SECTION II

INSTRUCTIONS BEFORE USING YOUR NEW HYTORC

READ CAREFULLY: Most malfunctions, in new equipment, are the result of improper operation

and/or set-up.

PREPARATION: Remove HYTORC equipment from shipping container.

INSPECTION: Visually inspect all components for any damage during transportation. If damages

are found, notify HYTORC immediately.

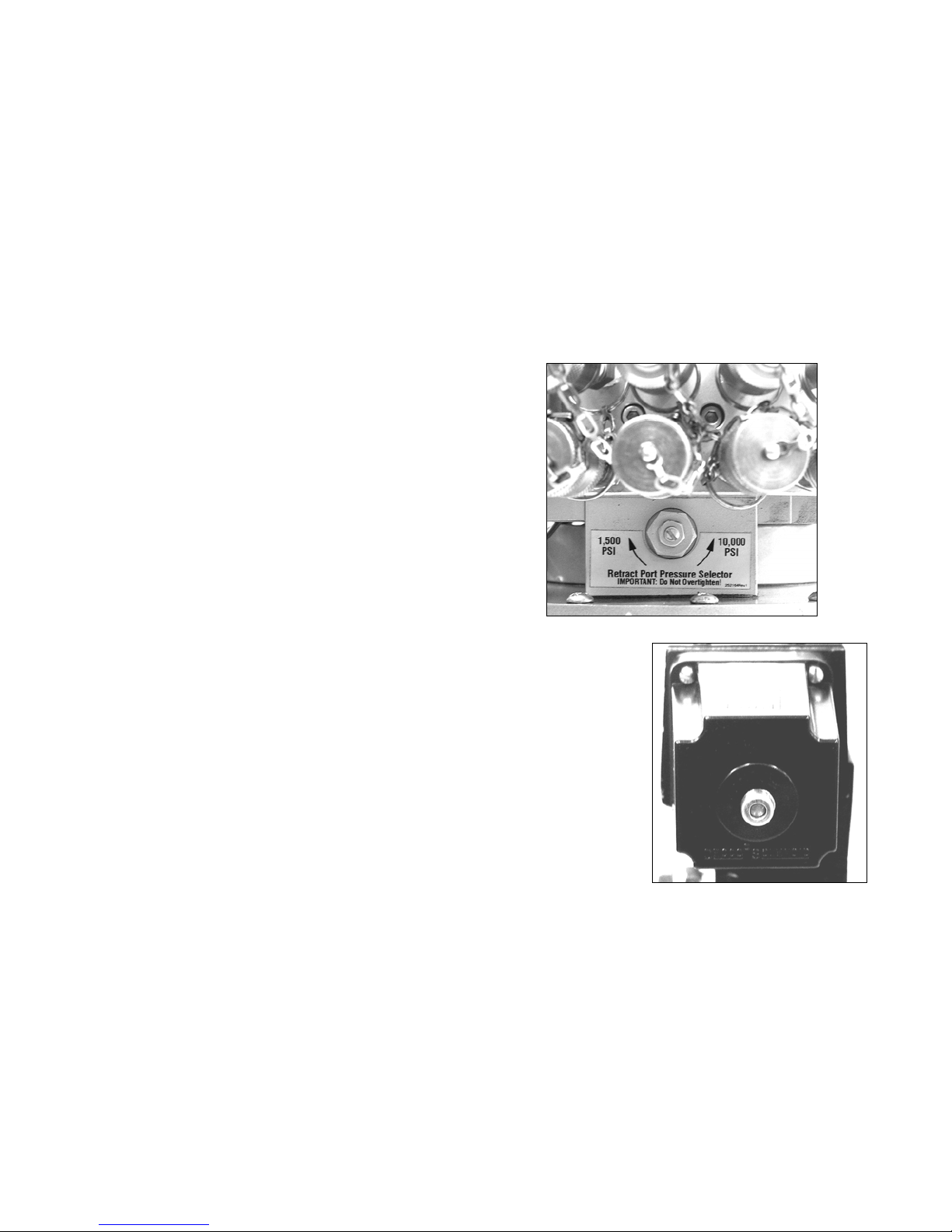

2-1 Working Pressure The tool’s maximum

working pressure is 10,000 PSI (700kg/cm2, 690 Bar)

Make sure that all hydraulic equipment used is rated

for 10,000 PSI operating pressure. To set pump

pressure for XXI models to 10,000 PSI for both

advance & retract, locate selector valve underneath

the couplers. Turn the pump off and loosen the lock

nut. Turn the center screw counter-clockwise until

it stops. Tighten the lock-nut. For Avanti & Stealth

models, turn the center screw clockwise until it stops.

Tighten the lock-nut to set the pump pressure to 1,500

PSI for retract.

2-2 Hydraulic Connections With older style pumps, (SST-10, SST-20),

the retract side of the system may remain pressurized after the pump

has been switched “off”. This trapped pressure makes it impossible to

loosen the retract-side fittings by hand. To release the pressure, find

the 5/16 manual override holes in the end of the black solenoids on the

pump. With a welding rod, Allen-key or similar device, push in on the

ends of both solenoids, each in turn, and the residual pressure will be

released. All fittings will, then, be hand tightened again. Hoses and

couplers must be free and unobstructed before and during the operation

of the tool. External impact on the couplers may break off the fittings.

Current pump models are equipped with an auto-pressure relief. Never disconnect or connect any

hydraulic hoses or fittings without first unloading wrench and the pump. Double check the gauge

reading to assure pressure has been released.

When making connections with quick disconnect couplings, make sure the cou

lin

s are full

en

a

ed.

Threaded connections such as fittings and gauges must be clean and securely tightened and leak free.

CAUTION: Loose or improper threaded fittings can be potentially dangerous if pressurized. Severe

over tightening can cause premature thread failure. Never grab, touch or in any way come in contact

with a hydraulic pressure leak. Escaping oil can penetrate the skin and cause injury.