I-Gard GCHK-100 User manual

Instruction Manual C-407

GROUND FAULT

PROTECTION SYSTEM

GCHK-100

GCHK-100

MINING RELAY

the power to protect

Each GCHK-100 relay and its auxiliary parts is carefully inspected before being packed for shipping. The unit

should be examined immediately upon receipt. If damage or indication of rough handling is apparent, I-Gard

should be notified promptly if replacements for damaged goods are necessary. If units received are not to be

installed immediately they should be stored in their original packaging in an area free of dust and moisture.

important

In our continuing effort to bring new and innovative products to the electrical

industry that provide additional safety and performance benefits,

I-Gard has developed a state of the art protection relay for mobile trailing

equipment.

Safety is enhanced by the addition of AC touch voltage protection, the only

relay in the market with this feature.

ground fault protection

GCHK-100 Instruction Manual I-GARD

1

taBle of contentS

1. Introduction 2

2. Catalog Numbers 3

3. Current Sensors 3

4. Pilot Wire Terminator 3

5. Remote Indication 4

6. Installation 5

7. Setup 7

8. Maintenance and Testing 11

9. Service 12

10. Specifications 13

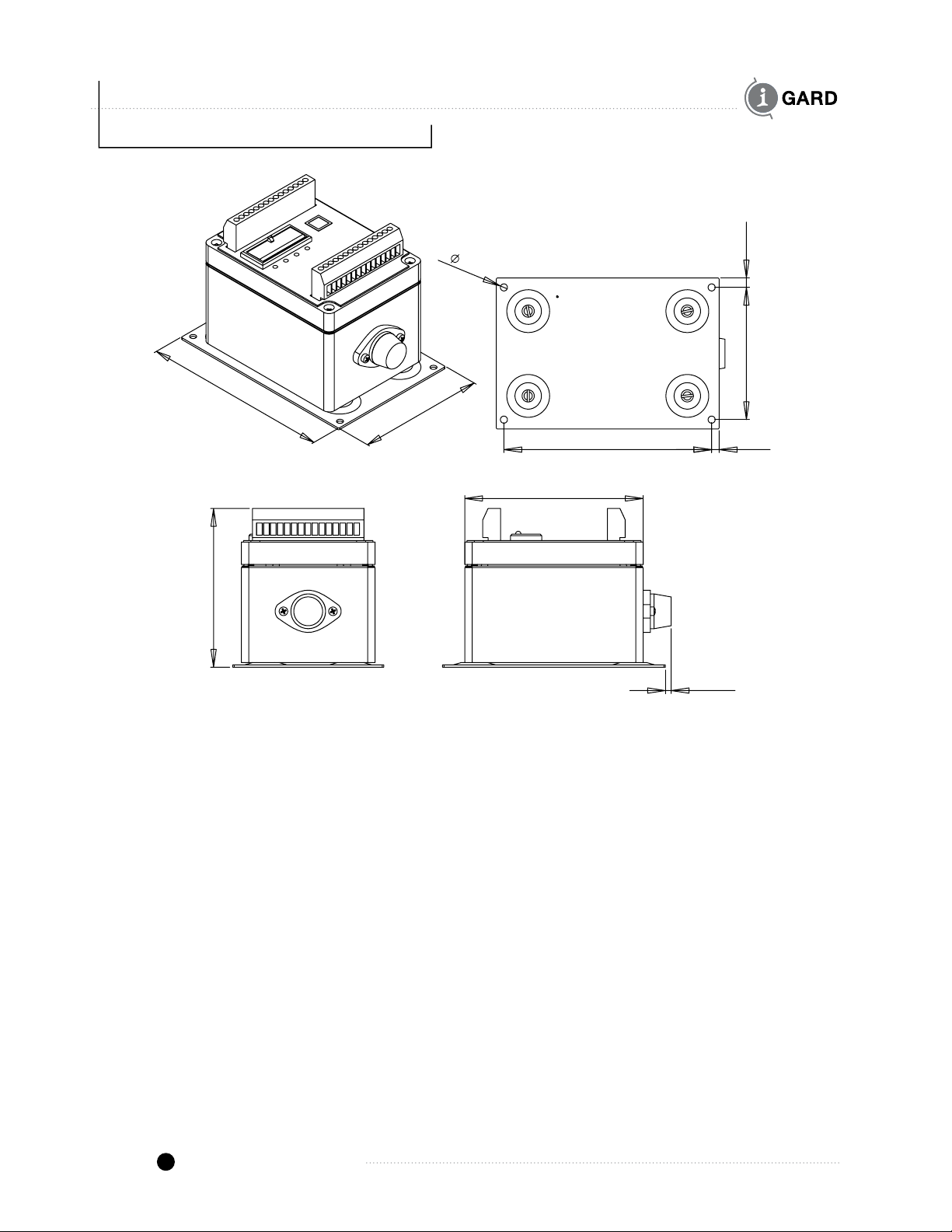

11. Outline Dimensions 14

12. Instruction Manuals ibc

taBle of figureS

Figure 5.1 GCHK-DRI Label 4

Figure 5.2 mGARD-SYM Label 5

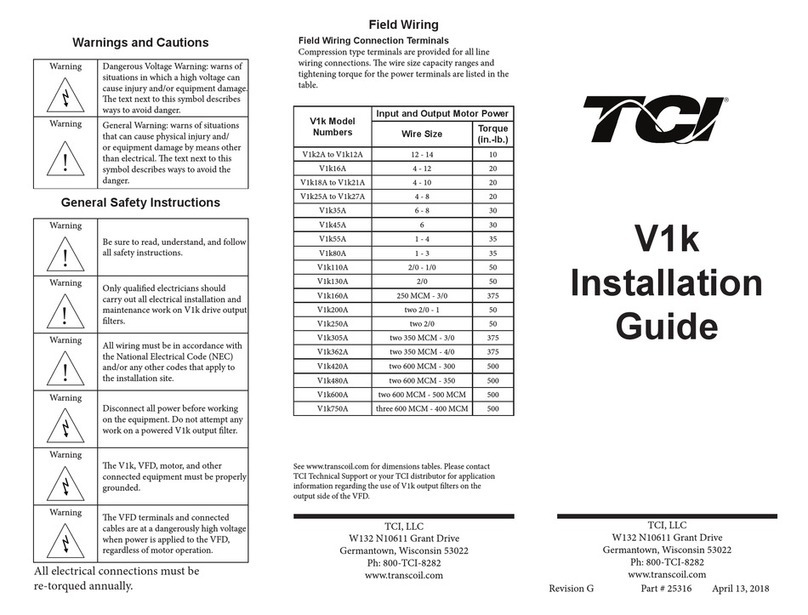

Figure 6.1 Connection Diagram 6

Figure 11.1 GCHK-100 Main Relay Outline Dimensions (inches) 14

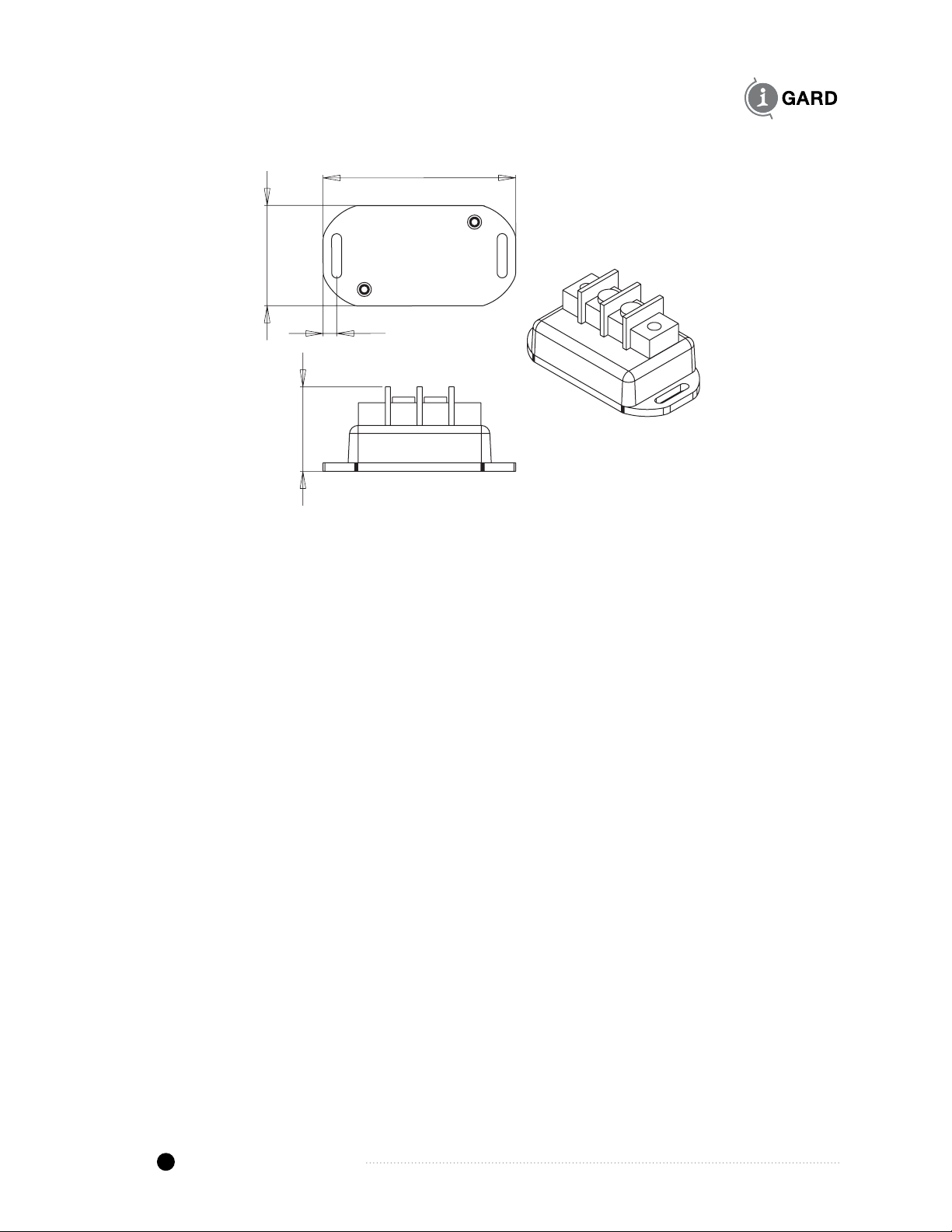

Figure 11.2 mGARD-SYM LCD Remote Indicator Dimensions (inches) 15

Figure 11.3 GCHK-DRI LED Remote Indicator Dimensions (inches) 15

Figure 11.4 GCHK-ZT Zener Diode Line Terminator Outline Dimensions (inches) 16

taBleS

Table 2.1 Catalog Numbers 3

Table 7.1 Modes of Operation 7

Table 7.2 Ground Fault Pickup Settings 8

Table 7.3 Ground Fault Trip Delay Settings 9

Table 7.4 Ground Fault Delay Reset Intervals 9

Table 7.5 Ground Check Settings 10

Table 7.6 Frame Voltage Settings 11

I-GARD GCHK-100 Instruction Manual

2

1introduction

To service the special needs of the mining industry I-Gard developed the GCHK-100 ground fault relay to protect

personnel and equipment in underground or above ground applications.

The GCHK-100 is state of the art protection for mobile, trailing cable equipment, providing superior accuracy

and flexibility to the user. The micro controller based design reduces the likelihood of false tripping. The relay

automatically operates in three distinct modes:

•GroundFaultDetectionandcontrol

•Groundresistancecheckingandcontrolthroughtheuseofanauxiliarypilotwire

•Frametouchvoltagedetectionandcontrol

•ExternalremotedisplaywithModbus

Designed for use with resistance grounded systems up to 4160V. It could also be used with any Grounded

System in branch circuit applications.

The relay can also be used with an external remote indicator (mGARD-SYM), capable of remotely displaying

readings and allowing remote RESET and TEST. The mGARD-SYM can monitor up to 50 GCHK-100 relays and

provides an isolated connection to an external Modbus network. Alternatively, a standard LED based remote

indicator (GCHK-DRI) can be used for remote indication.

Ground Fault detection requires the use of current sensors, and the GCHK-100 is designed to operate with

I-Gard TxA type sensors or a wide variety of sensors with ratios of 1000:1, 600:1 and 40:1 (200:5). The sensors

are typically mounted in the substation where the GCHK-100 is installed. Detection of ground faults is important

to prevent arcing faults in equipment where electric shock and fire can occur and cause serious equipment and

personnel hazards.

Operator safety from electrical shock depends to a large extent on the integrity of the grounding of energized

equipment. Therefore, it is vital to know if grounding has been compromised. To do this an auxiliary conductor

(pilot wire) is used in trailing cable to mobile equipment. The GCHK-100 monitors the loop resistance and trips

when it exceeds a preset value.

Additionally the relay detects if the ground loop has been shorted as can happen when the trailing cable is cut

accidentally. For this purpose a pilot wire terminator is connected between the pilot wire and ground. I-Gard

provides a special zener package for this purpose (GCHK-ZT).

In the event of a ground connection failure and internal leakage within the mobile equipment, it is possible for the

frame of the equipment to become live and present a shock hazard to personnel in the vicinity. The GCHK-100

has the capability to monitor and control dangerous frame voltages.

GCHK-100 Instruction Manual I-GARD

3

2catalog numBerS

Table 2.1 indicates the product group for the GCHK-100 family from I-Gard

TABLE 2.1 CATALOG NUMBERS

Catalog Number Description No Required/System

GCHK-100 Mining Relay 1

GCHK-DRI LED Based remote indicator 1*

GCHK-ZT Ground Check zener terminator 1

mGARD-SYM Remote Indicator 1*

T series ZSCS current sensors 1

*EitherGCHK-DRIormGARD-SYMcanbeused(orbothifdesired),howeveritisnotnecessary;infact,the

GCHK-100canbeusedwithouteitherofthem.

3current SenSorS

Ground fault detection is achieved by the use of an external Zero Sequence Current Sensor (ZSCS). The relay

supports the following zero sequence current sensors or current transformers:

Any I-Gard T type sensors (e.g. T2A, T3A, T6A and T9A)

1000:1

10:0.0167 (600:1) Bender

200:5 (40:1) Startco

Surge protection is built into the relay; please refer to the electrical specifications data for withstand ratings.

ZSCS with, or without, built-in protection can be used with the GCHK-100 relay. The terminal block provides a

common ground and a terminal location for each of the three sensor types.

*NOTE: Only one type of ZSCS can be used at a time.

4pilot Wire terminator

This terminating diode is standard throughout the industry. It has two terminals marked GC and G. The GC

terminal is connected to the pilot wire inside the mobile equipment enclosure. The G terminal of the GCHK-ZT

is connected to the frame ground of the mobile equipment. The purpose of the diode is to allow the ground fault

relay to determine if the ground loop has been shorted. A shorted ground loop would appear as normal loop

impedance if this were allowed to happen, while in fact, the mobile equipment may be completely ungrounded.

Loss of zener voltage therefore causes the TRIP relay to operate and disconnect the power.

I-GARD GCHK-100 Instruction Manual

4

5remote indication

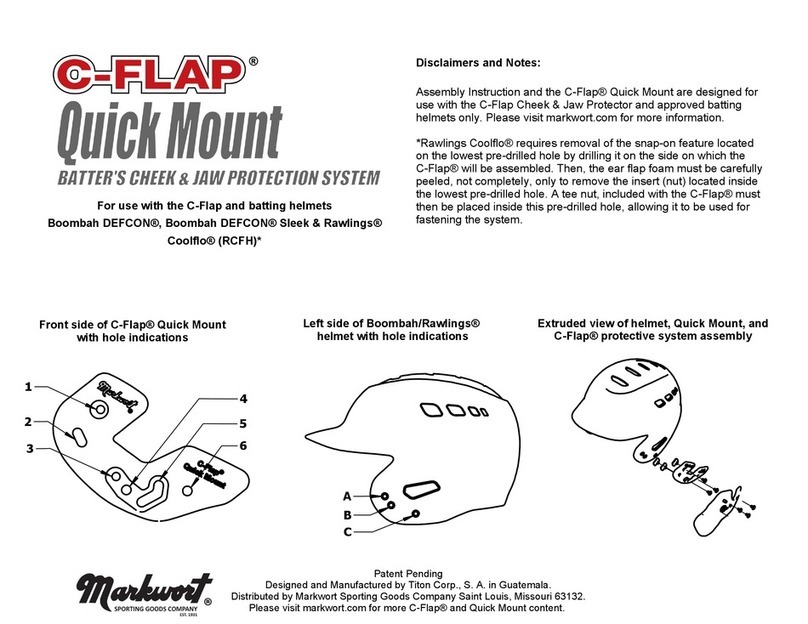

GHCK-DRI

A simple remote indicator is available as an option, which provides indication of the status of the GCHK-100.

The GCHK-DRI has all three status lights that are normally visible on the GCHK-100 as well as a reset button.

This allows the relay to be monitored conveniently and RESET if necessary. The relay may also be tested by

pressing the RESET/TEST button twice quickly.

The GCHK-DRI is flush-mounted in a panel with four ½ in x 6-32 screws with nuts. A rectangular opening of 82 x

51 mm (3 1/4 x 2 in) is required for mounting as shown in Figure 11.3.

A 5-conductor cable with 22 gauge or larger conductors may be used to connect the GCHK-DRI to the

GCHK-100 relay. No shielding is required. No additional power supply is required to power the indicator.

Figure 5.1 shows the faceplate of the GCHK-DRI. This simple indicator extends the 3 red LED’s and yellow push

button on the GCHK-100 to a panel or remote location. Press the yellow button once to reset the relay or twice

quickly to test (Warning: a test will cause the GCHK-100 to trip).

Figure 5.1 GCHK-DRI label

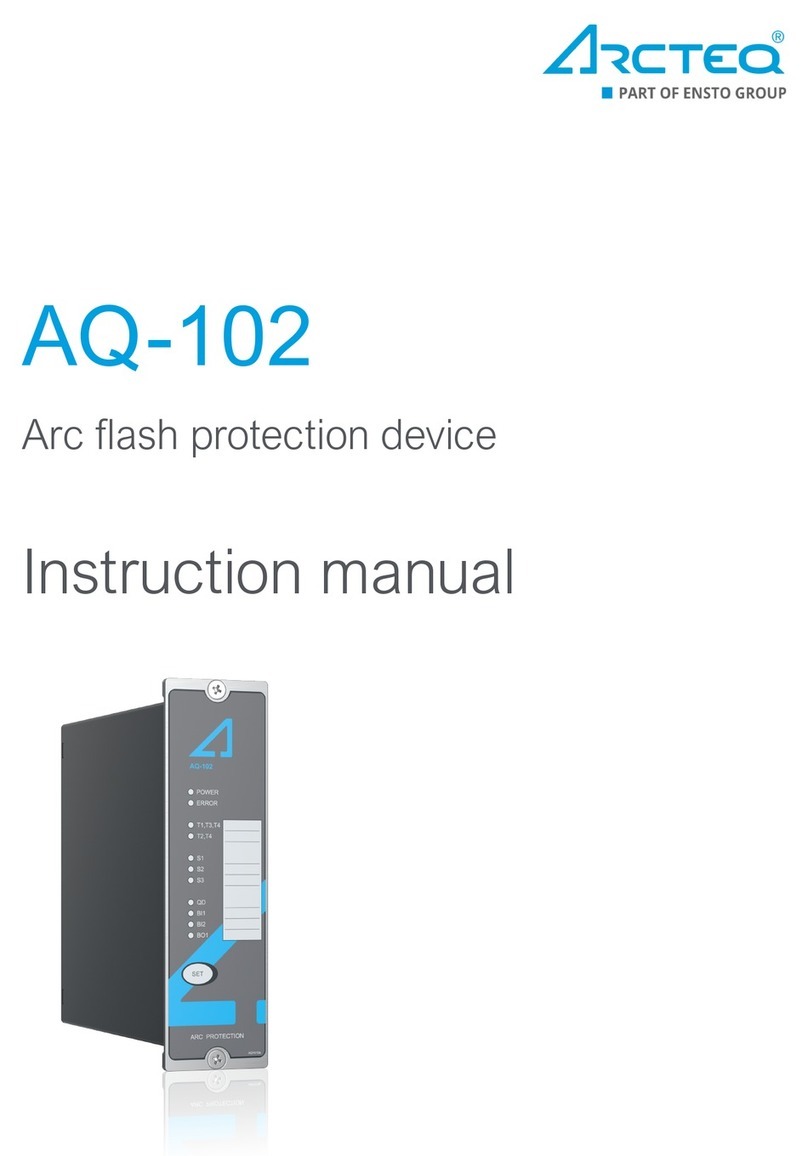

mGARD-SYM

The mGARD-SYM is a remote display indicator that is used in conjunction with I-Gard Corp. relays. The

indicator has the capability to interconnect with up to 50 GCHK-100 relays in a bus network topology and

provides detailed device status information.

The display has a 4-line screen that shows a list of connected devices. A device can be selected and viewed in

detail. The relay mode, delay and trip level settings can be viewed (but not altered). The reset and test functions

can be performed directly from the display.

Fault levels are displayed as a percentage of the selected trip level. If the trip level is 1 Amp and there is a

500 mA fault current, the reading on the display will appear as 50%. Ground check resistance and frame voltage

are also displayed as a percentage of the trip setting. Screen navigation is done using a 4-button interface.

The menus are displayed on the right side of the LCD, the left side is reserved for viewing relay information.

GCHK-100 Instruction Manual I-GARD

5

mGARD-SYM

Power Alarm

Add%Ig %Rg %Vg

154 0

2100 0VIEW

300 5 SET

www.i-gard.com

the power to protect

Figure 5.2 mGARD-SYM label

The mGARD-SYM also provides an isolated connection to an external Modbus RTU network. All 50 devices

can be monitored remotely using a single configurable Modbus address. Built in isolation protects the Modbus

network from hazardous voltages or transients. The display is compatible with several Modbus speeds: 1200,

2400, 4800, 9600, 19200 and 38400 baud. Stop bits are selectable (1 or 2). Data available through Modbus

includes relay status and fault levels as well as remote reset.

For more information on the mGARD-SYM display refer to the mGARD-SYM manual (C-416EM-R0).

6inStallation

Mounting

The main unit of the GCHK-100 is supplied with a surface-mounting back-plate to provide simple 4-hole

mounting, compatible with existing units. If holes do not exist, drill 4 holes in the mounting location for

4 No. 6 self-tapping or sheet metal screws.

Remote Units

The remote indicators are intended for flush mounting in a visible place. They require cutout areas

in the mounting panels. See Dimensional Drawings for details.

Wiring (See Figure 6.1 Connection Diagram)

Control Power

Control power is required for the GCHK-100 relay. The power may be either AC or DC and between 100 and

250V. A source should be rated at least 5VA in capacity.

I-GARD GCHK-100 Instruction Manual

6

Control transformers may be connected to the LINE side of the protective breaker through protective fuses

or any other reliable source of power. Failsafe operation cannot be achieved with LOAD side connection

since the breaker would trip before the GCHK-100 had energized the TRIP relay thus preventing closure.

Furthermore, indication would be defeated when the breaker tripped and the power removed.

Current Sensors

There are no restrictions on the location of the ZSCS sensor, No.14 unshielded wire may be used to

connect the SEC terminals of the T type sensor to the 1000 Terminal and SENSOR ground as shown in

Figure 6.1 connection diagram. For other sensor types, the 600 or 40 Terminal would be used depending on

the ratio of the chosen sensor.

All phases supplied to the trailing cable must pass through the window of the ZSCS, which must be sized

accordingly. I-Gard sensors range from 2in. to 9in. in diameter. Neither the ground conductor, nor the pilot

ground conductors pass through the sensor; otherwise the ground fault detection would be disabled.

Figure6.1ConnectionDiagramshowstheShuntTripcoiloftheprotectivecircuitbreakerconnectedtotheNO

contacts of the GCHK-100 relay. This is the non-failsafe connection. The NC contacts of the Form Z relay are not

usedinthiscase,butwouldberequiredincaseoffailsafemodeofoperation.

GC G

GCHK-ZT

X0 X1

ZSCS

TRIPCOIL

UNIT SUBSTATION TRAILING CABLE

CONTROL POWER

5VA AC OR 5W DC

110-240VAC / DC

TO OTHER

GCHK-100

RELAYS

TO MODBUS

NETWORK

OPTIONAL

mGARD-SYM

INDICATOR

AUXILARY

RELAYS

OPTIONAL

GCHK-DRI

REMOTE

INDICATOR

GCHK-100

GROUND

CHECK

RELAY

MOBILE

EQUIPMENT

FAULT GND

RELAY CHECK

GCHK-100 Instruction Manual I-GARD

7

Ground Check

Ground Check is achieved by the use of a pilot wire (GC). This wire is usually a part of the power cable.

It is used to carry a monitoring current to the machine being monitored. The pilot wire must be properly

terminated at its end point (the machine being monitored). A zener diode terminator such as the GCHK-ZT

or equivalent is required.

The ground terminal must be connected to a reliable system ground. This provides a return path for the

current and completes the ground check loop. Ensure that all wires are firmly connected to eliminate adding

resistance to the system.

Frame Voltage

The Frame Voltage monitor is an additional feature that is monitored through the ground-check pilot wire.

No additional wiring is required for the Frame Voltage monitor.

7Setup

The GCHK-100 can be operated in different modes selectable with Switch 1. See Table 7.1

Normal mode is with a non-energized TRIP relay which becomes energized when the trip level is exceeded for

a duration exceeding the selected time delay. Alternatively, the FAILSAFE mode can be selected which allows

operation with an energized TRIP relay. This permits disconnection of the TRIP device in the event that power is

interrupted in the case (for example) of loss of a control fuse. Note for Failsafe operation, the control power must

be connected to a source that is not interrupted by the breaker trip operation.

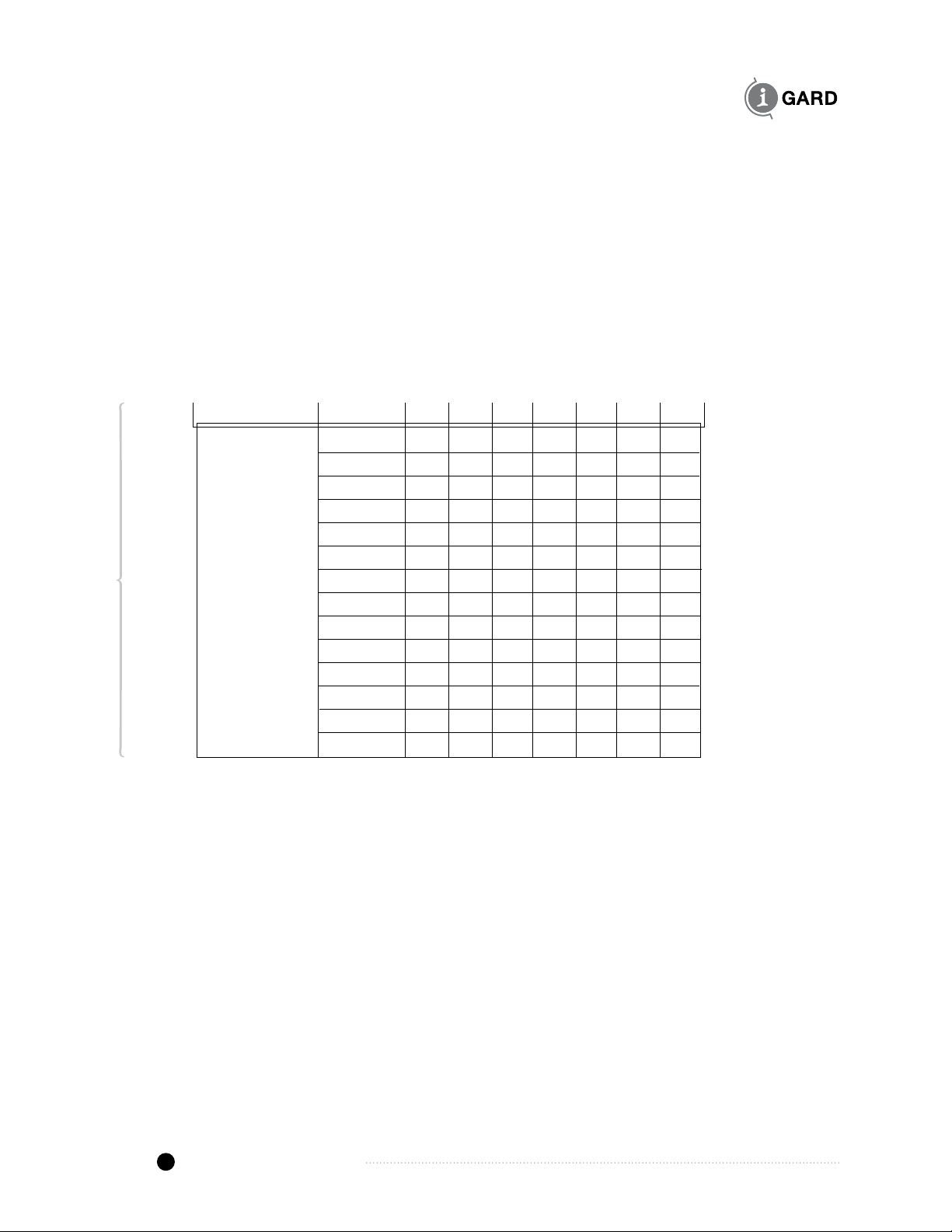

TABLE 7.1 MODES OF OPERATION (SWITCH 1)

Function 1 2 3 4 5 6 7

Normal Mode 0

Failsafe Mode X

Normal Trip 0

Pulse Trip X

Manual Reset 0

Auto Reset X

Note:Xindicatesswitchison.

Note:Failsafeoperationdoesnotapplytotheauxiliaryrelays–onlytheTRIPrelay.

TRIP operation can be modified by use of Switch 1 position 2. When ON the contacts of the TRIP relay are

pulsed instead of continuous. This function reduces the duty cycle of TRIP coils which are not continuously

rated and do not have auxiliary contacts which open and remove the trip current.

I-GARD GCHK-100 Instruction Manual

8

For a ground check trip condition only, the GCHK-100 TRIP relay, and its auxiliary relay, may be automatically

reset upon the removal of the fault condition without operator intervention. Otherwise all relays are manually

reset by pressing the RESET push buttons on the relay or on the remote indicators.

Ground Fault

The GCHK-100 is set-up by DIP switches for different modes of operation and Trip Levels.

The ground fault pickup settings are set using switches 1, 2, 3, and 4 on DIP Switch 2.

The following pickup settings are available:

TABLE 7.2 GROUND FAULT PICKUP SETTINGS

Function Setting 1 2 3 4 5 6 7

Switch2 0.25A 0 0 0 0

Ground Fault 0.25 A 0 0 0 0

Pickup 0.5 A 0 0 0 X

Settings 0.75 A 0 0 X 0

IG 1 A 0 0 X X

1.25 A 0 X 0 0

1.5 A 0 X 0 X

2 A 0 X X 0

2.5 A 0 X X X

3 A X 0 0 0

5 A X 0 0 X

7.5 A X 0 X 0

10 A X 0 X X

12.5 A X X 0 0

Note:Xindicatesswitchison.

Pickup Setting Tolerance: -15% / + 0% (in accordance with UL, CSA and IEC requirements)

When a Ground Fault is detected, two relays are operated i.e. the main TRIP relay (Form Z)

and an auxiliary relay with form C contacts.

Ground Fault Trip Delay

Switches 5, 6, 7 on DIP Switch 2 are used to select the Ground Fault Trip Delay (See Table 7.3) This is the

interval between detecting a fault and tripping the relay. The delay will be cancelled if the fault clears before the

delay expires, thus preventing unnecessary trip operation.

GCHK-100 Instruction Manual I-GARD

9

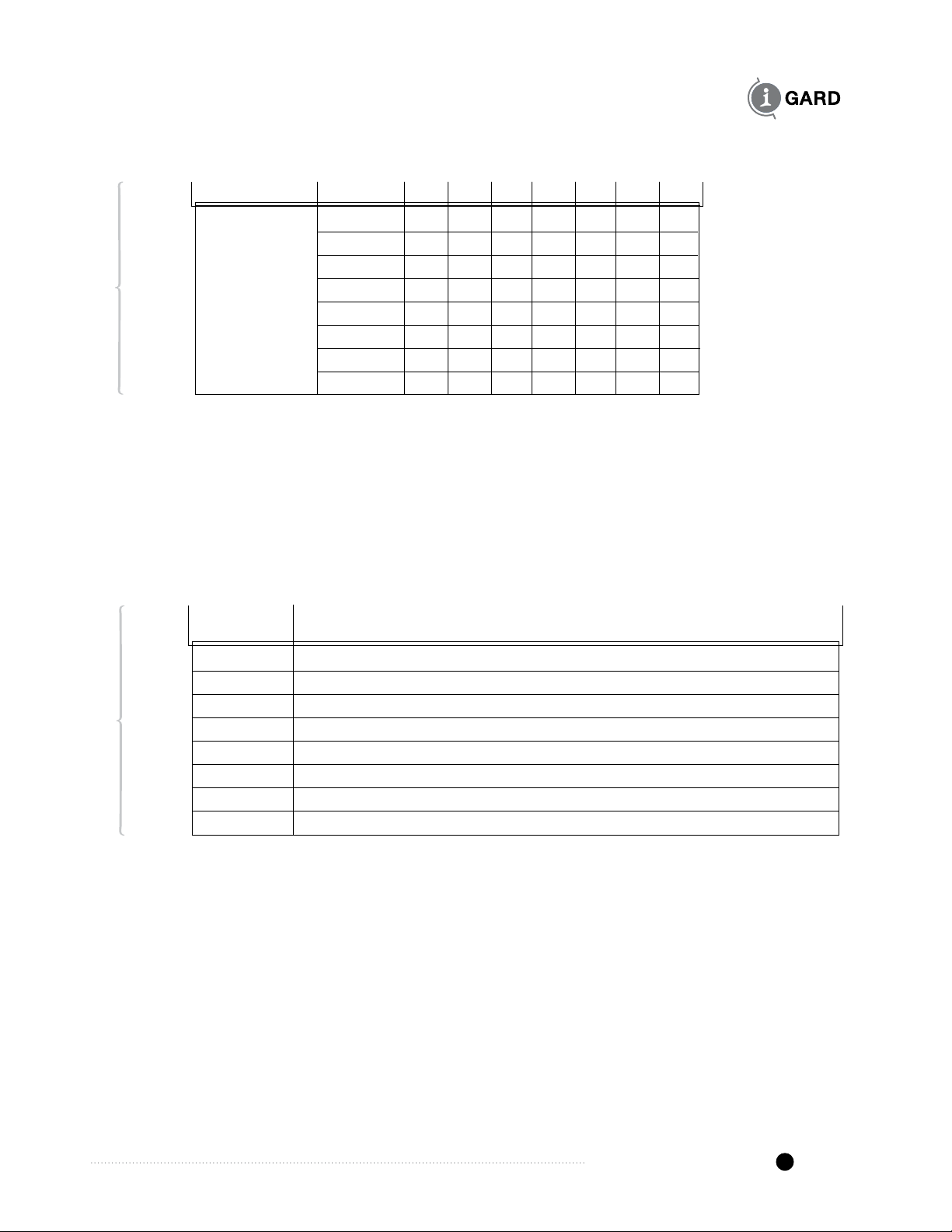

TABLE 7.3 GROUND FAULT TRIP DELAY SETTINGS

Function Setting 1 2 3 4 5 6 7

Switch2 0.02 s 0 0 0

Ground Fault 0.1 s 0 0 X

Delay 0.2 s 0 X 0

Settings 0.5 s 0 X X

1 s X 0 0

2 s X 0 X

5 s X X 0

10 s X X X

Note:Xindicatesswitchison.

Trip Delay Tolerance: -2 / +5 ms or ±2.5% of trip delay, whichever is greater

Once a Ground Fault is detected, the trip delay counter begins to time the trip interval. If the ground fault

disappears for the duration specified in the table below or more, the timer is reset and the relay does not trip.

TABLE 7.4 GROUND FAULT DELAY RESET INTERVALS

Trip Delay Clearance Interval (duration of time, fault-free, that is required to

prevent triggering a GF trip)

0.02 s Does not clear

0.1 s 18.3 ms

0.2 s 38.3 ms

0.5 s 98.3 ms

1 s 196.6 ms

2 s 398.3 ms

5 s 398.3 ms

10 s 398.3 ms

Ground Check

The ground check trip level can be adjusted using dipswitch 1, switches 4 and 5. Four resistance levels are

available as shown in Table 7.5

I-GARD GCHK-100 Instruction Manual

10

TABLE 7.5 GROUND CHECK SETTINGS

Function 1 2 3 4 5 6 7

10 Ohms 0 0

20 Ohms 0 X

30 Ohms X 0

*50 Ohms X X

Note:actual*levelincludestheimpedanceofthezenerdiodeaswellasthewireresistance.

Note:Xindicatesswitchison.

The TRIP relay will operate when the ground loop resistance exceeds the setting for a period exceeding 150 ms

to 300 ms. Also the RGindicator LED will light on the relay and remote indicators, if installed.

The current Ground Check resistance can be monitored using the mGARD-SYM remote indicator. The indicator

displays the ground resistance as a percentage of the current trip level. A Ground Check trip can be seen on

both the mGARD-SYM and on the GCHK-DRI (red LED will light).

Frame Voltage Operation

To provide a greater degree of operator protection, a voltage sensing function is included in the operation of the

GCHK-100 relay to detect if the frame to ground voltage of the mobile equipment has exceeded preset levels.

The voltage detection will operate within 100 ms (quicker than the ground check resistance detection) and within

30 ms if the frame voltage exceeds 100V AC. The intent is to provide a greater safety margin for the operator

and others in the vicinity of the equipment.

Frame Voltage can be monitored using the mGARD-SYM remote indicator. The indicator displays the Frame

Voltage as a percentage of the current trip level. A Frame Voltage trip can be seen on both the mGARD-SYM and

on the GCHK-DRI (red LED will light).

A flashing VGlight indicates a thermal overload, due to an elevated frame voltage (greater than 30 VAC, for

an extended period of time). The relay cannot be reset until it cools down to an acceptable internal operating

temperature.

Note: for higher frame voltages, the built in fuse may open prior to the thermal overload tripping. Replacement fuse type should be

BussFNQ-1⁄2orequivalent1⁄2Atimedelayfuse.

GCHK-100 Instruction Manual I-GARD

11

The frame voltage trip level can be adjusted to different levels as per Table 7.6 below

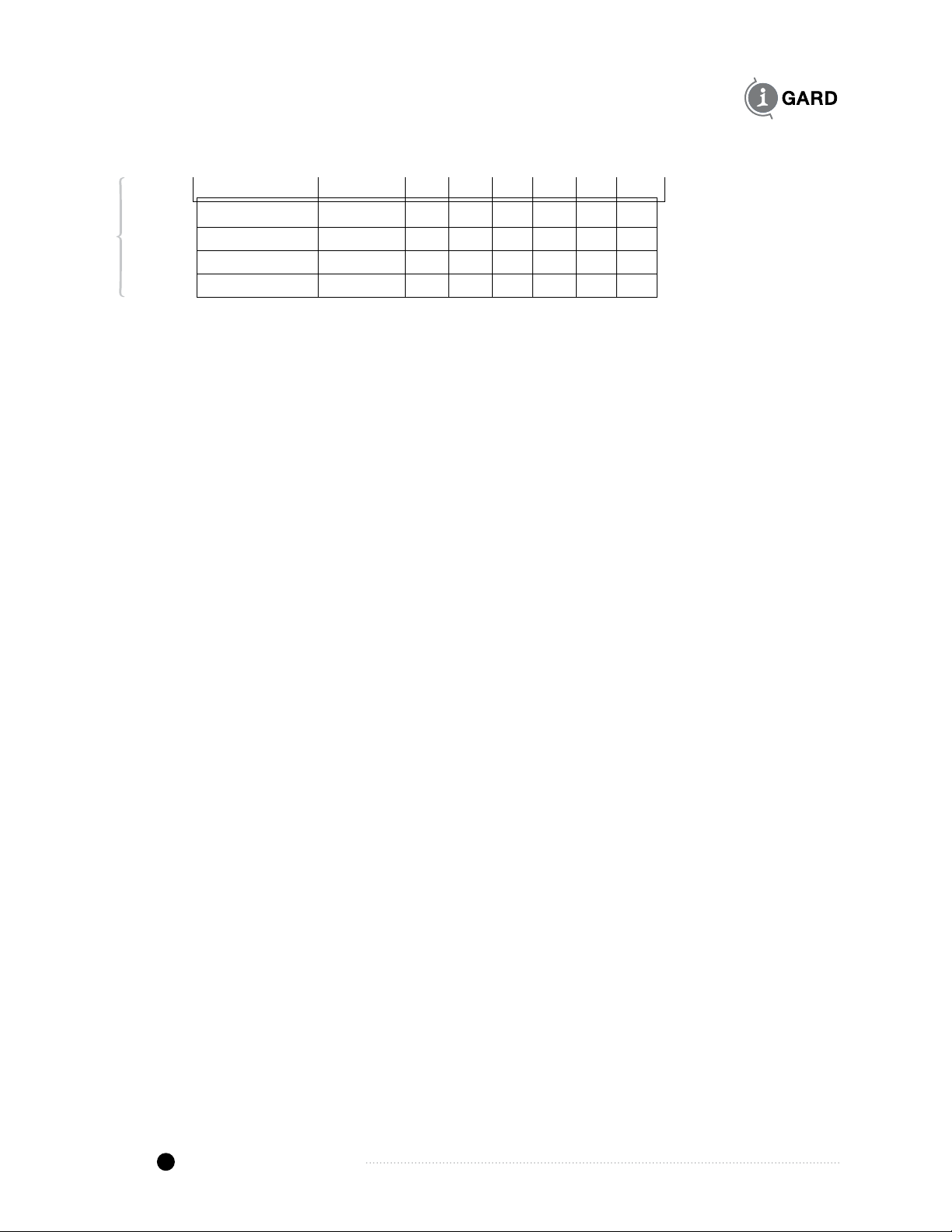

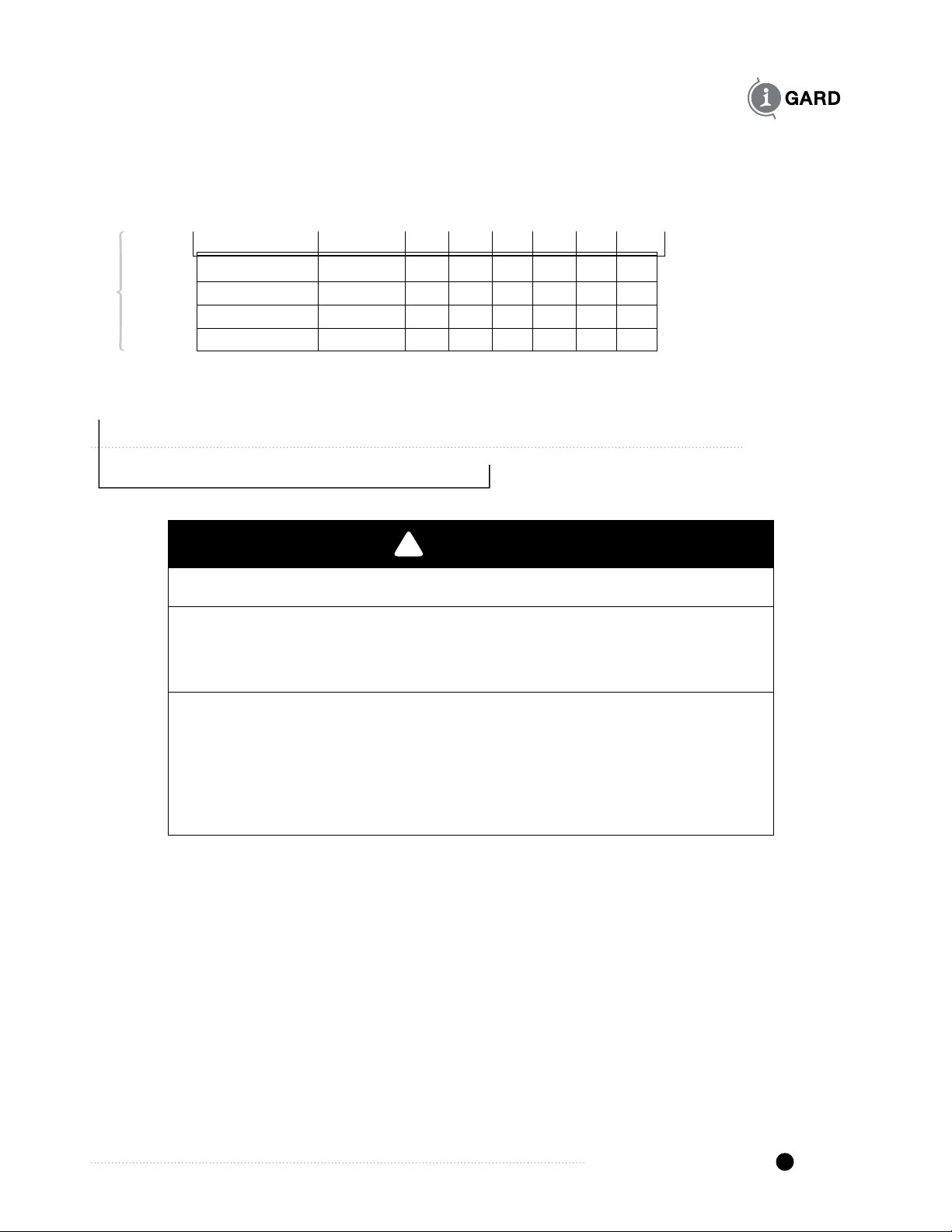

TABLE 7.6 FRAME VOLTAGE SETTINGS

Function 1 2 3 4 5 6 7

40V 0 0

60V 0 X

80V X 0

100V X X

Note:Xindicatesswitchison.

8maintenance and teSting

Due to the solid state design and the use of sealed components, it is not necessary to service the

GCHK-100 other than occasionally dusting with a damp cloth or vacuum cleaner during regular switchboard

maintenance.

DANGER

Hazard of Electrical Shock, Burn or Explosion

All installation, servicing and testing referred to in this manual must be performed by

qualified personnel. All power should be disconnected prior to removing covers or

enclosures and where live conductors may otherwise be exposed.

Failure to observe these precautions may result in death or severe personal injury

and damage to equipment

Before placing an intentional ground fault on the power system, check that a fault

does not already exist. Any test ground fault equipment must be rated for full

system voltage and interrupting capacity, and be fused for protection.

!

I-GARD GCHK-100 Instruction Manual

12

To test the GCHK-100 relay and remote indication, the RESET/TEST button is pressed twice quickly

in succession.

The relay will Trip and all red LED indicators will light on the Main Relay and Remote Indicator and hold

until RESET (by a single push of the RESET/TEST button). All relays will operate.

If annual inspection calls for more elaborate testing, this can be performed by primary injection of test current

through the window of the ZSCS and verifying that the pickup settings are within tolerance.

Testing should be done with a source of current, which is sinusoidal, has accurate metering and has a frequency

of 60 Hz.

Time delays may be measured with a digital storage oscilloscope. This can be done many ways but one way is

to apply a test “fault” resistor to the system with the oscilloscope connected to a current transformer arranged to

measure “fault” current. The Delay time will be the time that the current flows through the test “fault”. Note that

the resistor must be rated for continuous current at the rated voltage.

9Service

For assistance in installation, set-up or testing please call I-Gard toll free at the following number.

1-888-737-4787 (1-888-RESISTR)

There are no recommended, user-serviceable parts in the GCHK-100 other than replacement of the Pilot Wire

fuse. This fuse is a 600V rated 0.5A FNQ-½ by Bussman.

All other service should be referred to qualified factory representatives, other than direct replacement of entire

modules to I-Gard. Please visit the I-Gard website for information regarding field service representatives in your

area.

Note: Please ensure that proper authorisation is obtained from I-Gard before returning any material.

GCHK-100 Instruction Manual I-GARD

13

Control Power:

5VA AC or 5W DC

110-240 V AC/DC, 50/60 Hz

Maximum Range:

-45% to +10% (60-264 V AC/DC)

Temperature Range (Celsius):

Operating Temperature: -40 to +60

Storage Temperature: -40 to +80

Dielectric:

Relay contacts to chassis:

1480V rms. for 1 minute

Control terminals to chassis:

1480V rms. for 1 minute

Ground Fault:

Pickup Settings (Amps):

¼, ½, ¾, 1, 1¼, 1½, 2, 2½, 3, 5, 7½, 10, 12½

Pickup Tolerance:

–15%, +0%

Delay Settings (Sec.):

0.02, 0.1, 0.2, 0.5, 1, 2, 5, 10

Delay Tolerance:

–2, +5 ms or ±2.5% whichever is greater

Thermal Withstand:

5000 Amps for ¹/³seconds

Harmonic Filter:

Low pass analog filter

Zero Sequence Sensors:

Toroidal, with window diameter up to 225 mm.

Ratios supported:

Any I-Gard T type ZSCS (e.g. T2-A, T3-A, T6-A and T9-A)

1000:1, 600:1 and 40:1

(Input impedance 50, 50 and 1 ohm respectively.)

Ground Check:

Pickup Settings (Ohms):

10, 20, 30, 50 ohms

Pickup Tolerance:

±20% or 3 Ohms

Delay (for open loop and/or shorted terminator):

150 ms to 300 ms

Fuse (½ Amp, time-delay):

Bussman FNQ ½

LittelFuse FLQ ½

Edison MEQ ½

Operating Mode:

Manual Reset or Auto Reset

Induced AC Withstand:

30V Continuous (at 25°C ambient)

50V for 10 minutes (at 25°C ambient)

60V for 5 minutes (at 25°C ambient)

100V for 20s

Frame Voltage:

Pickup Settings (AC Volts rms.):

40, 60, 80, 100

Pickup Tolerance:

–15%, +0%

Delay (Sec.):

0.1 ±5% if voltage < 100 V AC.

Less than 0.03 if voltage ≥100 V AC.

Output Contacts:

Main Trip Relay:

Type: Form Z (NO and NC pair)

Rating:

10A @ 250V AC,

10A @ 30V DC,

½ HP @ 240V AC

Auxiliary Ground Fault Relay:

Type: 1 Form C (NO/NC)

Rating:

10A @ 240V AC,

8A @ 24V DC, ½ HP @ 240V AC

Auxiliary Ground Check Relay:

Type: 1 Form C (NO/NC)

Rating:

10A @ 240V AC,

8A @ 24V DC,

½ HP @ 240V AC

Terminal Contact Material:

Clamping screw: nickel-plated brass

Plug contacts: tin-plated bronze

Physical:

Weight: GCHK-100 855g

GCHK-DRI 45g

mGARD-SYM 600g

GCHK-ZT 35g

Dimension: See Figs. 11.1 to 11.4

Standards: CSA

I-Gard reserves the right to change specifications of its

products without notice.

10 SpecificationS

I-GARD GCHK-100 Instruction Manual

14

11 outline dimenSionS

Figure 11.1 GCHK-100 Main Relay Outline Dimensions (inches)

5.50 0.20

0.253.50

0.19

4.20

5.90

4.00

0.15

4.72

GCHK-100 Instruction Manual I-GARD

15

Figure 11.2 mGARD-SYM LCD Remote Indicator Dimensions (inches)

5.16

5.16 2.15

3.94

3.94 0.41

3.94

3.94

0.41

Figure 11.3 GCHK-DRI LED Remote Indicator Dimensions (inches)

4.34

2.20

0.35

1.50

3.87

0.23

0.36

0.61

0.26

0.64

3.05

1.92

0.14

1.18

2.29

4.34

2.20

0.35

1.50

3.87

0.23

0.36

0.61

0.26

0.64

3.05

1.92

0.14

1.18

2.29

I-GARD GCHK-100 Instruction Manual

16

Figure 11.4 GCHK-ZT Zener Diode Line Terminator Outline Dimensions (inches)

1.16

2.65

1.38

0.19

12 inStruction manualS

C-407 GCHK-100 Mining Relay

Ground Fault Protection

System Manual

C-408 Sleuth

High Resistance

Grounding System Manual

C-403 GFR-RM Sigma

Resistor Monitoring

and Ground Fault Relay

C-322 MGFR

Ground Fault Relay Manual

C-409 DSP Ohmni

High Resistance

Grounding System Manual

C-102 Gemini

High Resistance Grounding

System Manual

C-101 StopLight

High Resistance Grounding

System Manual

C-105 Fusion

Ground Fault Protection

System Manual

C-107 Sentinel

High Resistance

Grounding System

thepower to protect

Table of contents

Other I-Gard Protection Device manuals

Popular Protection Device manuals by other brands

Global Power Products

Global Power Products SURGE SAFE SM Series Installation, operation and maintenance manual

i4Technology

i4Technology BugHunter DAudio bda-4 Voice user manual

Kelley

Kelley AQUASHIELD SYSTEM AQS-900 Series installation instructions

Array Solutions

Array Solutions AS-309H Operation and installation

ABB

ABB RELION 650 SERIES Commissioning manual

Renkforce

Renkforce RS232 operating instructions