IDEC MicroSmart pentra FC5A-C10R2 User manual

FC5A SERIES

FC9Y-B1268

User’s Manual Basic Volume

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

Comparison FC5A MicroSmart User’s Manual FC9Y-B1268

MICROSMART FC4A VS. FC5A

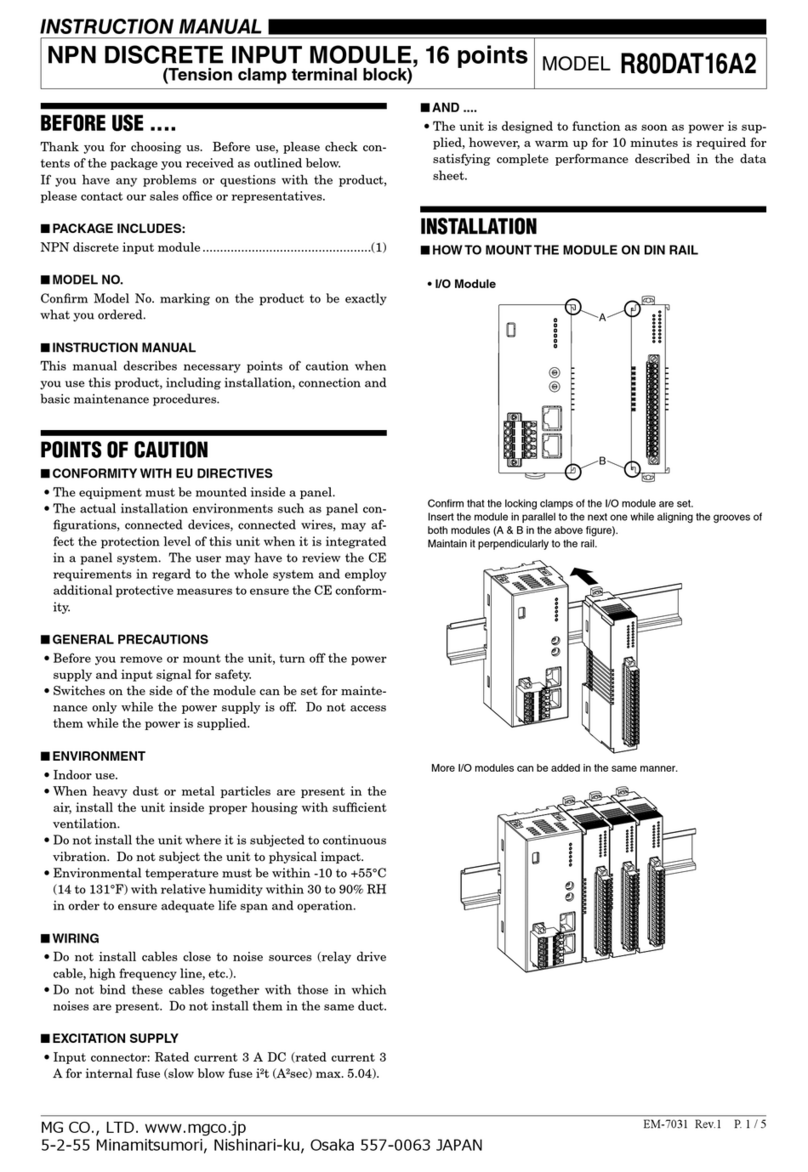

Comparison between FC4A and FC5A CPU Module Functions

CPU Module FC4A FC5A

Program Capacity 31,200 bytes maximum

(5,200 steps)

62,400/127,800 bytes maximum

(10,400/21,300 steps) (Note 1)

I/O Points 264 points maximum 512 points maximum

Advanced Instruction 72 maximum 152 maximum

32-bit Processing —Possible

Floating Point Data Processing —Possible

Trigonometric/Logarithm —Possible

Processing Time

LOD Instruction 1 µs 0.056 µs minimum

MOV Instruction 66 µs 0.167 µs minimum

Basic Instruction 1.65 ms (1000 steps) 83 µs (1000 steps)

END Processing (Note 2) 0.64 ms 0.35 ms

Internal Relay 1,584 maximum 2,048 maximum

Shift Register 128 maximum 256 maximum

Data Register 7,600 maximum 48,000 maximum

Bit Addressing in Basic Instruction —Possible

Counter 100 maximum 256

Timer 100 maximum 256

Catch Input / Interrupt Input Minimum turn on pulse width / Minimum turn off pulse width

Four Inputs (I2 through I5) 40 µs / 150 µs 40 µs / 150 µs (I2 and I5)

5 µs / 5 µs (I3 and I4)

High-speed Counter

Counting Frequency 20 kHz maximum 100 kHz maximum

Counting Range 0 to 65535 (16 bits) 0 to 4,294,967,295 (32 bits)

Multi-stage Comparison —Possible

Comparison Action Comparison output Comparison output

Interrupt program

Frequency Measurement —Possible

Pulse Output

Output Points 2 points maximum 3 points maximum

Output Pulse Frequency 20 kHz maximum 100 kHz maximum

Communication

Baud Rate 19,200 bps maximum

(Data link: 38,400 bps maximum) 115,200 bps maximum (Note 3)

Modbus Master/Slave Communication —Possible

Quantity of AS-Interface Modules 1 maximum 2 maximum

PID Advanced Auto Tuning —Possible

Edit / Test Program Download —Possible

Run-Time Program Download Size 600 bytes maximum Without limit

System Program Download —Possible

Program Download from Memory Cartridge Possible Possible

Note 1: For FC5A-D12K1E and FC5A-D12S1E, it is possible to select whether to use a program capacity of 62,400 bytes or 127,800 bytes.

If 127,800 bytes is selected, the run-time program download cannot be used.

Note 2: END processing does not include expansion I/O service, clock function processing, data link processing, and interrupt processing.

Note 3:

To use 115200 bps, CPU modules with system program version 220 or higher and FC5A-SIF4 or FC5A-SIF2 (version 200 or higher) are required.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

FC5A MicroSmart User’s Manual FC9Y-B1268 Preface-1

SAFETY PRECAUTIONS

•Read this user’s manual to make sure of correct operation before starting installation, wiring, operation, maintenance,

and inspection of the MicroSmart.

•All MicroSmart modules are manufactured under IDEC’s rigorous quality control system, but users must add a backup or

failsafe provision to the control system when using the MicroSmart in applications where heavy damage or personal

injury may be caused in case the MicroSmart should fail.

•In this user’s manual, safety precautions are categorized in order of importance to Warning and Caution:

Warning Warning notices are used to emphasize that improper operation may cause

severe personal injury or death.

•Turn off power to the MicroSmart before installation, removal, wiring, maintenance, and inspection of the MicroSmart.

Failure to turn power off may cause electrical shocks or fire hazard.

•Special expertise is required to install, wire, program, and operate the MicroSmart. People without such expertise must

not use the MicroSmart.

•Emergency stop and interlocking circuits must be configured outside the MicroSmart. If such a circuit is configured inside

the MicroSmart, failure of the MicroSmart may cause disorder of the control system, damage, or accidents.

•Install the MicroSmart according to the instructions described in this user’s manual. Improper installation will result in

falling, failure, or malfunction of the MicroSmart.

Caution Caution notices are used where inattention might cause personal injury or dam-

age to equipment.

•The MicroSmart is designed for installation in a cabinet. Do not install the MicroSmart outside a cabinet.

•Install the MicroSmart in environments described in this user’s manual. If the MicroSmart is used in places where the

MicroSmart is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive vibrations, and

excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

•The environment for using the MicroSmart is “Pollution degree 2.” Use the MicroSmart in environments of pollution

degree 2 (according to IEC 60664-1).

•Prevent the MicroSmart from falling while moving or transporting the MicroSmart, otherwise damage or malfunction of

the MicroSmart will result.

•Prevent metal fragments and pieces of wire from dropping inside the MicroSmart housing. Put a cover on the MicroSmart

modules during installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunc-

tion.

•Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

•Use an IEC 60127-approved fuse on the power line outside the MicroSmart. This is required when equipment containing

the MicroSmart is destined for Europe.

•Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the MicroSmart is des-

tined for Europe.

•Use an EU-approved circuit breaker. This is required when equipment containing the MicroSmart is destined for Europe.

•Make sure of safety before starting and stopping the MicroSmart or when operating the MicroSmart to force outputs on

or off. Incorrect operation on the MicroSmart may cause machine damage or accidents.

•If relays or transistors in the MicroSmart output modules should fail, outputs may remain on or off. For output signals

which may cause heavy accidents, provide a monitor circuit outside the MicroSmart.

•Do not connect the ground wire directly to the MicroSmart. Connect a protective ground to the cabinet containing the

MicroSmart using an M4 or larger screw. This is required when equipment containing the MicroSmart is destined for

Europe.

•Do not disassemble, repair, or modify the MicroSmart modules.

•Dispose of the battery in the MicroSmart modules when the battery is dead in accordance with pertaining regulations.

When storing or disposing of the battery, use a proper container prepared for this purpose. This is required when equip-

ment containing the MicroSmart is destined for Europe.

•When disposing of the MicroSmart, do so as an industrial waste.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

Preface-2 FC5A MicroSmart User’s Manual FC9Y-B1268

Revision Record

The table below summarizes the changes to this manual since the first printing of FC9Y-B927-0 in April, 2006.

Upgraded and new functions listed below have been implemented in the FC5A MicroSmart CPU modules. The availability

of these functions depends on the model and the system program version of the FC5A MicroSmart CPU modules.

To confirm the system program version of the MicroSmart CPU module, use WindLDR on a computer connected with the

CPU module. The system program version is indicated on the PLC Status dialog box. See page 13-1.

To confirm the WindLDR version, select the WindLDR application button at the upper-left corner of the WindLDR screen,

followed by WindLDR Options > Resources. The WindLDR version is found under About WindLDR.

Upgraded and New Functions List

CPU Module

All-In-One Type Slim Type

WindLDR Page

FC5A-C10R2

FC5A-C10R2C

FC5A-C10R2D

FC5A-C16R2

FC5A-C16R2C

FC5A-C16R2D

FC5A-C24R2

FC5A-C24R2C

FC5A-C24R2D

FC5A-D16RK1

FC5A-D16RS1

FC5A-D32K3

FC5A-D32S3

FC5A-D12K1E

FC5A-D12S1E (Note 1)

HMI Module Upgrade (Note 2) 110 or higher

110 or higher

101 or higher — 5-60

FC5A-SIF2 Expansion RS232C Communi-

cation Module Compatibility (Note 3) —

110 or higher

5.1 or

higher

2-86,

Advanced

Vol. 25-1

Modbus Master Upgrade (Note 4) —12-6

Modbus Slave Upgrade (Note 4) 110 or higher 110 or higher 12-14

32-bit Data Storage Setting

5.2 or

higher

5-46

Forced I/O

200 or higher 200 or higher 200 or higher

5-72

RUN LED Flashing Mode 5-49

Memory Cartridge Upload Function

(Note 5) 2-93

Off-Delay Timer Instructions

(TMLO, TIMO, TMHO, and TMSO) 7-11

Double-Word Counter Instructions

(CNTD, CDPD, and CUDD) 7-15

MOV and IMOV Instructions Upgrade

(New data type F)

Advanced

Vol. 3-1

N Data Set and N Data Repeat Set

Instructions (NSET and NRS)

Advanced

Vol. 3-13,

Advanced

Vol. 3-14

Timer/Counter Current Value Store

Instruction (TCCST)

Advanced

Vol. 3-16

CMP Instructions Upgrade Advanced

Vol. 4-4

Load Comparison Instructions

(LC=, LC<>, LC<, LC>, LC<=, and LC>=)

Advanced

Vol. 4-8

BTOA and ATOB Instructions Upgrade

(New data type D)

Advanced

Vol. 8-9

Advanced

Vol. 8-12

Data Divide, Combine, and Swap

Instructions (DTDV, DTCB, and SWAP)

Advanced

Vol. 8-21,

Advanced

Vol. 8-22,

Advanced

Vol. 8-23

User Communication Instructions

Upgrade (TXD and RXD) 10-6, 10-15

File Data Processing Instructions

(FIFOF, FIEX, and FOEX)

Advanced

Vol. 19-1,

Advanced

Vol. 19-3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

FC5A MicroSmart User’s Manual FC9Y-B1268 Preface-3

Note 1: All functions are available on FC5A-D12K1E and FC5A-D12S1E with system program version 100.

Note 2: Optional HMI module (FC4A-PH1) is needed to use this function.

Note 3: Expansion RS232C and RS485 communication modules (FC5A-SIF2 and FC5A-SIF4) cannot be used with the FC5A-C24R2D CPU module.

Note 4: Modbus Master communication can be used on port 2 through port 7. Modbus Slave communication can be used on port 1 through

port 7. Optional communication adapter (FC4A-PC1 or FC4A-PC3) or communication module (FC4A-HPC1 or FC4A-HPC3) is needed to use

port 2. Expansion RS232C or RS485 communication modules (FC5A-SIF2 or FC5A-SIF4) are needed to use port 3 through port 7.

Note 5: Memory cartridge (FC4A-PM32, FC4A-PM64, or FC4A-PM128) is required to use this function.

Note 6: Key matrix inputs cannot be used on the FC5A-C24R2D CPU module.

Revision History

Date Manual No. Description

March, 2011 B-1268(0) First print

Key Matrix Input (Note 6) —

210 or higher 210 or higher 5.3 or

higher

5-38

User Program Protection Upgrade

210 or higher

5-44

Exchange Instruction (XCHG) Advanced

Vol. 3-15

Increment Instruction (INC) Advanced

Vol. 5-13

Decrement Instruction (DEC) Advanced

Vol. 5-13

Sum Instruction (SUM) Advanced

Vol. 5-16

Random Instruction (RNDM)

210 or higher 210 or higher 210 or higher 5.3 or

higher

Advanced

Vol. 5-19

Decrement Jump Non-zero (DJNZ) Advanced

Vol. 11-5

N Data Search Instruction (NDSRC) Advanced

Vol. 19-5

Clock Instructions

(TADD, TSUB, HTOS, STOH, and HOUR)

Advanced

Vol. 20-1

All-in-one 12V DC Power CPU Modules — — — 2-1

Analog I/O Modules Upgrade

(Version 200 or higher) —Any Any Any 2-56

Modbus TCP Communication

210 or higher 210 or higher 210 or higher 5.3 or

higher

Advanced

Vol. 23-1

Modbus Slave Communication for Port 1

(Note 4) 12-11

Run/Stop Selection at Power Up 220 or higher

220 or higher 220 or higher 6.2 or

higher

5-4

FC5A-SIF4 Expansion RS485 Communica-

tion Module Compatibility (Note 3)

—

2-86,

Advanced

Vol. 25-1

Data Link and Modbus Communication

for Port 3 to Port 7 (Note 4) 11-1, 12-1

Communication Refresh Selection for

Port 3 to Port 7 5-43

CPU Module

All-In-One Type Slim Type

WindLDR Page

FC5A-C10R2

FC5A-C10R2C

FC5A-C10R2D

FC5A-C16R2

FC5A-C16R2C

FC5A-C16R2D

FC5A-C24R2

FC5A-C24R2C

FC5A-C24R2D

FC5A-D16RK1

FC5A-D16RS1

FC5A-D32K3

FC5A-D32S3

FC5A-D12K1E

FC5A-D12S1E (Note 1)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

Preface-4 FC5A MicroSmart User’s Manual FC9Y-B1268

Slim Type CPU Module Instruction Execution Time

Execution times of some instructions have been reduced on slim type CPU modules with Logic Engine version 200 or

higher and system program version 210 or higher as shown below.

Instruction Conditions for Reduced Execution Time Execution Time (µs)

New Old

TML, TIM, TMH, TMS T0 through T127 with preset values designated by constants 0.389 17

CC=, CCPreset values designated by devices valid for Logic Engine 0.111 8

DC=, DCData register numbers and preset values designated by devices valid for Logic

Engine 0.167 8

ADD (W, I) Without repeat designation, and S1, S2, and D1 designated by devices valid

for Logic Engine 0.278 44

SUB (W, I) 60

Note 1: Devices valid for Logic Engine are constants, data registers D0 through D1999, special data registers D8000 through D8399,

timer/counter preset values, and timer/counter current values.

Note 2: The new instruction execution time applies to FC5A-D12K1E and FC5A-D12S1E regardless of its system program version.

If the control system performance is affected by the reduced scan time, the scan time can be adjusted using the constant scan time

(D8022, 1 to 1,000 ms). For details about constant scan time, see page 5-50. The DISP or DGRD instruction may not operate correctly

due to the reduced scan time. If this is the case, adjust the scan time using the constant scan time (D8022, 1 to 1,000 ms), as

required. For minimum scan times required for the DISP and DGRD instructions, see pages 10-1 and 10-3 (Advanced Vol.).

Logic Engine version is found in the lower right corner of the label on the side of the slim type CPU module. To confirm the system

program version of the MicroSmart CPU module, use WindLDR on a computer connected with the CPU module. The system program

version is indicated on the PLC Status dialog box. See page 13-1.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

FC5A MicroSmart User’s Manual FC9Y-B1268 Preface-5

About This Manual

This user’s manual primarily describes entire functions, installation, and programming of the MicroSmart CPU, I/O, and

all other modules. Also included are powerful communications of the MicroSmart and troubleshooting procedures.

Chapter 1: General Information

General information about the MicroSmart, features, brief description on special functions, and various system setup

configurations for communication.

Chapter 2: Module Specifications

Specifications of CPU, input, output, mixed I/O, analog I/O, and other optional modules.

Chapter 3: Installation and Wiring

Methods and precautions for installing and wiring the MicroSmart modules.

Chapter 4: Operation Basics

General information about setting up the basic MicroSmart system for programming, starting and stopping MicroSmart

operation, and simple operating procedures from creating a user program using WindLDR on a PC to monitoring the

MicroSmart operation.

Chapter 5: Special Functions

Stop/reset inputs, run/stop selection at memory backup error, keep designation for internal relays, shift registers, coun-

ters, and data registers. Also included are high-speed counter, frequency measurement, catch input, interrupt input,

timer interrupt, input filter, user program protection, constant scan time, online edit, and many more special functions.

Chapter 6: Device Addresses

Device addresses available for the MicroSmart CPU modules to program basic and advanced instructions. Special internal

relays and special data registers are also described.

Chapter 7: Basic Instructions

Programming of the basic instructions, available devices, and sample programs.

Chapter 8: Advanced Instructions Reference

General rules of using advanced instructions, terms, data types, and formats used for advanced instructions.

Chapter 9 through Chapter 12:

Analog I/O control and various communication functions such as user, data link, and Modbus communication.

Chapter 13: Troubleshooting

Procedures to determine the cause of trouble and actions to be taken when any trouble occurs while operating the

MicroSmart.

Appendix

Additional information about execution times for instructions, I/O delay time, and MicroSmart type list.

Index

Alphabetical listing of key words.

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting

from the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit

their application and for choosing an application appropriate for the component, individually or in combination with other

equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and

examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all

programs, prior to installation, is the responsibility of the end user.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

Preface-6 FC5A MicroSmart User’s Manual FC9Y-B1268

RELATED MANUALS

The following manuals related to the FC5A series MicroSmart are available. Refer to them in conjunction with this manual.

Type No. Manual Name Description

FC9Y-B1268

FC5A Series

MicroSmart Pentra

User's Manual

Basic Volume (this manual)

Describes module specifications, installation instructions, wiring instructions,

basic operation, special function, device addresses, instruction list, basic

instructions, analog modules, user communication, data link communication,

Modbus ASCII/RTU communication, and troubleshooting.

FC9Y-B1273

FC5A Series

MicroSmart Pentra

User's Manual

Advanced Volume

Describes instruction list, move instructions, data comparison instructions,

binary arithmetic instructions, boolean computation instructions, shift/

rotate instructions, data conversion instructions, week programmer instruc-

tions, interface instructions, program branching instructions, refresh instruc-

tions, interrupt control instructions, coordinate conversion instructions,

average instructions, pulse output instructions, PID instructions, dual/teach-

ing timer instructions, intelligent module access instructions, trigonometric

function instructions, logarithm/power instructions, file data processing

instructions, clock instructions, computer link communication, modem com-

munication, Modbus TCP communication, expansion RS232C/RS485 commu-

nication modules, and AS-Interface master modules.

FC9Y-B1278

FC5A Series

MicroSmart Pentra

User's Manual

Web Server CPU Module Volume

Describes FC5A Slim Type Web Server CPU Module specifications and func-

tions.

FC9Y-B1283

FC5A Series

PID Module

User's Manual

Describes PID Module specifications and functions.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

FC5A MICROSMART USER’SMANUAL FC9Y-B1268 i

TABLE OF CONTENTS

CHAPTER 1: General Information

About the MicroSmart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

CHAPTER 2: Module Specifications

CPU Modules (All-in-One Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

CPU Modules (Slim Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

CPU Modules (Slim Type Web Server) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Mixed I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Analog I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Expansion Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

AS-Interface Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

HMI Base Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

Communication Adapters and Communication Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-82

Expansion RS232C/RS485 Communication Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

Memory Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-91

Clock Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

CHAPTER 3: Installation and Wiring

Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Assembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Disassembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installing the HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing the HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Securing USB Extension Cable Using Cable Tie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Removing the Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Removing the Communication Connector Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Mounting on DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Removing from DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Direct Mounting on Panel Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Installation in Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Mounting Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Maximum Quantity of Applicable Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Terminal Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

CHAPTER 4: Operation Basics

Connecting MicroSmart to PC (1:1 Computer Link System) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Start WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PLC Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Communication Port Settings for the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Start/Stop Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Simple Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

TABLE OF CONTENTS

ii FC5A MICROSMART USER’SMANUAL FC9Y-B1268

CHAPTER 5: Special Functions

Function Area Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Stop Input and Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Run/Stop Selection at Memory Backup Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Run/Stop Selection at Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Keep Designation for Internal Relays, Shift Registers, Counters, and Data Registers . . . . . . . . . . . . . 5-5

High-speed Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Catch Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Interrupt Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Timer Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Key Matrix Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Input Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Communication Refresh for Port 3 through Port 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

User Program Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

32-bit Data Storage Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

RUN LED Flashing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

Constant Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Online Edit, Run-Time Program Download, and Test Program Download . . . . . . . . . . . . . . . . . . . . 5-51

Analog Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Analog Voltage Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

Forced I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

CHAPTER 6: Device Addresses

Device Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

I/O, Internal Relay, and Special Internal Relay Device Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Device Addresses for END Refresh Type Analog I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Device Addresses for AS-Interface Master Module 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Device Addresses for Data Link Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Device Addresses for Data Link Slave Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Special Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Special Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Expansion Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Expansion I/O Module Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

CHAPTER 7: Basic Instructions

Basic Instruction List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

LOD (Load) and LODN (Load Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

OUT (Output) and OUTN (Output Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

SET and RST (Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

AND and ANDN (And Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

OR and ORN (Or Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

AND LOD (Load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

OR LOD (Load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

BPS (Bit Push), BRD (Bit Read), and BPP (Bit Pop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

TML, TIM, TMH, and TMS (Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

TMLO, TIMO, TMHO, and TMSO (Off-Delay Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

CNT, CDP, and CUD (Counter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

CNTD, CDPD, and CUDD (Double-Word Counter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

CC= and CC≥(Counter Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

DC= and DC≥(Data Register Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

SFR and SFRN (Forward and Reverse Shift Register) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

SOTU and SOTD (Single Output Up and Down) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

MCS and MCR (Master Control Set and Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

JMP (Jump) and JEND (Jump End) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

TABLE OF CONTENTS

FC5A MICROSMART USER’SMANUAL FC9Y-B1268 iii

Restriction on Ladder Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

CHAPTER 8: Advanced Instructions Reference

Advanced Instruction List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Advanced Instruction Applicable CPU Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Structure of an Advanced Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Input Condition for Advanced Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Source and Destination Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Using Timer or Counter as Source Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Using Timer or Counter as Destination Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Data Types for Advanced Instructions (Integer Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Discontinuity of Device Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

NOP (No Operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

CHAPTER 9: Analog I/O Control

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Analog I/O Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Data Register Device Addresses for Analog I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Analog Input Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Analog Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

CHAPTER 10: User Communication Instructions

User Communication Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

User Communication Mode Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Connecting RS232C Equipment through RS232C Port 1 or 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

RS232C User Communication System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Connecting RS485 Equipment through RS485 Port 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

RS485 User Communication System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

TXD (Transmit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

RXD (Receive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

User Communication Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-32

ASCII Character Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-33

RS232C Line Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-34

Sample Program – User Communication TXD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-38

Sample Program – User Communication RXD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

CHAPTER 11: Data Link Communication

Data Link Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Data Link System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Data Register Allocation for Transmit/Receive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Special Data Registers for Data Link Communication Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Data Link Communication between Master and Slave Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

Special Internal Relays for Data Link Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

Data Refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Sample Program for Data Link Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Operating Procedure for Data Link System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Data Link with Other PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

CHAPTER 12: Modbus ASCII/RTU Communication

Modbus Communication System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Modbus Master Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

Modbus Slave Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-11

Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

TABLE OF CONTENTS

iv FC5A MICROSMART USER’SMANUAL FC9Y-B1268

Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

CHAPTER 13: Troubleshooting

ERR LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Reading Error Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Special Data Registers for Error Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

General Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

CPU Module Operating Status, Output, and ERR LED during Errors . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Error Causes and Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

User Program Execution Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

Troubleshooting Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-8

APPENDIX

Execution Times for Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Breakdown of END Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Instruction Bytes and Applicability in Interrupt Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Upgrade FC5A MicroSmart System Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Communication Ports and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

Type List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

INDEX

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

FC5A MicroSmart User’s Manual FC9Y-B1268 1-1

1: GENERAL INFORMATION

Introduction

This chapter describes general information about the powerful capabilities of the upgraded FC5A series MicroSmart

micro programmable logic controllers and system setups to use the MicroSmart in various ways of communication.

About the MicroSmart

IDEC’s FC5A MicroSmart is an upgraded family of micro programmable logic controllers available in two styles of CPU

modules; all-in-one and slim types.

The all-in-one type CPU module has 10, 16, or 24 I/O terminals and is equipped with a built-in universal power supply to

operate on 100 to 240V AC, or 24 or 12V DC. Using four optional 16-point I/O modules, the 24-I/O type CPU module

(except 12V DC power type) can expand the I/O points up to a total of 88 points. Program capacity of the all-in-one type

CPU modules is 13,800 bytes (2,300 steps) on the 10-I/O type CPU module, 27,000 bytes (4,500 steps) on the 16-I/O type,

and 54,000 bytes (9,000 steps) on the 24-I/O type.

The slim type CPU module has 16 or 32 I/O terminals and operates on 24V DC. The total I/O points can be expanded to a

maximum of 512. When using two AS-Interface master modules, a maximum of 1,380 I/O points can be connected. The

program capacity of slim type CPU modules is 62,400 bytes (10,400 steps).

Slim type CPU modules feature Logic Engine for superior ladder processing capabilities to achieve fast execution of

instructions — 0.056 µs for a basic instruction (LOD) and 0.167 µs for an advanced instruction (MOV).

User programs for the MicroSmart can be edited using WindLDR on a Windows PC. Since WindLDR can load existing user

programs made for IDEC’s previous PLCs such as OpenNet Controller and FC4A MicroSmart, your software assets can be

used in the new control system.

Features

Powerful Communication Functions

The MicroSmart features five powerful communication functions.

Maintenance

Communication

(Computer Link)

When a MicroSmart CPU module is connected to a computer, operating status and I/O status can be

monitored on the computer, data in the CPU can be monitored or updated, and user programs can

be downloaded and uploaded. All CPU modules can set up a 1:N computer link system to connect a

maximum of 32 CPU modules to a computer.

User Communication

All MicroSmart CPU modules can be linked to external RS232C devices such as computers, printers,

and barcode readers on port 1 to port 7, using the user communication function. RS485 user com-

munication is also available on port 2 to port 7.

Expansion communication modules (FC5A-SIF2/-SIF4) can be used with all-in-one 24-I/O (except 12V

DC power type) and slim type CPU modules to expand up to five or seven communication ports,

respectively.

Modem Communication All MicroSmart CPU modules can communicate through modems using the built-in modem protocol.

Modem communication is available through port 2.

Data Link

All MicroSmart CPU modules can be used as data link master or slave station. One CPU module at the

master station can communicate with 31 slave stations through an RS485 line to exchange data and

perform distributed control effectively.

Modbus Communication

All MicroSmart CPU modules can be used as Modbus master or slave, and can be connected to other

Modbus devices. Modbus Master communication is available on port 2 to port 7. Modbus Slave com-

munication is available on port 1 to port 7.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

1: GENERAL INFORMATION

1-2 FC5A MicroSmart User’s Manual FC9Y-B1268

Communication Adapter (All-in-one type CPU modules)

Communication Module (Slim type CPU modules)

In addition to the standard RS232C port 1, all-in-one type CPU modules feature a port 2 connector to install an optional

RS232C or RS485 communication adapter. Any slim type CPU module can be used with an optional RS232C or RS485 com-

munication module to add communication port 2. With an optional HMI base module mounted with a slim type CPU

module, an optional RS232C or RS485 communication adapter can also be installed on the HMI base module.

RS232C Communication Adapter

RS232C Communication Module Used for computer link 1:1 communication, user communication, and modem communication.

RS485 Communication Adapter

RS485 Communication Module

Available in mini DIN connector and terminal block styles. Used for computer link 1:1 or 1:N

communication, user communication, data link communication, and Modbus communication.

Expansion RS232C/RS485 Communication Module (slim CPU modules and all-in-one 24-I/O types except 12V DC type)

All-in-one 24-I/O type CPU modules (except 12V DC power type) can be used with a maximum of three expansion

RS232C/RS485 communication modules (FC5A-SIF2/-SIF4) to expand up to five communication ports. Slim type CPU

modules can be used with a maximum of five expansion RS232C/RS485 communication modules to expand up to seven

communication ports. Expansion RS232C/RS485 communication modules can be used for computer link communication,

user communication, data link, and Modbus communication.

HMI Module (all CPU modules)

An optional HMI module can be installed on any all-in-one type CPU module, and also on the HMI base module mounted

next to any slim type CPU module. The HMI module makes it possible to manipulate the RAM data in the CPU module

without using the Online menu options in WindLDR.

HMI module functions include:

• Displaying timer/counter current values and changing timer/counter preset values

• Displaying and changing data register values

• Setting and resetting bit device statuses, such as inputs, outputs, internal relays, and shift register bits

• Displaying and clearing error data

• Starting and stopping the PLC

• Displaying and changing calendar/clock data (only when using the clock cartridge)

• Confirming changed timer/counter preset values

Clock Cartridge (all CPU modules)

An optional clock cartridge can be installed on the CPU module to store real time calendar/clock data for use with

advanced instructions to perform time-scheduled control.

Memory Cartridge (all CPU modules)

A user program can be stored on an optional memory cartridge using WindLDR. The memory cartridge can be installed

on another CPU module to replace user programs without the need for connecting to a computer. The original user pro-

gram in the CPU module is restored after removing the memory cartridge.

The user program can be downloaded to the CPU module. Memory cartridge upload is also available on upgraded CPU

modules with system program version 200 or higher. The upload and download options are selected using WindLDR.

Analog I/O Modules (slim CPU modules and all-in-one 24-I/O types except 12V DC power type)

The analog input channel can accept either voltage (0 to 10V DC) and current (4 to 20 mA) signals or thermocouple (types

K, J, and T) and resistance thermometer (Pt100, Pt1000, Ni100, and Ni1000) signals. The output channel generates volt-

age (0 to 10V DC or –10 to +10V DC) and current (4 to 20 mA) signals.

AS-Interface Master Module (slim CPU modules and all-in-one 24-I/O types except 12V DC power type)

One or two AS-Interface master modules can be mounted to communicate with a maximum of 124 slaves, or 496 inputs

and 372 outputs, such as actuators and sensors, through the AS-Interface bus.

Web Server Module (all CPU modules)

The web server module is used to connect the MicroSmart to Ethernet. Remote monitoring is made possible, sending E-

mail messages to personal computers or mobile phones.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

1: GENERAL INFORMATION

FC5A MicroSmart User’s Manual FC9Y-B1268 1-3

Special Functions

The MicroSmart features various special functions packed in the small housing as described below. For details about

these functions, see the following chapters.

Stop and Reset Inputs

Any input terminal on the CPU module can be designated as a stop or reset input to control the MicroSmart operation.

RUN/STOP Selection at Startup when “Keep” Data is Broken

When data to be kept such as “keep” designated counter values are broken while the CPU is powered down, the user can

select whether the CPU starts to run or not to prevent undesirable operation at the next startup.

“Keep” or “Clear” Designation of CPU Data

Internal relays, shift register bits, counter current values, and data register values can be designated to be kept or cleared

when the CPU is powered down. All or a specified range of these devices can be designated as keep or clear types.

High-speed Counter

The MicroSmart has four built-in high-speed counters to count high-speed pulses which cannot be counted by the normal

user program processing. All-in-one type CPU modules can count up to 65,535 pulses at 50 kHz. Slim type CPU modules

can count up to 4,294,967,295 pulses at 100 kHz. Both CPU modules can use either single-phase or two-phase high-speed

counters. The high-speed counters can be used for simple positioning control and simple motor control.

Frequency Measurement

The pulse frequency of input signals to four input terminals can be counted using the high-speed counter function at a

maximum of 50 kHz (all-in-one type CPU modules) or 100 kHz (slim type CPU modules).

Catch Input

Four inputs can be used as catch inputs. The catch input makes sure to receive short input pulses from sensors without

regard to the scan time — rising and falling pulse widths of 40 µs and 150 µs (all-in-one type CPU modules) or 5 µs and 5

µs (slim type CPU modules).

Interrupt Input

Four inputs can be used as interrupt inputs. When a quick response to an external input is required, such as positioning

control, the interrupt input can call a subroutine to execute an interrupt program.

Timer Interrupt

In addition to the interrupt input, all CPU modules have a timer interrupt function. When a repetitive operation is

required, the timer interrupt can be used to call a subroutine repeatedly at predetermined intervals of 10 through 140

ms.

Input Filter

The input filter can be adjusted for eight inputs to reject input noises. Selectable input filter values to pass input signals

are 0 ms, and 3 through 15 ms in 1-ms increments. The input filter rejects inputs shorter than the selected input filter

value minus 2 ms. This function is useful for eliminating input noises and chatter in limit switches.

User Program Read/Write Protection

The user program in the CPU module can be protected against reading and/or writing by including a password in the user

program. This function is effective for security of user programs. Upgraded CPU modules with system program version

210 or higher have an option for read protection without a password, making it possible to inhibit reading completely.

Constant Scan Time

The scan time may vary whether basic and advanced instructions are executed or not depending on input conditions to

these instructions. When performing repetitive control, the scan time can be made constant by entering a required scan

time value into a special data register reserved for constant scan time.

Online Edit, Run-Time Program Download, and Test Program Download

Normally, the CPU module has to be stopped before downloading a user program. All CPU modules have online edit, run-

time program download, and test program download capabilities to download a user program containing small changes

while the CPU is running in either 1:1 or 1:N computer link system. This function is particularly useful to make small mod-

ifications to the user program and confirm the changes while the CPU is running.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

1: GENERAL INFORMATION

1-4 FC5A MicroSmart User’s Manual FC9Y-B1268

Analog Potentiometer

All CPU modules have an analog potentiometer, except the all-in-one 24-I/O type CPU module has two analog potenti-

ometers. The values (0 through 255) set with analog potentiometers 1 and 2 are stored to special data registers. The ana-

log potentiometer can be used to change the preset value for a timer or counter.

Analog Voltage Input

Every slim type CPU module has an analog voltage input connector. When an analog voltage of 0 through 10V DC is

applied to the analog voltage input connector, the signal is converted to a digital value of 0 through 255 and stored to a

special data register. The data is updated in every scan.

Pulse Output

Slim type CPU modules have pulse output instructions to generate high-speed pulse outputs from transistor output ter-

minals used for simple position control applications, illumination control, trapezoidal control, and zero-return control.

PID Control

All CPU modules (except the all-in-one 10- and 16-I/O types) have the PID instruction, which implements a PID (propor-

tional, integral, and derivative) algorithm with built-in auto tuning or advanced auto tuning to determine PID parameters.

This instruction is primarily designed for use with an analog I/O module to read analog input data, and turns on and off a

designated output to perform PID control in applications such as temperature control. In addition, the PID instruction can

also generate an analog output using an analog I/O module.

Expansion Data Register

Slim type CPU modules have expansion data registers D2000 through D7999. Numerical data can be set to expansion

data registers using WindLDR. When downloading the user program, the preset values of the expansion data registers are

also downloaded to the ROM in the CPU module. Since the data in the ROM is non-volatile, the preset values of the

expansion data registers are maintained semi-permanently and loaded to the RAM each time the CPU is powered up.

32-bit and Floating Point Data Types

Some advanced instructions can select 32-bit data types from D (double word), L (long), and F (float) in addition to W

(word) and I (integer).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

1: GENERAL INFORMATION

FC5A MicroSmart User’s Manual FC9Y-B1268 1-5

System Setup

This section illustrates system setup configurations for using powerful communication functions of the MicroSmart.

User Communication and Modem Communication System

The all-in-one type MicroSmart CPU modules have port 1 for RS232C communication and port 2 connector. An optional

RS232C or RS485 communication adapter can be installed on the port 2 connector. With an RS232C communication

adapter installed on port 2, the MicroSmart CPU module can communicate with two RS232C devices at the same time.

Expansion RS232C/RS485 communication modules (FC5A-SIF2/-SIF4) can also be mounted to the CPU modules to add

port 3 to port 5, so that MicroSmart CPU module can communicate with more RS232C/RS485 devices at the same time.

The figure below illustrates a system setup of user communication and modem communication. In this example, the

operating status of a remote machine is monitored on a computer through modems connected to port 2 and the data is

transferred through port 1 to a pager transmitter using the user communication.

The same system can be set up using any slim type CPU module and an optional RS232C communication module.

For details about the user communication, see page 10-1.

For details about the modem mode, see page 21-1 (Advanced Vol.).

All-in-One Type CPU Module

Pager Transmitter

Pager

Modem

Data

Communication

Modem

Computer

Data

Transmission

RS232C

Communication

Adapter on

Port 2 Connector

Port 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

1: GENERAL INFORMATION

1-6 FC5A MicroSmart User’s Manual FC9Y-B1268

Computer Link System

When the MicroSmart is connected to a computer, operating status and I/O status can be monitored on the computer,

data in the CPU module can be monitored or updated, and user programs can be downloaded and uploaded. When an

optional RS485 communication adapter is installed on the port 2 connector of the all-in-one type CPU modules or when

an optional RS485 communication module is mounted with any slim type CPU modules, a maximum of 32 CPU modules

can be connected to one computer in the 1:N computer link system. FC5A-SIF4 expansion RS485 communication modules

can also be mounted to the CPU modules to add port 3 through port 7, so that the CPU modules can be added in the 1:N

computer link system.

For details about the computer link communication, see pages 4-1 (this manual) and 21-1 (Advanced Vol.).

Computer Link 1:1 Communication

Slim Type CPU Module

Computer Link Cable 4C

FC2A-KC4C

3m (9.84 ft.) long

All-in-One Type CPU Module

Port 1

RS232C Communication

Adapter on Port 2 Connector

Port 2

Computer Link Cable 4C

FC2A-KC4C

3m (9.84 ft.) long

Port 1

RS232C Communication Module

Computer Link 1:N Communication

RS485 Communication Adapter

on Port 2 Connector

All-in-One Type CPU Module

RS232C Cable

HD9Z-C52

1.5m (4.92 ft.) long

RS232C/RS485 Converter

FC2A-MD1

Twisted-pair Shielded Cable

1st Unit

2nd Unit

32nd Unit

Slim Type CPU Module

Port 2

RS485 Communication Module

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

1: GENERAL INFORMATION

FC5A MicroSmart User’s Manual FC9Y-B1268 1-7

Data Link System

With an optional RS485 communication adapter installed on the port 2 connector or an FC5A-SIF4 expansion RS485 com-

munication module mounted, one CPU module at the master station can communicate with 31 slave stations through the

RS485 line to exchange data and perform distributed control effectively. The RS485 terminals are connected with each

other using a 2-core twisted pair cable.

The same data link system can also be set up using any slim type CPU modules mounted with RS485 communication

modules.

For details about the data link communication, see page 11-1.

Master Station Slave Station 1 Slave Station 31

Modbus Communication System

With an optional RS232C/RS485 communication adapter installed on the port 2 connector or an FC5A-SIF4 expansion

RS485 communication module mounted, any FC5A MicroSmart CPU module can be used as a Modbus master or slave

station. Using the Modbus communication, the MicroSmart CPU module can exchange data with other Modbus devices.

For details about the Modbus communication, see page 12-1.

Master Station Slave Station 1 Slave Station 31

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

1: GENERAL INFORMATION

1-8 FC5A MicroSmart User’s Manual FC9Y-B1268

Operator Interface Communication System

The MicroSmart can communicate with IDEC’s HG series operator interfaces through RS232C or RS485 port. When using

the expansion RS232C/RS485 communication modules (FC5A-SIF2/-SIF4), the all-in-one 24-I/O CPU module, except the

12V DC type, can expand up to port 5 and the slim type CPU module can expand up to port 7. For the expansion RS232C/

RS485 communication, see page 25-1 (Advanced Vol.).

Optional cables are available for connection between the MicroSmart and HG series operator interfaces. When installing

an optional RS232C communication adapter on the all-in-one type CPU module or an optional RS232C communication

module on the slim type CPU module, two operator interfaces can be connected to one MicroSmart CPU module.

For details about communication settings, see the user’s manual for the operator interface.

HG series Operator Interface

To RS232C Port 1 or 2

O/I Communication Cable

Applicable Cables to Operator Interfaces

Operator Interface O/I Communication Cable

For Use on MicroSmart

All-in-one 24-I/O CPU Module

(except 12V DC type) Slim CPU Module

HG1B, HG2A Series

FC4A-KC1C Port 1 to port 5 (RS232C) Port 1 to port 7 (RS232C)

HG9Z-XC183 (Note) Port 2 (RS232C) Port 2 (RS232C)

Shielded twisted-pair cable Port 2 to port 5 (RS485) Port 2 to port 7 (RS485)

HG2F, HG3F, HG4F Series

FC4A-KC2C Port 1 to port 5 (RS232C) Port 1 to port 7 (RS232C)

HG9Z-3C125 (Note) Port 2 (RS232C) Port 2 (RS232C)

Shielded twisted-pair cable Port 2 to port 5 (RS485) Port 2 to port 7 (RS485)

HG1F FC4A-KC1C Port 1 to port 5 (RS232C) Port 1 to port 7 (RS232C)

Shielded twisted-pair cable Port 2 to port 5 (RS485) Port 2 to port 7 (RS485)

HG2G

FC4A-KP1C Port 1 to port 2 (RS232C) Port 1 to port 2 (RS232C)

Shielded twisted-pair cable Port 3 to port 5 (RS232C)

Port 2 to port 5 (RS485)

Port 3 to port 7 (RS232C)

Port 2 to port 7 (RS485)

Note: HG series communication cables HG9Z-XC183 and HG9Z-3C125 can be used on port 2 only.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]

This manual suits for next models

14

Table of contents

Other IDEC Control Unit manuals

IDEC

IDEC MicroSmart Series User manual

IDEC

IDEC FC5A-F2M2 User manual

IDEC

IDEC HR6S Series User manual

IDEC

IDEC HR6S-S User manual

IDEC

IDEC MicroSmart pentra FC5A-D12K1E User manual

IDEC

IDEC MICROSmart FC5A Series User manual

IDEC

IDEC MICROSmart FC6A-C16K1CE Use and care manual

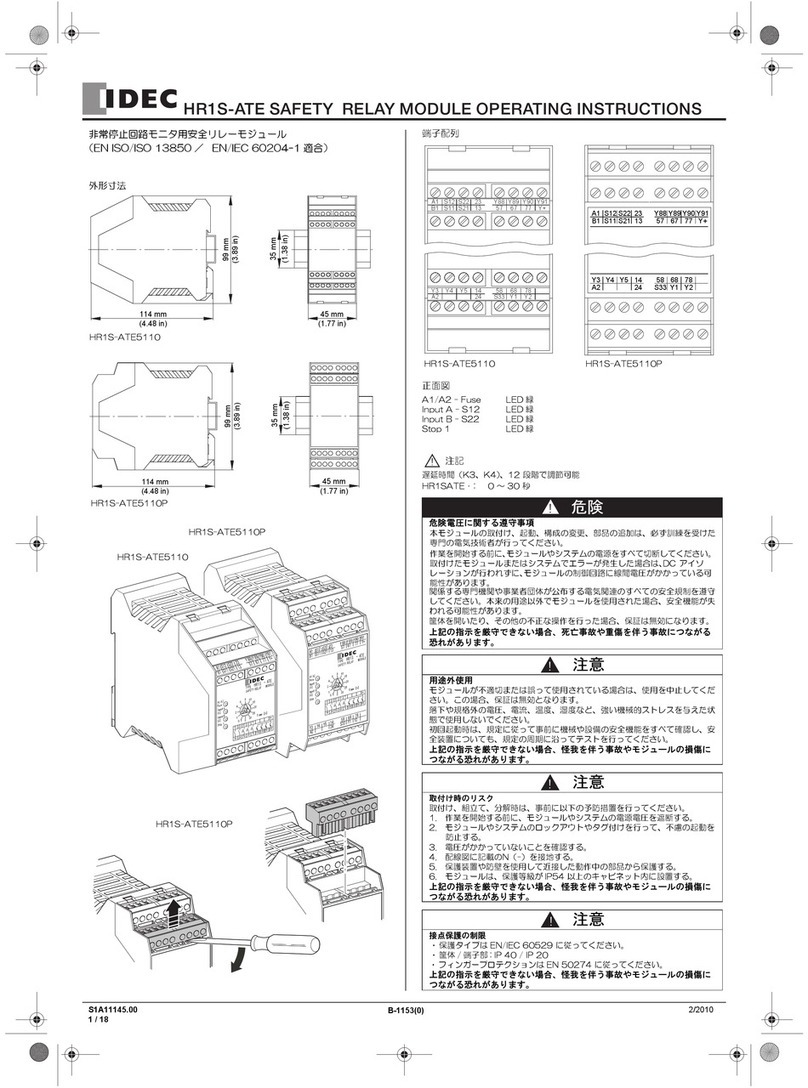

IDEC

IDEC HR1S-ATE User manual

IDEC

IDEC LONWORKS User manual

IDEC

IDEC HR6S-DN User manual