Table of contents

1. SAFETY....................................................................................................................... 4

1.1 General safety and warning information .................................................................................. 4

1.2 Notes on handling the service measuring kit........................................................................... 5

1.3 Information about the handling of sensors and cables ............................................................ 6

2. BASICS ....................................................................................................................... 7

2.1 Scope....................................................................................................................................... 7

2.2 Copyright.................................................................................................................................. 7

2.3 Limitation of liability.................................................................................................................. 7

2.4 Intended use ............................................................................................................................ 8

2.5 Warranty................................................................................................................................... 8

2.6 Customer obligations ............................................................................................................... 8

2.7 Authorized personnel............................................................................................................... 9

3. DESCRIPTION OF THE SERVICE MEASURING KIT................................................10

3.1 General................................................................................................................................... 10

3.2 Dimensions of the service measuring kit ............................................................................... 11

3.3 Scope of delivery of the service measuring kit ...................................................................... 12

4. START-UP OF THE SERVICE MEASURING KIT ......................................................13

4.1 Connection to a hydraulic system.......................................................................................... 13

4.1.1 Installation in the pressure line ......................................................................................... 14

4.1.2 Installation in the return line.............................................................................................. 15

4.1.3 Setting the flow.................................................................................................................. 16

4.2 Ventilating the service measuring kit ..................................................................................... 16

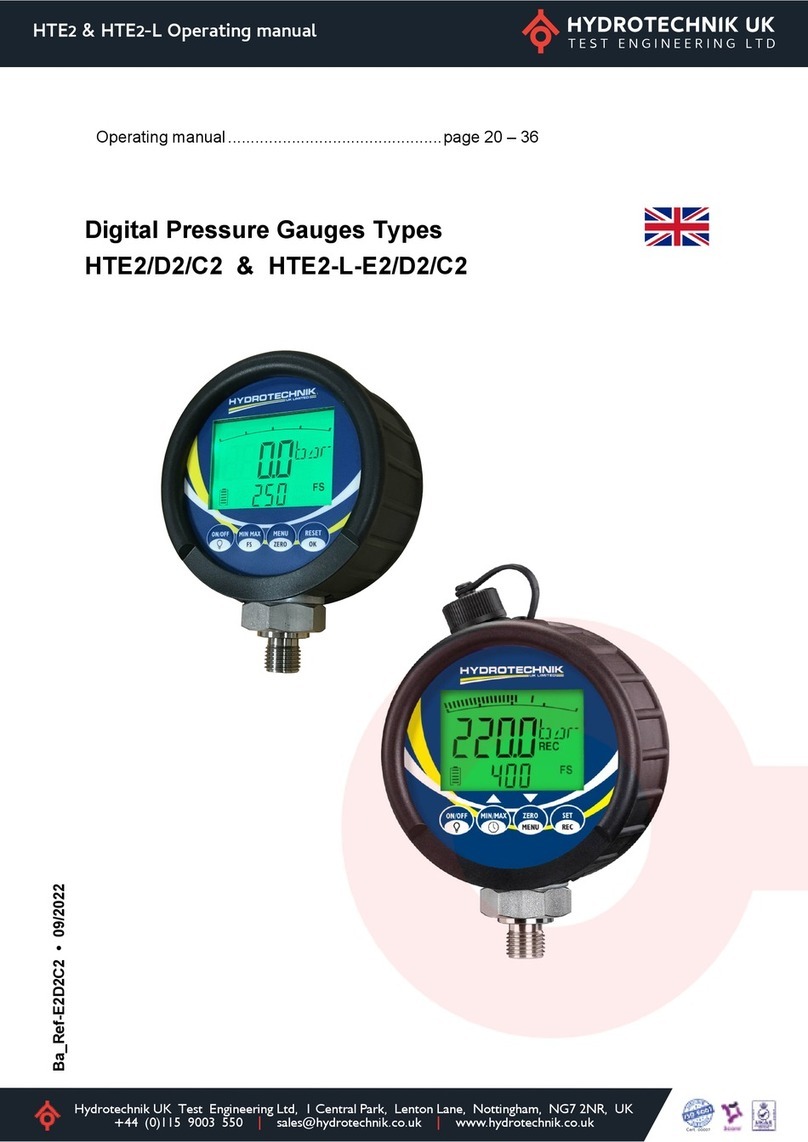

4.3 Connecting the sensors ......................................................................................................... 17

5. USE WITH A MULTISYSTEM MEASUREMENT INSTRUMENT................................19

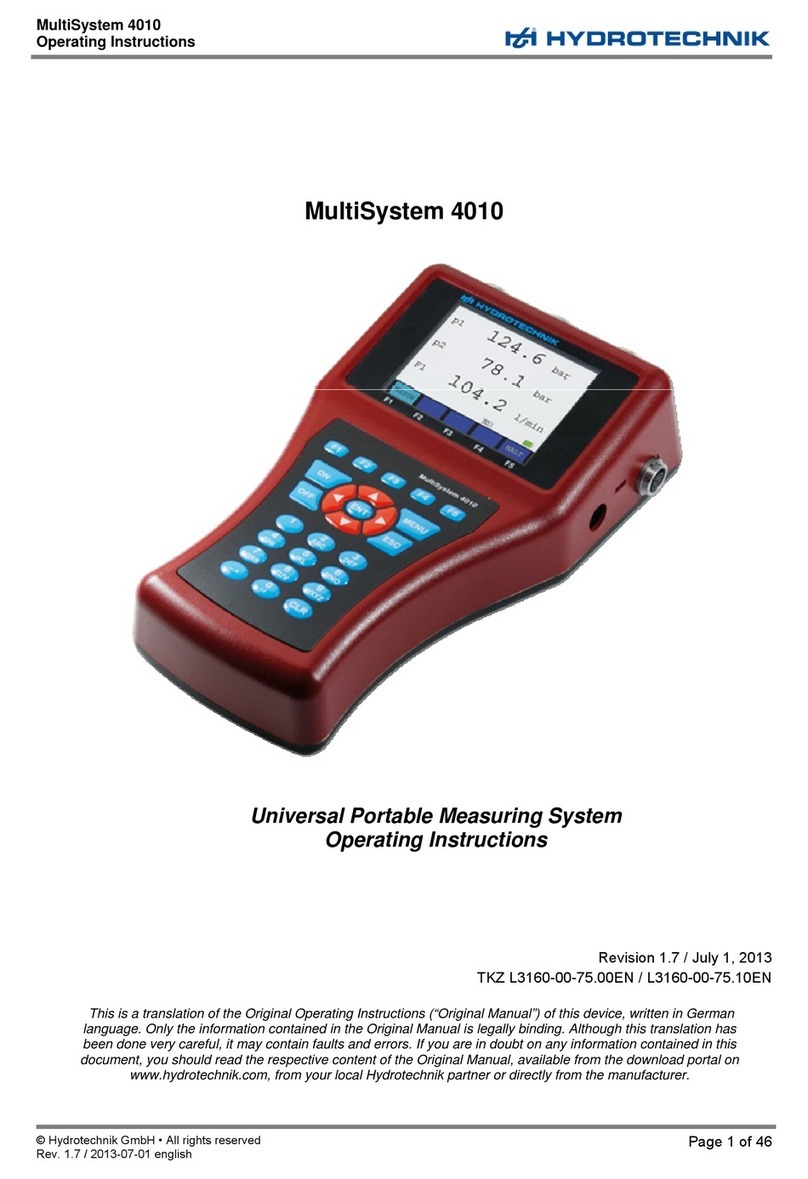

5.1 Use with the MultiSystem 5070/4070..................................................................................... 20

5.1.1 Opening the “HySense CX 197” function.......................................................................... 20

5.1.2 Operating the “HySense CX 197” function ....................................................................... 21

5.1.3 Selection of the metering point ......................................................................................... 22

5.1.4 Evaluation of the measurements - Condition menu.......................................................... 25

5.1.5 Display of the measurement values.................................................................................. 29

5.1.6 Exporting the measurement data...................................................................................... 30

5.1.7 Evaluating measurements ................................................................................................ 31

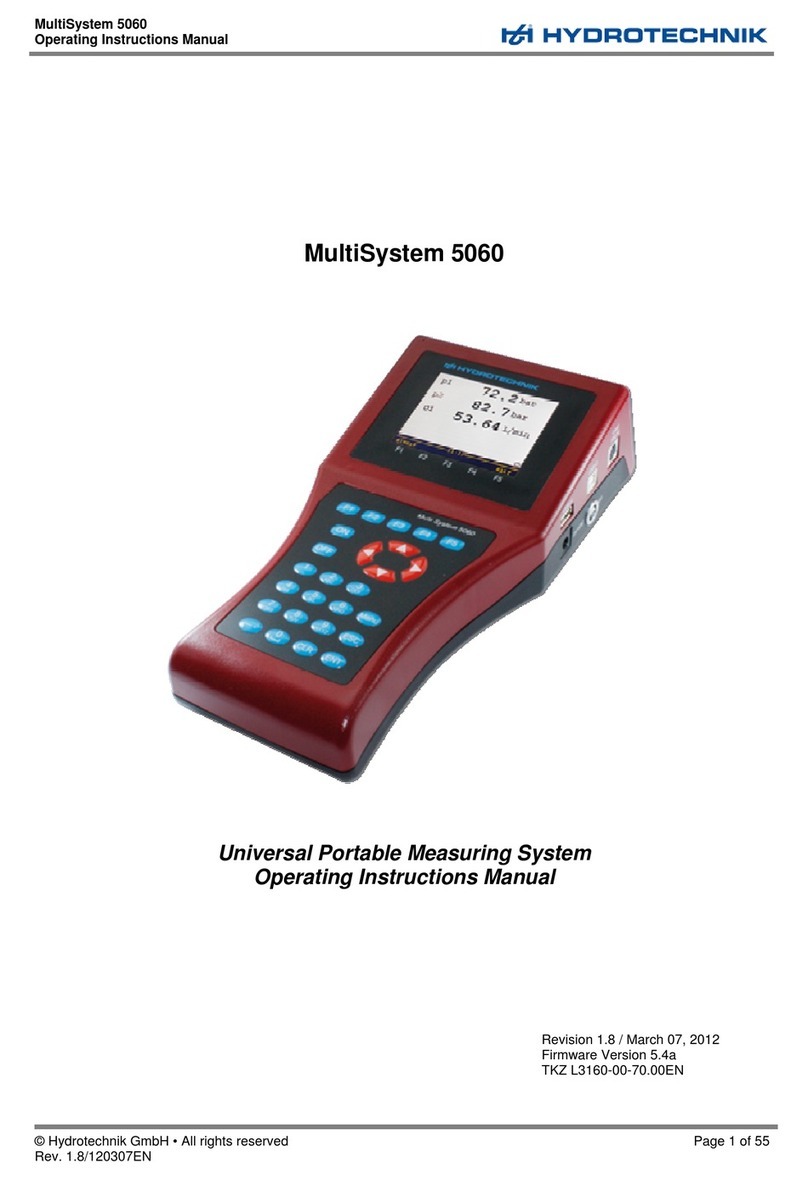

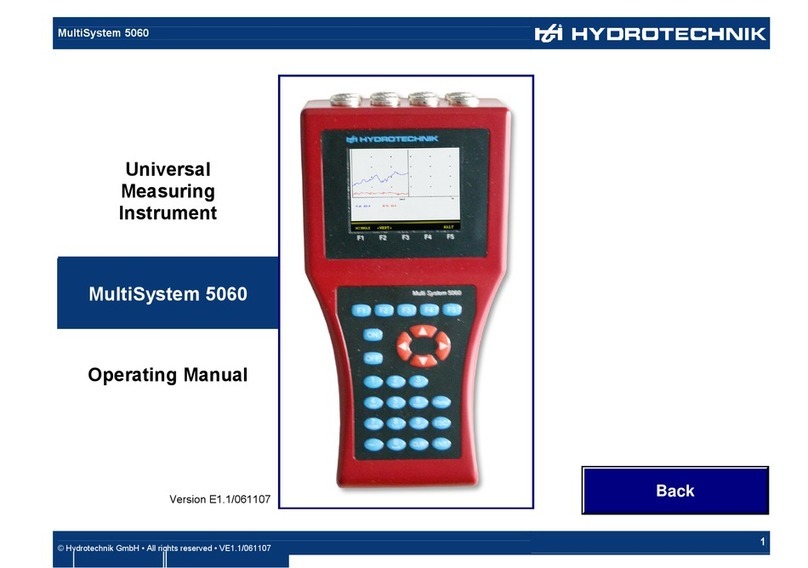

5.2 Use with the MultiSystem 5060Plus....................................................................................... 32

5.2.1 Opening the “Measuring section CX 197” function ........................................................... 32