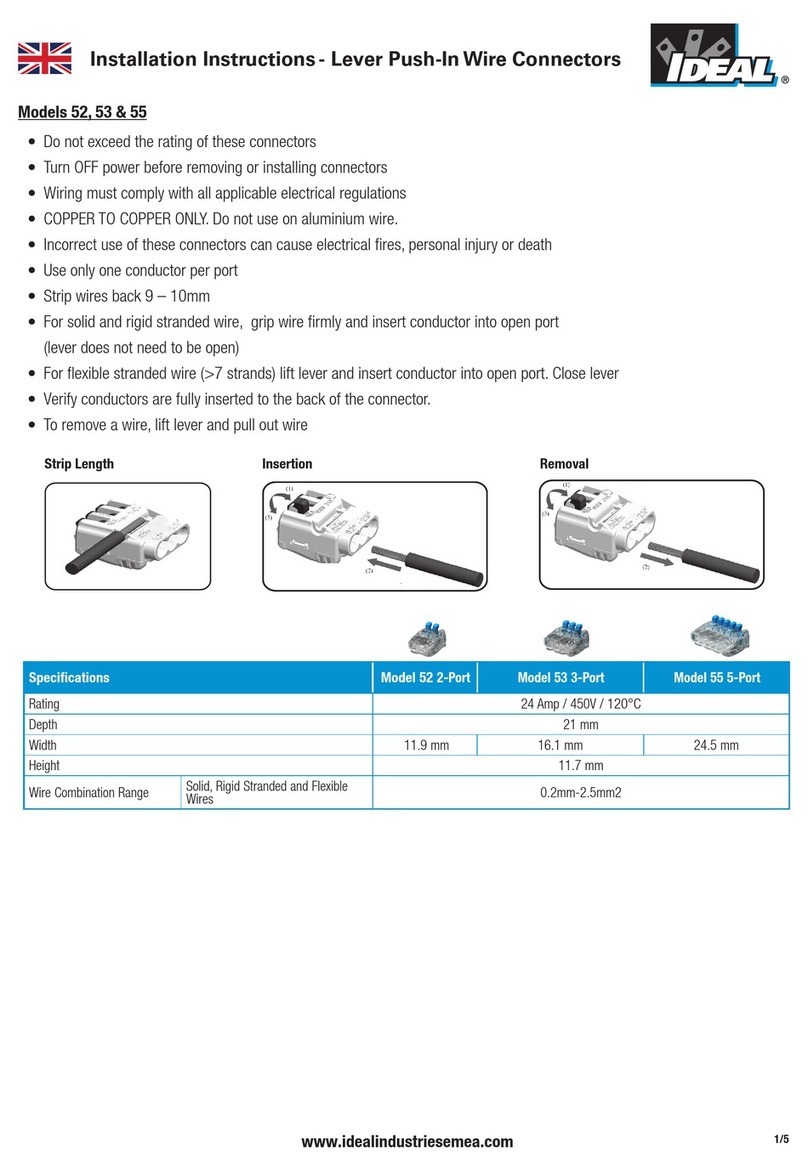

1. CONNECTOR RATINGS

2. TOOLING CHART

3. REDUCING BUSHING

SBE®& SBX®Connectors

Assembly instruction for SBE160, SBE320, SBX175 and SBX350 Series

two pole battery connectors with option for auxiliary contacts.

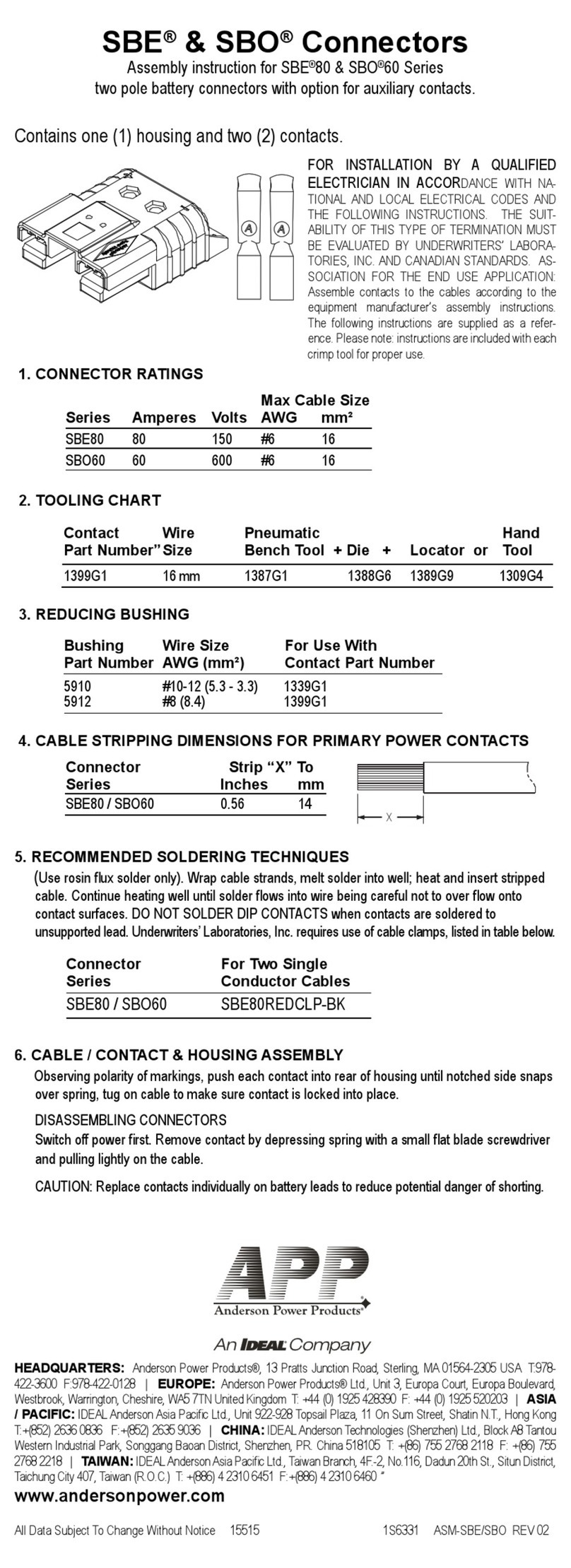

FOR INSTALLATION BY A QUALIFIED ELECTRICIAN IN

ACCORDANCE WITH NATIONAL AND LOCAL ELECTRICAL CODES

AND THE FOLLOWING INSTRUCTIONS. THE SUITABILITY OF THIS

TYPE OF TERMINATION MUST BE EVALUATED BY UNDERWRITERS’

LABORATORIES, INC. AND CANADIAN STANDARDS. ASSOCIATION

FOR THE END USE APPLICATION: Assemble contacts to the cables

according to the equipment manufacturer’s assembly instructions. The

following instructions are supplied as a reference. Please note: instruc-

tions are included with each crimp tool for proper use.

CAUTION: When using cable with jacket diameter less

than 0.423 inches (11mm) on the SBE160 / SBX175 and

less than 0.709 inches (18mm) on the SBE320 / SBX350

thin wall heat shrink insulation should be evenly applied

across the cable and contact barrel junction to insure

nger protection.

Contains one (1) housing and two (2) contacts.

Max Cable Size

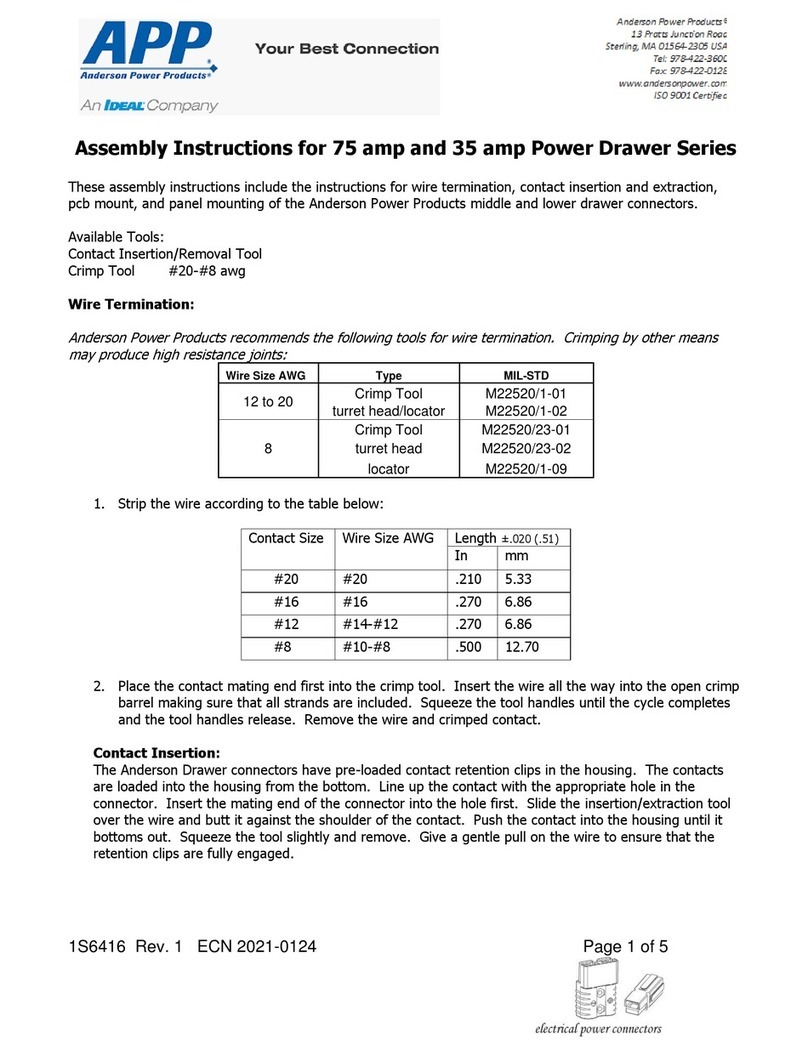

Series Amperes Volts AWG mm²

SBE160 160 150 1/0 50

SBE320 320 150 300mcm 150

SBX175 175 600 1/0 50

SBX350 350 600 300mcm 150

Bushing Wire Size For Use With

Part Number AWG (mm²) SBE160 / SBX175 SBE320 / SBX350

5687 #1 (42.4) 6384G1 contact 6354 contact + 5918 bushing

5690 #2 (33.6) 6384G1 contact 6354 contact + 5918 bushing

5693 #4 (21.2) 6384G1 contact 6354 contact + 5918 bushing

5663 #6 (13.3) 6384G1 contact 6354 contact + 5918 bushing

5648 #10 (5.3) 6384G1 contact 6354 contact + 5918 bushing

5920 N/A (16) 6384G2 contact 6394 contact

5918 1/0 (53.5) N/A 6354 contact

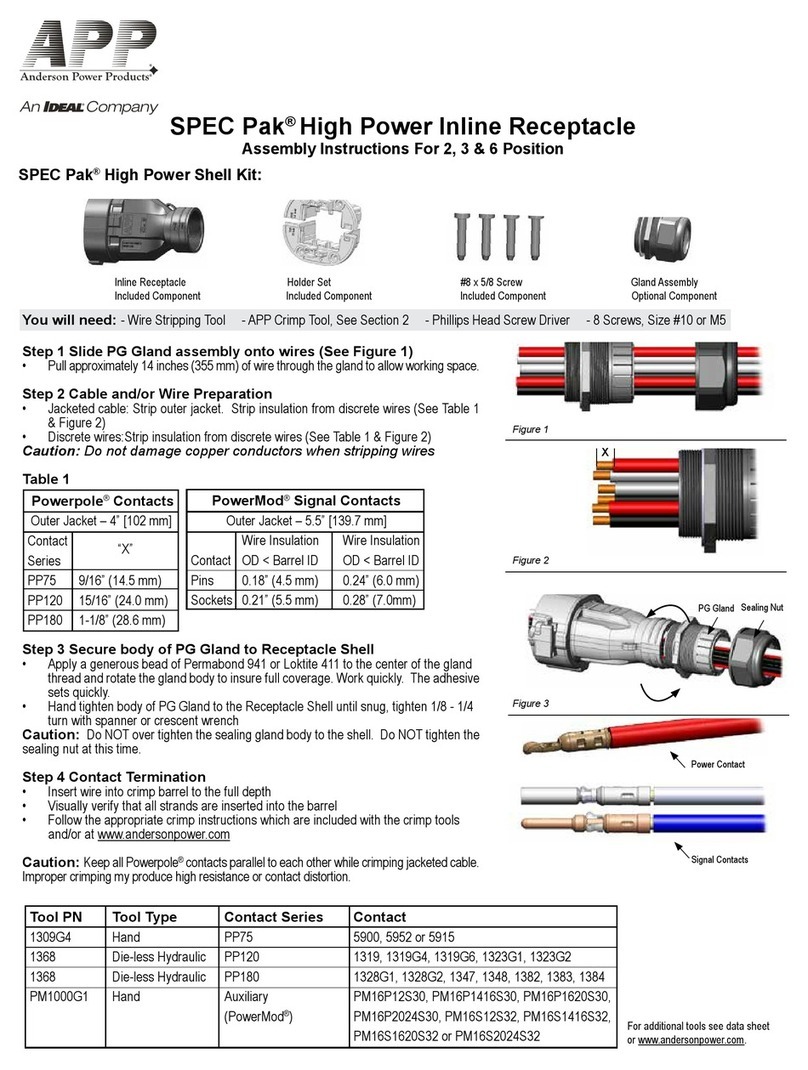

Contact Wire Pneumatic Dieless

Part Number Size Bench Tool + Die + Locator or Hydraulic Tool

6384G2 35 mm² 1387G1 1388G3 1389G3

6384G1 1/0 AWG 1387G2 1303G2 1304G2

6354 2/0 AWG 1387G1 1388G2 1389G2

6354 2/0 AWG 1387G2 1303G12 1304G28

6355 3/0 AWG TBD TBD TBD

6356 4/0 AWG TBD TBD TBD

6358 300 MCM TBD TBD TBD

1341G1 50 mm² 1387G2 1303G8 1304G27

1341G2 70 mm² 1387G2 1303G7 1304G27

1341G3 95 mm² TBD TBD TBD

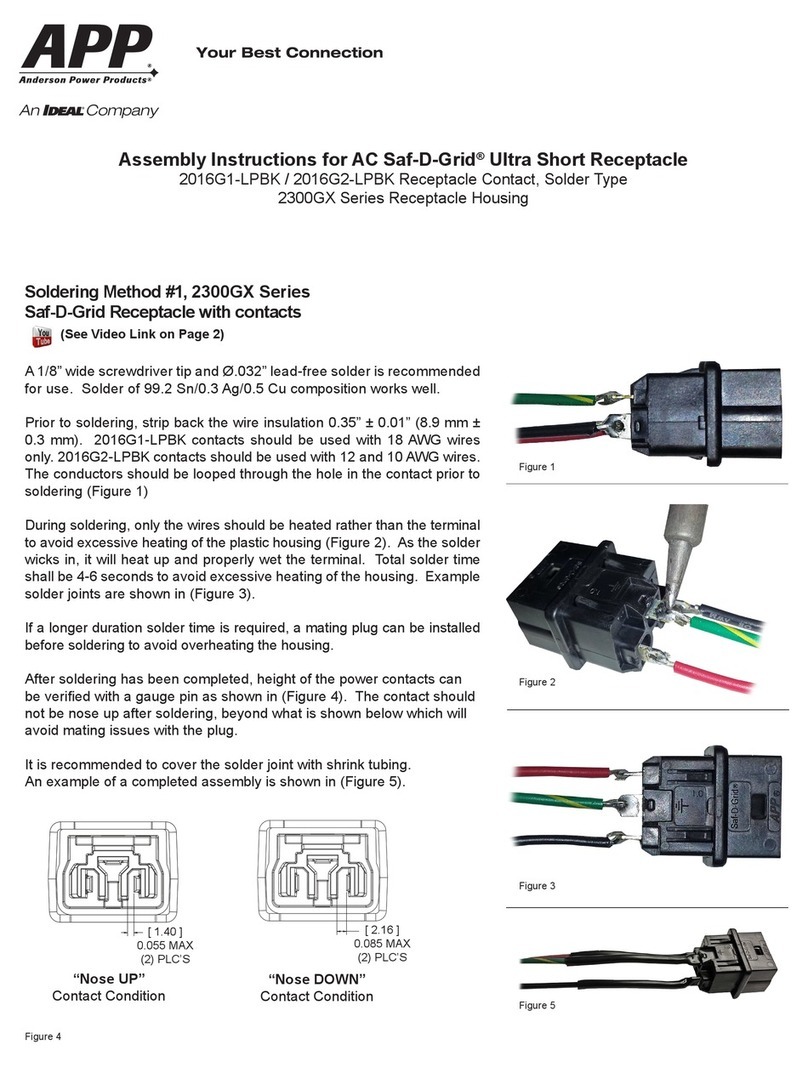

HEAT SHRINK INSULATION SPECIFICATIONS

Connector Nominal Minimum Maximum

Series Tubing Size Length Wall Thickness

SBE320 / SBX350 0.75 in (19mm) 2.0 in (51mm) 0.030 in (.76mm)

SBE160 / SBX175 0.50 in (12.7mm) 2.0 in (51mm) 0.025 in (.63mm)

1368

1368

1368

1368

1368

1368

1368

1368

1368

1368

[19.0] 0.75 MIN

[3.2] 0.12 MIN [3.2] 0.12 MIN