INSTRUCTIONS

A-6691H-1EX-uPrinted in Japan

© 2008–2016 Icom Inc.

1-1-32 Kamiminami, Hirano-ku, Osaka 547-0003, Japan

TRUNKING/NETWORK CONTROLLER

UC-FR5000

- 4 -

Thank you for choosing this Icom product.

The controller is designed to be installed into the IC-

FR5000/IC-FR6000 series vhf /uhf fm repeaters and

enables the on-line control and digital trunking operation

on the repeater.

READ ALL INSTRUCTIONS carefully and completely

before using this product.

- 1 -

1. Unscrew the seven screws from the top, and the two

screws on both sides of the repeater, then slide the top

cover off in the direction of the arrow.

Top cover

Repeater

2. Disconnect the control cable from the channel module.

Then, unscrew the seven screws that affix the channel

module to the repeater chassis, and then remove it.

P

0

P

1

P

2

P

3

P

4

Control cable

Channel module

Front panel*

Repeater

* The front panel is removed in this illustration so the details are

easier to see. However, you can remove the channel module

without removing the front panel of the repeater.

3. Unscrew the eight screws from the top, the nine screws

from bottom, and the three screws from rear of the

channel module. Then remove each cover from it.

Channel module

RWARNING! Turn OFF the repeater before installing the

controller. Otherwise a re, electric shock may occur, or the

repeater could malfunction.

CAUTION: NEVER expose the repeater or controller to

rain, snow or any liquids.

CAUTION: NEVER let metal, wire or other objects touch

any internal part of the controller.

CAUTION: Install the controller in only the specied repeater.

BE CAREFUL! When you install the controller, wear gloves

to avoid cutting your hand on the sharp edges of the repeater.

PRECAUTIONS

The controller enables the repeater to be used for the

following modes, depending on the congurations. (This

table is shown in controllers whose revision number is 3.5

or later. Ask your dealer for details.)

Single Site Multi Site

Conventional Trunking Conventional Trunking

UC-FR5000#01 ✔*1✔ ✔*2✔*3

UC-FR5000#02

( CF-FR5000MC is

supplied)

✔ ✔ ✔ ✔*3

UC-FR5000#03

( CF-FR5000MT is

supplied)

✔ ✔ ✔ ✔

UC-FR5000#04 ✔*1✔ ✔*2✔*3

*1When the optional RS-FS10 remote communicator is used, ei-

ther the CF-FR5000MC or CF-FR5000MT is required.

*2Either the optional CF-FR5000MC or CF-FR5000MT is required.

*3The optional CF-FR5000MT is required.

CONFIGURATIONS

The supplied or optional CF card must be inserted to enable

the Multi Site Conventional or Trunking mode use. Before

inserting a CF card to the controller’s card slot, carefully

read the card’s instructions.

ABOUT THE CF CARD

DISPOSAL

DISASSEMBLING THE UNITS

The crossed-out wheeled-bin symbol on your

product, literature, or packaging reminds you

that in the European Union, all electrical and

electronic products, batteries, and accumulators

(rechargeable batteries) must be taken to

designated collection locations at the end of their working

life. Do not dispose of these products as unsorted municipal

waste. Dispose of them according to the laws in your area.

NOTE: Internet Explorer 6.0 or later is required to

correctly open the setting screen of the controller. The

following instructions are based on using Internet Explorer

7.0. JavaScript must be installed to open the side menu

and help window of the Setting screen.

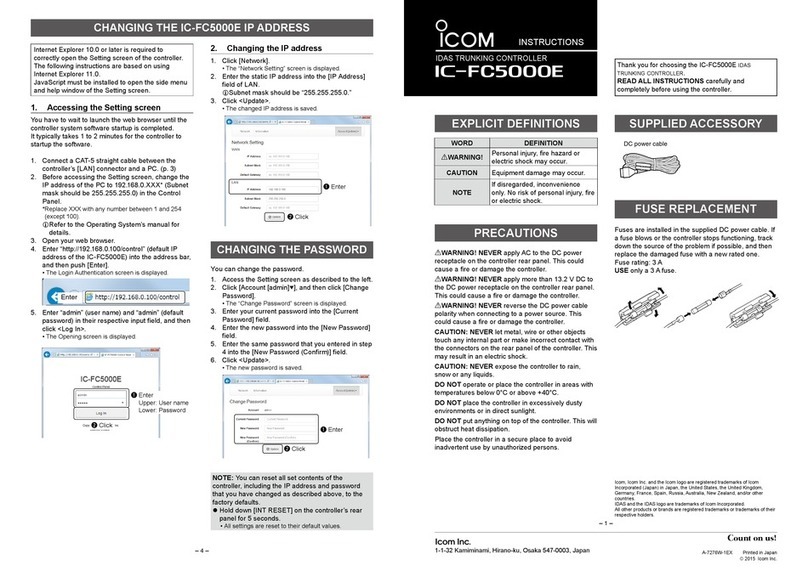

DAccessing the setting screen

NOTE: You must wait to launch the web browser until the

controller system software startup is completed.It typically

takes 2 ~ 3 minutes for the controller to

startup the application.

1. Connect a CAT-5 straight cable between the

controller’s [LAN] connector and a PC (p. 3) and then

turn ON the repeater.

2. Before accessing the Setting screen, change the IP

address of the PC to 192.168.0.XXX* (A subnet mask

should be 255.255.255.0) in the Control Panel.

*

Replace XXX with any number between 1 and 254 (except 11).

LRefer to the Operating System’s manual for details.

3.

Open your web browser, enter “http:// 192.168.0.11/”

(default IP address of the UC-FR5000) into the address

bar, and then push [Enter].

•The Login Authentication screen is displayed.

LAsk your system administrator for details.

4.

Enter “cbadmin” (default user name) and “ucfr5000”

(default password) in their respective input field in the

Login Authentication screen, and then click <OK>.

If you want the screen to remember not only the

user name but also the password, check the box,

“Remember my password”.

•The Opening screen is displayed.

TIP: You can change the user name and password

in the Setting screen. Refer the help window of the

Setting screen for details.

Enter

Enter

Check

Click

THE SETTING SCREEN OF THE UC-FR5000

DOpening the help window

The Setting screen of the controller has a help window to

describe functions and settings.

If you don’t understand the meaning of an item, or how to

congure the controller, click a question mark icon on the

screen to open the help window.

Click to open the help window for

“General Settings,” for example.

DInitialization

You can reset all set contents, including the network settings

of the controller, to the factory default from the PC.

1. Connect the controller to the PC, and then turn ON the

repeater.

2. Open your web browser, enter the initialize address into

the address bar, and then push [Enter].

•The initialize screen is displayed.

LInitialize address: http://(IP address):8080/init.html

LWhen the IP address of the controller is 192.168.0.11*, enter

“http://192.168.0.11:8080/init.html” as the initialize address.

* The IP address is an example only. Check the IP address

of the controller.

3. After checking the box “Yes, I agree,” click <RESET>

to initialize the settings.

TIP: If you use the UC-FR5000 #03, you can

select whether or not to reset the Network settings

as well as other settings. Refer to the help window

for details.

LThis screen slightly differs, depending on the Operating

System version.

*This illustration

is described with

the UT-105.

Enter

Check

Click