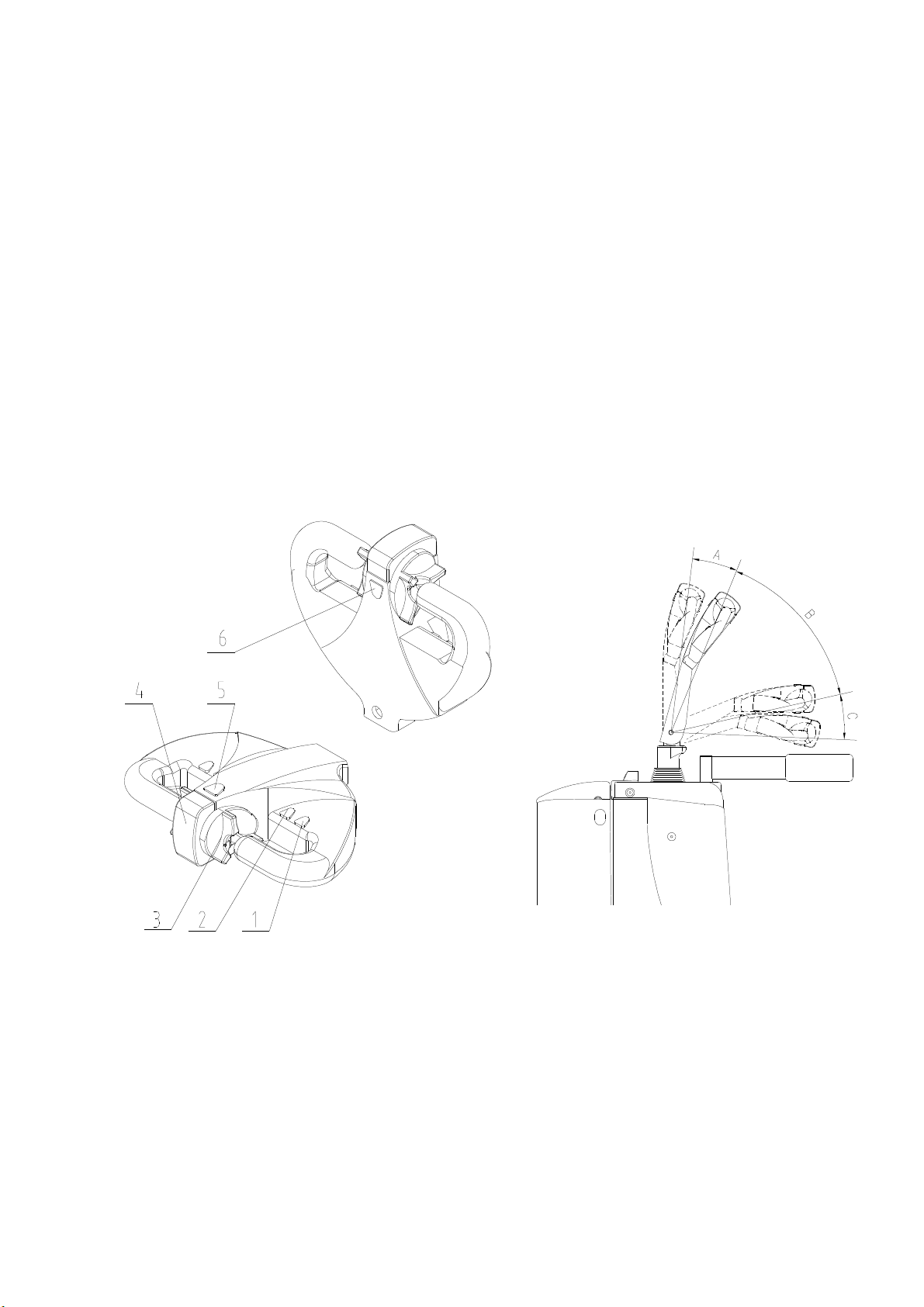

6

the truck will speed up with the increasing of rotation amplitude of the knob

3) Horn button

:

Horn of the truck will be turned on if you press the button

4) Emergency reverse button: when the operation handle is placed in area B and the emergency reverse button

is pressed, the truck will travel in an opposite direction away from the operator immediately This is a safety

switch which can avoid the operator from being squeezed under unexpected condition

5) Slow-down button: When this button is pressed, the truck will travel at an extremely slow speed This

button is applicable for operation on especially narrow field or on the condition that the truck needs to be

accurately located

6) Electric lock

:

It is used to control switching-on and switching-off of main power supply of the truck Key of

the electric lock shall be kept by the truck driver or personnel who have been specially assigned Be sure to

cut off the main power supply when you leave the truck, and take the key of electric lock, for fear

occurrence of accident due to operation carried out by others

7) Power switch

:

It is used to control emergency power-off of the truck Pulling up the switch, then main

power supply will be cut off, and inserting down represents switching-on Please immediately pull up the

switch to cut off power supply for sake of any occurrence of accident, if your truck were out of control due

to some reason

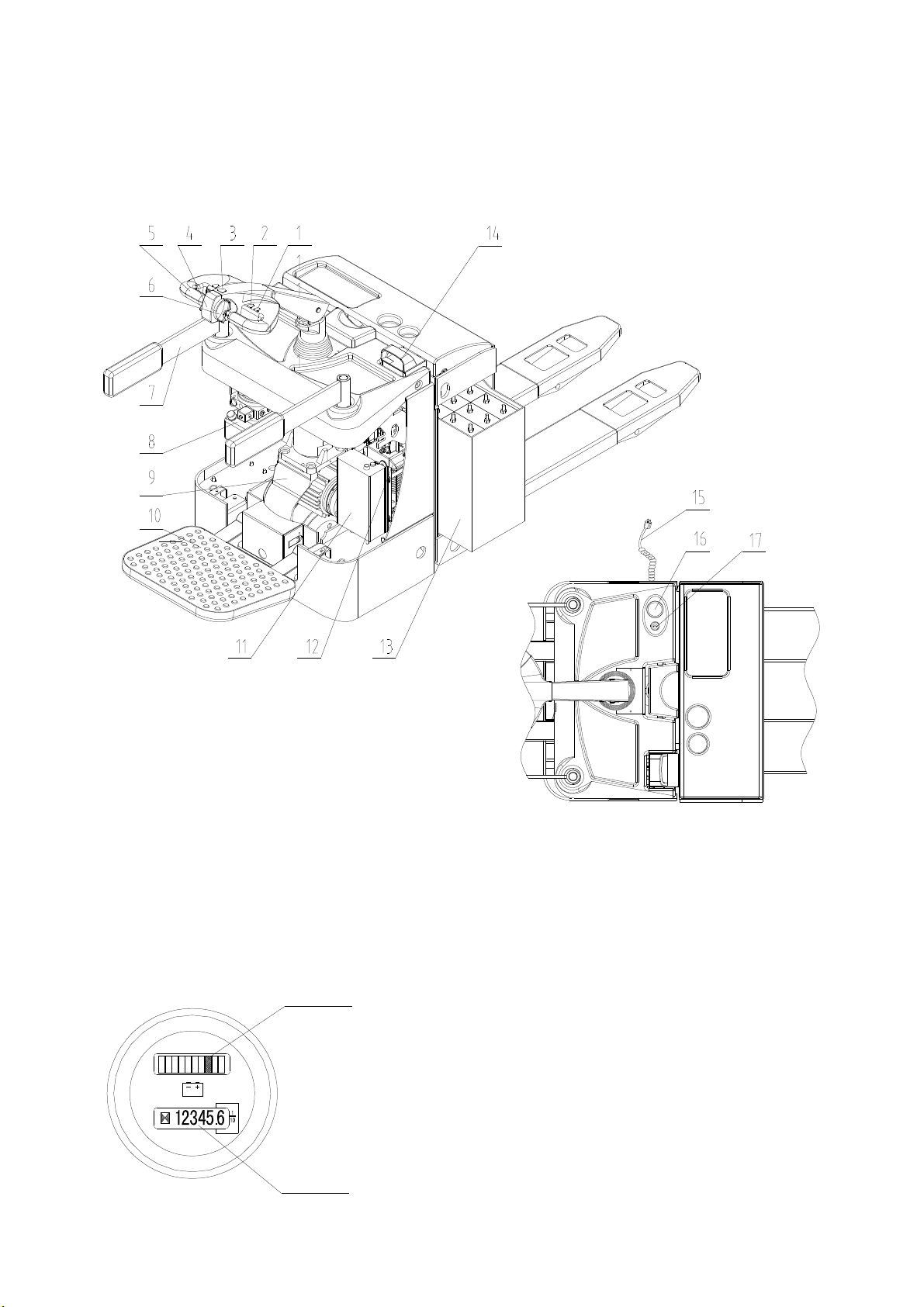

8) Charging plug: This plug is placed in the side hole of the truck And this plug is connected to the charger

with a spring cable When the battery needs to be charged, take down the plug and insert it into the socket

which is connected to network Then the battery can start to charge (Battery charger and its accessories

are optional parts of the truck, please consult with the authorized representative to buy authentic parts

This part shall fulfill the related safety requirements)

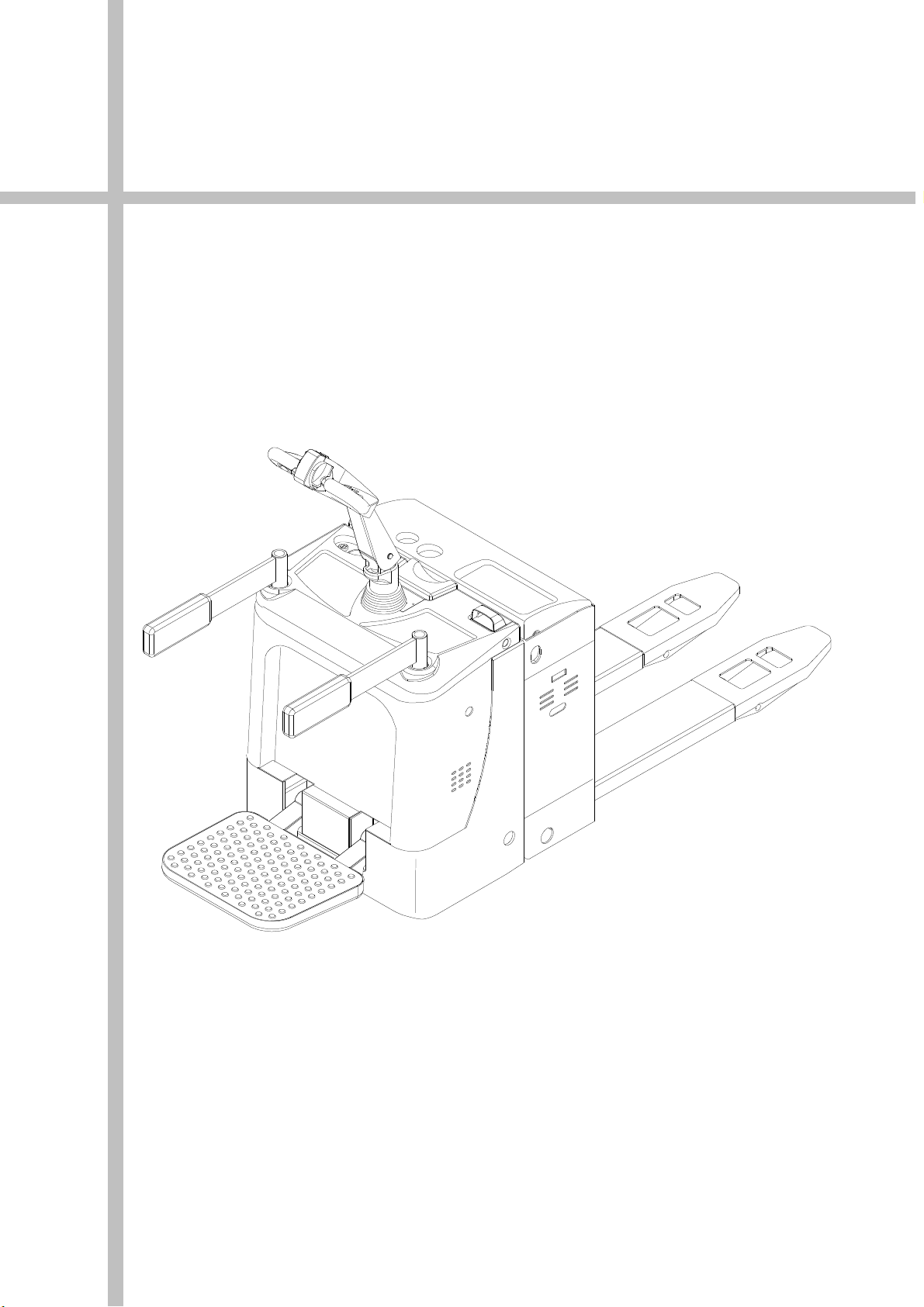

9) Pedal and guardrail: The operation mode of this truck is stand driving Under normal conditions, the

standing pedal and guardrail should be open before driving the truck During operation of the truck, the

driver should stand on the pedal When the working area is relatively narrow, the standing pedal and

guardrail can be put away Then, the maximum traveling speed should not be over 6km/h

Ⅲ

ⅢⅢ

Ⅲ. Safet Norms:

::

:

Warning

Please pay attention to the following items first before operation of the truck:

1) This electric truck is only limited to utilization indoor with a hard flat floor Operation in inflammable, explosive

environment or corrosive environment such as acid or alkaline condition shall be strictly forbidden

2) Only drivers who have received formal training or are authorized can be allowed to drive the truck

3) Read this instruction carefully before operation so as to master the performance of the truck; check the truck

whether it is in its normal condition before each operation It is forbidden to use faulty truck; repair by

untrained persons is forbidden as well

4) Overloading operation is forbidden

5) As for goods carrying and operation, center of gravity of the goods must be within range of the two forks It is

forbidden to transport loose goods

6) The truck shall travels slowly when forks pass in or out of pallet

7) It is strictly forbidden to press the lifting or lowering button during the traveling of the truck Meanwhile, don’t

switch lifting and lowering buttons rapidly or frequently, because rapid and frequent lifting or lowering will

cause damage to the truck and goods

8) Don’t load heavy goods on the forks rapidly