Installation and Operation:

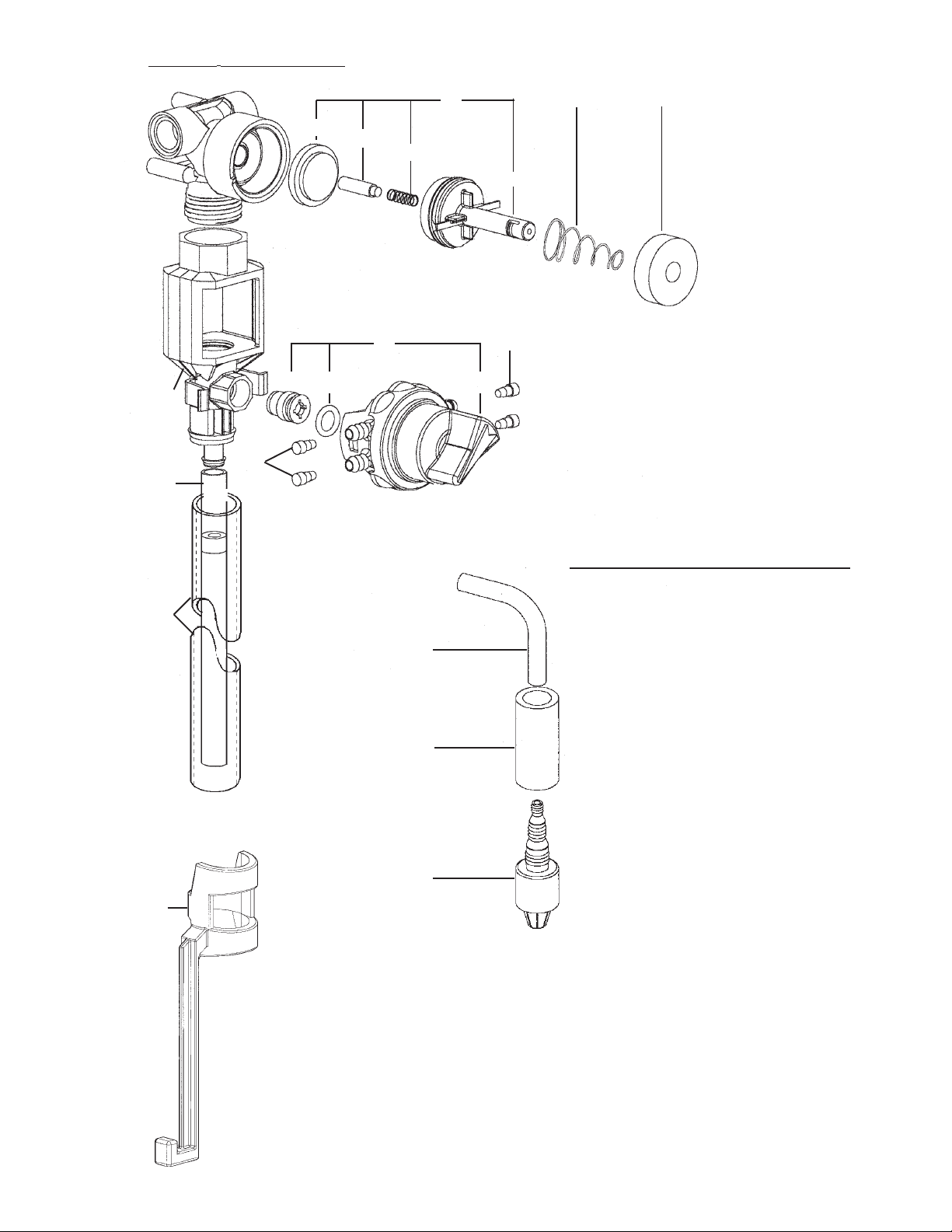

1. Remove cabinet cover. Install the short, white inner discharge tubes on the outlets of the eductors. They go over the

smaller barbed parts on the bottom of the eductors. These tubes must be in place for the eductors to function. The

inner discharge tube for the 3.5 GPM (yellow) eductor has a yellow flooding ring inside it. The inner discharge tube

for the 4 LPM (grey) eductor has a grey flooding ring inside it. Install the end of the tube nearest the flooding ring on

the eductor's inner discharge barb. To ensure the IDTs are on correctly, the metal rings must be above the small

barbs.

2. Drill holes for the three wall anchors with a 6mm drill bit, using the cabinet back as a template for correct spacing of

the mounting screws. Install mounting anchors, and then screws in top two anchors. Slide key holes in cabinet back

over screw heads, tighten screws, then install bottom screw. Do not mount more than 1.8 metres above the bottom

of the concentrate container, or below the highest concentrate level (never mount concentrate higher than the

proportioner).

3. Select metering tips (up to 4) for the selector valve (see next two sections). Push each tip firmly into a separate hose

barb extending from the selector valve. A tip with no hole (clear plastic color) can be used to block any valve port not

being used. (This may be used for dispensing water only.)

4. Cut tubing supplied for chemical inlet (6mm ID) into lengths required so that tubes reach from barbs on selector valve

to bottom of concentrate containers. For each inlet tube, slide a weight over one end and slip end over the barb on

a footvalve. Slide weight down to foot valve and attach opposite end of each tube over one of the hose barbs on the

selector valve.

5. Slide tubes from each side through the notches in the cabinet.

6. Place footvalve ends of supply tubes into concentrate containers. REMEMBER TO CHECK FOOT VALVE

STRAINERS PERIODICALLY FOR CLOGGING: CLEAN IF NECESSARY.

7. A short discharge tube is used with a 4 LPM (grey) eductor – Model 3875GBA-2 ; minimum tube length is 20 cm

for correct operation. A longer tube (1.2m) is used with a 14 LPM (yellow) eductor – Model 3874GBA-2. Slide end

of tube over inner discharge tube and onto eductor discharge outlet. The hose hook supplied with Model 3874GBA-

2 may be installed on the long tube to allow it to hang from dispenser when not in use.

8. Replace cabinet cover. Push the sides in, behind the latch holes, to snap the cover in place. The two screws provided

may be installed in the holes in the cabinet sides to prevent easy removal of cover.

9. Connect water supply hose of at least 13mm ID to water inlet swivel. (Minimum 1.76 Bar pressure, with water

running, is required for correct operation.) Connect opposite end of hose to water supply. Turn water supply on.

10. Purge air from the system by pressing the buttons briefly. There may be some water discharge from the eductor vents

until the air is purged.

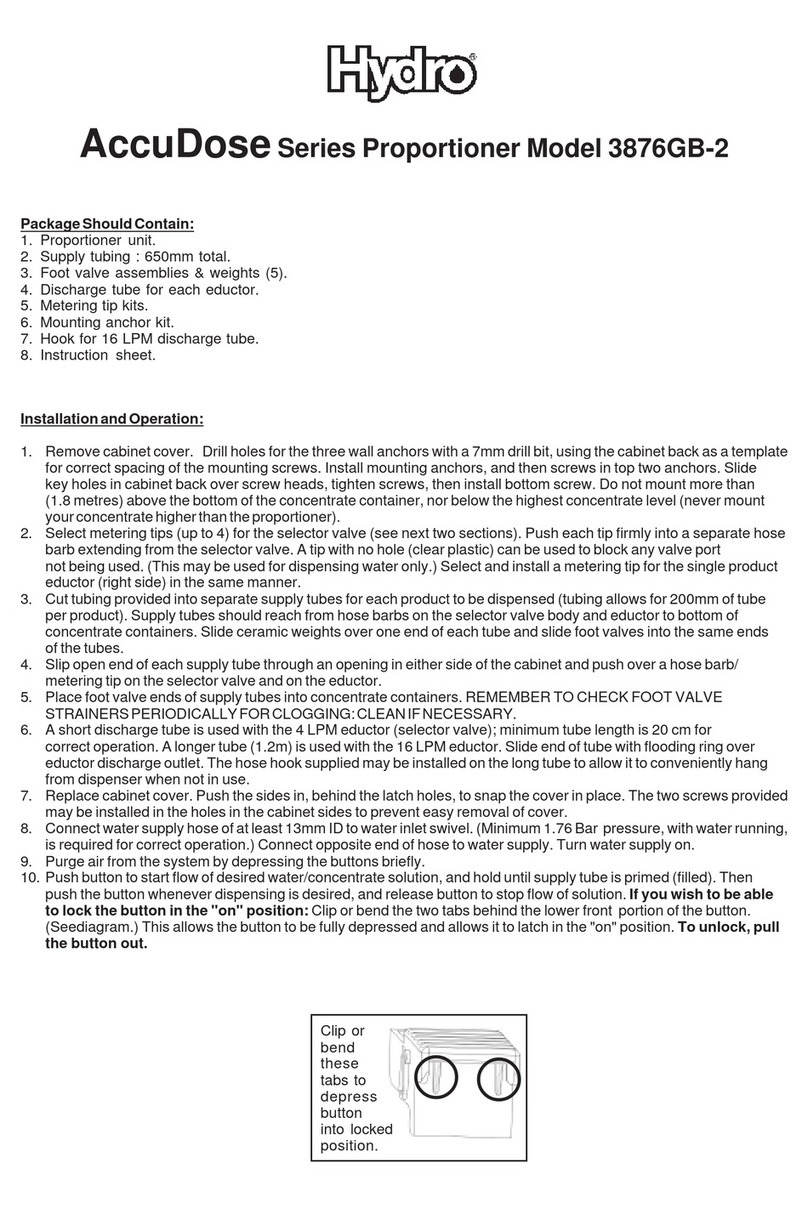

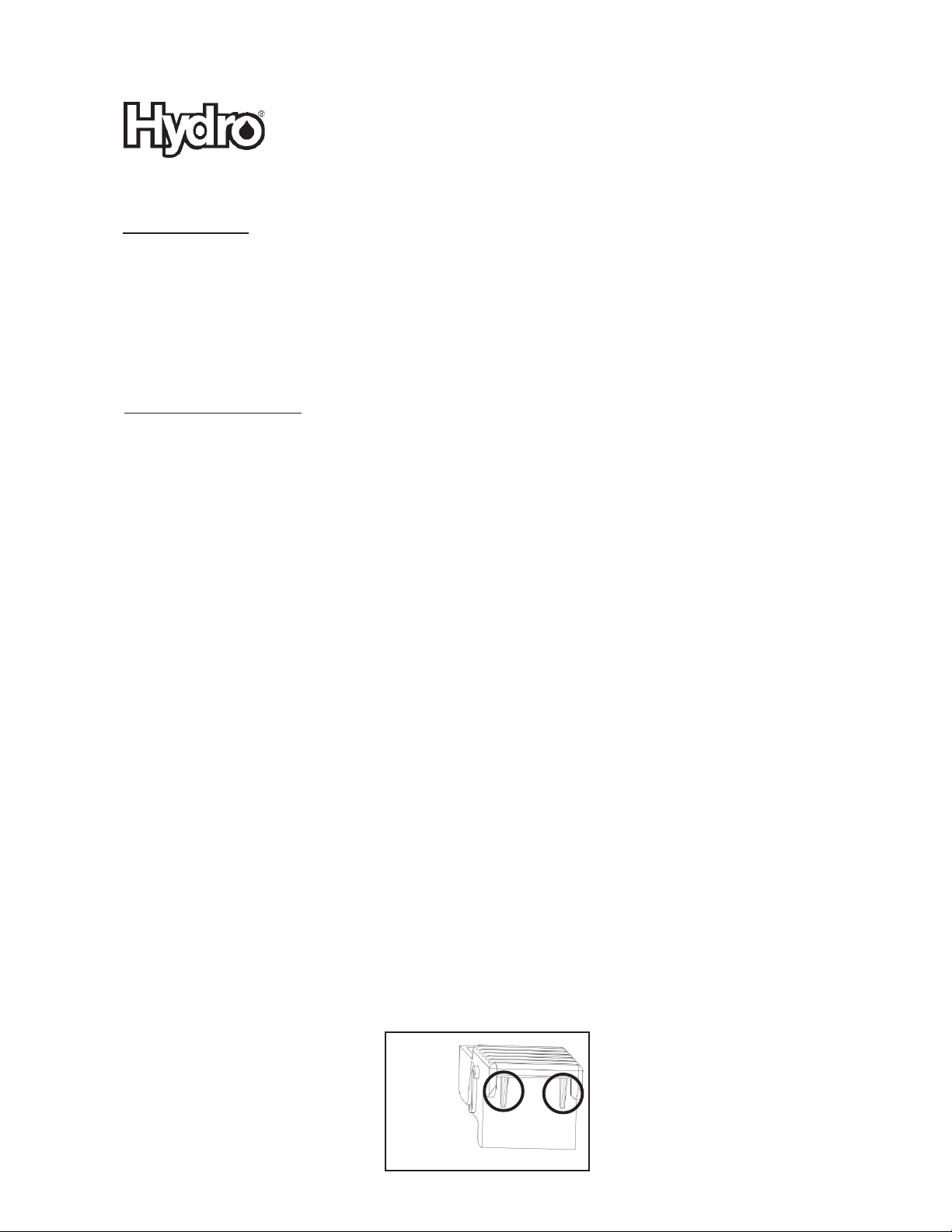

11. Push button to start flow of desired water/concentrate solution, and hold until supply tube is primed (filled). Then push

the button whenever dispensing is required, and release button to stop flow of solution. If you wish to be able to lock

the button in the "on" position: Clip or bend the two tabs behind the lower front portion of the button. (Seediagram

below.) This allows the button to be fully depressed and allows it to latch in the "on" position. TO UNLOCK, PULL

THE BUTTON OUT!

12. It is essential that the discharge hose is not obstructed. If discharge is restricted, water will flow out of the

eductor vents. Do not start to operate the dispenser with liquid in the discharge tube.

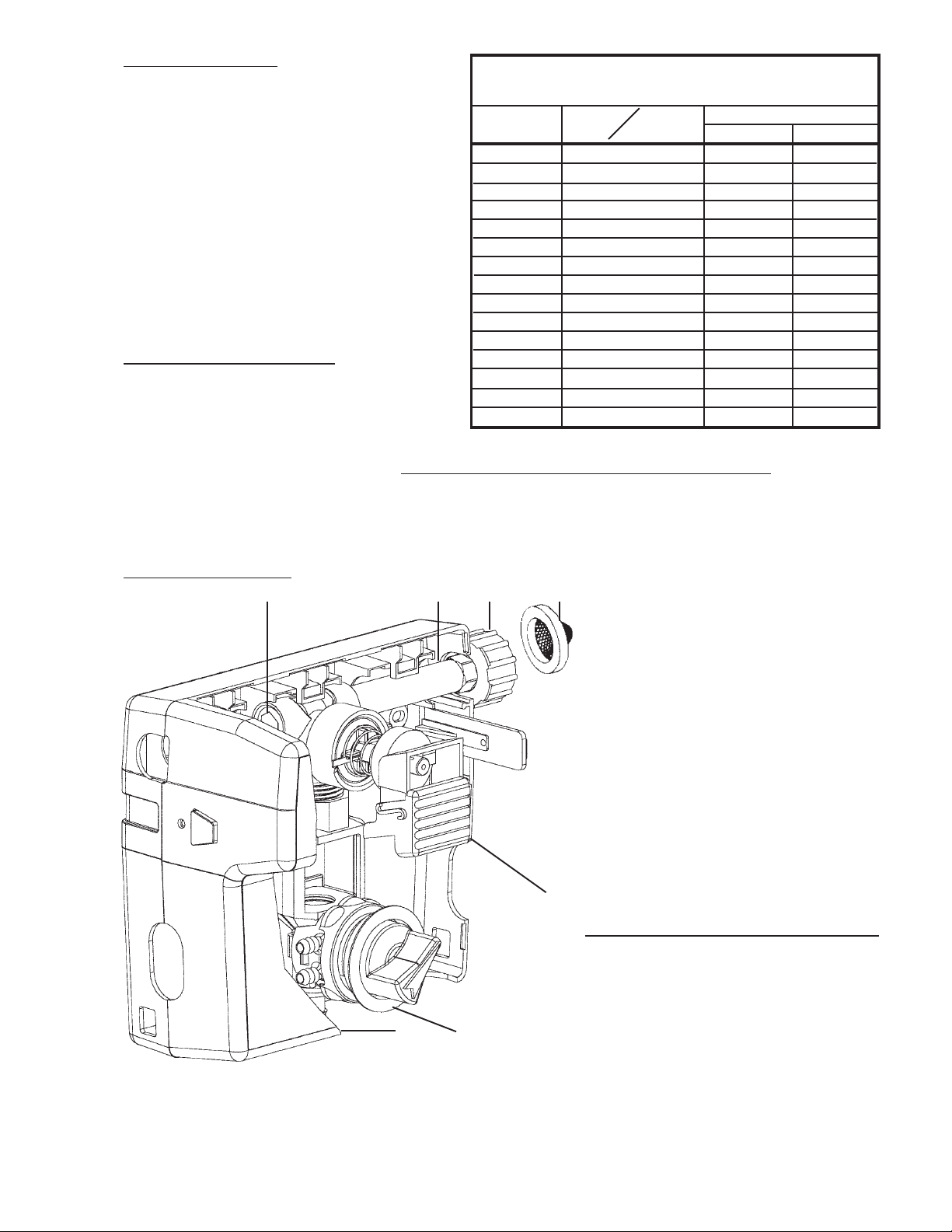

AccuDose 3874GBA-2 & 3875GBA-2

with HydroGapTM Air Gap Eductors

Package Contains:

1. Proportioner unit.

2. Chemical inlet tubing .

3Foot valves (4) and

weights (4).

3. Discharge tube.

4. Metering tip kit.

5. Mounting hardware.

6. Hook for discharge tube

(Model 3874GBA-2 only).

7. Instruction sheet.

Clip or

bend

these

tabs to

depress

button

into locked

position.