2

CONTENTS

INTRODUCTION........................................................................... 3

Warnings ...................................................................................3

Parts..........................................................................................3

Tools Required ..........................................................................3

General Guidelines ...................................................................3

FEATURES AND COMPONENTS ................................................ 5

DEVICE CONFIGURATIONS........................................................ 6

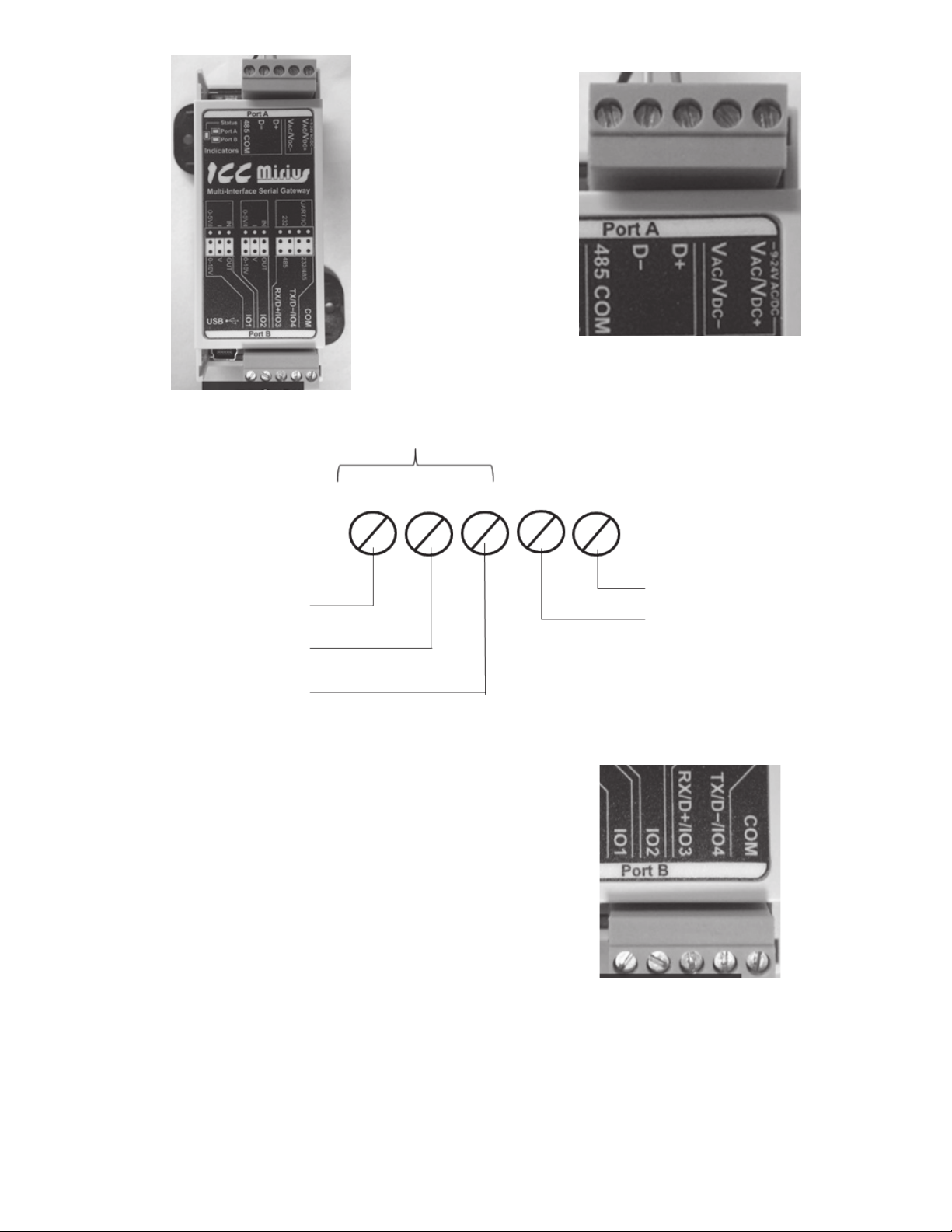

ETH-1000 Wiring.......................................................................6

Mirius Wiring .............................................................................6

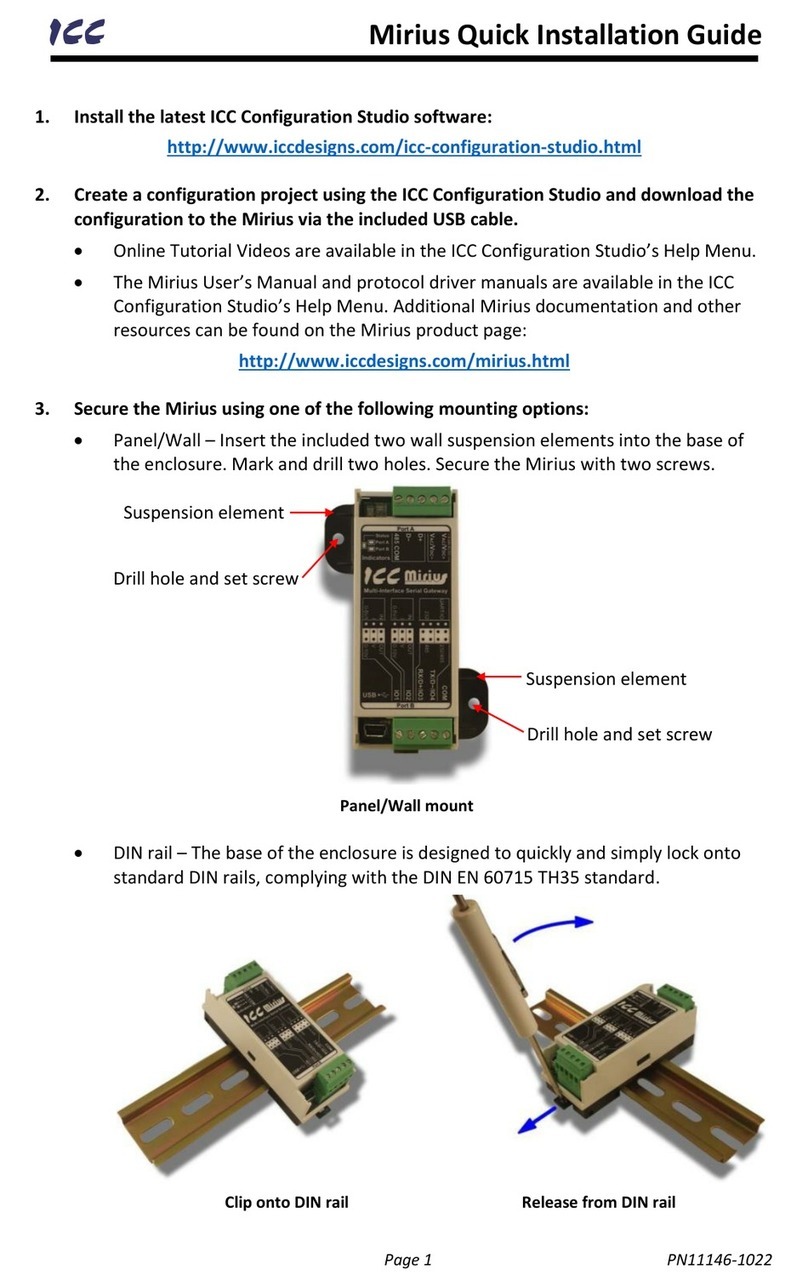

INSTALLATION CONSIDERATIONS ............................................ 8

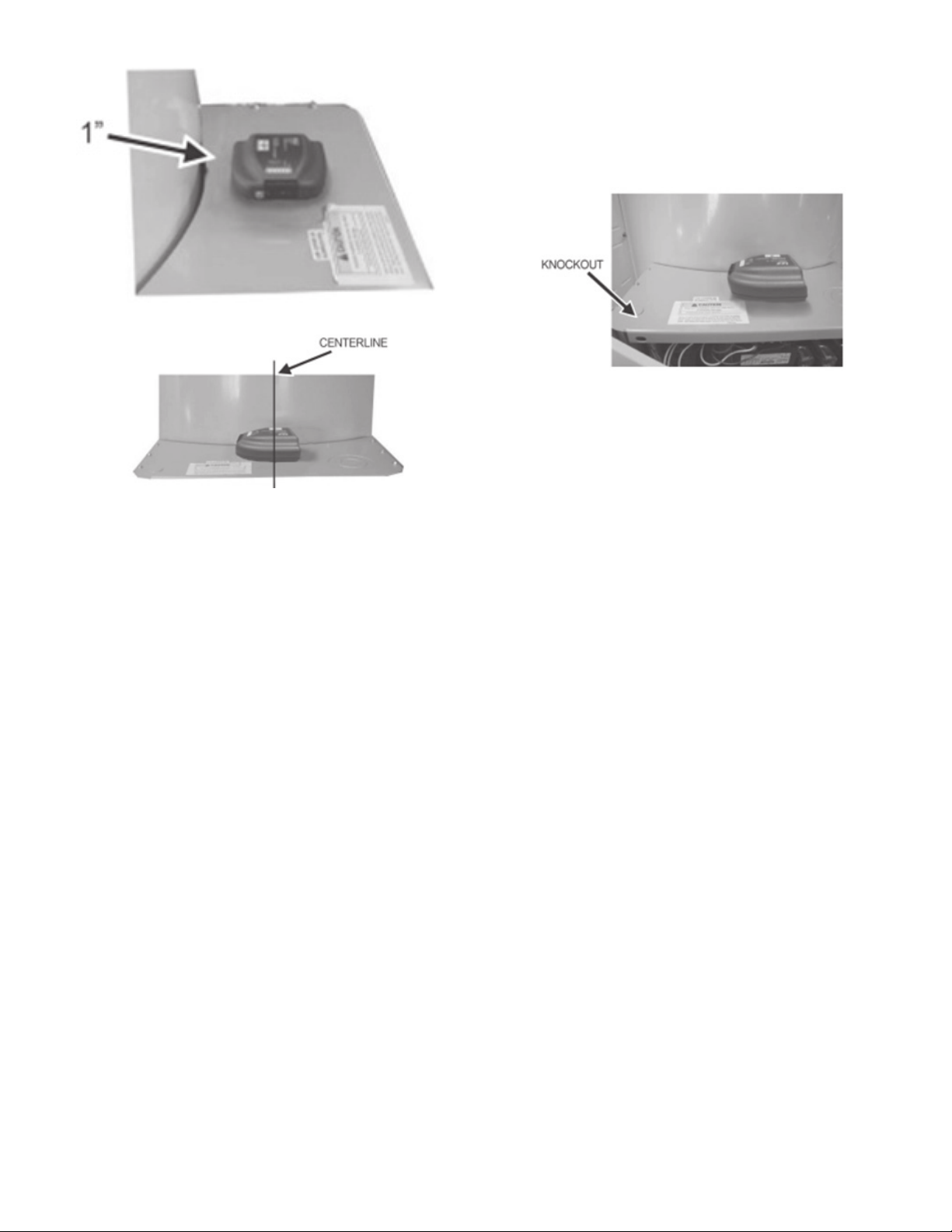

Touch Screen Style Display Installation ....................................8

High Efciency Water Heater Installation – (BTH Or BTX

Models)................................................................................. 8

Commercial Electric Water Heater (Touch Screen

Installation) ........................................................................... 8

Membrane Switch Style Display Installation ..........................10

High Efciency Water heater Installation............................ 10

Commercial Electric Water heater Installation.................... 10

Boiler Installation.....................................................................12

XP XWH Boiler Installation................................................. 12

ECC DEVICE VERSIONS........................................................... 13

BACnet / Gas Water Heaters ..................................................13

Product Description ............................................................ 13

Protocol Implementation Conformance

Statement (PICS) ............................................................... 14

BACnet Standardized Device Prole (Annex L): .....................14

BACnet Interoperability .............................................................14

Segmentation Capability ...........................................................14

Data Link Layer Options............................................................ 14

Device Address Binding ............................................................14

Character Sets ..........................................................................15

Data Types ................................................................................15

Object Types and Properties..................................................... 16

Device Object Listings........................................................ 16

Object Min/Max Values ............................................................. 16

BACnet/Gas Water Heaters Object List .................................... 17

Central Control Board Major State Denitions .......................... 20

Xi 1.0 Energy Management System (EMS) Control..................20

Mxi Energy Management System (EMS) Control .....................21

Fault Codes and Warnings........................................................ 22

BACnet / Electric Water Heaters ............................................23

Product Description ............................................................ 23

Protocol Implementation Conformance

Statement (PICS) ............................................................... 23

BACnet Standardized Device Prole (Annex L):.......................23

BACnet Interoperability ............................................................ 23

Data Link Layer Options............................................................ 24

Device Address Binding ............................................................24

Networking Options...................................................................24

Character Sets .......................................................................... 24

Data Types ................................................................................25

Object Types and Property Support ..........................................25

Device Object Listings........................................................ 26

Device Objects Initial Values..................................................... 26

Device Objects Minimum/Maximum Values ..............................26

Central Control Board Major State Denitions .......................... 30

Energy Management System (EMS) Control ............................ 30

Fault Codes and Warnings........................................................ 30

BACnet / Boilers......................................................................32

Product Description ............................................................ 32

Protocol Implementation Conformance

Statement (PICS) ............................................................... 32

BACnet Standardized Device Prole (Annex L): ......................32

BACnet Boiler Interoperability ................................................... 32

Segmentation Capability: .......................................................... 32

Data Link Layer Options............................................................ 33

Device Address Binding ............................................................33

Character Sets .......................................................................... 33

Data Types Supported...............................................................33

Boiler Device Object Types/Property Support.......................... 34

Object Listings.................................................................... 34

Boiler Device Object Initial Values ............................................ 34

Boiler Device Object Min/Max Values .......................................35

Boiler Slave States....................................................................36

Boiler Modbus Register Access ................................................ 36

Boiler Modulating Sensor Select/DHW Demand Switch ........... 37

Lock and Hold Codes................................................................37

Modbus / Gas Water Heaters .................................................44

Product Description ............................................................ 44

Modbus Gas Water Heater Register Listings ..................... 44

Modbus Gas Water Heater Register Properties........................ 44

Central Control Board Major State Denitions .......................... 47

Xi 1.0 Energy Management System (EMS) Control..................47

Mxi Energy Management System (EMS) Control .....................47

Fault Codes and Warnings........................................................ 48

Modbus / Electric Water Heaters.............................................49

Product Description ............................................................ 49

Electric Water Heater Register Listings.............................. 49

Modbus Electric Water Heaters Register Properties................. 49

Central Control Board Major State Denitions .......................... 52

Energy Management System (EMS) Control ............................ 52

Fault Codes and Warnings........................................................ 52

ICC PROGRAM INFORMATION................................................. 53