Table of Contents

1. Safety ...............................................................................................................................4

1.1 General safety instructions......................................................................................................4

1.2 Notes on handling with the measuring system........................................................................6

1.3 Notes on handling with cables and hoses...............................................................................6

2. INTRODUCTION ..............................................................................................................7

2.1 Scope......................................................................................................................................7

2.2 Copyright.................................................................................................................................7

2.3 Limitation of liability.................................................................................................................7

2.4 Intended use ...........................................................................................................................8

2.5 Warranty..................................................................................................................................8

2.6 Customer obligations ..............................................................................................................9

2.7 Authorized personnel..............................................................................................................9

2.8 Disposal ..................................................................................................................................9

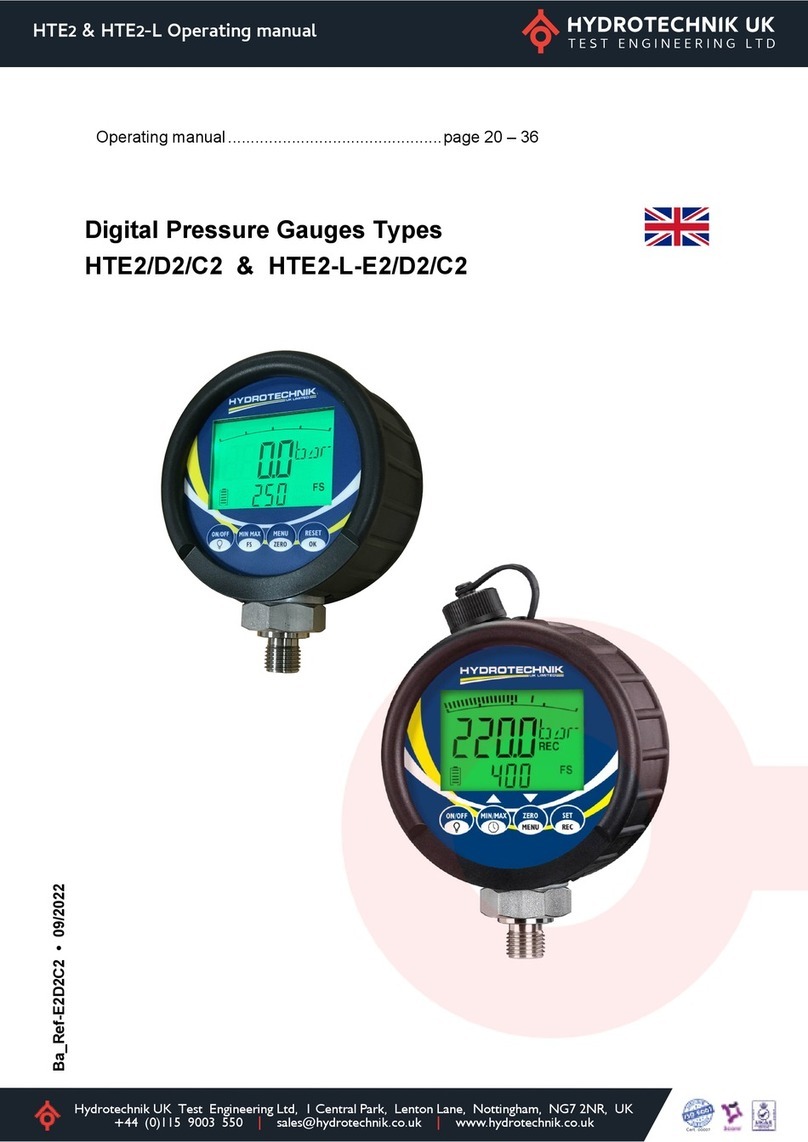

3. DESCRIPTION OF THE PORTABLE PARTICLE MONITOR......................................10

3.1 Properties..............................................................................................................................10

3.2 Dimensions of the instrument................................................................................................11

3.3 Specifications........................................................................................................................11

3.4 Description of the instrument.................................................................................................12

4. INSTALLATION AND START-UP.................................................................................14

4.1 Measurement via bottle samples / direct withdrawal from the tank.......................................14

4.2 Direct connection to the hydraulic line...................................................................................16

4.3 Deaerate the device and the hose lines................................................................................17

4.4 Electrical connections ...........................................................................................................18

4.5 Evaluation .............................................................................................................................19

4.6 Sequential data output..........................................................................................................20

5. DESCRIPTION OF THE PATRICK................................................................................23

5.1 Menu tree..............................................................................................................................24

6. COMMUNICATION SETTING........................................................................................32

6.1 Configuration of the serial interface.......................................................................................32

6.1.1 Interface parameters........................................................................................................32

6.1.2 Interface parameters........................................................................................................32

6.2 Communication via USB .......................................................................................................33

6.3 CANopen...............................................................................................................................33

7. SERVICE AND ACCESSORIES....................................................................................39