For these pumps the maximal sand content in water cannot exceed 5%. It must be

remembered that even the life of pumps with increased resistance against sand will be

significantly shorter when the pump will pump water with sand contamination. The wear and

tear of elements that pump sand is not subject to warranty repair. This is regarded as operating

wear and tear.

The pump is not adjusted to pump caustic, flammable, destructive or explosive substances

(e.g. petrol, nitro, oil, etc.), foodstuffs or salty water. Failure caused by pumping of the same

type of liquid is not subject to warranty repair.

The maximal temperature of the pumped water is 35oC.

The pump is not adjusted to pump water containing excessive amounts of mineral

elements causing deposition of scale on the pumping elements. The use of the pump in

such conditions results in premature wear and tear of the operating elements of the

pump. In such a case, only paid repair of the pump is available.

The pump cannot pump water containing oils and petroleum derivatives. The pump operation

in such water can lead to destruction of rubber elements, e.g. cables or sealing, and result in

leakage in the pump and motor failure. In such a case, only paid repair of the pump is

available.

Pumped water cannot contain any long-fibrous contamination.

Prior to any installation works, power supply must be disconnected. Provide

security against accidental switch-on. Pumps 3ti, 3t2i, 3SDm, 4SD i 4SDm,

4ISP, 4ISPm, 6ISP, 3STm due to their dimensions can be delivered in two

elements. One element is a hydraulic part of the pump, the other is a motor.

Prior to connection of two elements, the clamping screws must be unscrewed

from the strip protecting the cable. Next, the screws clamping the strainer

must be unscrewed and the strainer removed. The clamping nuts with

washers must be unscrewed and removed. When the motor is placed in a

vertical position, the hydraulic element must be mounted on the motor shaft

ended with splines is placed in the clutch of the pump. If, in the course of

mounting, there are any difficulties with coupling, the motor shaft must be

turned to make the splines match the motor clutch. A hydraulic element,

correctly mounted on the motor, is fully supported by the top bearing body of

the motor. The aggregate prepared in this manner can be screwed with screw

nuts and washers. Screw nuts must be tightened crosswise. The minimal

moment of tightening screw nuts for motors 4” is 18 Nm.

If the screws are not tightened accurately, it can result in their unscrewing on operation

and motor “sinking” in the borehole. Upon installation of hydraulic element on the

motor, placing the power supply cable on the pump, the strainer must be installed and

screwed prior to the installation of the strip protecting the cable.

The lowering of the pump into the borehole without a surge protector can result in

destruction of cable isolation which can be the cause of pumpfailure or electrocution of

the operators.

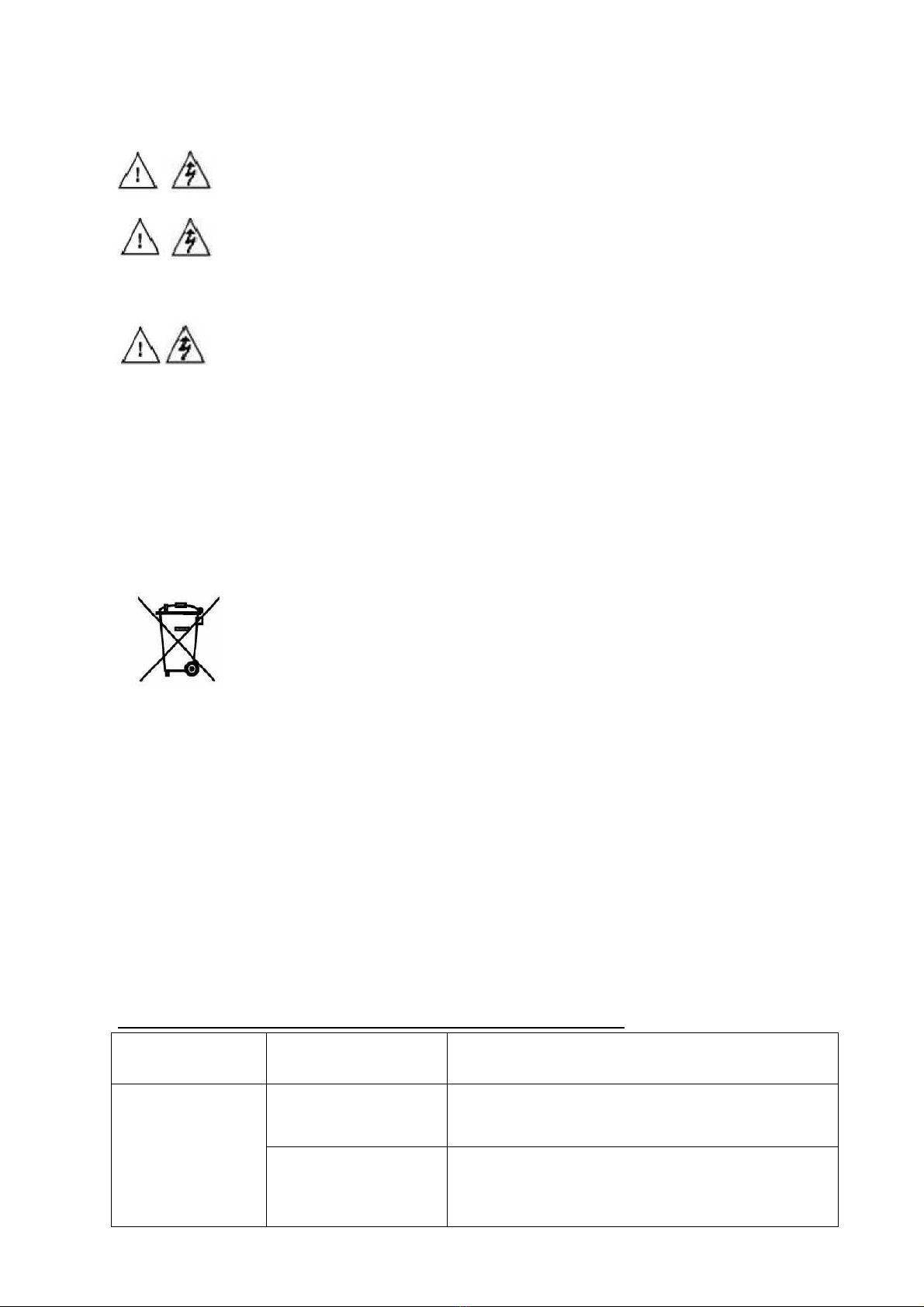

For pumps SD, SDm, SCM, ISPm, ISP, STm, due to th necessity to ensure motor

cooling on operation, the diameter of a borehole where the pump operates cannot

exceed the values presented in the table below. The values are in mm. The diameters

are consistent with the pump efficiency.