IBM AR-B3001 User manual

Other IBM Control Unit manuals

IBM

IBM BladeCenter Copper Pass-thru User manual

IBM

IBM BladeCenter Management Module User manual

IBM

IBM 5294 Manual

IBM

IBM Redbooks ServeRAID-MR10k User manual

IBM

IBM Nways 8260 User manual

IBM

IBM BladeCenter Advanced Management Module User manual

IBM

IBM BladeCenter 4-Port User manual

IBM

IBM WebSphere DataPower XI50B User manual

IBM

IBM 2702 Technical manual

IBM

IBM 5394 User manual

IBM

IBM 3270 User manual

IBM

IBM 3274 51C Setup guide

IBM

IBM 3274 User manual

IBM

IBM MegaBasic IC697PCM711 User manual

IBM

IBM Power System PCIe3 User manual

IBM

IBM 1620 Manual

IBM

IBM 4769 User manual

IBM

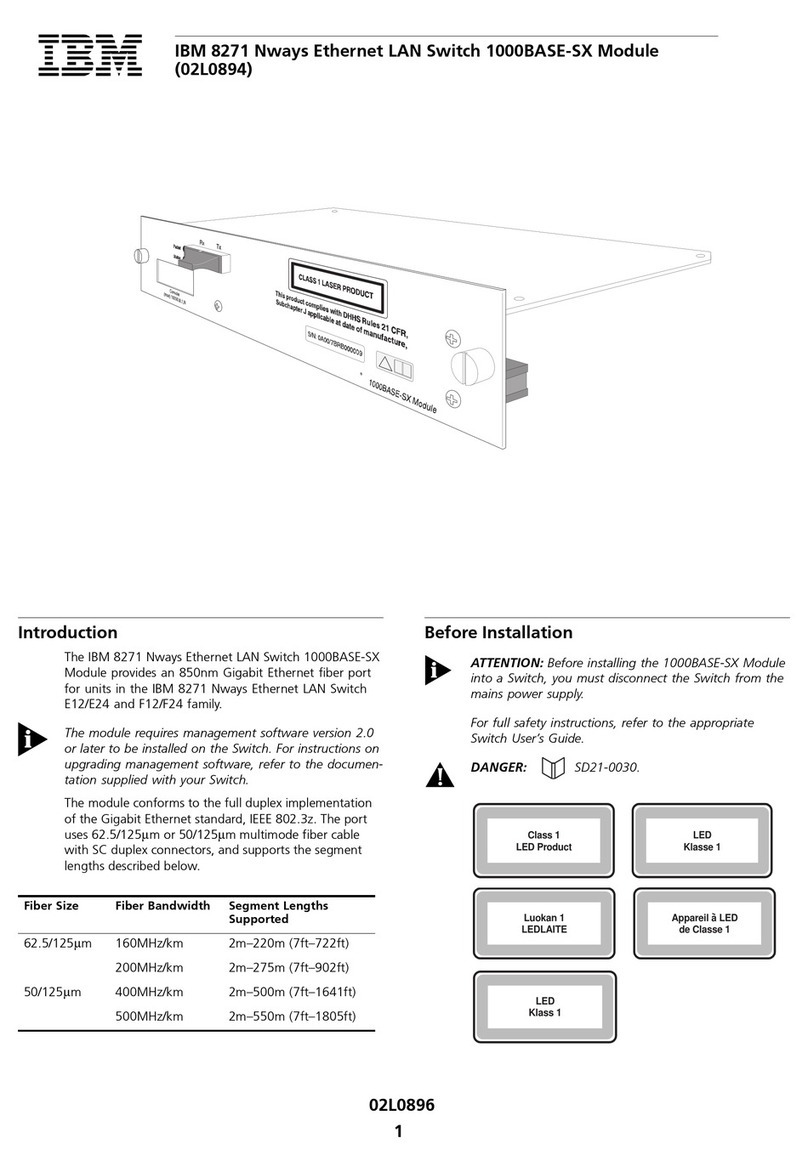

IBM 8271 Nways Ethernet LAN Switch User manual

IBM

IBM 8250 User manual

IBM

IBM color LaserJet 5500 Operating manual