• When possible, use one hand only to connect or disconnect signal cables.

• Never turn on any equipment when there is evidence of re, water, or structural damage.

• Do not attempt to switch on power to the machine until all possible unsafe conditions are corrected.

• When performing a machine inspection: Assume that an electrical safety hazard is present. Perform

all continuity, grounding, and power checks specied during the subsystem installation procedures to

ensure that the machine meets safety requirements. Do not attempt to switch power to the machine

until all possible unsafe conditions are corrected. Before you open the device covers, unless instructed

otherwise in the installation and conguration procedures: Disconnect the attached AC power cords,

turn off the applicable circuit breakers located in the rack power distribution panel (PDP), and

disconnect any telecommunications systems, networks, and modems.

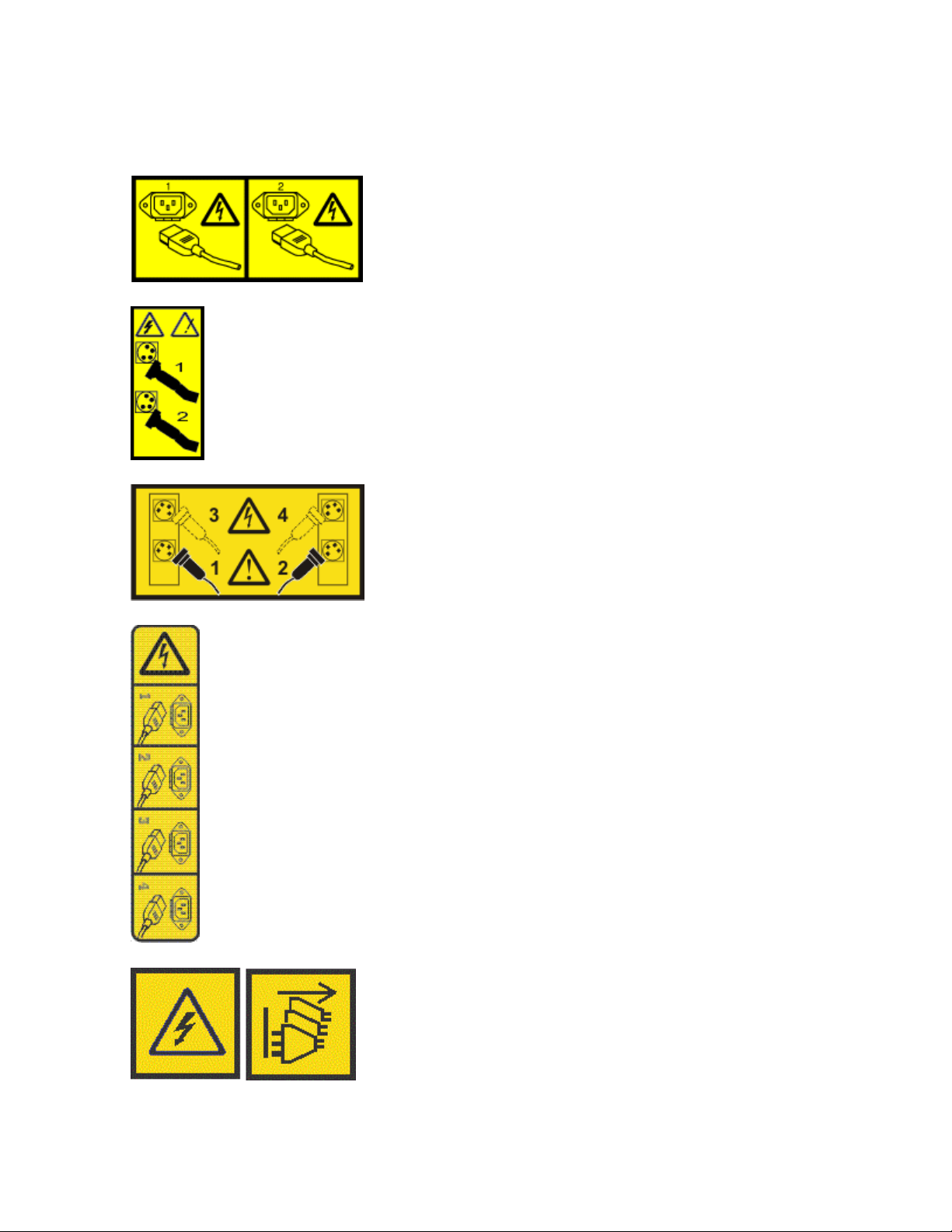

• Connect and disconnect cables as described in the following procedures when installing, moving, or

opening covers on this product or attached devices.

To Disconnect: 1) Turn off everything (unless instructed otherwise). 2) For AC power, remove the power

cords from the outlets. 3) For racks with a DC power distribution panel (PDP), turn off the circuit

breakers located in the PDP and remove the power from the Customer's DC power source. 4) Remove

the signal cables from the connectors. 5) Remove all cables from the devices.

To Connect: 1) Turn off everything (unless instructed otherwise). 2) Attach all cables to the devices. 3)

Attach the signal cables to the connectors. 4) For AC power, attach the power cords to the outlets. 5)

For racks with a DC power distribution panel (PDP), restore the power from the Customer's DC power

source and turn on the circuit breakers located in the PDP. 6) Turn on the devices.

• Sharp edges, corners and joints may be present in and around the system. Use

care when handling equipment to avoid cuts, scrapes and pinching. (D005)

(R001 part 1 of 2):

DANGER: Observe the following precautions when working on or around your IT rack system:

• Heavy equipment–personal injury or equipment damage might result if mishandled.

• Always lower the leveling pads on the rack cabinet.

• Always install stabilizer brackets on the rack cabinet if provided, unless the earthquake option is

to be installed.

• To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest

devices in the bottom of the rack cabinet. Always install servers and optional devices starting

from the bottom of the rack cabinet.

• Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top

of rack-mounted devices. In addition, do not lean on rack mounted devices and do not use them

to stabilize your body position (for example, when working from a ladder).

• Stability hazard:

– The rack may tip over causing serious personal injury.

– Before extending the rack to the installation position, read the installation instructions.

– Do not put any load on the slide-rail mounted equipment mounted in the installation position.

– Do not leave the slide-rail mounted equipment in the installation position.

• Each rack cabinet might have more than one power cord.

– For AC powered racks, be sure to disconnect all power cords in the rack cabinet when directed

to disconnect power during servicing.

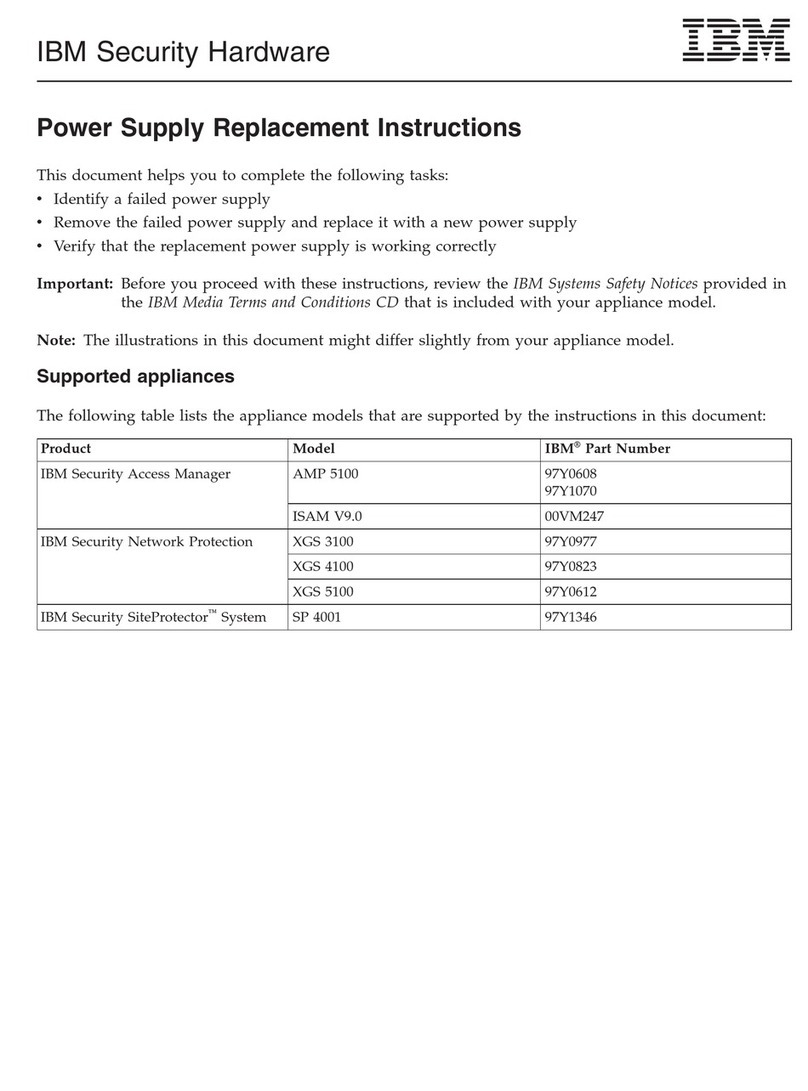

viPower Systems: Adapter placement for the 5105-22E, 9008-22L, 9009-22A, 9009-22G, 9223-22H, or

9223-22S