I-Gard IPC DSP OHMNI User manual

Instruction Manual C-409

HIGH RESISTANCE

GROUNDING SYSTEM

DSP OHMNI

DSP OHMNI

the power to protect

HIGH RESISTANCE GROUNDING

IMPORTANT

Each DSP module is carefully inspected before packed in a specially designed carton. The unit should be examined

immediately upon receipt. If damage or indication of rough handling is apparent, a claim should be filed without

delay with the transport company. I-Gard should be notified promptly if replacements for damaged goods are

necessary. If units received are not to be installed immediately they should be stored in their original containers in an

area free of dust and moisture.

DSP Second Fault Protection – unnecessary outages of electrical power in continuous process industries or

in critical systems applications such as hospitals, air traffic control towers etc cannot be tolerated and this has

increased the usage of high resistance grounding systems.

The new DSP Ohmni System is designed to provide an alarm, but not trip when one ground fault occurs in the

system thus retaining system continuity. If a second fault develops on the system, before an existing fault has

been cleared, then the potential for serious damage results.

TABLE OF CONTENTS

1 Introduction 3

2Application 4

3Installation 5

4Wiring 6

5Display 10

6Setup 11

7Operation 18

8Alarm Indications 20

9 Self-Test 22

10 Events 23

11 Maintenance and Testing 24

12 Service 25

13 Communications 25

14 Specifications 31

15 Outline Dimensions 33

16 Additional Information 36

17 Instruction Manuals ibc

TABLES

Table 3.1 System Module Requirements 5

Table 3.2 Standard Ribbon Cables 5

Table 6.1 Pulsing Frequency Selection 17

Table 13.1 MODBUS RTU Standard 8 Byte Holding Register Read Function (03) 26

Table 13.2 Returned Information Structure for Holding Register Request 26

Table 13.3 Request to Write to Set a Bit on a Register (Modbus Force Coil) 26

Table 13.4 Returned Information from Dsp Following a Force Bit Request 27

Table 13.5 Feeder Module Ground Current Addresses 28

Table 13.6 Feeder Module Status Addresses 29

Table 13.7 Feeder Module Priority Addresses 30

Table 13.8 System Function Registers 31

I-GARD DSP-OHMNI Instruction Manual

2

TABLE OF FIGURES

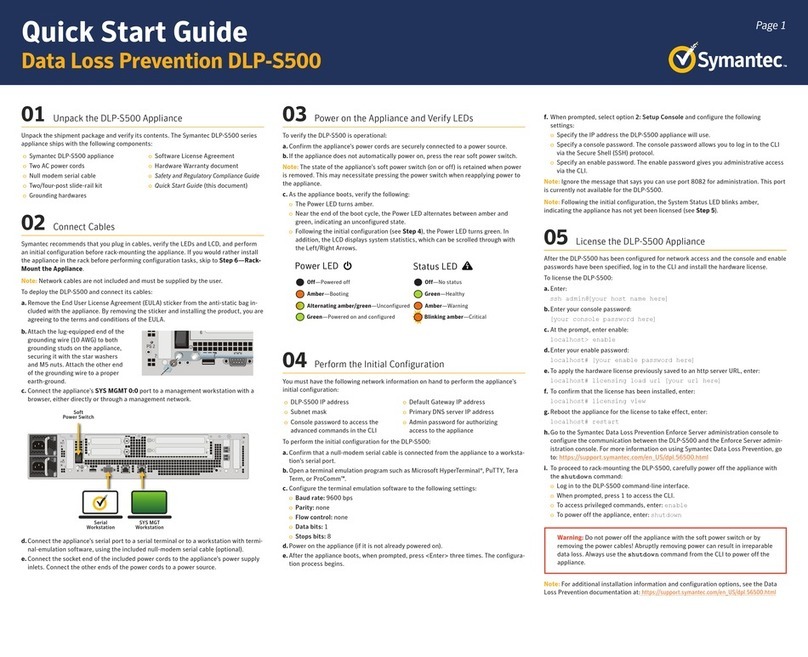

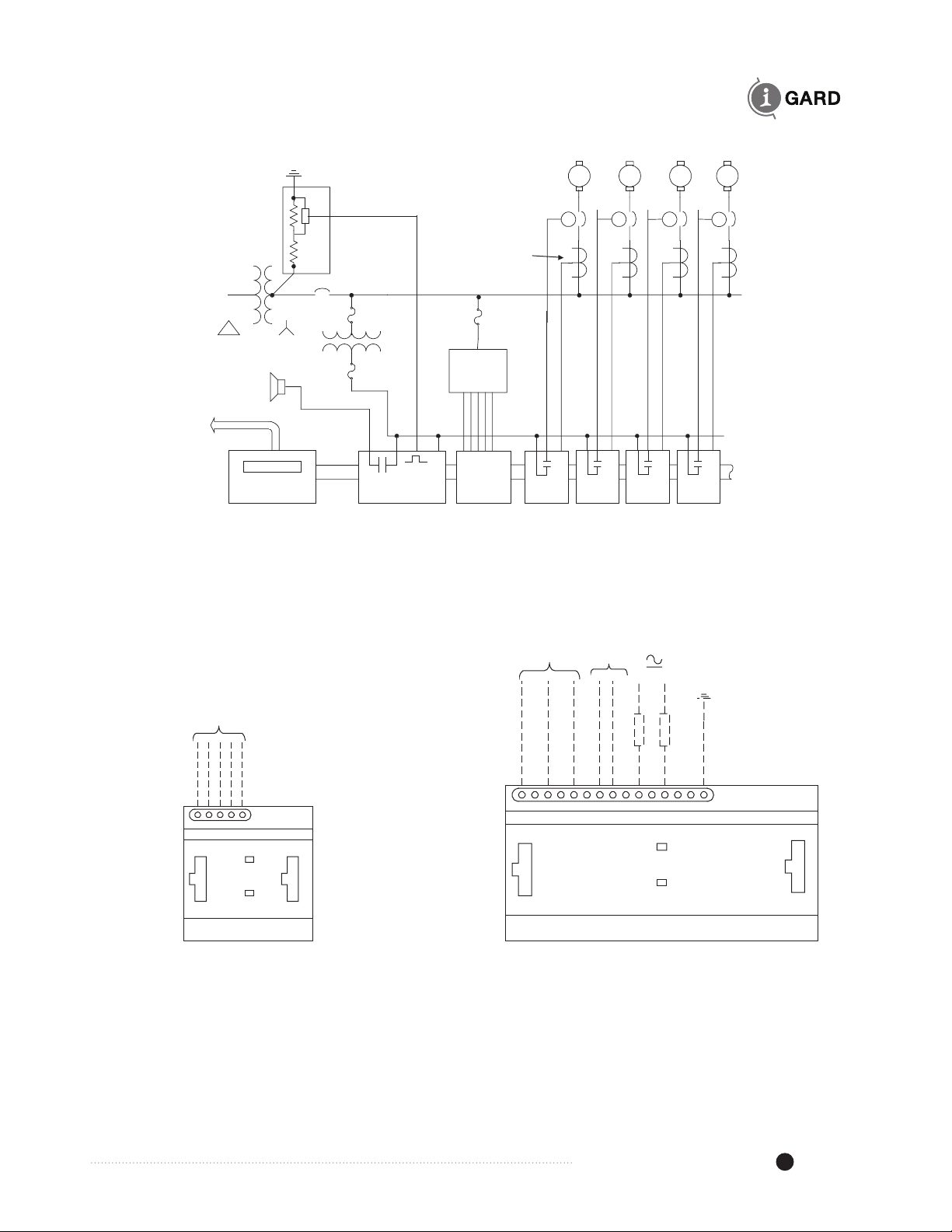

Figure 4.1 a) Typical One-Line Installation - Unit Substation b) System Module DSP-DSM Wiring 7

Figure 4.1 c) Power Supply DSP-DPS wiring 7

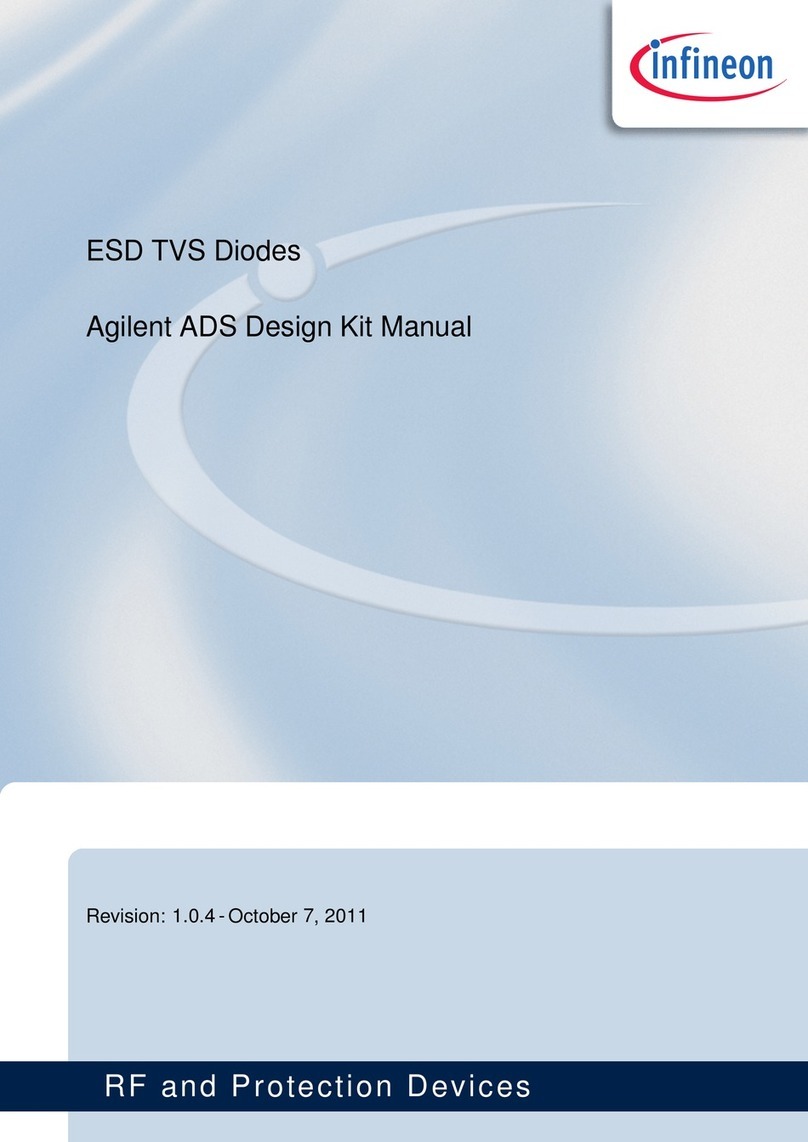

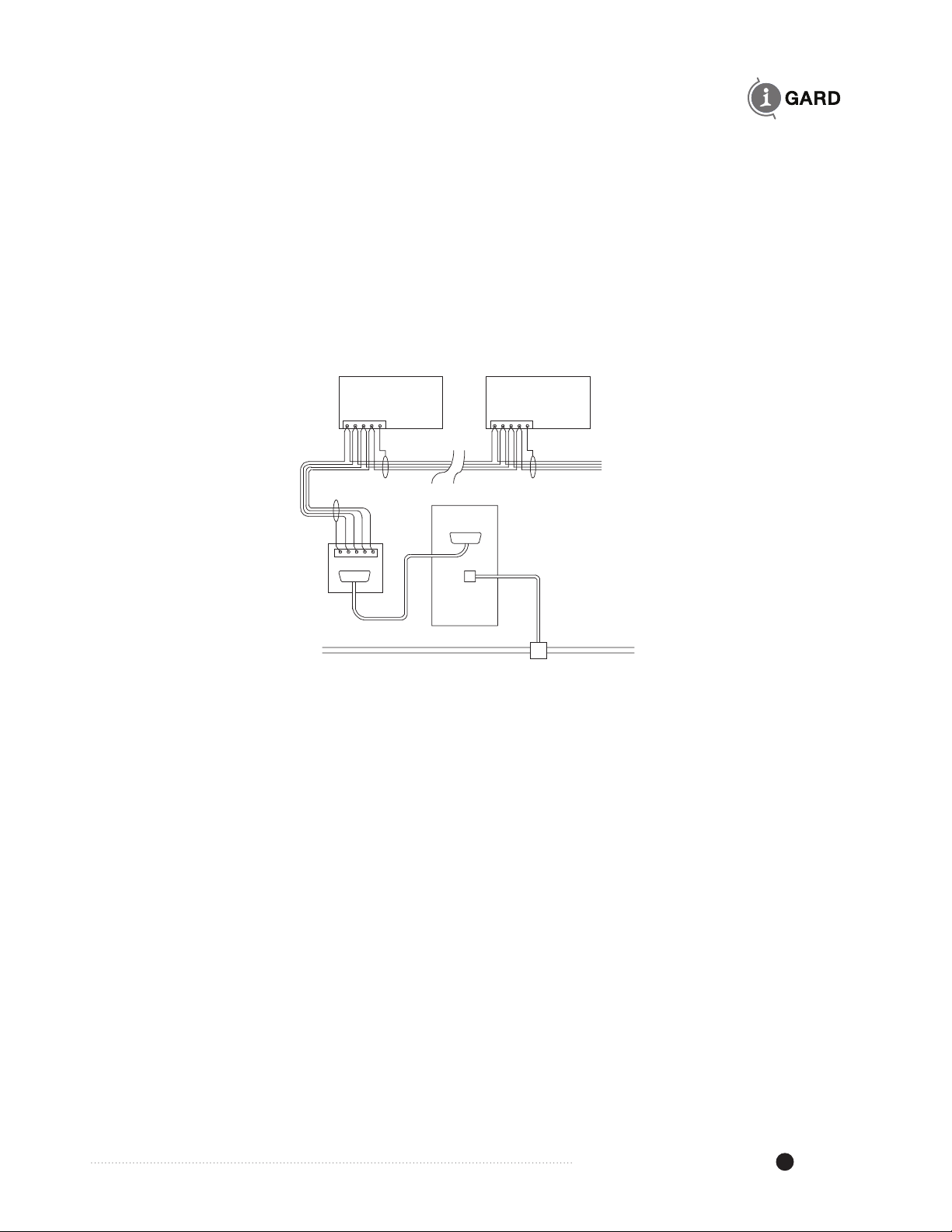

Figure 4.2 Preferred Feeder Module DSP-DFM Wiring 8

Figure 4.3 Alternative Sensor Wiring 8

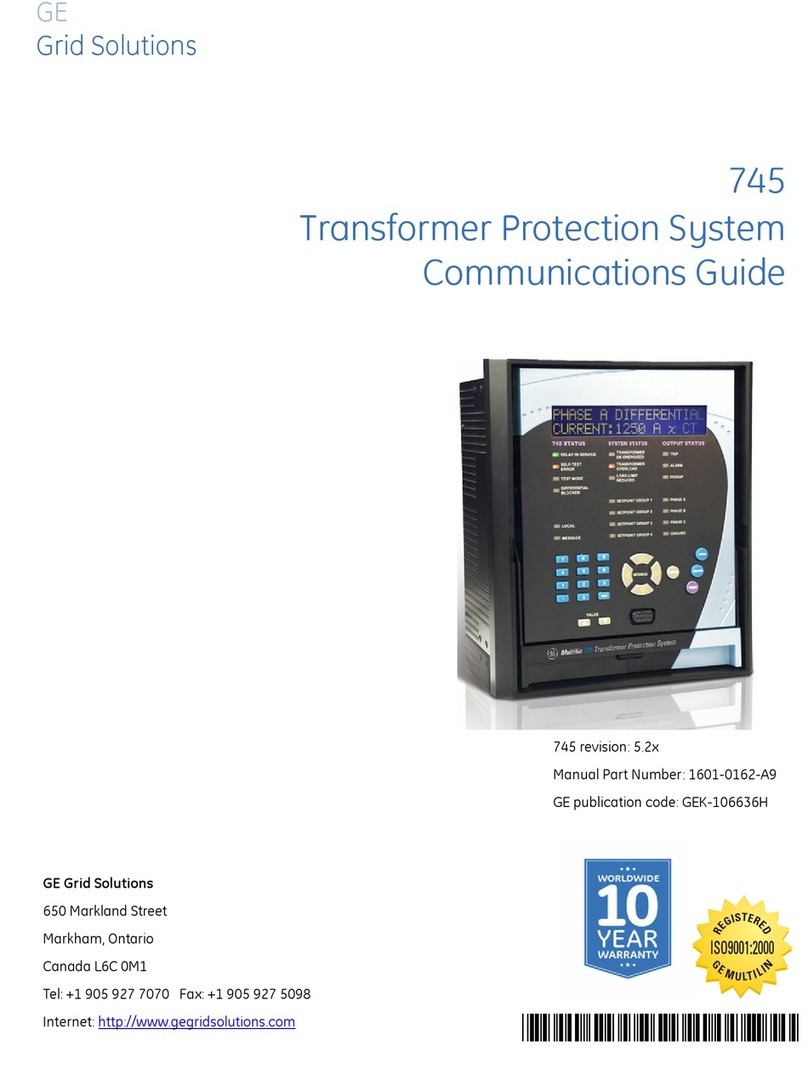

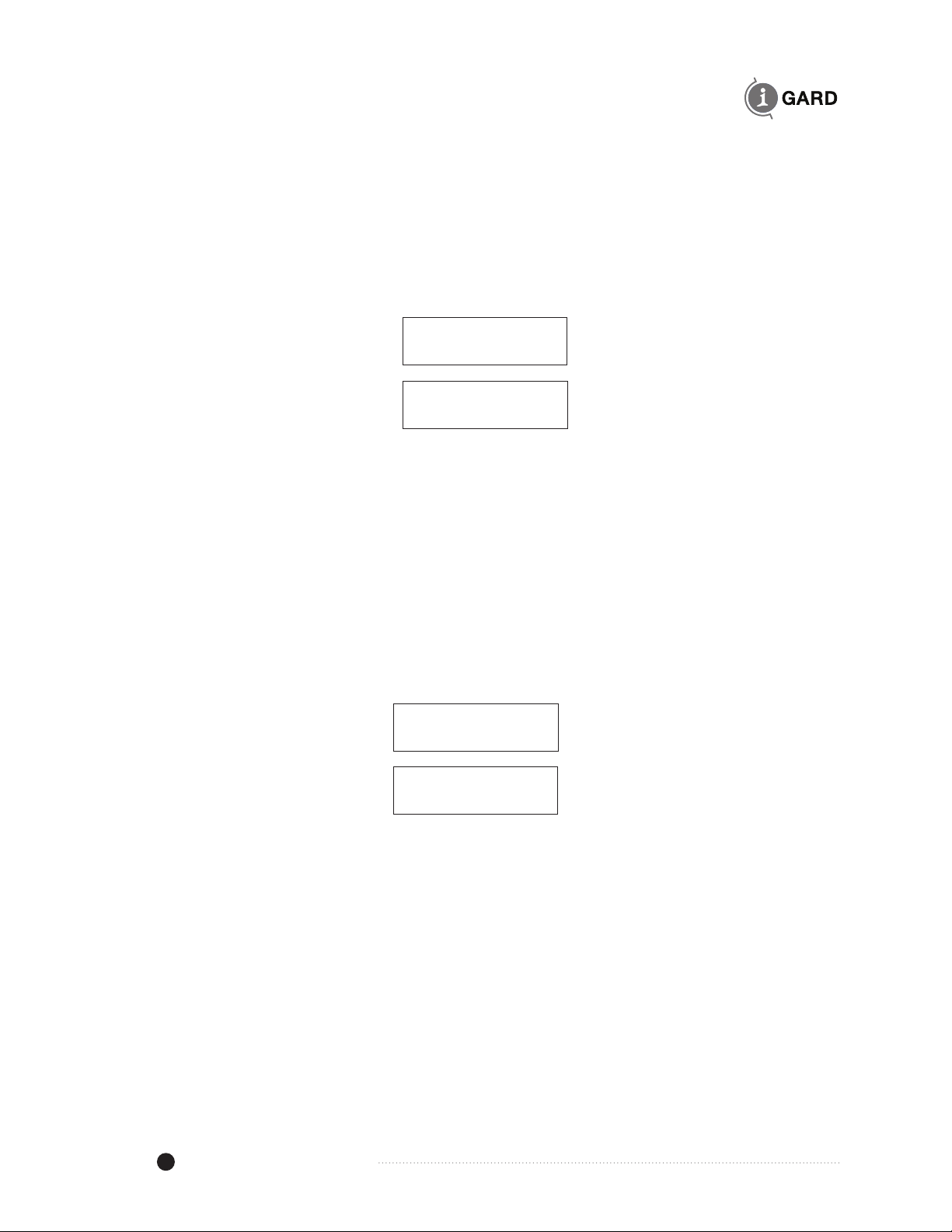

Figure 4.4 Typical 4-wire Communications Connection 9

Figure 4.5 Alternative two-wire connection for RS-485 10

Figure 5.1 Home Screen 10

Figure 5.2 Alarm Screen 10

Figure 6.1 Communications Set-up 11

Figure 6.2 Communications Set-up 11

Figure 6.3 Grounding Resistor Set-up 12

Figure 6.4 Feeder Module Set-up 12

Figure 6.5 I/D Check indication 13

Figure 6.6 Feeder Module Set-up 14

Figure 6.7 a) Feeder Module Successful b) Set-up Not Successful 14

Figure 6.8 a) DSP-DM allows further Feeder Module set-up b) If previous set-up had not been successful 14

Figure 6.9 Pulse Set-up Request 15

Figure 6.10 Pulse Mode Set-up 15

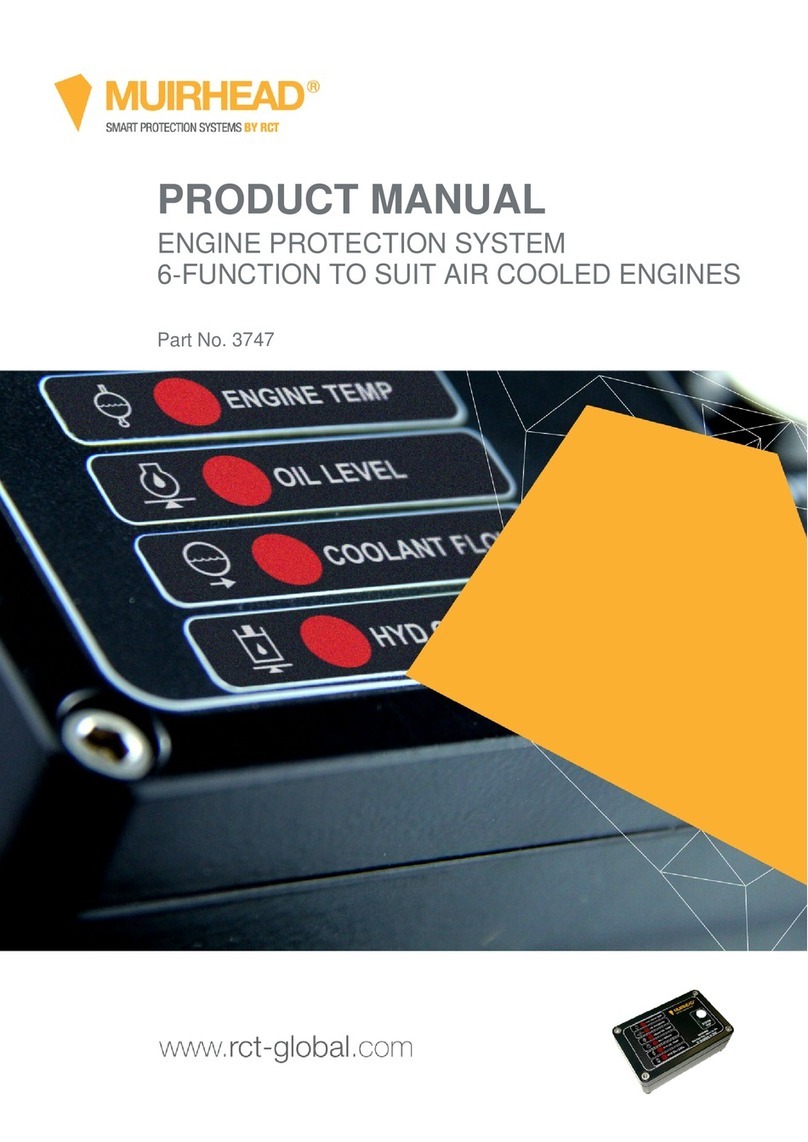

Figure 6.11 Typical Examples of Pulse Circuit Connection 16

Figure 6.12 Alarm relay Setup 17

Figure 6.13 Alarm relay Options 17

Figure 6.14 Save Screen 18

Figure 6.15 Self-Test Prompt 18

Figure 7.1 Normal Home Screen 18

Figure 7.2 System leakage current lG19

Figure 7.3 Feeder Current IGf 19

Figure 7.4 Trip Defeated 19

Figure 7.5 Pulse Control 20

Figure 7.6 New Home screen indicates Pulsing ON 20

Figure 8.1 Alarm Screen 21

Figure 8.2 Bus Fault 22

Figure 9.1 System-Test Prompt 22

Figure 9.2 Prompt for Feeder Test 22

Figure 9.3 Feeder Module Test 23

Figure 9.4 Test Result 23

Figure 10.1 Event Notification 23

Figure 10.2 Momentary Feeder Fault Example 23

Figure 15.1 DIN Rail Mounted Modules 33

Figure 15.2 DSP-DM Display Module with cut-out detail 34

Figure 15.3 DSP-DPS Power Supply Connections 35

Figure 15.4 DSP-DSM System Module Connection 35

Figure 15.5 DSP-DFM Feeder Module Connection 35

Figure 15.6 DSP-DM Display Module Connections 36

DSP-OHMNI Instruction Manual I-GARD

3

1INTRODUCTION

High-Resistance-Grounding is becoming more prevalent in industrial and commercial electrical power

systems. As the need for reliable and stable power increases the inconvenience of unwanted downtime

in processing, robotics and data service also become more critical and costly.

Single Ground Faults in motors and equipment are common and will cause interruption of service

in Solidly Grounded systems. HRG prevents this event from happening by limiting the fault current to

a sustainable level for an indefinite time.

The DSP system is designed to detect the event of a single fault and signal an alarm condition and point

to the affected branch or feeder. Thus maintenance can be immediately alerted to the problem and an

operator dispatched to locate the fault to isolate it promptly. The DSP system can assist in locating the

fault with a pulsing fault location circuit that modulates the current in the fault. This allows the operator to

identify which branch circuit is carrying fault current using a portable clamp-on current probe connected

to an ordinary Multi-meter.

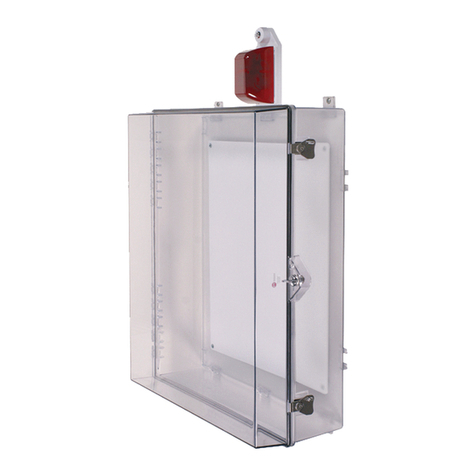

The DSP system consists of a number of modules that are mounted on a 35mm DIN rail typically located in

a control compartment of switchgear. The modules are connected together through 20-conductor

standard ribbon cable. A panel-mounted Display module provides a human interface to the system

and communications to a RS-485 network allows set-up and control.

There are four DSP modules as follows:

DSP-DM Display Module

DSP-DPS Power Supply

DSP-DSM System Module

DSP-DFM Feeder Module

The Display Module is a panel-mounted enclosure designed for flush mounting in a door. It is connected by

a ribbon cable to the Power Supply unit. The DSP-DM indicates faulted phase, total

system leakage current, feeder branch current level and provides other information such as priority

settings and Resistor setting etc. It is used to set-up the system and provide manual control of the

pulse location system.

The POWER Supply unit DSP-DPS is a DIN rail-mounted modular unit constructed with an ABS enclosure

and provides +5V, +12V and -12V regulated supplies to all of the modules through the front ribbon cables. It

is capable of operation with a wide range of voltage supplies from 100V to 240V ac without selection of any

jumpers or switches. DC voltage can also be used from 125V to 250V DC.

The System Module monitors the system line-to-ground voltages through a standard I-Gard Corp. DDR2

voltage dividing resistor unit. It determines if there is voltage unbalance in the system and the level

of ground fault current in the grounding resistor, without any connection to the Resistor.

I-GARD DSP-OHMNI Instruction Manual

4

The Feeder Modules measure the fault current level in the branch circuits that are protected. This module

uses standard I-Gard current sensors Type T2A, T3A, T6A and T9A. It is equipped with a form C 10A

output Relay that can be used for breaker control. The DSP-DFM detects two fault levels. Firstly it detects

the single fault, which creates a System Alarm condition, and secondly through a priority level system it

provides breaker control to disconnect the least important circuit breaker.

Communications is provided by a 4-wire RS-485 network connection from a jack located at the rear of the

DSP-DM Display module. The communications protocol supported is MODBUS RTU, which is a master/

slave system with selectable baud rates from 4800 to 19200. The DSP supports the MODBUS function Read

Holding Registers only, without exception support. Additionally it will support remote RESET using the Force

Coil function.

2APPLICATION

The DSP system is used in conjunction with I-Gard, Alarm Resistor Unit Type DDR2. The DDR2 matches

the DSP-DSM input circuits to the system voltage and is available in 4 types as follows:

Type System Voltage

DDR2-1 120V*

DDR2-2 240V

DDR2-4 480V

DDR2-6 600V

* Also used with potential transformers up to 13.8KV

The DDR2 provides output voltages VAG, VBG, VCG that are proportional to the phase to ground voltage and

also voltage VNG that is proportional to the neutral resistor voltage. ( i.e. Total leakage/fault current of the

system)

On large systems provision is usually made to ground the system using a current-limiting resistance

(I-Gard Type OHMNI-PM or NGR). On ungrounded systems there is always leakage capacitance to ground

from each line. Re-striking ground faults may cause an excessive build up of line to ground voltage due to

this capacitance. It may be stabilized with the addition of a grounding resistance, thus preventing costly

breakdown of insulation.

The Type OHMNI-PM is connected between ground and the star point of the transformer on Wye systems.

On Delta systems an artificial neutral device (I-Gard Type DDAI) is required to provide a star point. Both

OHMNI-PM and DDAI devices are selected for appropriate current ‘let-through’,i.e.: The current, which will

flow to ground, if there is a direct short from line to ground (on any one phase).

NOTE: A good Rule-of-Thumb for Resistor current selection is 1 ampere per 2000KVA, if no surge capacitors are on the system,

and 1 ampere per 1000KVA with surge capacitors. For further information please refer to www.i-gard.com/appguides.htm

DSP-OHMNI Instruction Manual I-GARD

5

DDAI and OHMNI-PM devices are available for continuous currents of 1 ampere to 10 amperes for

most systems. For further information regarding the use of these devices refer to:

Instruction Manual Type DDAI Artificial Neutrals C-430EM

Instruction Manual Type DDR2 Alarm Resistor Units C-440EM

Instruction Manual Type OHMNI-PM Neutral Grounding Resistors C-450EM

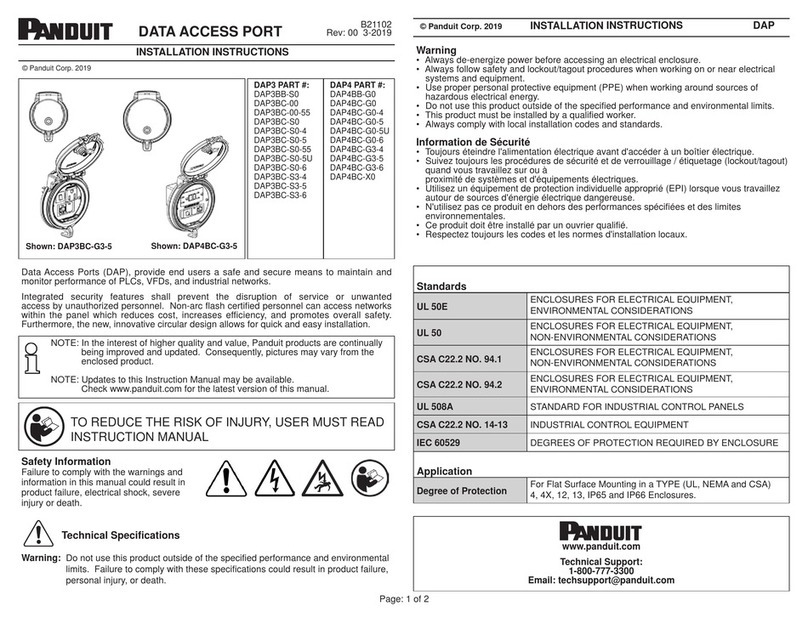

3INSTALLATION

A typical installation will include for each power source (transformer/generator) 1 DSP-DM, 1 DSP-DPS,

1 DSP-DSM and a number of DSP-DFM Feeder Modules as required with 1 for each branch protected.

Additionally there will be a DSP-PM pulsing resistor to ground the system. A voltage-sensing resistor DDR2

is required for the DSP-DSM input, as well as one current sensor for each DSP-DFM for current detection.

See Table 3.1 for typical requirements.

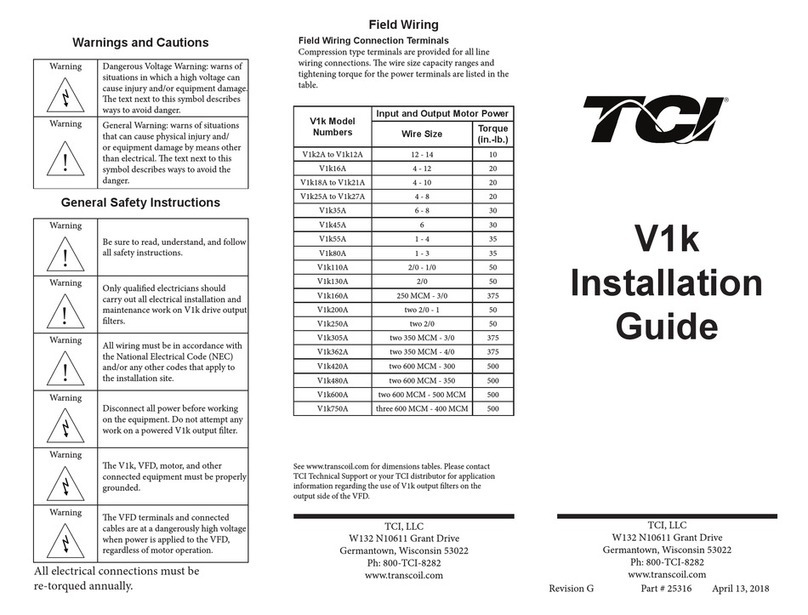

TABLE 3.1 SYSTEM MODULE REQUIREMENTS

Catalog Number Description No Required/System

DSP-DM Display Module 1

DSP-DPS Power Supply 1

DSP-DSM System Voltage Module 1

DSP-DFM Feeder Module As required 1/ Circuit

OHMNI-PM Pulse Equipped Resistor 1

DDR2 Voltage Sensing Resistor 1

DDAI Artificial Neutral Required only for delta system

T Toroidal Current Sensor 1/Feeder Module

TABLE 3.2. STANDARD RIBBON CABLES

Length Function Catalog Number

365cm (12ft) DSP-DM to DSP-DPS DRC-365

150cm (5ft) DSP-DM to DSP-DPS DRC-150

5cm (2 in.) Module to Module connection RC-3

30cm (12 in.) Module to Module connection RC-30

DSP modules are mounted on a 35mm DIN Rail generally located at the rear wall of a switchgear

compartment. They should be mounted side by side and connected with 20-conductor ribbon cable in a

daisy chain configuration. This applies to the DSP-DPS, DSP-DSM and DSP-DFM modules only.

I-GARD DSP-OHMNI Instruction Manual

6

DSP (Outline Dimensions). Care should be taken not to over tighten the 8-32 nuts used to retain the

DSP-DM

It will be necessary to provide a reliable power source (which is not interrupted by operation of the DSP

output contacts) for control power. The supply should be 100-240 V AC/DC. The control supply must be

fused by 1 Ampere fuses as shown in Fig. 4.1 a (Connection Diagram). Ideally the alarm, warning bell should

be connected to a separate control supply from the DSP (see para. 8.3.1).

4WIRING

No.14 or No.16 switchboard wire is used for all current sensor, control and DDR2 connections, which need

not be shielded. 4-wire shielded cable should be used for the serial communications, however. A typical

wiring schematic is shown in Figure 4.1a.

Sensor wiring is not generally limited by length and may be up to a kilometer without degradation of

performance, since the sensor is a current source. Sensor wiring should be run in separate conduit from

Power wiring. The recommended sensor wiring connections are shown in Figure 4.2. Two wires should

be run from each sensor X1 and X2 as indicated to prevent cross coupling between Modules. If existing

wiring does not allow this connection because of common connection at X2 as has been common in some

installations, then the G terminals of the DSP-DFM modules should be connected as shown in Figure 4.3.

Ribbon cables are available in different lengths as shown in Table 3.2. For other lengths contact

I-Gard. The DRC-cable from the DSP-DM to the DSP-DPS, apart from being different in length, also differs

in the orientation of the connector. This allows the cable to be run easily from the DSP-DM towards the

DSP-DPS power supply. The RC-cables are used for Module to Module connections and are short in

length. Note the orientation of the plug as marked on the DSP-DM display module. If a second row of

modules is installed on another DIN rail,the last module on the right can be connected to the last module

on the right on the second row using the RC-30 cable. Either slot can be used on the DSP-DFM feeder

modules for connection.

DSP-OHMNI Instruction Manual I-GARD

7

13 15 17

GCA

TO DDR2-

RESISTOR

BN

14 16

Figure 4.1b System Module DSP-DSM Wiring

27 29 31 33 34 36 38 40 41

NC COM NO + - VAC VAC G G

100-240V

ALARM

RELAY TO

HORN

12V DC

PULSE

OUT

SYSTEM

GROUND

CONTROL

1A1A

Figure 4.1c Power Supply DSP-DPS wiring

DDR2

25VA CPT

120V

OHMNI-PM NGR

MAIN BUS

HORN

1A

PULSE SIGNAL

DSP-DSM

ZSCS

BREAKER

TRIP SIGNAL

ALARM

CONTACTS

ABCNG

AB NGC

POWER

AC/DC

DSP-

DFM

LOADS

DSP-

DFM

DSP-DPS

DSP-DM

RS-485 TO NETWORK

DSP-

DFM

DSP-

DFM

1A

1A

N

G

20 COND

RIBBON

Figure 4.1a Typical One-Line Installation - Unit Substation

I-GARD DSP-OHMNI Instruction Manual

8

Figure 4.3 Alternative Sensor Wiring

Shunt Trip

Supply

Sensor 1 Sensor 2 Sensor 3 Sensor 4

To

DSP-DSM

G S NO NC COM

678910

DSP-DFM

G S NO NC COM

678910

DSP-DFM

G S NO NC COM

678910

DSP-DFM

G S NO NC COM

678910

DSP-DFM

Figure 4.2 Preferred Feeder Module DSP-DFM Wiring

NOTE: For Main-Tie-Main systems and multiple sources with tie breakers the priority buses can be joined together with the use

of I-Gard devices DSP-CAS and DSP-CA Modules. The DSP-CA module converts ribbon cable to an8-conductor shielded cable

for this purpose. The DSP-CAS does the same thing except that it includes an electronic switch to make or break the connections

when the tie breakers are closed or open. This eliminates the use of 8-pole contactor arrangements of previous systems. The two

modules are DIN rail mounted similar to the other DSP modules in 70mm wide housing. See information on DSP-CA(S) or manual

C-414EM for typical wiring.

Shunt Trip

Supply

Sensor 1 Sensor 2 Sensor 3 Sensor 4

To

DSP-DSM

X1

X2

X1

X2

X1

X2

X1

X2

G S NO NC COM

678910

DSP-DFM

G S NO NC COM

678910

DSP-DFM

G S NO NC COM

678910

DSP-DFM

G S NO NC COM

678910

DSP-DFM

DSP-OHMNI Instruction Manual I-GARD

9

The RS-485 cable shield should be grounded at the ground terminal provided on the 5–pin jack as shown

in Figure 4.4, which shows a typical installation with a local computer and LAN.

Communications may be supported as a node in an existing MODBUS network or may be connected

through a standard RS-485 to RS-232 converter to a PC with supporting software.

The Alarm contacts are available at the DSP-DPS as a Form C type and should be connected to operate

a horn or other means to alert an operator to the fact that a fault has occurred on the HRG system. The

contacts are rated at 10A, 240VAC Resistive.

Figure 4.4 Typical 4-wire Communications Connection

Communications wiring may be 2-wire or 4-wire but must use shielded cable with low capacitance. Wire

lengths up to 2000 metres can generally be used without the need for termination resistors.

Figures 4.4 and 4.5 show typical RS-485 arrangements with a RS-485/RS-232 converter and a host PC

connected to a LAN.

DSP-DM

(01)

DSP-DM

(nn)

RS-232

COM Port

Computer

Host

Other 485 Devices

Network

TCP/IP

I-GARD DSP-OHMNI Instruction Manual

10

Figure 4.5 Alternative two-wire connection for RS-485

For Fault location the DSP system is equipped with Pulse modulation for the ground current to identify the

fault more readily. Pulse current is provided at the DSP-DPS (+) and (-) terminals, which may be directly

connected to the Pulse Relay in the DSP-PM grounding Resistor. It is important to observe the polarity of

the connection. This 12V wiring need not be shielded but should be 14 AWG switchboard wire for durability.

5DISPLAY

Following successful installation of the DSP system and connection of the control voltage,the DSP-DM

display module should indicate a Green NORMAL light and the screen should show the following message.

I-GARD

HRG SYSTEM OK

Figure 5.1 Home Screen

If the following screen appears and the local Alarm sounds, then most likely the DDR2 resistor is not

energized or connected.

3 PHASES LOST

CHECK DDR2 FUSE

Figure 5.2 Alarm Screen

DSP-DM

(01)

DSP-DM

(nn)

RS-485 to RS232

Converter

RS-232

COM Port

Computer

Host

Other 485 Devices

Network

TCP/IP

Tx+Tx-Rx+Rx-

Tx+ Tx-Rx+Rx- G

G

Tx+Tx-Rx+Rx- G

DSP-OHMNI Instruction Manual I-GARD

11

Most of the screen navigation is done with the ukey on the faceplate label of the DSP-DM. Pressing this

key once will switch screens to the System Status screen which shows the total system leakage IG. This

is derived from voltage measurement of the system voltages and is proportional to the current through the

grounding resistor of the system. It should appear as in Figure 5.1. This is the Home Screen, Screen1, which

is the NORMAL starting screen after RESET is pressed. Various messages may modify this screen following

an event such as a fault, loss of fuse, or during pulsing to provide some diagnostic information.

6SETUP

On a new installation some simple set-up is required with at least Maximum System Current (NGR set-up)

and Feeder Modules being set prior to use of the equipment. Optional settings are Communications and

Pulse Control.

6.1 Communications

To enter the Set-Up Mode press SETUP when the Home Screen or Alarm Screen is showing (SETUP

will not enter from any other screens). If confused at any point, press RESET and the Home Screen (or

Alarm Screen - if a fault has occurred) will be shown. Figure 6.1 shows the first set-up screen that will be

encountered – COMMS set-up mode.

SETUP COMMS? Y/N

Figure 6.1 Communications Set-up

If you are not using the RS-485 connection, then press ENTER to skip to the next set-up, otherwise press

tto move the flashing cursor to select Y (for Yes) and press ENTER. The communications screen will

appear similar to Figure 6.2. The screen will show the set-up presently in use, or the default as shown.

MODBUS 1/D 01

BAUD RATE 4800

Figure 6.2 Communications Set-up

The DSP system must be identified by a number from 01 to 32, to distinguish between it and other

MODBUS devices that may be connected on the same RS-485 network. If only one device is used then it

will typically be set to 01, which is the default value. (Ensure that no other device has the same I/D setting

on the RS-485 network or data will not be valid). To change the number, use the pq arrows to increase/

decrease the digit under the flashing cursor and ut to change digits.

I-GARD DSP-OHMNI Instruction Manual

12

When a desired number has been entered press ENTER to change the Baud Rate setting if required. The

present rate will be shown. Press pto select another setting. Only three baud rates are provided (4800,

9600 and 19.2K).

Keep pressing the pbutton and the selection will simply scroll through the three settings until ENTER is

pressed to finalize the Communications Set-up and show the screen of Figure 6.3. Select Y to enter this

set-up or ENTER to move to Feeder Module Set-up.

6.2 NGR

a)

SETUP NGR? Y/N

b)

IG CURRENT A 05

SET TO NGR 1-16A

Figure 6.3 Grounding Resistor Set-up

The next screen following Communications is the Grounding Resistor Setting. This setting must be set

according to the current limiting value of the grounding Resistor of the HRG system. The default value is

1A. To change the number, use the pq arrows to increase/decrease the digit under the flashing cursor

and ut to change digits.

The final value must be between 01 and 16 for 1-16A range. Press ENTER when completed.

CAUTION! THE SYSTEM WILL ALLOW YOU TO SELECT INVALID NUMBERS OUT OF RANGE, WITHOUT WARNING,

BUT THE RESULTS WILL BE INDETERMINATE.

6.3 Feeder Module SETUP FM? Y/N

FEEDER SEL 01

TRIP ON PRIOR 00

Figure 6.4 Feeder Module Set-up

Following the OHMNI-PM set-up the display prompts for Feeder Module Set-up. Select Y to enter the

Feeder Module setup screen as shown in Figure 6.4 (b).

After installation of Feeder Modules they must be given identification numbers from 01 to 50 (maximum)

so that the Display unit can determine which module it is talking to. Each module must have a different

number. To change the number, use the pq arrows to increase/decrease the digit under the flashing

cursor and ut to change digits.

DSP-OHMNI Instruction Manual I-GARD

13

The Display module is the master module and is constantly sending requests for data from each feeder

module from 1 to 50. The Feeder Modules compare the request I/D with their own I/D to decide whether

or not they are being asked for data. If the I/D is the same then that Feeder Module replies with Current,

Priority and Status information to the master Display Module. Therefore it is very important that there

are not modules in the chain with the same I/D. The Feeder Select program checks for duplicate I/D

when ENTER is pressed following an entry of FEEDER SEL xx. If an existing I/D is detected, the screen will

indicate as in Figure 6.5.

I/D IN USE 01

TRIP ON PRIOR 00

Figure 6.5 I/D Check indication

In this case the user must enter a different I/D number before proceeding further. The user is allowed

another chance to enter a valid I/D number before the cursor moves to TRIP ON/OFF selection. This

permits the TRIP and Priority of previously set modules to be changed while retaining the same I/D number.

CAUTION! IT IS ENTIRELY POSSIBLE FOR THE USER TO ENTER A NUMBER OUTSIDE THE RANGE 01 TO 50 AND

THE SYSTEM WILL ACCEPT IT WITHOUT WARNING, DATA WILL NOT BE COLLECTED FROM SUCH MODULES,

ALTHOUGH THEY WILL CONTINUE TO PROVIDE FAULT PROTECTION.

Typically, the numbers will be in the sequence 1,2,3,4…. but they can be in any order physically. The

Display Module does not care. The identification number, however, must be known for each feeder circuit

since the Display does not support the use of Text Labelling to identify circuits. Note: This can be done

with user-provided software from the RS-485 network if required or by use of the DSP.net server package

downloadable from the I-Gard web site. See communications section.

Press ENTER to select the Ident Number. The cursor then drops to TRIP ON setting which is the normal

setting. To disable the TRIP function of the Feeder Module press tarrow in which case no priority is

required to be set and the Screen of Figure 6.6 is presented.

If the TRIP feature is to be retained (normal setting) pressing ENTER will then allow the user to set the priority

of the selected Feeder I/D. To change the number, use the pq arrows to increase/decrease the digit under

the flashing cursor and ut to change digits. The range of priority numbers is from 00 to 15 with 0 being a

lower priority than 15. In the case of Priority numbers it is OK to use the same number more than once unlike

the I/D numbers, so that unimportant circuits can all be set to 00, for example.

I-GARD DSP-OHMNI Instruction Manual

14

When the desired priority for a given I/D number has been selected, press ENTER. You will then be

prompted with the screen of Figure 6.6

PUSH FM BUTTON

AND THEN ENTER

Figure 6.6 Feeder Module Set-up

At this point select the DSP-FM module that is to have the I/D that was set-up, and press the TEST button

on that module. The red FAULT light will turn on to indicate the received I/D signal.

Press ENTER to complete the process. The DSP-DM will display either of the following messages

depending on whether or not the setup was successful.

FM ACCEPTED

CONTINUE ®

a) Feeder Module Successful

FM NOT ACCEPTED

CONTINUE ®

b) Set-up Not Successful

Figure 6.7

Press uto exit the screen and the DSP-DM will allow the user to set-up more Feeder Modules with screen

10 a) and b)

FM ACCEPTED

ANOTHER? Y/N

a) DSP-DM allows further Feeder Module set-up

FM NOT ACCEPTED

ANOTHER? Y/N

b) If previous set-up had not been successful

Figure 6.8

DSP-OHMNI Instruction Manual I-GARD

15

If more Feeder Modules need to be set-up then select Y and ENTER to repeat, or if not select N and ENTER

to exit the Feeder Module Set-up and enter the PULSE Set-up. The Pulse set-up screen allows the pulsing

mode for fault location to be changed for different frequencies and mode of operation. The screen of Figure

6.9 is shown.

6.4 Pulsing SETUP PULSE? Y/N

Figure 6.9 Pulse Set-up Request

PULSE INVRT? OFF

FREQ 0 LOCK? OFF

Figure 6.10 Pulse Mode Set-up

Select Y to enter the Pulse Set-up Screen which looks like Figure 6.10 which will show the existing set-up

of the PULSE module. The pulsing information is stored in the DSP-DSM, which must be installed during

setup. Press tto toggle the setting ON or OFF as required.

6.4.1 Invert / NDR MAL

The output from the DSP-DPS module is connected to a solid state relay. Normally (non Inverted operation)

the output from the ‘+’ and ‘-‘ terminals of the DSP-DPS module is zero prior to any pulsing operation,

and the relay is OFF. If Inverted mode is selected, then this voltage is 12V dc. And the relay is, therefore,

energized continuously. The choice of NORMAL or INVERTED operation depends on how the Grounding

Resistor current is connected. If the Grounding resistor consists of two series or two parallel resistors (one

main resistor and one pulse resistor) with the pulse resistor to be switched in and out by a solid state relay

then the following two options exist.

a) Pulse Up current

Pulsing upwards means to increase current from IGmax 5A to IGmax 10A, for example. In this case the

pulse resistor is normally OFF and the INVRT OFF would be selected. Pulsing would then change the

current to a higher level from 5A to 10A alternating when a 100% fault exists.

b) Pulse Down current

Pulsing downwards means to reduce the current from IGmax 5A to IGmax 2.5A, for example. In this case

the pulse resistor will be Normally ON and thus the INVRT ON mode would have to be selected. This

will mean that the solid state relay will be ON when the system is normal (no fault) and will open when

pulsing is started thus reducing current.

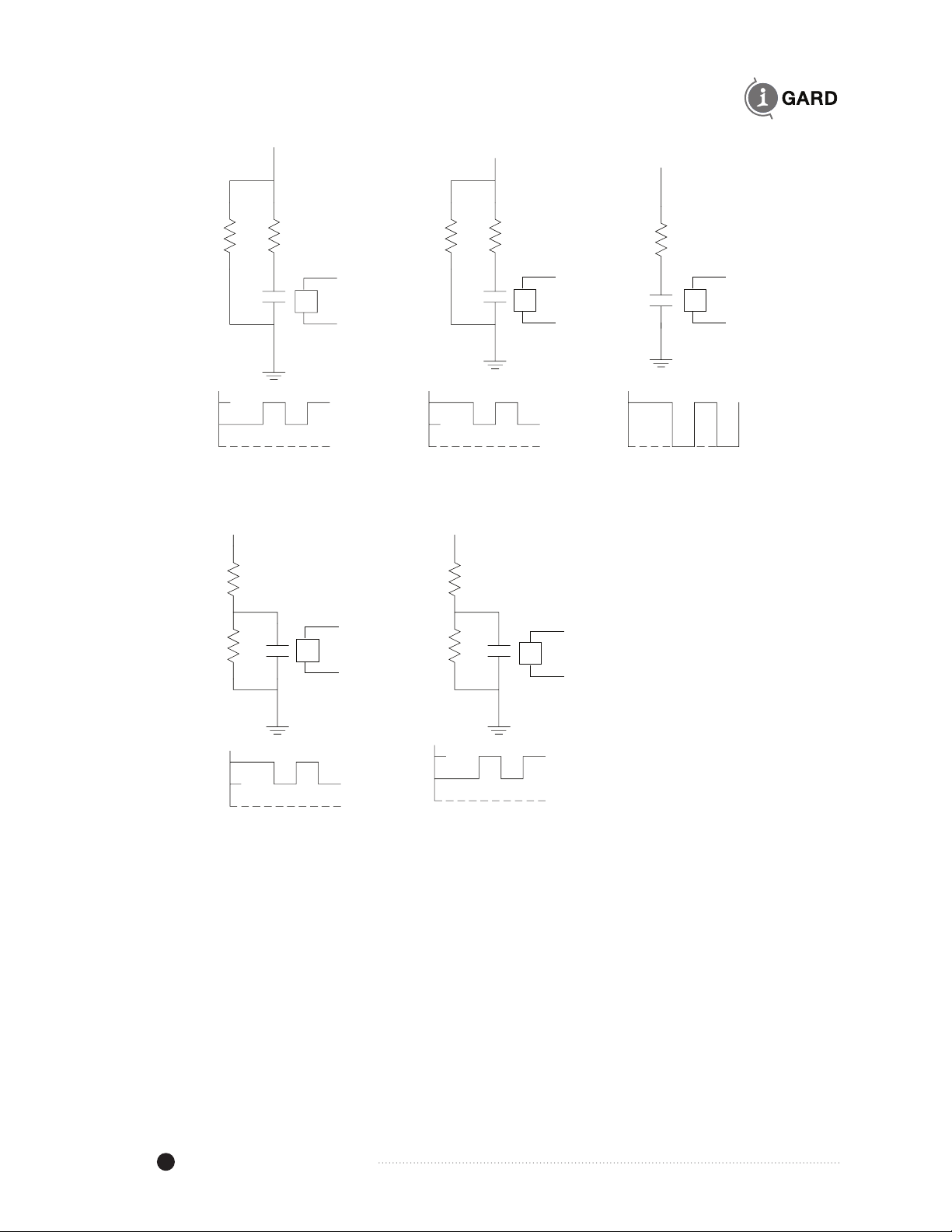

See Diagram 6.11 for examples of both series and parallel connected resistor arrangements.

NOTE: the INVRTed mode is the mode used with the standard OHMNI-PM resistors as supplied by I-GARD.

I-GARD DSP-OHMNI Instruction Manual

16

Figure 6.11 Typical Examples of Pulse Circuit Connection

X

0

X

0

X

0

X

0

X

0

R

G

R

G

R

G

R

G

R

P

R

P

R

P

R

P

5A

5A 2.5A 2.5A 5A

5

10

0

2.5

5

0

5

0

INVRT

OFF

INVRT

ON

INVRT

ON

INVRT

ON

INVRT

OFF

5

10

0

2.5

5

0

a) Pulse UP Parallel

Resistors

b) Pulse Down Parallel

Resistors

c) Single Resistor

a) Pulse UP Parallel

Resistors

a) Pulse UP Parallel

Resistors

RG

+

-

+

-

+

-

+

-

+

-

DSP-OHMNI Instruction Manual I-GARD

17

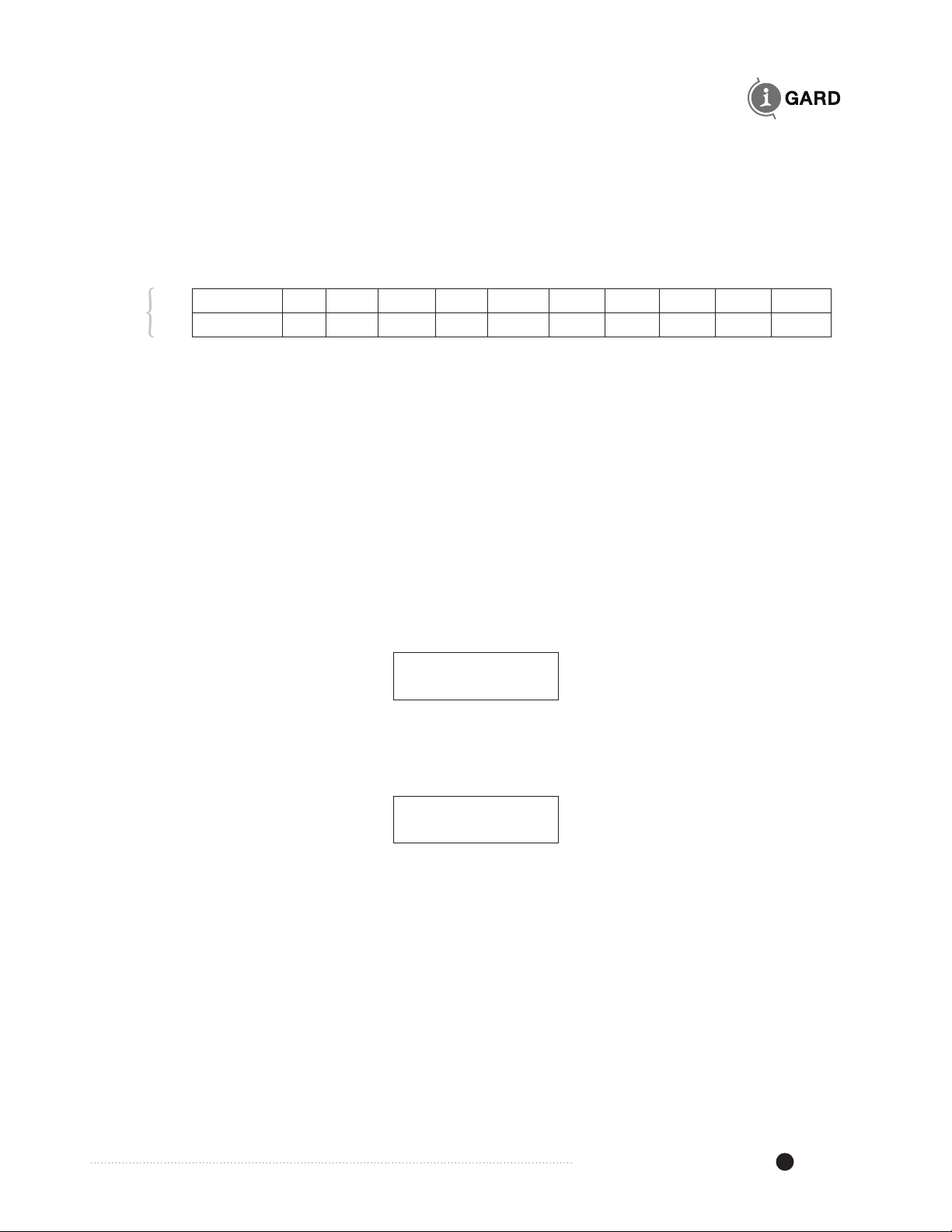

6.4.2 Pulsing Frequency

Press ENTER when the selection is chosen. The cursor will then move to the FREQuency position.

Press pq to select a pulse frequency from 0 to 9 with frequency increasing with the number selected.

It is not important to know exactly the frequency selected, however, Table 6.1. Indicates the frequency

for each setting.

TABLE 6.1 PULSING FREQUENCY SELECTION

Select 0 123456789

Freq Hz. 1.0 1.25 1.50 1.75 .2.00 .2.25 2.50 2.75 3.00 3.25

6.4.3 Interlock

Press ENTER after a value has been selected and the cursor moves to the interLOCK position. The

interlock prevents pulsing from occurring when there is no fault on the system. Press tto toggle ON or

OFF and then ENTER to complete the Pulse set-up.

6.5 Alarm Relay

For the next Setup the user will then be presented with the option to change the operation of the MUTE

function. The MUTE button normally disables the Alarm Relay and the local Beeper Alarm when pressed

to following a fault. However, the designer might use the Alarm Relay for some other function, for example

another contactor or cooling fan operation of the grounding resistors. In this case it is undesirable to MUTE

the relay. For this reason the operator may choose to disallow the MUTE button to change the state of

the Alarm Relay. The Screen of Figure 6.12 is presented.

ALARM RELAY Y/N

Figure 6.12 Alarm relay Setup

Selection of ‘Y’ provides the option selection screen of Figure 6.13.

MUTE ALARM RLY

—ENABLED

Figure 6.13 Alarm relay Options

The default is with the Alarm Relay MUTE control Enabled to allow Silence control of an external Horn system.

Pressing —button will toggle the ENABLED to DISABLED to defeat the MUTE switch operation of the Alarm

Relay and allow it to be used for other purposes which depend on whether or not the system is in a Faulted

condition.

NOTE: This does not affect the local Beeper function which will still continue to be MUTEdby the MUTE button.

I-GARD DSP-OHMNI Instruction Manual

18

That completes the set-up. At this point you may be presented with the option of saving the values

changed or not with the screen of Figure 6.14.

SAVE CHANGES Y/N

Figure 6.14 Save Screen

Note: You may not see this screen. If no changes were made in the set-up, or changes were made to the

Feeder Module set-up or the Pulse Set-up,it will not appear. This is because those changes are actually

saved in the DSP-DFM and DSP-DSM respectively. The changes selected will be saved in non-volatile

EEPROM memory until the next time the set-up is changed and re-saved.

Pressing ENTER after selecting Y/N.

6.6 Self Test

At this point the user is asked if SELF-TEST is desired with screen of Figure 6.15.

SELF-TEST? Y/N

Figure 6.15 Self-Test Prompt

The user can just press ENTER to ignore and return to the Home Screen, or select Y ENTER to perform

Self-Test on the system. See Self-Test section for details. See Section 9 for Self-Test.

7OPERATION

7.1 Screen Navigation

Normally with an un-faulted system and recent RESET, the Display Module will display the Normal Home

screen of Figure 7.1 with a green NORMAL light on the front panel and no Alarm. The System Module will

indicate a green NORMAL light and the DSP-DFM modules will show no light indication at all. The DSP-DPS

supply will also indicate POWER with a green light when power is supplied to it. The yellow PULSE light may,

or may not, be ON, depending on whether, or not, the INVERTed mode of operation has been selected for

the pulse operation. If the Inverted Mode is selected the Pulse Relay will be normally energized and will de-

energize with each pulse. The PULSE light will indicate when the pulse relay is energized. In the Normal pulse

mode, the light will be OFF and will light with each pulse. The Display Module will indicate the Normal Home

screen as in Figure 7.1.

I-GARD RESISTORS

HRG SYSTEM OK

Figure 7.1 Normal Home Screen

Table of contents

Other I-Gard Protection Device manuals