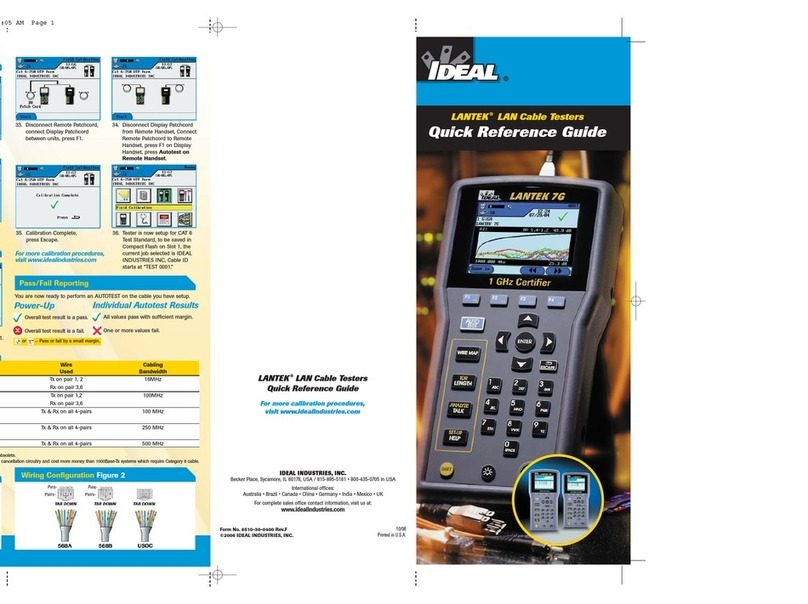

LT 8000 Series: Quick Reference Card - 2

6510-30-0326 Rev. A

VII. Test Setup

Basic Link Test Setup

1. Attach the Basic Link Adapters to both the DH and RH.

2. On the horizontal network cable to be tested, disconnect

the corresponding user patch cords from the network

patch panel and the RJ-45 wall outlet.

3. Connect the DH Basic Link Adapter to the network patch

panel, and the RH Basic Link Adapter to the wall outlet.

Note: Don’t forget to change the Cable Type to Basic Link.

Channel Link Test Setup

1. Attach the Channel Link Adapters to both the Display and

Remote Handsets.

2. On the horizontal network cable to be tested, disconnect

the corresponding user patch cords from the network

equipment.

3. Connect the DH Basic Link Adapter to the network patch

panel user patch cord, and the RH Basic Link Adapter to

the wall outlet user patch cord.

Note: Don’t forget to change the Cable Type to Channel Link.

VIII. Running Autotest

1. Press the Autotest key .

2. If the RH unit is not found, a Searching for Remote

Handset warning message is displayed on the DH.

Press to cancel the test and return to the Tools

menu.

3. If the RH is found, Autotest compares the cable test

readings to standards for the cable type selected and

issues pass/fail statements for each test.

4. While Autotest is in progress, a circular timer displays test

progress and indicates pass or fail for each completed

test.

Note: Press and hold Stop/Cancel prior to Autotest

completion to stop Autotest after completion of the

test in progress.

Running Autotest (Continued)

5. When the Autotest is completed, an overall result of pass

or fail is displayed at the top right of the test

information columns. Results for individual tests are

displayed opposite each test name.

6. To begin the next Autotest, press Autotest .

7. If results from the current test have not been printed, or

you did not have AutoSave enabled in the Autotest

Preference screen, you will be prompted to discard

or save the current test results before the next

Autotest will run.

Overall Test Result Symbols

Overall test result is a pass if each individual test is a

pass or a pass*.

Overall test result is a fail if one or more individual test

is either a fail or a fail*.

IX. Individual Test Pass/Fail Reporting

1. Autotest results can be viewed at the completion of the test

sequence or saved for later viewing.

2. Use the Arrow keys to position the cursor bar on the

desired test.

3. Press Enter to view test results.

4. When finished, press to return to the Autotest screen.

Individual Autotest Results

Pass

All values passed with sufficient margin.

Pass*

All values passed, but one or more test values

passed by a margin smaller than the unit’s specified

accuracy for the measurement. The pass* result

does not fail the cable.

Fail

One or more values failed by a significant margin.

Individual Test Pass/Fail Reporting (Continued)

Fail*

One or more values failed, but the margin of failure is

smaller than the unit’s specified accuracy for the

measurement. The fail* result fails the cable and

must be cleared up, just like a standard fail.

X. Saving Current Autotest Results

Autotest results can be saved immediately following the test.

1. To manually save an Autotest, press the key.

2. The Test Saved screen will be displayed for a brief period,

showing the name the test is saved under.

3. If the current name already exists, the following Warning

screen appears.

4. Press to Escape and return to the previous screen

without performing a save operation, or Press to

Overwrite the existing file.

5. Press to select the Save As option to rename the

current test. The Save Test screen will display with a new

name option.

XI. Printer Setup

Once a serial printer is connected to the DH, test results are

printed by pressing the print key.

1. Connect a serial printer to the tester’s DB-9 serial port

(RS 232). Parallel printers will not function with tester.

2. From the Ready screen, select the Preferences icon

to open the Preferences screen.

3. In the Preferences screen, use the Arrow keys to select

the PC & Printer I/F option.

4. In the PC & Printer I/F screen, set the correct printer

parameters.

- Baud Rate: 9600 - Data Bits: 8 - Stop Bit: 1

- Parity: None - Flow Control: XON/XOFF

5. Press Enter to save changes.

6. Press to return to the previous screen after setting

the printer communication settings.