E2 / D2 / C2 Operation

Technical changes reserved - 27 -

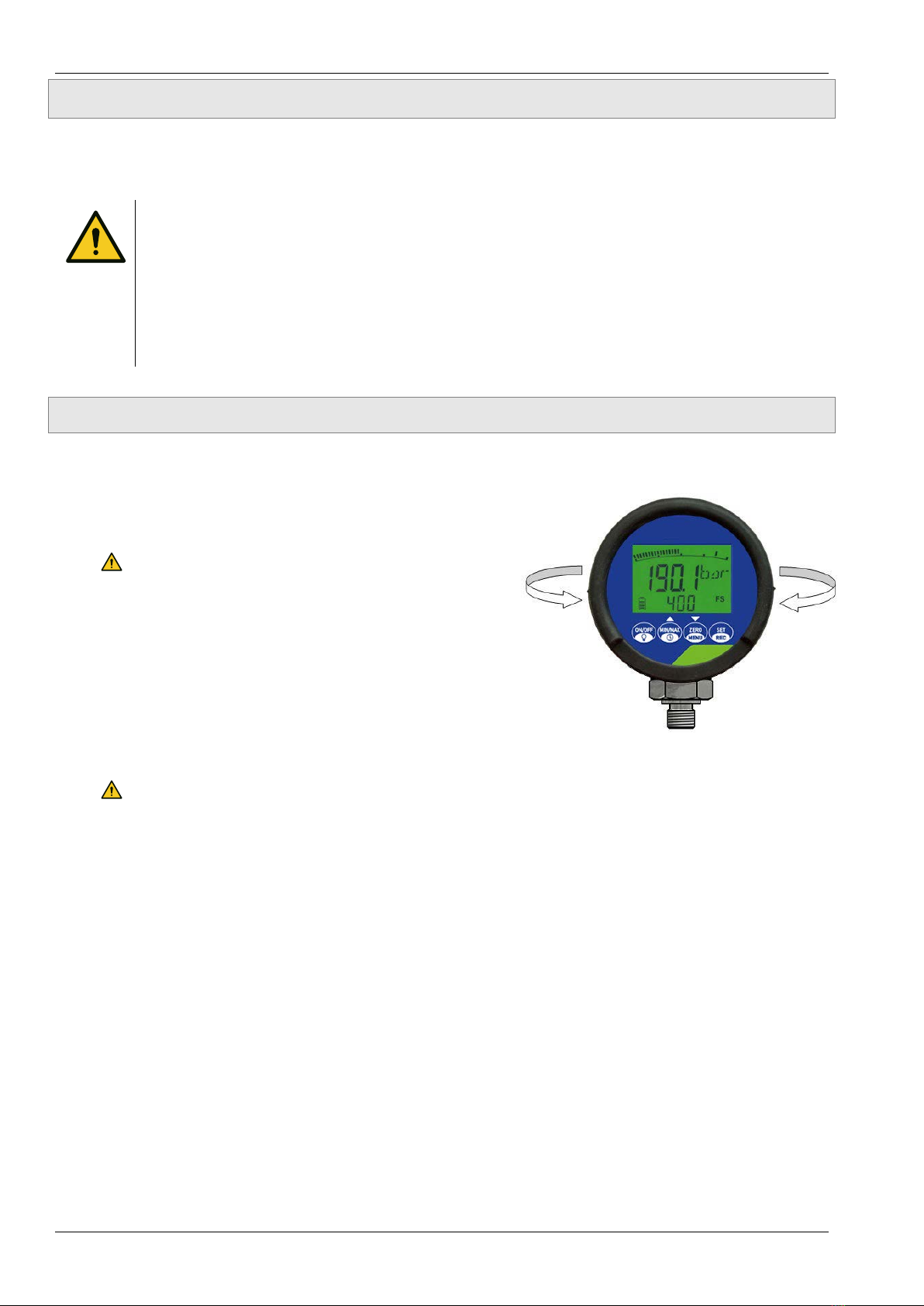

Press the ZERO/MENU button.

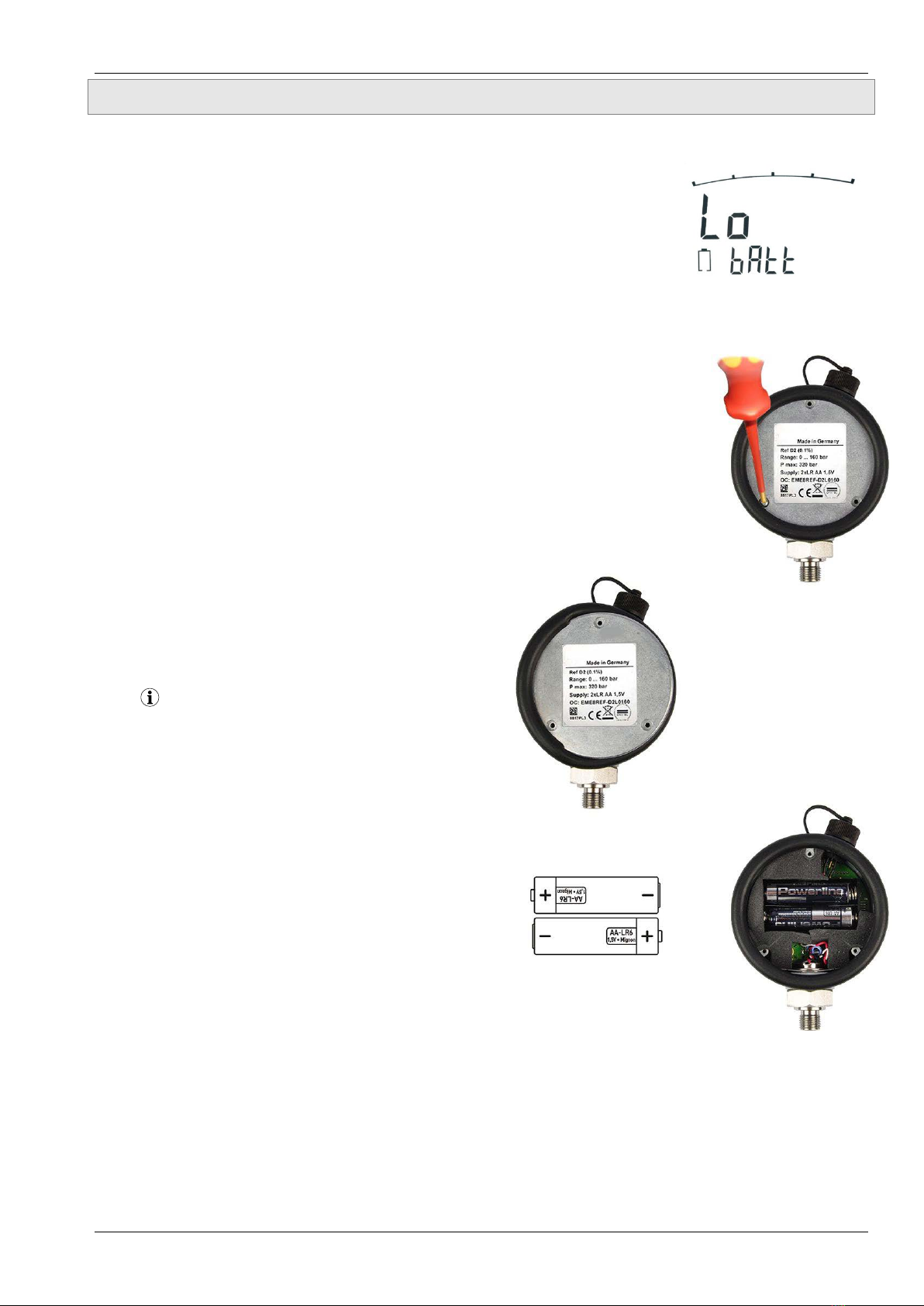

2Ero on appears in the display for 2 s. The ZERO function can

be activated.

Press the SET/OK button to perform the zero point correction.

The display and the MIN/MAX values are reset.

or

oFL 2Ero appears in the display for 2 s. The measured pres-

sure (0 bar) is greater than 5% of the pressure range. The ZERO

function cannot be performed.

The device switches back to measuring mode.

Depressurise and press the ZERO/MENU button again.

Resetting the zero point correction

The zero point correction stays activated until the device is switched

off. After it is switched on again, the zero point correction is no longer activated.

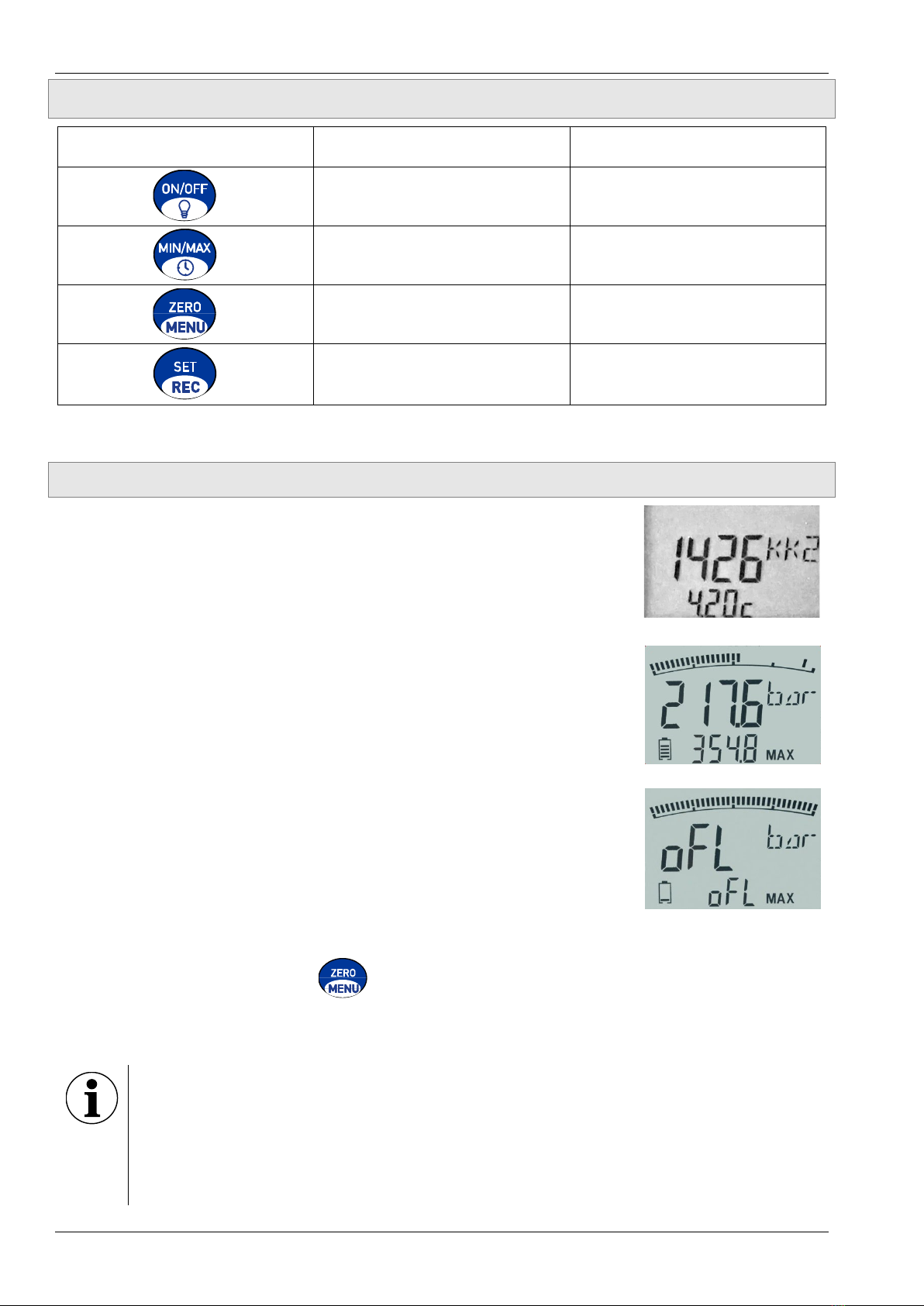

5.2 Device Settings

Press the ZERO/MENU button for 2 s.

Press ZERO/MENU button to continue.

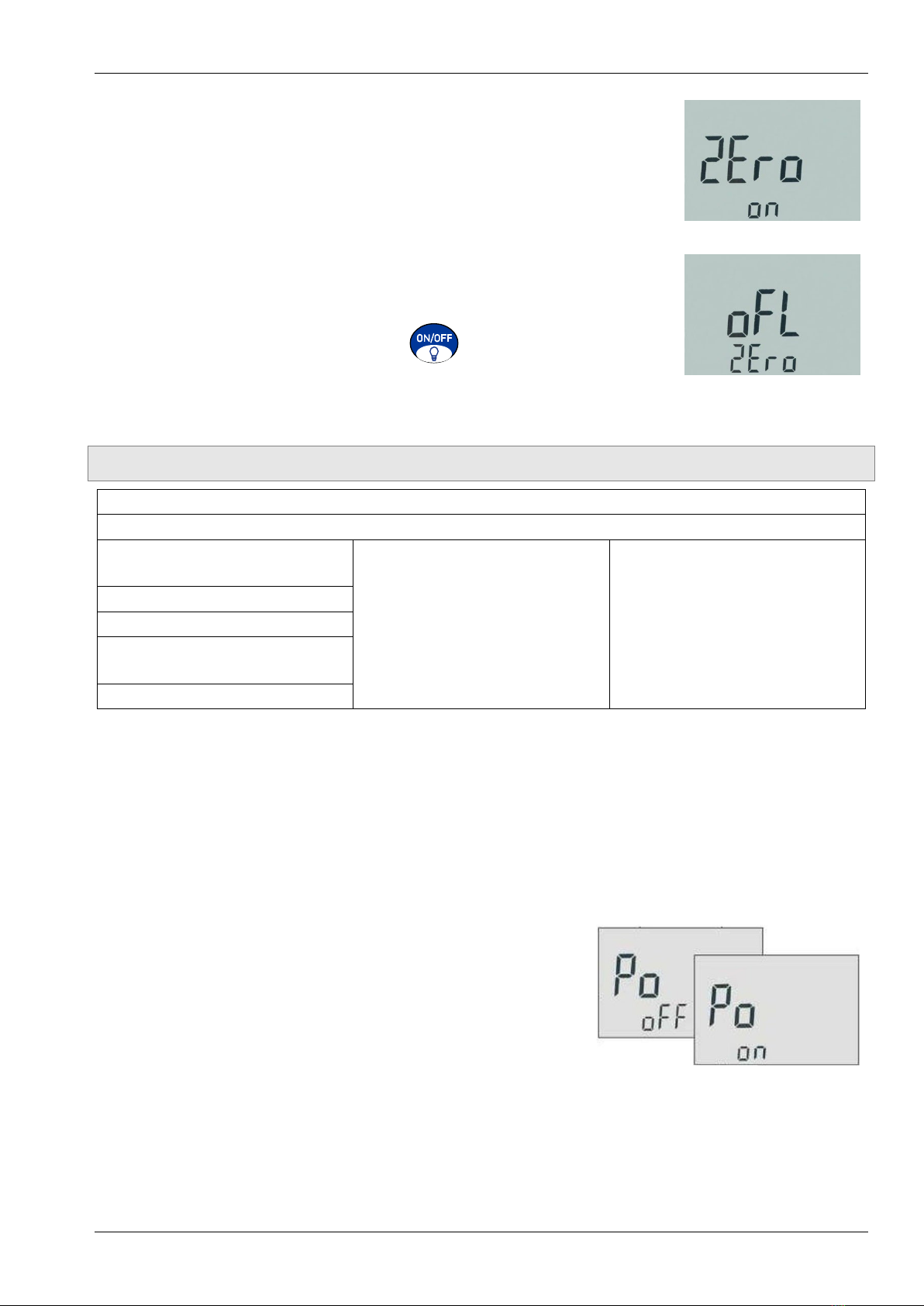

Po off

Po on

Press the ZERO/MENU

button for the next menu item.

Confirm your selection with

the SET/REC button. You

return to the display mode.

unit

Filt

Delete all measured data**

(dEL dAtA)

* Value selection: 0...7 (0 = no damping)

** Only version with data logger

You will automatically return to the display mode if you do not press any button for about 5 s.

Automatic shut-off

When the function is activated, the device automatically switches off after 5 minutes.

The automatic shut-off is deactivated for devices with data logger during data recording.

If the function is deactivated, the device is in continuous duty and has to be manually

switched off with the ON/OFF button.

The current setting is displayed when the digital pressure

gauge is switched on:

Po on = activated (automatic shut-off);

Po off = deactivated (continuous duty).

The settings Po on or Po off remain stored and are ac-

tive again when the device is switched on.