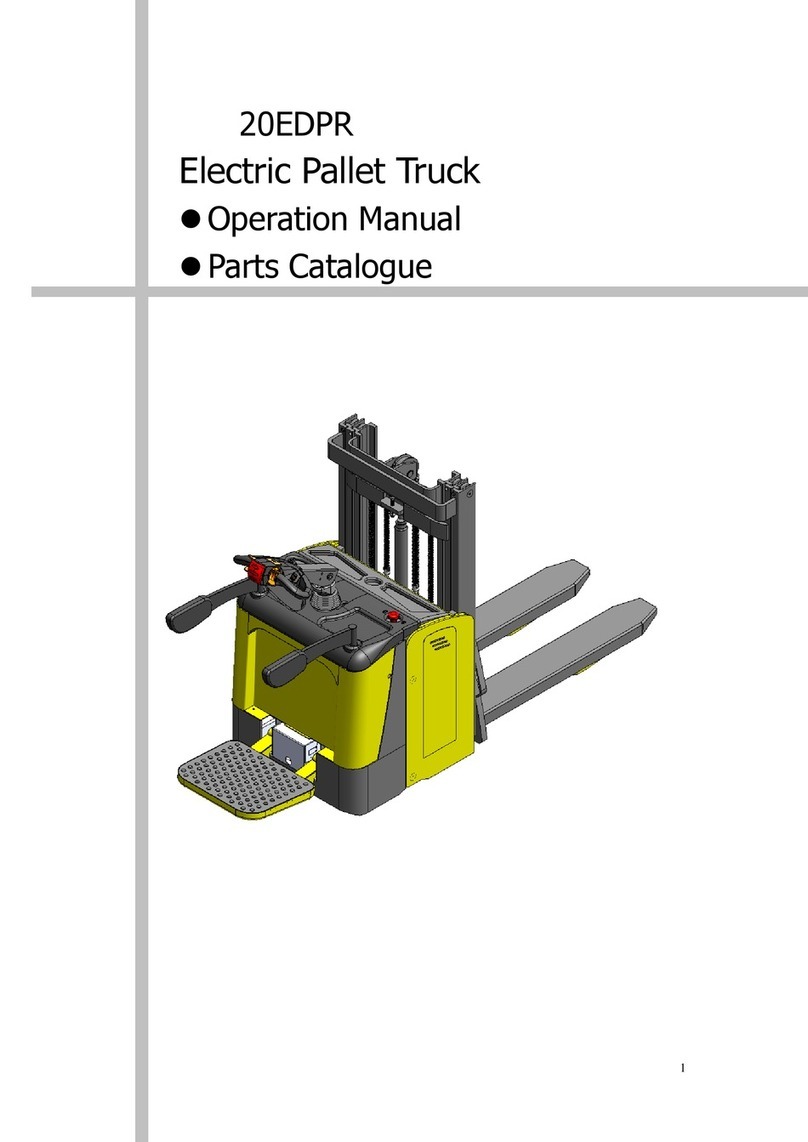

0-3

This manual is a digest of essential information about the safe operation, the features and functions

and explains how to maintain your lift truck. This manual is organized into ten major parts:

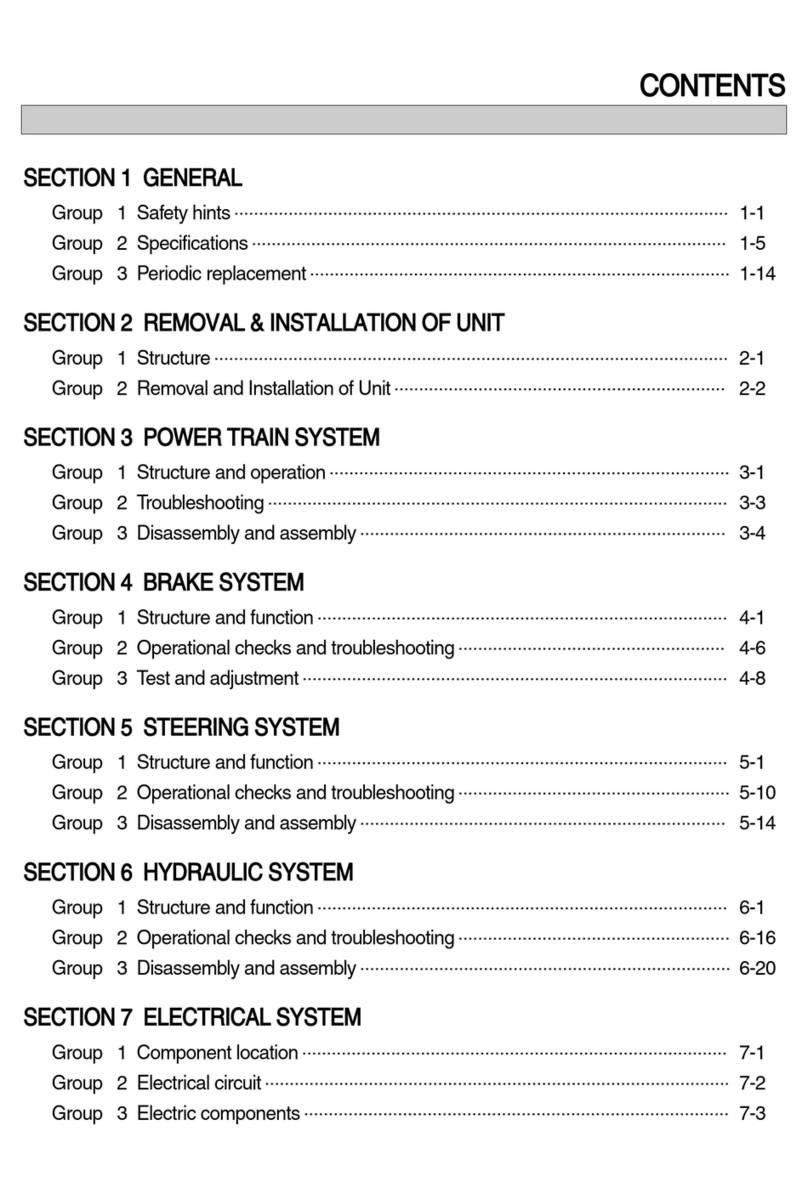

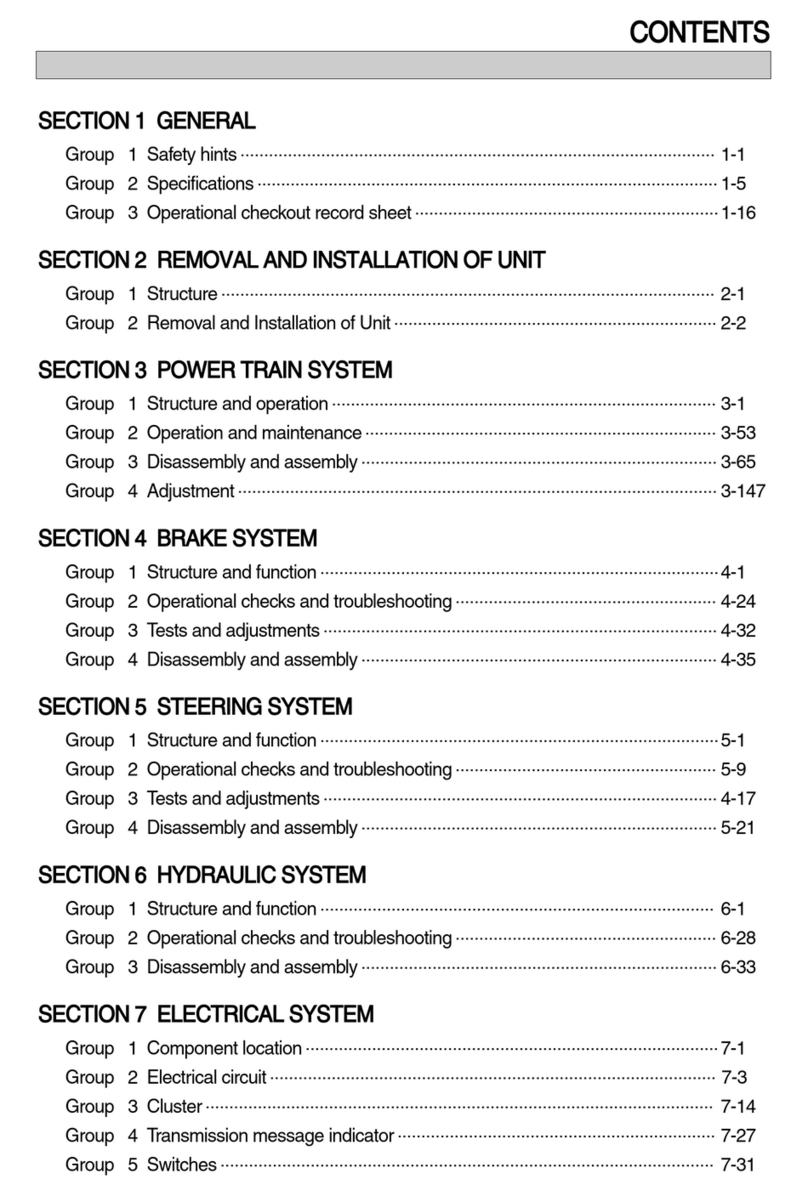

Section 1. Safety hints, reviews and illustrates accepted practices for safe operation of a lift truck.

Section 2. Operating Hazards

Section 2. Operating Hazards, warns of conditions that could cause damage to the truck or injury to

the operator or other personnel.

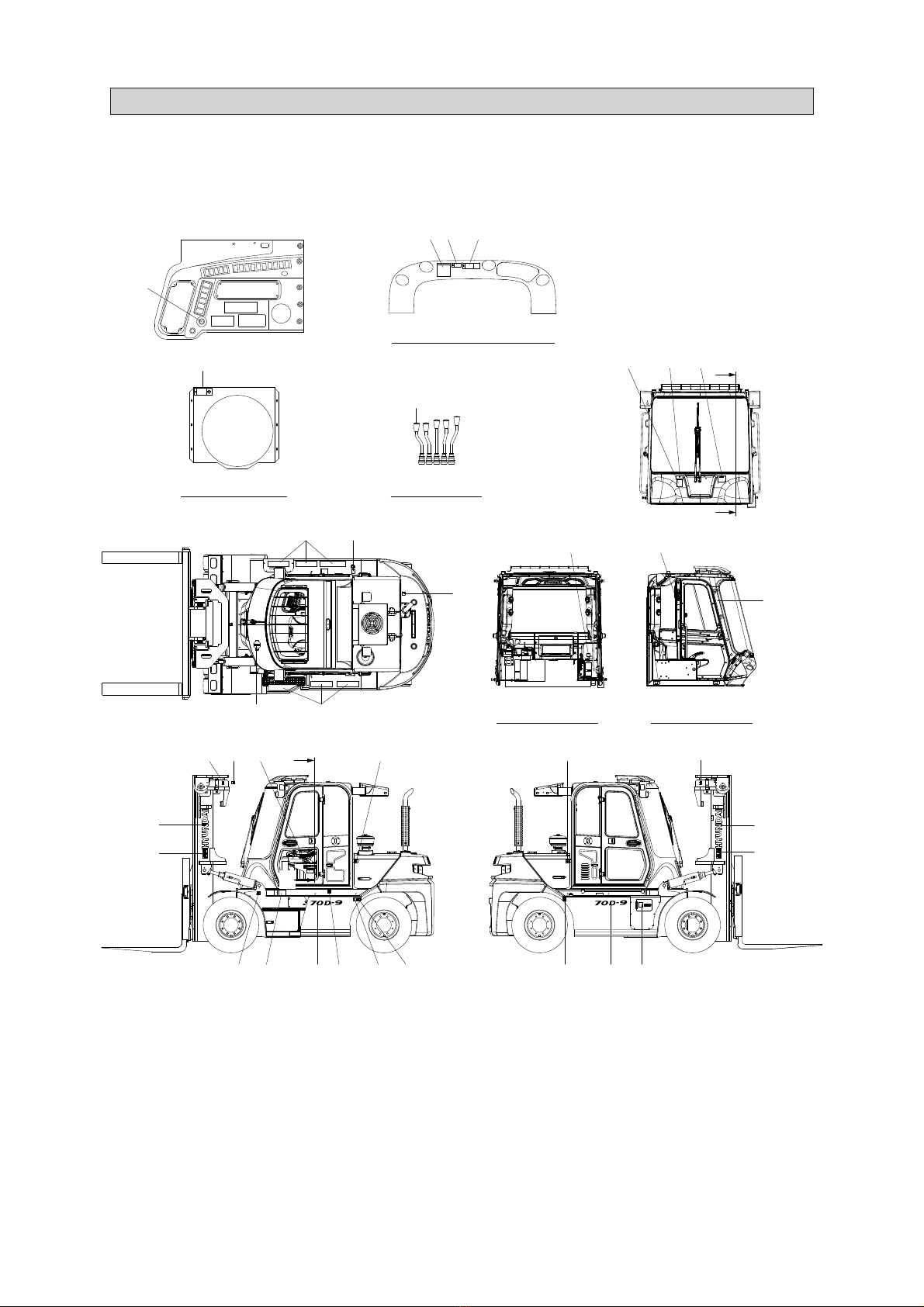

Section 3. Know Your Truck

Section 3. Know Your Truck, describes the major operating components, systems, controls, and other

features of your truck and tells how they function.

Section 4. Operator Maintenance and Care

Section 4. Operator Maintenance and Care, presents details on how to perform the operator's daily

safety inspection and refuel the lift truck.

Section 5. Starting and Operating Procedures

Section 5. Starting and Operating Procedures, discusses specific instructions on the safe, efficient

operation of your lift truck.

Section 6. Emergency Starting and Towing

Section 6. Emergency Starting and Towing, gives instructions for towing your truck in an emergency

and for using battery jumper cables to start your truck in an emergency.

Section 7. Planned Maintenance and Lubrication

Section 7. Planned Maintenance and Lubrication, describes the PM (Planed Maintenance) program.

Section 8. Specifications

Section 8. Specifications, provides reference information and data on features, components, and

maintenance items.

Section 9. Troubleshooting

Section 9. Troubleshooting, provides trouble symptoms, causes and methods of remedy.

Section10. Testing and Adjusting

Section10. Testing and Adjusting, gives instructions for testing and adjusting.

※

The descriptions and specifications included in this manual were in effect at the time of printing.

The descriptions and specifications included in this manual were in effect at the time of printing.

HYUNDAI reserves the right to make improvements and changes in specifications or design, without

notice and without incurring obligation. Please check with your authorized HYUNDAI dealer for

information on possible updates or revisions.

The examples, illustrations, and explanations in this manual should help you improve your skill and

knowledge as a professional lift truck operator and take full advantage of the capabilities and safety

features of your new lift truck.

The first section of the manual is devoted to a review, with illustrations and brief messages, of general

safety rules and the major operating hazards you can encounter while operating a lift truck. Next, you

will find description's of the components of your specific lift truck model and how the instruments,

gauges, and controls operate. Then, you will find a discussion of safe and efficient operating

procedures, followed by instruction's on how to tow a disabled lift truck. The later sections of the

manual are devoted to maintenance and truck specifications.

Take time to carefully read the

Know Your Truck section. By acquiring a good basic understanding of

your truck's features, and how they function, you are better prepared to operate it both efficiently and

safely.

In

Planned Maintenance, you will find essential information for correct servicing and periodic

maintenance of your truck, including charts with recommended maintenance intervals and component

capacities. Carefully follow these instructions and procedures.

Each major section has its own table of contents, so that you can find the various topics more easily.

HOW TO USE THIS MANUAL