charger Adapter w/ Aligator Clips optional

PKGA10 Diode 1

Complete List of Parts

• Run fresh water through the sprayer after each day of use to flush

chemical from the pump and hoses.

• Keep chemical containers and strainer screen clean.

• Keep charger connected to sprayer and plugged into to van power

supply when not in use to maintain fully charged battery. See

Charging section for details.

• While sprayer and pump are made with chemical resistant materials,

and can handle a wide range of chemicals, do not assume chemical

compatibility.

• Contact your distributor or the manfacturer if you have questions

regarding your chemicals compatibility.

• No warranty, expressed or implied, can be considered where

component failure is caused by chemical effects.

• Label all containers to properly identify chemicals.

• Do not use to spray liquids with temperatures above 160°F. (71°C)

• Do not use to spray flammable or combustable liquids.

• Do not use sprayer where flammable vapors are present.

• Pump can run dry without damage.

• If stored in possible freezing conditions the sprayer must be liquid free

or winterized with anti-freezing chemical.

• Do not operate without inlet strainer.

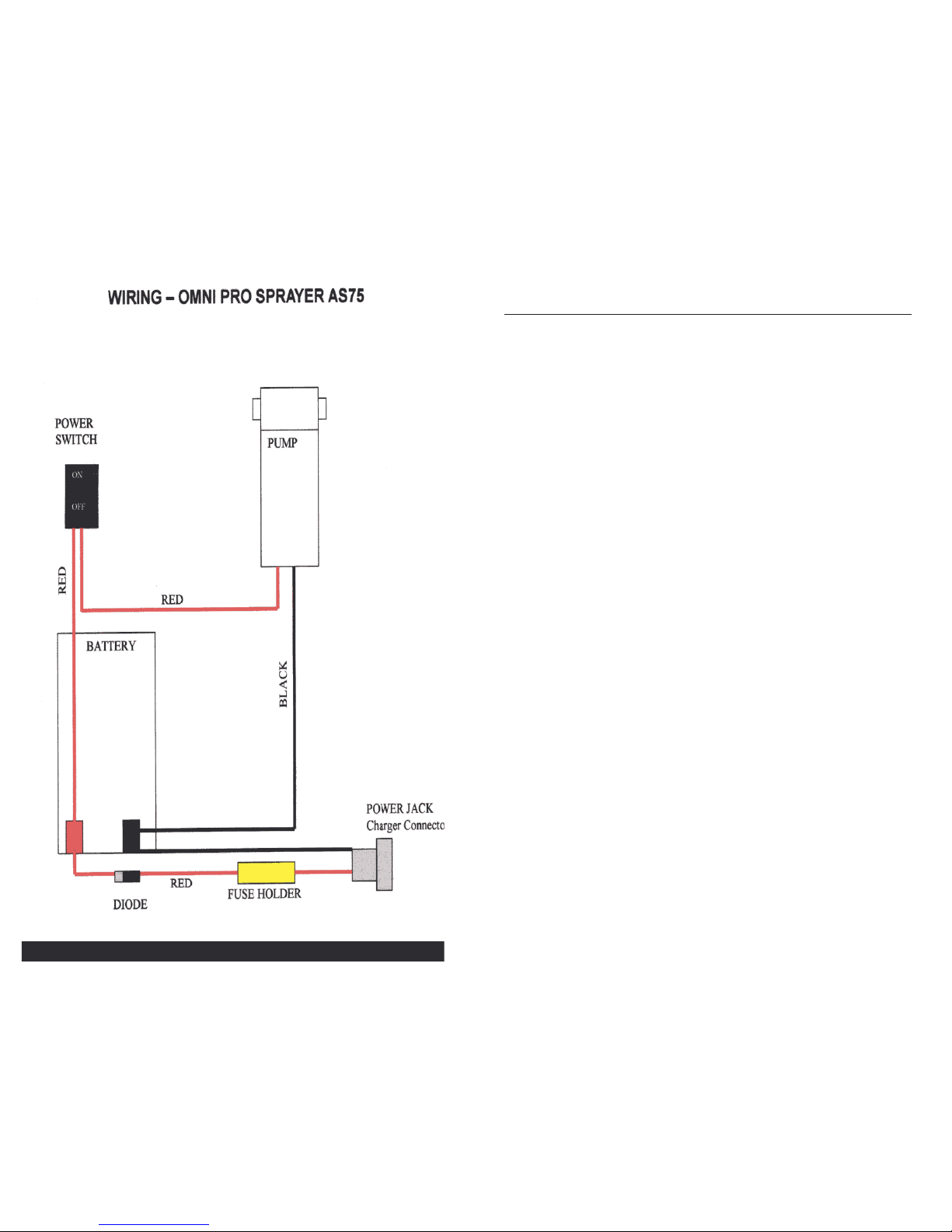

The Omni-Pro Sprayer is the strongest, best-built 12 volt sprayer on the

market. With proper use,the Omni-Pro’s robust “non-memory” battery

and charging system will give long, reliable service.

The following facts apply to ANY 12-volt charging device (cell phones,

ipods, and sprayers included):

• The 12 volt vehicle accessory outlet charger is a“trickle”charger and

takes 10 or more hours to fully charge a discharged battery. The ve-

hicle charger can“top-off” the battery between jobs.

• The vehicle’s accessory/lighter outlet MUST be “live”in order for the

charger to do its job. Many accessory outlets are NOT powered when

the vehicle’s ignition is“off”.

• If the accessory/cigarette plug is NOT powered when the ignition is

“off”, an accessory outlet with alligator clip ends is available (Hydro-

Force part # NM4118). This cord can be attached directly to the termi-

nals of a truckmount or van battery, and will enable the charger to be

“on”and constantly charging the battery.

Safety and General Maintenance

Charging

512