10094778 Rev B 11/10 © Hydro Systems Company, Inc. 2010 HydroSystemsCo.com Toll Free: 1.800.543.7184 1

This guide contains instructions for installing, programming, and troubleshooting

the AutoDose™ Dispensing System. Throughout the guide, the following icons are

used to indicate the model(s) to which each step pertains.

AutoDose™ Automatic Dispensing System

The AutoDoseTM is a battery or A/C-powered peristaltic pumping dispenser that runs automatically at preset times as

programmed with an electronic timer / control. Product operates reliably and consistantly, even in demanding environments.

Please use this equipment carefully and

observe all warnings and cautions.

ALWAYS observe safety and handling instructions of

the chemical manufacturers.

ALWAYS direct discharge away from you or other

persons or into approved containers.

ALWAYS dispense cleaners and chemicals in accordance

with manufacturer’s instructions. Exercise CAUTION

when maintaining your equipment.

KEEP equipment clean for proper operation.

WEAR protective clothing and eyewear when working

in the vicinity of all chemicals, filling or emptying

equipment, or changing tubes.

ALWAYS re-assemble equipment according to

instruction procedures. Be sure all components are

firmly screwed or latched into position. Ensure that

hoses and electrical wires are properly placed and not

kinked or pinched.

ONLY USE ALKALINE BATTERIES.

Tube life will vary depending on the type of treatment

product used. To prevent emergency service, schedule

replacement at least once per year.

NOTE: The batteries should be scheduled for periodic

replacement. Using a total of 40 running (pumping)

hours, create a schedule for servicing the unit and

changing the batteries. Maintaining the power source

as such will help to provide the proper dosing by

providing a more consistent pumping rate.

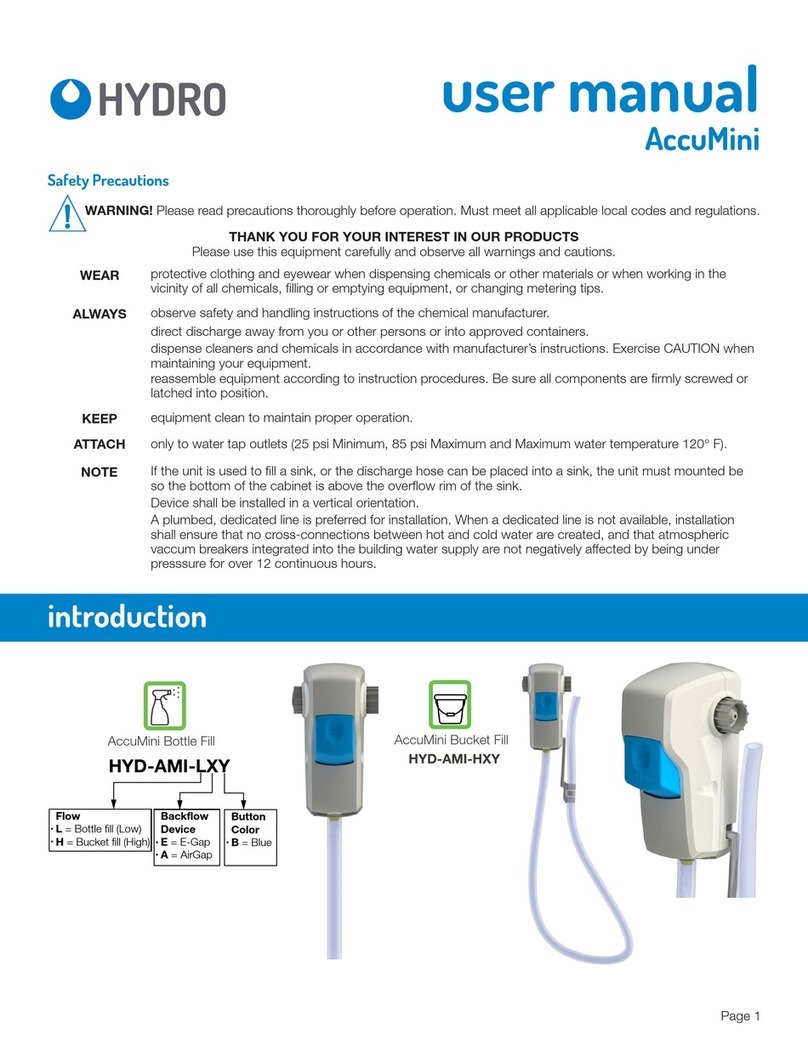

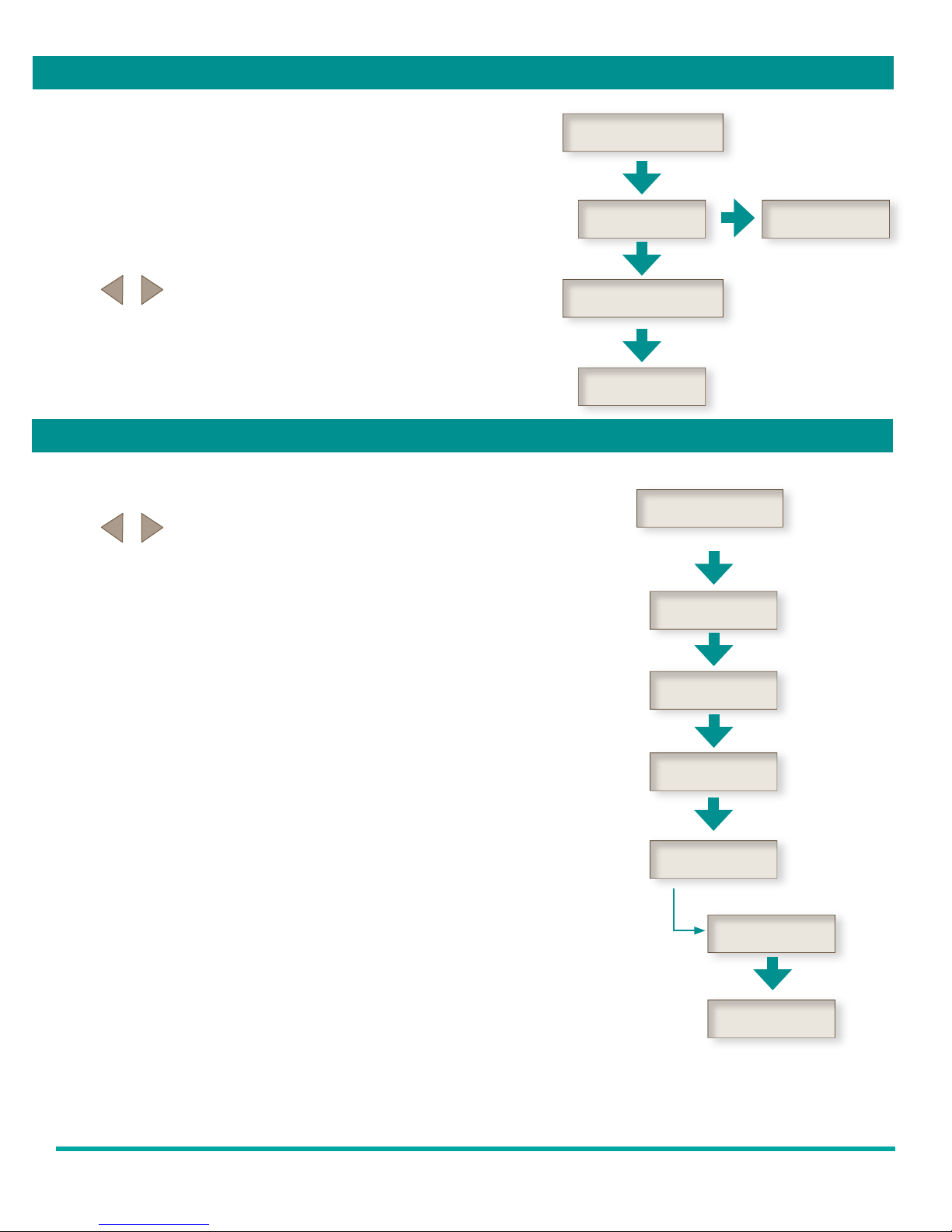

Models:

Mounts:

Power:

Pail Mount

(3.5 – 5 gal pail)

8 D-cell batteries

Wall Mount

8 D-cell batteries

Wall Mount

A/C Power or 8 D-cell batteries

1170 1180 1190

AutoDose™ Dispenser Specifications:

PUMP

Flow Rate Approx 3.5 oz / min

Tube Material EPDM

Inlet Vacuum 20+ in Hg

Outlet Pressure 20 psi

SYSTEM CABINET

Material Polypropylene and ABS

Size (Model 1170) Approx. 7 3/4” tall X 14” diameter

(does not include container 1170 model system sits on)

Size (Models 1180 and 1190) 4 3/4” X 6 3/4” X 8 1/3”

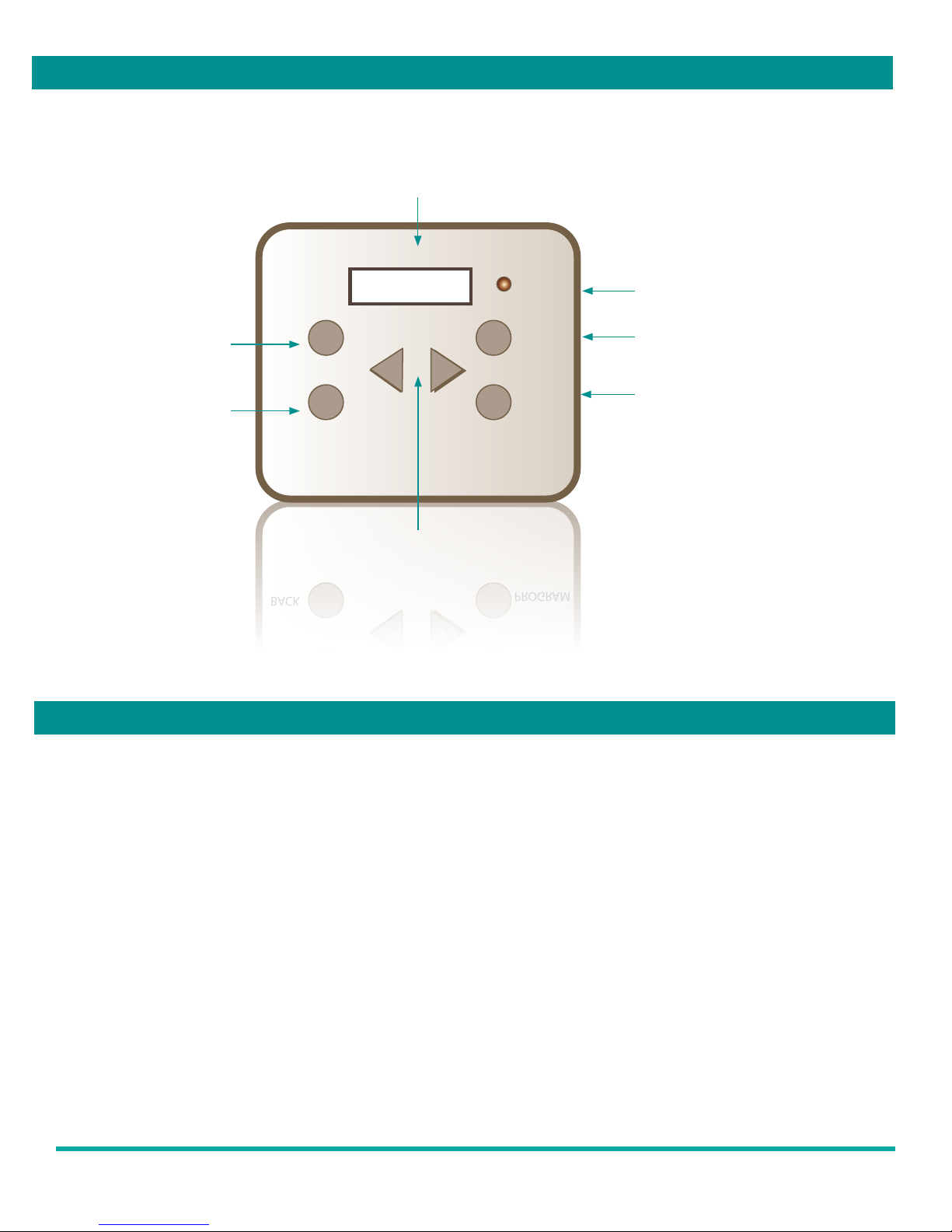

PROGRAMMABLE TIMER / CONTROL

Program Duration Daily / Weekend / Week Days/Special

Maximum # of Events 24

Dispense Amount per Event 1 oz – 30 oz (dispensed in 1 oz increments)

or 30 – 900 ml (dispensed in 30 ml increments)

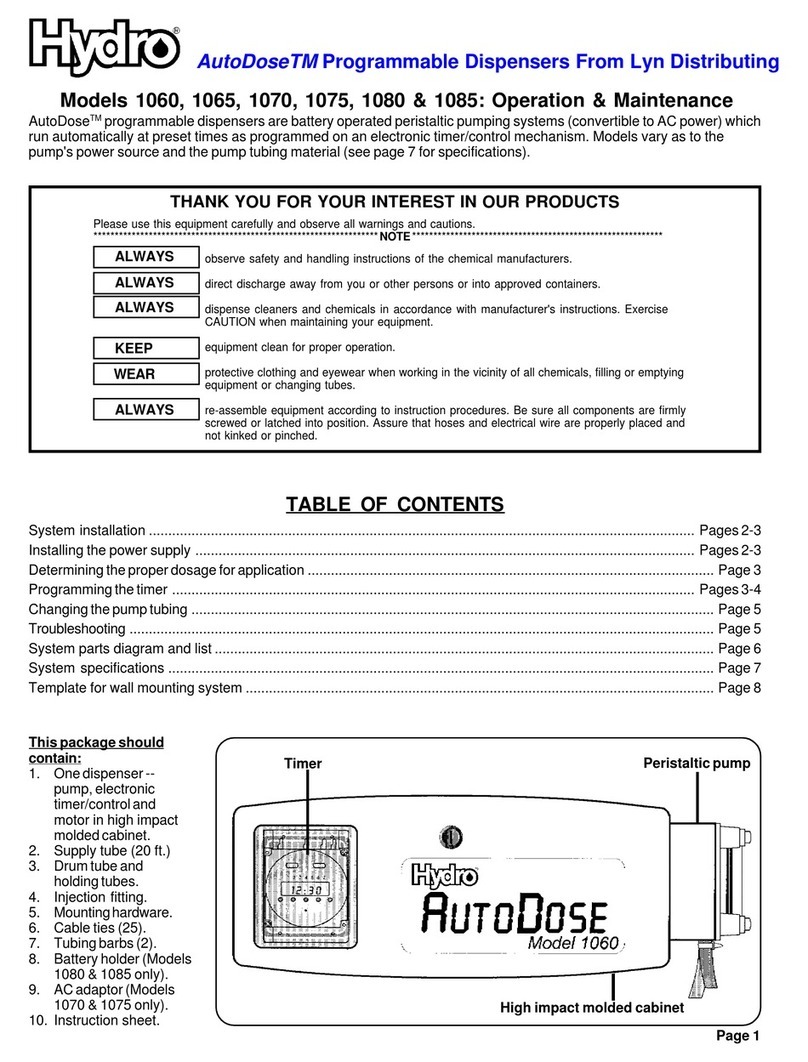

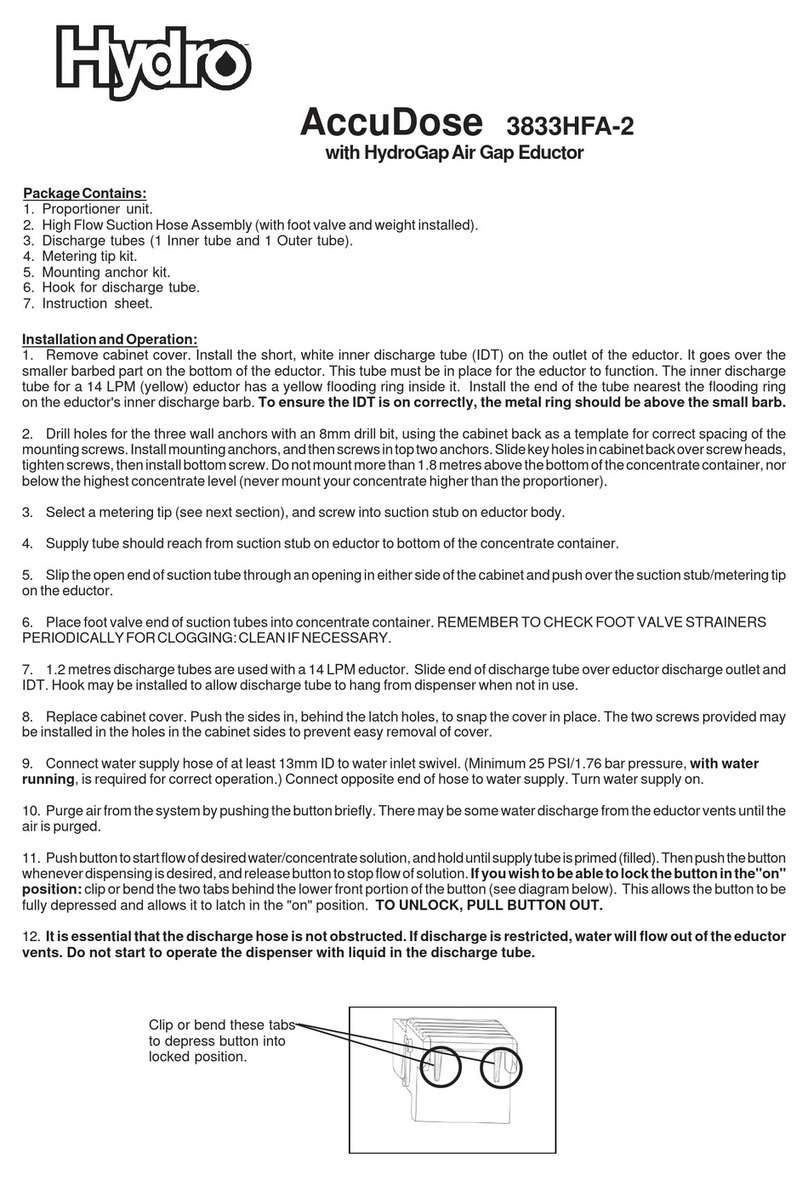

This package should contain:

• One AutoDoseTM dispenser

INSTALL PACKAGE CONTAINING:

• Ceramic weight and strainer for inlet tubing

• Polyethylene tubing (10 ft)

• Cable ties

• Mounting Bracket (Some Models)

• AC Adapter (Some Models)

• Injection Fitting