2. description

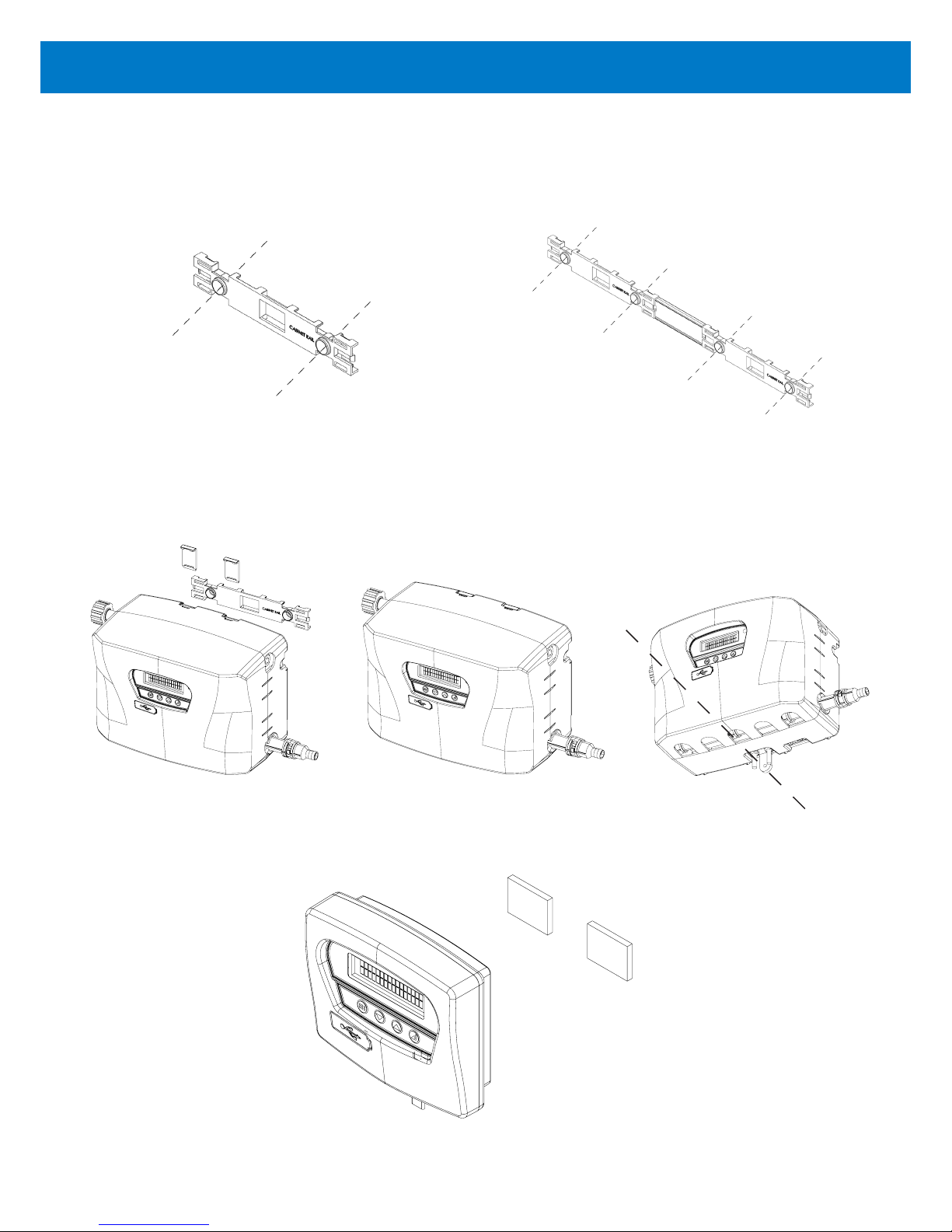

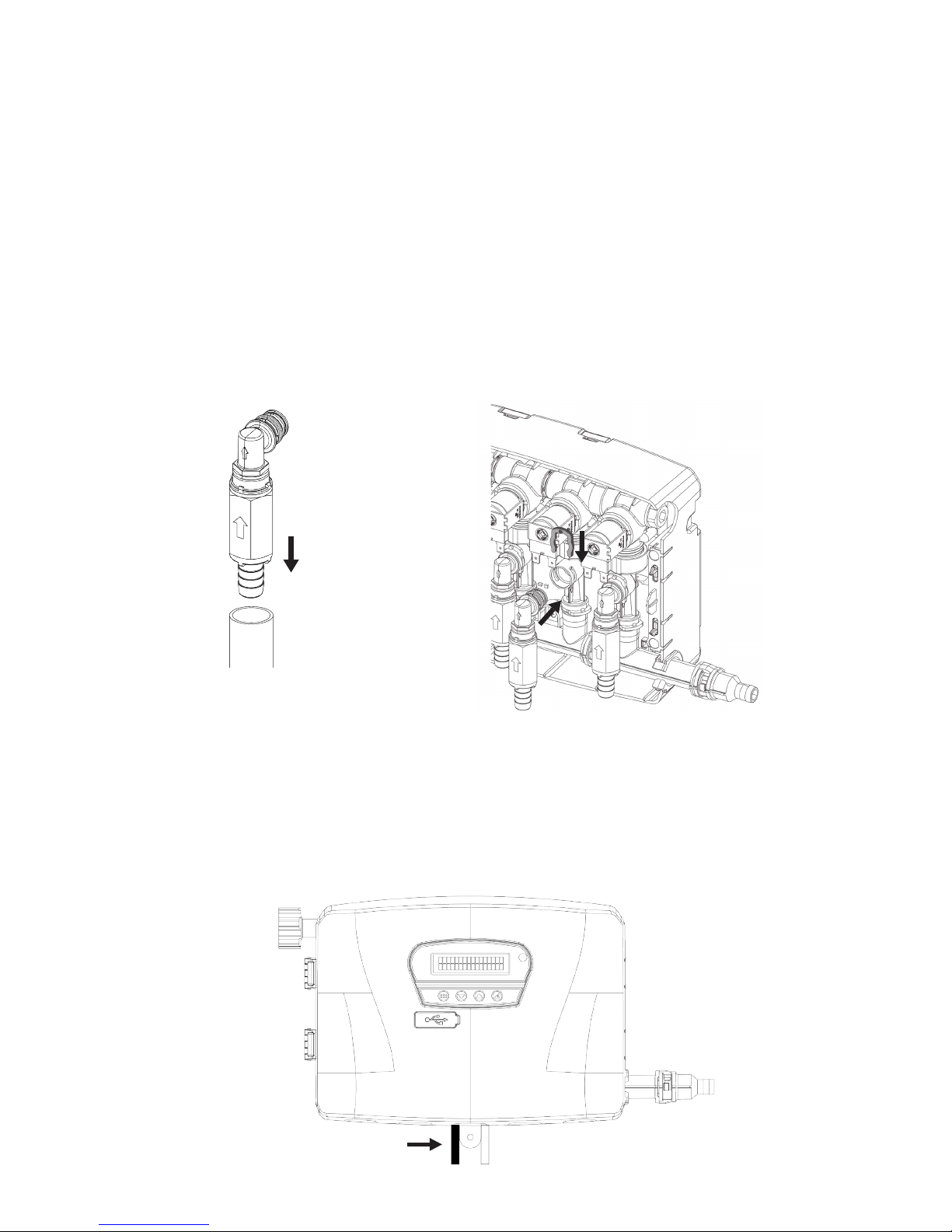

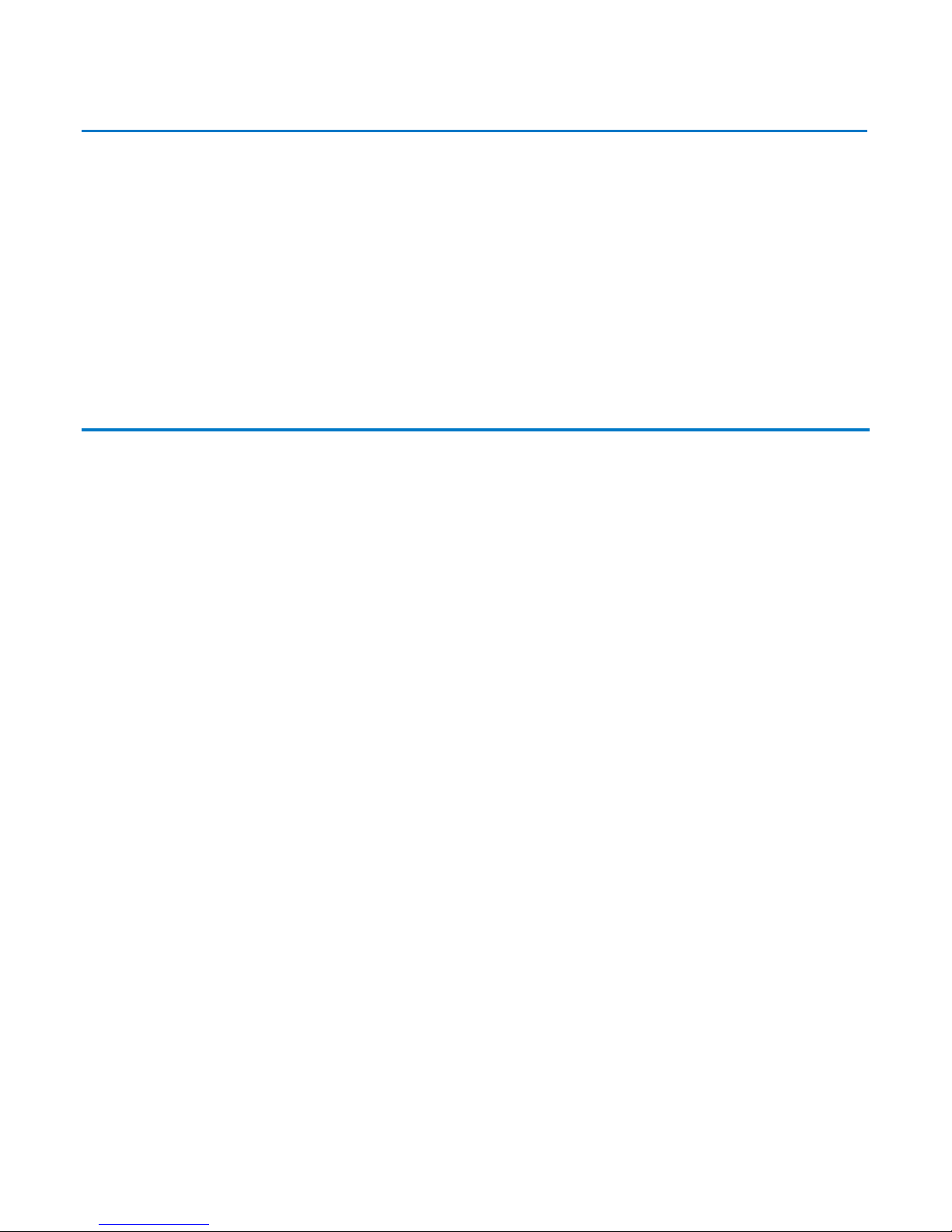

The EvoClean (Patent Pending GB1708496.3) is a low maintenance, venturi-based, water-powered laundry unit. It features an

integrated control system that can either be supplied on-board the unit or off-board within a housing. The EvoClean can be

used for applications requiring up to four, six or eight products and also offers an integrated flush manifold, ‘out-of-product’

alarm, optional remote formula select and downloadable reports. This guide contains instructions for installing, programming,

operating and troubleshooting the EvoClean. For further information and the option to download the PC formula editor please

navigate to:

http://hydrosystemseurope.com/product/evoclean/

2.1 Intended Use

• The EvoClean is intended for use in industrial applications. It is not suitable for domestic use and it must not be

used outside of its intended use.

• The product must only be used for washing and rinsing of laundry that are marked accordingly. The manufacturer

waives any responsibility arisen from incorrect usage or transportation.

2.2 EMEA models:

• 1221GB – EvoClean 2, 6 Product Unit – Low Flow, RFS

• 1222GB – EvoClean 2, 6 Product Unit – Low Flow, Off BC

• 1223GB – EvoClean 2, 6 Product Unit – High Flow, Off BC

• 1224GB – EvoClean 2, 6 Product Unit – High Flow

• 1225GB – EvoClean 2, 4 Product Unit – Low Flow, Off BC

• 1226GB – EvoClean 2, 4 Product Unit – High Flow, Off BC

• 1227GB – EvoClean 2, 4 Product Unit – Low Flow

• 1228GB – EvoClean 2, 4 Product Unit – High Flow

• 1230GB – EvoClean 2, 8 Product Unit – Low Flow, Off BC

• 1231GB – EvoClean 2, 8 Product Unit – High Flow, Off BC

• 1232GB – EvoClean 2, 8 Product Unit – Low Flow

• 1233GB – EvoClean 2, 8 Product Unit – High Flow

• 1234GB – EvoClean 2, 6 product unit – Low flow, RFS

• 1235GB – EvoClean 2, 6 product unit – High flow, RFS

• 1236GB – EvoClean 2, 4 product unit – Low flow, RFS

• 1237GB – EvoClean 2, 4 product unit – High flow, RFS

• 1238GB – EvoClean 2, 8 product unit – Low flow, RFS

• 1239GB – EvoClean 2, 8 product unit – High flow, RFS

APAC models:

• 1214RAPAPAC – EvoClean 2, 4 Product Unit – Low Flow, RFS

• 1216RAPAPAC – EvoClean 2, 4 Product Unit – High Flow, RFS

• 1234GBAPAC – EvoClean 2, 6 Product Unit – Low Flow, RFS

• 1235APAC2 – EvoClean 2, 6 Product Unit – High Flow, RFS

• 1235GBAPAC – EvoClean 2, 6 Product Unit – High Flow, RFS, EP

• 1218RAPAPAC – EvoClean 2, 8 Product Unit – High Flow, RFS

• 1218RGBAPAC2 – EvoClean 2, 8 Product Unit – High Flow, RFS, EP

*other versions are available on request