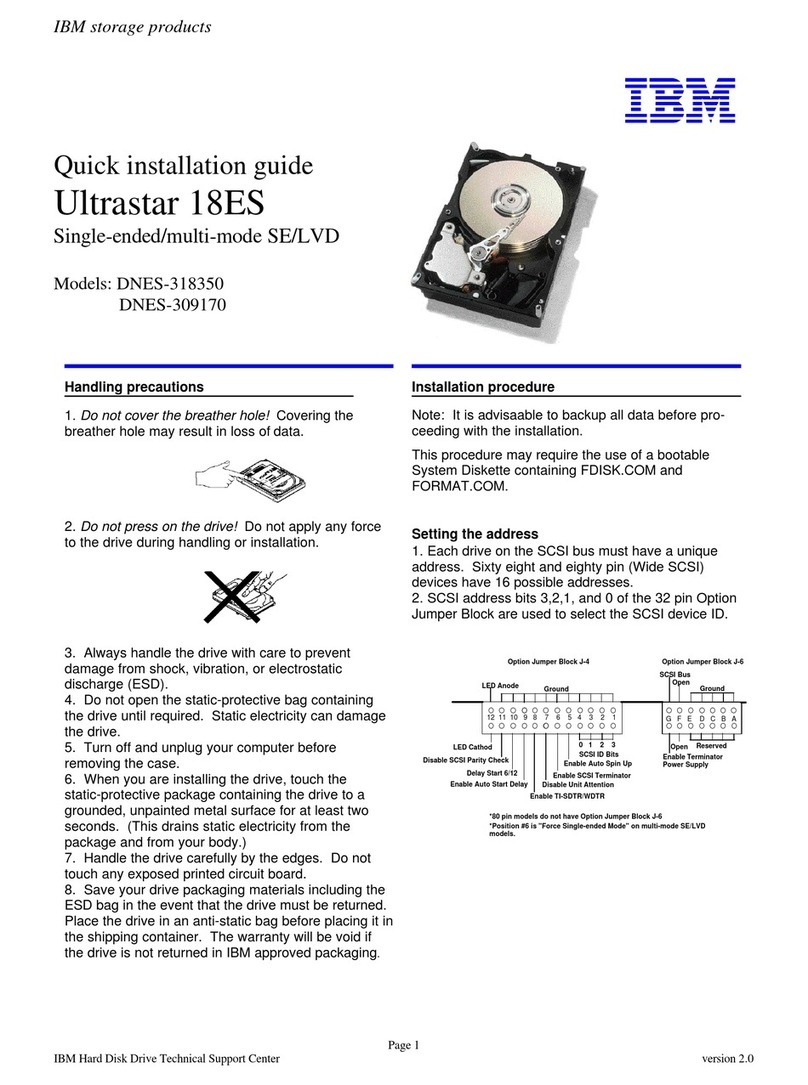

Disable T.I. Sync. Negotiation Pin

If a Disable Target Initiated

Synchronous Negotiation pin is

grounded then an Initiator is required to

start a negotiation handshake if

Synchronous and/or ‘Wide’ (Double

Byte) SCSI transfers are desired.

Please refer to the Ultrastar 9LP &

18XP Interface Specification for more

details on this feature.

Disable SCSI Parity Pin

Grounding this pin will disable SCSI

Parity checking.

Disable Unit Attention Pin

Grounding this pin will disable the drive

from building Unit Attention Sense

information for commands immediately

following a Power On Reset (POR) or

SCSI Bus Reset. Any pending Unit

Attention conditions will also be cleared

at POR or SCSI Reset times.

Disable Wide Negotiations

Jumpering pin 31 to 32, will cause the

68 pin SE, 80 pin SCA, or the 68

Differential to operate in a Single Byte

mode. The drive will not negotiate for

‘Wide’ (Double Byte) operation.

Enable Active Termination

Single Ended 50 and 68 pin models are

available with on card SCSI Bus Active

Terminators. The Active Termination

feature can be enabled by installing a

jumper between pins 13 and 14 of the

Front Option Jumper Block or

connecting pins 9 and 10 of the

Auxiliary Connector on 68 SCSI pin

models. SCA-2 80 pin has no

termination.

Data Organisation

Model 9.11GB 18.22GB

Disks 5 10

User data heads 10 20

Seek times (in milliseconds)

Single Cylinder (Read) 0.7 0.7

(Write) 2.0 2.0

Average(weighted)(Read) 6.5 7.5

(Write) 7.5 8.5

Full stroke (Read) 14.0 17.0

(Write) 16.0 19.0

User capacity for several block

lengths 9.11 GB Models

User bytes/ formatted logical

logical capacity blocks/

block (bytes) drive

512 9,173,114,880 17,916,240

514 9,138,663,000 17,779,500

520 9,063,381,600 17,429,580

522 9,048,400,200 17,334,100

524 9,046,346,480 17,264,020

528 9,085,718,400 17,207,800

536 9,118,437,360 17,012,010

688 9,377,508,800 13,630,100

732 9,413,388,240 12,859,820

18.22 GB Models

User bytes/ formatted logical

logical capacity blocks/

block (bytes) drive

512 18,351,959,040 35,843,670

514 18,283,057,100 35,570,150

520 18,132,478,000 34,870,150

522 18,102,432,780 34,678,990

524 18,098,346,920 34,538,830

528 18,177,133,920 34,426,390

536 18,242,658,160 34,034,810

688 18,760,955,040 27,268,830

732 18,832,742,280 25,727,790

User bytes/logical block 512 to 732

Mode Select Options

Certain parameters are alterable using

the SCSI ‘Mode Select’ command. This

allows certain drive characteristics to be

modified to optimise performance on a

particular system. Refer to the Ultrastar

SCSI Functional Specification for a

detailed definition of Mode Select

parameters.

DC Power Requirement Limits

The following voltage specification

apply at the drive power connector.

There are no special power on/off

sequencing requirements.

+5 Volt Supply ±5.0%(during run and spin up)

+12 Volt Supply ±5.0% (during run)

+5.0% / -7.0%(during spin up)

9.11GB Power Supply Current +5VDC

Population

Notes Mean

Idle average 0.78 Amps1

R/W average 1.03 Amps

R/W pulse peak 1.25 Amps

18.22GB Power Supply Current +5VDC

Idle average 0.78 Amps

R/W average 1.03 Amps

R/W pulse peak 1.25 Amps

9.11GB Power Supply Current +12VDC

Idle average 0.45 Amps

Seek peak 2.07 Amps

Spin-up 1.6 Amps2

18.22GB Power Supply Current +12VDC

Idle average 0.77 Amps

Seek peak 2.43 Amps

Spin-up 2.7 Amps2

Notes:

1. 5 Volt Current is given with

termination power provided by the

using system.

2. The current at start is the total 12

volt current required (i.e.. the motor

start current, module current and

voice coil retract current).

Externally generated ripple

Power Supply Generated Ripple as

seen at drive power connector.

Voltage Maximum Notes

+5V DC 200mV peak-to-peak 0-20 MHz

+12V DC 200mV peak-to-peak 0-20 MHz

During drive start up and seeking, 12

volt ripple is generated by the drive

(referred to as dynamic loading). If

several drives have their power daisy

chained together then the power supply

ripple plus other drives dynamic loading

must remain within the regulation

tolerance window of ±5%. A common

drive supply with separate power leads

to each drive is a more desirable

method of power distribution.