Middleton, WI, USA 53562

Tel: (608) 831-1255

Fax: (608) 831-2045

Email: sales@iccdesigns.com

Troubleshooting

This section details some troubleshooting tips to follow if any issues are encountered when installing the gateway

and Chillgard LC onto a BACnet MS/TP network.

1. Power

a. Confirm that the gateway is receiving power from the 7 - 24V DC supply. The MS (Module Status)

LED should light green when the gateway is powered.

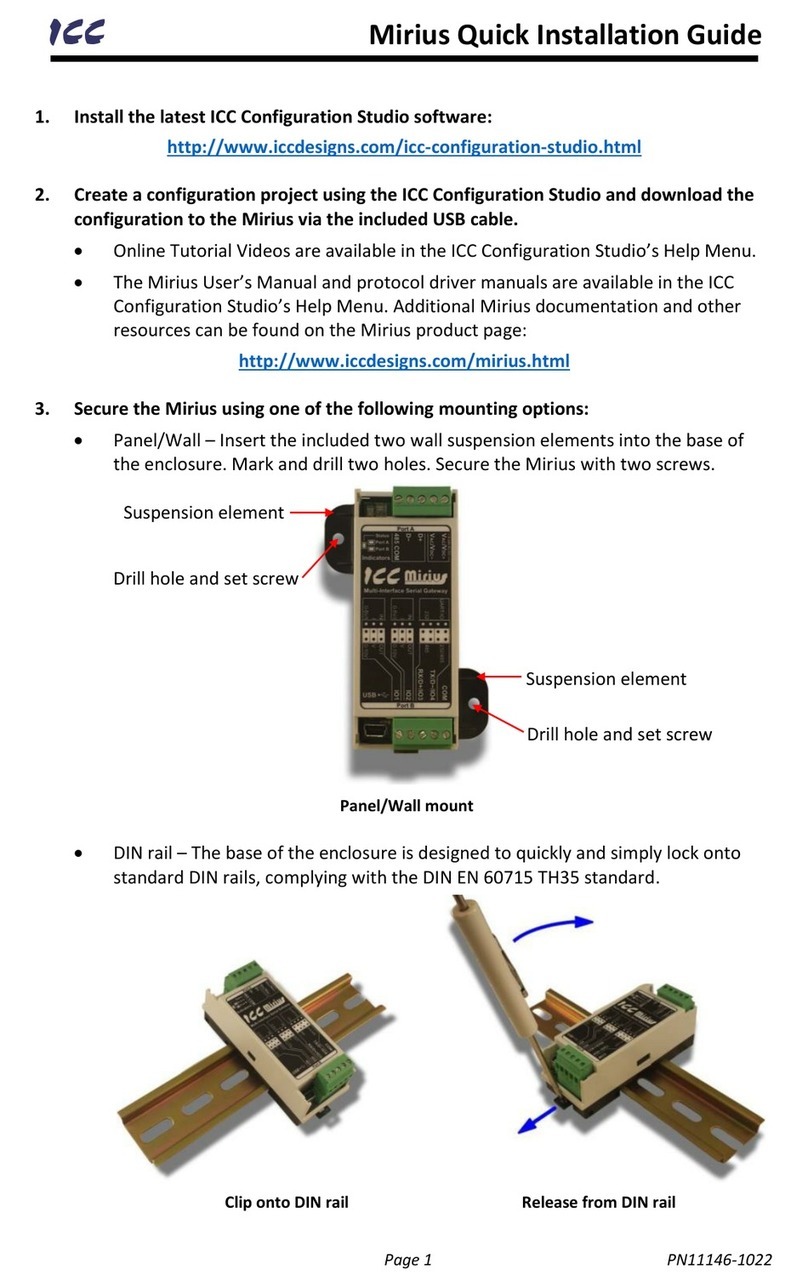

2. Wiring

a. Confirm the wiring matches the connections shown in Figure 2.

3. Configuration

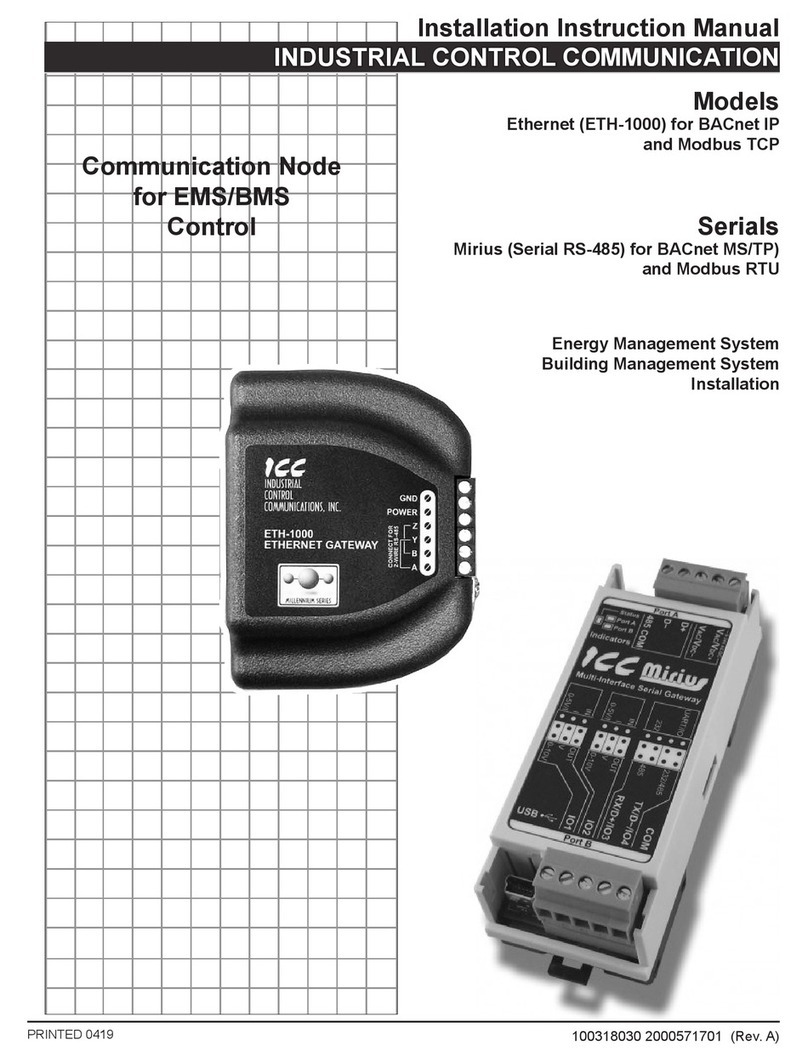

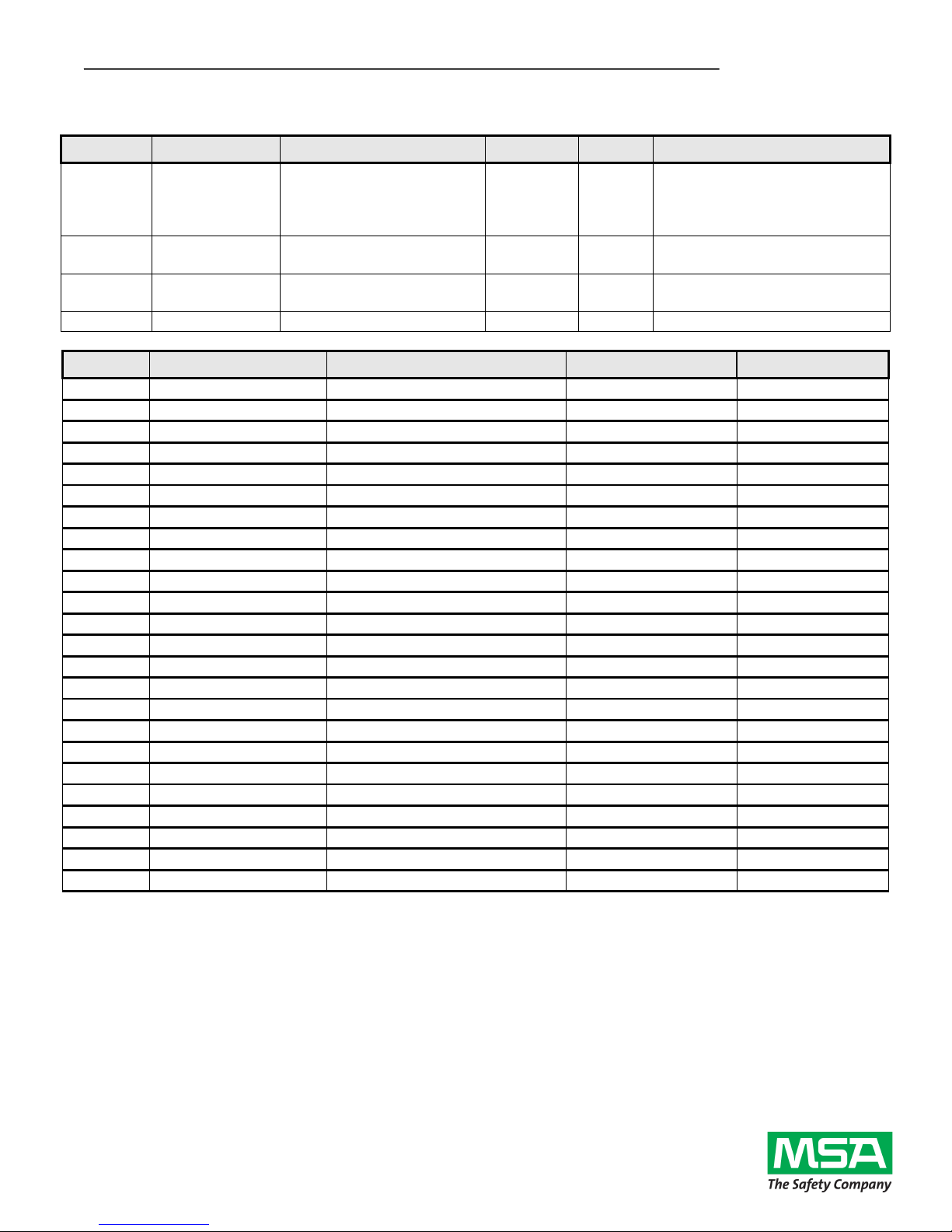

a. Confirm that the gateway is configured with the appropriate network parameters (baud rate, MAC

address, device instance, etc) using the ICC Configuration Studio as described in the

Customizing the ETH-1000’s Configuration section.

4. Gateway LEDs

a. The MS (Module Status) LED should light green when the gateway is powered and should flash

green when the gateway is connected via USB.

i. If this is not observed, check the gateway’s power.

b. The RS-485 RX LED should flash red. The TX LED will always be off.

i. If this is not observed, check the wiring between the gateway and the Chillgard LC.

ii. Check the gateway’s configuration using the ICC Configuration Studio and confirm that

the RS-485 port is configured for Modbus Sniffer.

5. Chillgard LC Data Confirmation

a. View the gateway’s internal database via the Database pane in ICC Configuration Studio and

select the 16-bit Unsigned data type from the dropdown. There should be some highlighted cells

which do not show a value of 0.

6. BACnet Data Confirmation

a. View the gateway’s internal database via the Database pane in ICC Configuration Studio and

select the 16-bit Unsigned data type from the dropdown. The data shown in the highlighted cells

should match the data read on the BACnet system. The specific BACnet object mapped at an

address is shown when the mouse is hovered over a cell in the Database Pane.