IDEC MICRO3C User manual

onlinecomponents.com

U

SER

’

S

M

ANUAL

P

REFACE

-1

S

AFETY

P

RECAUTIONS

• Read this user’s manual to make sure of correct operation before starting installation, wiring, operation, maintenance, and

inspection of the

MICRO

3

C.

• All

MICRO

3

C

’s are manufactured under IDEC’s rigorous quality control system, but users must add a backup or failsafe

provision to the control system using the

MICRO

3

C

in applications where heavy damage or personal injury may be caused in

case the

MICRO

3

C

should fail.

• In this user’s manual, safety precautions are categorized in order of importance to Warning and Caution:

• Turn power off to the

MICRO

3

C

before starting installation, removal, wiring, maintenance, and inspection on the

MICRO

3

C

.

Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the

MICRO

3

C

. People without such expertise must not use

the

MICRO

3

C

.

• Emergency and interlocking circuits must be configured outside the

MICRO

3

C

. If such a circuit is configured inside the

MICRO

3

C

, failure of the

MICRO

3

C

may cause disorder of the control system, damage, or accidents.

• Install the

MICRO

3

C

according to instructions described in this user’s manual and the

MICRO

3

user’s manual. Improper

installation will result in falling, failure, or malfunction of the

MICRO

3

C

.

•

MICRO

3

C

is designed for installation in equipment. Do not install the

MICRO

3

C

outside of equipment.

• Install the

MICRO

3

C

in environments described in this user’s manual and the

MICRO

3

user’s manual. If the

MICRO

3

C

is used

in places where the

MICRO

3

C

is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive

vibrations, and excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

•

MICRO

3

C

is designed for use in “Pollution degree 2.” Use the

MICRO

3

C

in environments of pollution degree 2 (according to

IEC664-1).

• All DC power type

MICRO

3

C

units are “PS2” type (according to EN61131).

• Prevent the

MICRO

3

C

from falling while moving or transporting the

MICRO

3

C

, otherwise damage or malfunction of the

MICRO

3

C

will result.

• Prevent metal fragments and pieces of wire from dropping inside the

MICRO

3

C

housing. Put a cover on the

MICRO

3

C

during

installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunction.

• Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

• Use wires of a proper size to meet voltage and current requirements. Tighten M3 terminal screws to a proper tightening

torque of 0.3 to 0.5 N-m.

• Use an IEC127-approved fuse (2A maximum) on the power line outside the

MICRO

3

C

. This is required when exporting

equipment containing

MICRO

3

C

to Europe.

• Use an IEC127-approved fuse on the output circuit. This is required when exporting equipment containing

MICRO

3

C

to

Europe.

• Use an EU-approved circuit breaker. This is required when exporting equipment containing

MICRO

3

C

to Europe.

• Make sure of safety before starting and stopping the

MICRO

3

C

or when operating the

MICRO

3

C

to force outputs on or off.

Incorrect operation on the

MICRO

3

C

may cause machine damage or accidents.

• If relays in the

MICRO

3

C

output circuit fail, outputs may remain on or off. For output signals which may cause heavy acci-

dents, provide a monitor circuit outside of the

MICRO

3

C

.

• Do not connect to the ground directly from the

MICRO

3

C

. Connect a protective ground to the equipment containing

MICRO

3

C

using an M4 or larger screw. This is required when exporting equipment containing

MICRO

3

C

to Europe.

• Do not disassemble, repair, or modify the

MICRO

3

C

.

• When the battery in the

MICRO

3

C

is dead, dispose of the battery in accordance with pertaining regulations. When taking

back the dead battery to the store or disposing of the dead battery, use a proper container installed for that purpose. This is

required when exporting equipment containing

MICRO

3

C

to Europe.

• When disposing of the

MICRO

3

C

, do so as an industrial waste.

• When the battery in the memory card is dead, dispose of the battery in accordance with pertaining regulations.

Warning

Caution

Warning notices are used to emphasize that improper operation may cause

severe personal injury or death.

Caution notices are used where inattention might cause personal injury or

damage to equipment.

Warning

Caution

onlinecomponents.com

P

REFACE

-2 U

SER

’

S

M

ANUAL

MICRO

3

C USER’S MANUAL

This user’s manual primarily describes

MICRO

3

C

’s additional functions not included in the

MICRO

3

programmable control-

lers. For installation instructions, general specifications, and common functions shared with the

MICRO

3

such as basic and

advanced instructions, allocation numbers, and FUN settings, see the

MICRO

3

user’s manual.

MICRO

3

C and MICRO

3

Comparison

Program Loader for MICRO

3

C

To use the expanded capabilities of the

MICRO

3

C

such as new advanced instructions for communication and comparison

and increased data registers, use an upgraded program loader of version 2.00 or later. To check the program loader version,

read FUN31 (program loader version readout/hardware check) using the FUN31 and keys on the program loader.

To edit user programs for

MICRO

3

C

, read FUN11 (program capacity and PLC type selection) on the program loader, and

set the fourth line in the FUN11 screen to 1 to select

MICRO

3

C

as the PLC type, using the FUN11, , , , 1, and keys.

Since the loader port on the

MICRO

3Cuses RS232C communication while the loader port on the MICRO3uses RS485, a dif-

ferent loader cable is needed to connect the program loader to MICRO3Cor MICRO3. Use loader cable 3C (FC2A-KL3C) to

connect a program loader to the MICRO3Cloader port. A program loader can also be connected to the data link terminals on

the MICRO3Cusing loader cable 4C (FC2A-KL4C). In either case, loader protocol must be selected for the loader port or

data link terminals using the protocol selector switch. For selection of the protocol selector switch, see page 1-2.

Note: The upgraded program loader of version 2.00 or later can also be connected to the MICRO3using MICRO3loader

cable FC2A-KL1 or FC2A-KL2.

PLC MICRO3C MICRO3

Advanced Instructions 40

(TXD, RXD, CMP2 added; ANR1 deleted) 38

Data Registers Standard Processing 500 points 100 points

High-speed Processing 32 points 32 points

Analog Potentiometers 1 point 1 point (10 I/O type)

2 points (16/24 I/O types)

Communication

Specifications

Loader Port Standards EIA RS232C EIA RS485

Data Link

Terminal

Standards EIA RS485 EIA RS485

Baud Rate

Expansion/data link communication:

19,200 bps (fixed)

Loader protocol communication:

9,600 bps (fixed)

Expansion/data link communication:

19,200 bps (fixed)

Weight (approx.) 380g (16 I/O type)

430g (24 I/O type)

290g (10 I/O type)

350g (16 I/O type)

390g (16 I/O AC input type)

400g (24 I/O type)

Standards

EN55011 Group 1, Class A

EN50082-2

UL508, CSA C22.2, No. 142

EN61131-1, EN61131-2, EN60204-1

EN61131-1, EN61131-2, EN60204-1

IEC801-2, -3, -4

PrEN50082-2, EN55011

UL508, CSA C22.2, No. 142

Certification File No.

TÜV Product Service B950913332

UL E102542

CSA LR66809

TÜV Product Service E9 95 09 13332

313

UL E102542

CSA LR66809

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting

from the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their appli-

cation and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and

examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all pro-

grams, prior to installation, is the responsibility of the end user.

onlinecomponents.com

USER’SMANUAL i

TABLE OF CONTENTS

CHAPTER 1: GENERAL INFORMATION

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Parts Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

CHAPTER 2: ALLOCATION NUMBERS

Allocation Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

I/O Allocation Numbers for Expansion Link System . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Special Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Data Register Allocation Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Expansion Control Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

CHAPTER 3: COMMUNICATION MONITOR

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

FUN29: User Communication Status Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

FUN50: User Communication Data Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

CHAPTER 4: MODEM MODE

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Applicable Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Internal Relays for Modem Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Data Registers for Modem Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Originate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Disconnect Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

AT General Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Answer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Initialization String Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Preparation before Using Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Setting Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Programming Data Registers and Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Sample Program for Modem Originate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Checking Modem Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

CHAPTER 5: USER COMMUNICATION INSTRUCTIONS

B1 TXD (Transmit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

B2 RXD (Receive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

CHAPTER 6: COMPARISON INSTRUCTION

B3 CMP2 (Double-word Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

CHAPTER 7: COMPUTER LINK

Computer Link 1:N Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Computer Link 1:N Communication Using Modems . . . . . . . . . . . . . . . . . . . . . . . . 7-2

RS232C/RS485 Converter FC2A-MD1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

RS232C Cable HD9Z-C52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

onlinecomponents.com

TABLE OF CONTENTS

ii USER’SMANUAL

CHAPTER 8: SAMPLE PROGRAM – USER COMMUNICATION TXD

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Programming Expansion Control Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Setting Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Ladder Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

CHAPTER 9: SAMPLE PROGRAM – USER COMMUNICATION TXD & RXD

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Setting Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

BASIC Program Display Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

BASIC Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Ladder Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

CHAPTER 10: SAMPLE PROGRAM – MODEM COMMUNICATION

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Allocation Numbers (Remote Station) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Allocation Numbers (Local Station) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Ladder Diagram (Remote Station) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Ladder Diagram (Local Station) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

CHAPTER 11: TROUBLESHOOTING

Error Causes and Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

User Communication Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Troubleshooting Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

APPENDIX

Type List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

ASCII Character Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

INDEX

onlinecomponents.com

USER’SMANUAL 1-1

1: GENERAL INFORMATION

Introduction

This chapter describes general information about additional functions and specifications incorporated in the MICRO3C. For

general information, functions, and specifications inherited from the MICRO3, see the MICRO3User’s Manual.

Features

MICRO3Chas upgraded functions for communications. The new functions are particularly useful for modem communica-

tion, user communication, and monitoring data communication.

User Communication Function

MICRO3Chas an RS232C loader port in place of the RS485 loader port on the MICRO3. The more widely applicable

RS232C loader port can be directly connected to any equipment with an RS232C communication port.

New advanced instructions for transmitting and receiving data make it possible to set up a communication system using

various communication formats.

The user communication function can be used only in the standard processing mode, not in the high-speed processing

mode.

Increased Data Registers

Since data communication requires more data registers, MICRO3Chas 500 data registers (D0 through D499) expanded

from 100 data registers in the MICRO3. All expanded data registers except D499 can be used to program instructions.

In the high-speed processing mode, available data registers are limited to 32 (D0 through D31) as with the MICRO3.

Double-word Comparison of Data Registers

Double-word comparison instruction is added to compare data in data registers. Two consecutive data registers designated

by a source operand are compared with two consecutive data registers designated by another source operand. When used

with a repeat designation, one double-word comparison instruction can execute a maximum of 31 double-word compari-

son operations. With a repeat designation, the results of all double-word comparisons can not only be available individu-

ally but also be ANDed; so the comparison results can be easily determined even when comparing a large quantity of data.

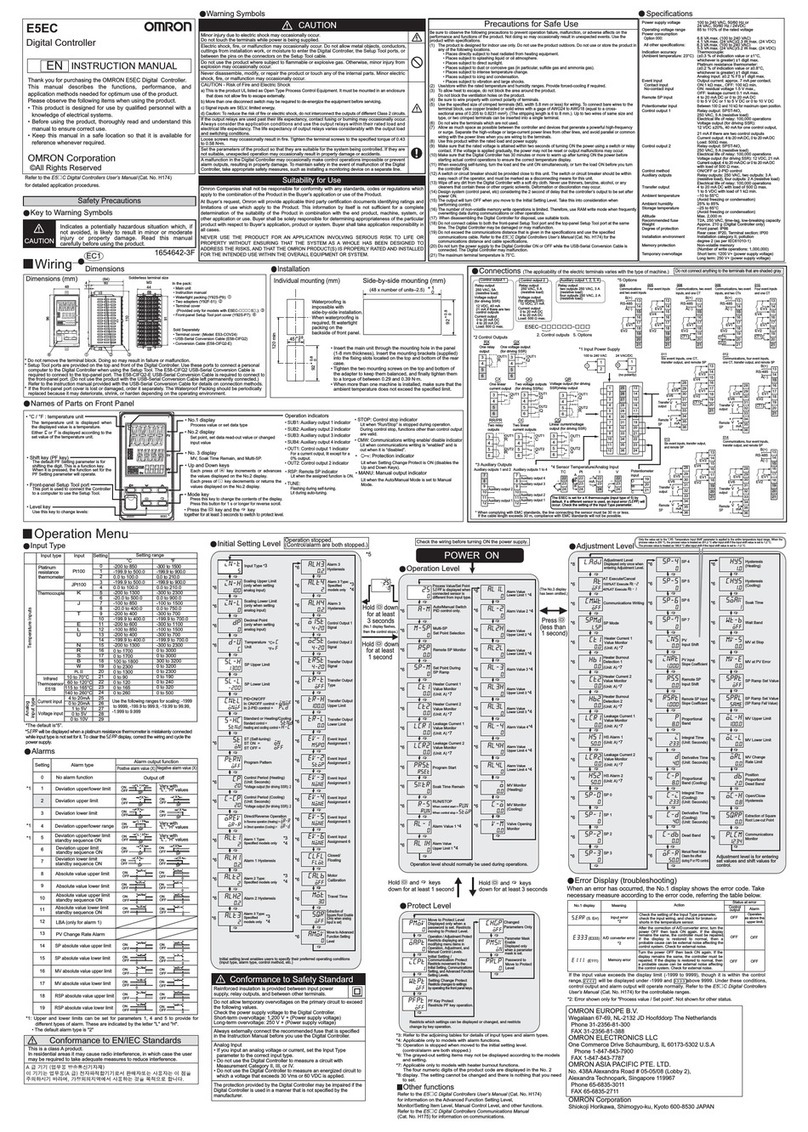

Parts Description

The figure above illustrates the 16-I/O

type MICRO3Cbase unit.

Function Selector Switch

Selects the station function in the expansion or data link system.

Analog Potentiometer

Sets the analog value for the analog timer, frequency, or pulse width

of pulse outputs.

MICRO3Chas only one potentiometer while 16- and 24-I/O type

MICRO3base units have two potentiometers.

Loader Port

For connecting the program loader or computer. The loader port can

also be used as a user communication port when user protocol is

selected with the protocol selector switch.

01

3

701

26

54

DATA LINK

ASGB

56710

3

701

26

54

Protocol Selector Switch

Selects the communication protocol for the loader port (loader proto-

col or user protocol) and the data link terminals (data link/expansion

link or loader protocol).

Data Link Terminals

For connecting the data link line in the expansion link or data link

system. The data link terminals can also be used for connecting the

program loader or computer when loader protocol is selected with the

protocol selector switch.

Communication Enable Button

Enables the communication mode selected with the protocol selector

switch. When the protocol selector switch setting is changed while

the MICRO3Cis powered up, press this button to enable the new com-

munication mode for the loader port and data link terminals.

onlinecomponents.com

1: GENERAL INFORMATION

1-2 USER’SMANUAL

Protocol Selector Switch

The protocol selector switch is used to select communication modes for the RS232C loader port and the RS485 data link

terminals. When the MICRO3Cis powered up, the selected communication modes are enabled automatically. If the protocol

selector switch setting is changed after the MICRO3Cis powered up, the new setting does not take effect until the commu-

nication enable button is depressed.

Communication Protocols for Loader Port and Data Link Terminals

Loader protocol: The protocol used for communication between MICRO3Cand program loader or CUBIQ on computer.

User protocol: The protocol used for user communication instructions (RS232C)

Data link protocol: The protocol used for communication in the expansion link or data link (RS485).

Note 1: When the protocol selector switch is set to 4, the communication parameters for the loader port are arbitrarily set

to the default values of FUN8 (loader port communication mode setting); baud rate 9,600 bps, terminator code 0D, 7 data

bits, even parity, 1 stop bit, and receive timeout 500 msec. Any change in FUN8 values does not take effect. The communi-

cation parameters for the data link terminals using the loader protocol are fixed and the same as the FUN8 default values.

Note 2: When the protocol selector switch is set to 5 through 7, the ERR1 indicator on the MICRO3Cblinks and the

MICRO3Cdoes not start to run.

Communication Enable Button

While the MICRO3Cis powered up, pressing the communication enable button for more than 4 seconds until the ERR1

indicator blinks once makes the MICRO3Cread the settings on the protocol selector switch and function selector switch.

Then the MICRO3Cupdates the communication modes for the loader port and data link terminals. This button is useful

when you want to change the communication mode without turning power off.

Function Selector Switch

When the protocol selector switch is set to 0 or 1, the data link terminals can be used for expansion link or data link com-

munication. Then the function selector switch selects the station function for each MICRO3Cin the expansion link or data

link system. The function of the function selector switch on the MICRO3Cis the same as that on the MICRO3. When the pro-

tocol selector switch is set to 2 through 4 to select loader protocol for the data link terminals, the function selector switch

setting has no effect.

MICRO3C Station Function by Function Selector Switch Position

Protocol Selector Switch Position Loader Port Protocol Data Link Terminal Protocol Remarks

0Loader protocol Data link protocol

1User protocol Data link protocol

2Loader protocol Loader protocol

3User protocol Loader protocol

4Loader protocol Loader protocol For maintenance (Note 1)

5 through 7 Reserved Reserved (Note 2)

Function Selector Switch Position MICRO3C Station Function

0Base or master station

1Slave station 1

2Slave station 2

3Slave station 3

4Slave station 4

5Slave station 5

6Slave station 6

7Expansion station

Warning If the communication enable button is pressed while the MICRO3Cis in operation, the user program

execution is stopped and all outputs are forced off.

onlinecomponents.com

1: GENERAL INFORMATION

USER’SMANUAL 1-3

System Setup

This section describes various system configurations using the MICRO3Cand required settings.

Selecting Communication Mode

Set the function selector switch and the protocol selector switch to select a desired communication mode for the loader

port and data link terminals. After changing the settings of the function selector switch and protocol selector switch while

the MICRO3Cis powered up, press the communication enable button for more than 4 seconds until the ERR1 indicator

blinks once; then the new communication mode takes effect. When the MICRO3Cis powered up, the MICRO3Cchecks the

settings of the function selector switch and protocol selector switch and enables the selected communication mode auto-

matically. You have to press the communication enable button only when you change the communication mode while the

MICRO3Cis powered up.

Connecting Program Loader to the Loader Port

When connecting a program loader to the loader port on the MICRO3C, set the protocol selector switch to 0, 2, or 4 to select

loader protocol for the loader port. Use the loader cable 3C to connect the program loader to the MICRO3Cloader port.

Connecting the Cable

The program loader has a cover on the top to select the loader cable

connection port or AC adapter jack. Slide the cover to the right to open

the loader cable connection port.

Connect the connector of the loader cable to the loader cable connec-

tion port on the program loader and the other connector of the cable to

the loader port on the MICRO3Cas indicated on the direction labels.

Warning If the communication enable button is pressed while the MICRO3Cis in operation, the user program

execution is stopped and all outputs are forced off.

Caution Special cables are needed to connect to the loader port on the MICRO3C. Loader cables for the

MICRO3such as FC2A-KL1 (2m/6.56 ft. long) and FC2A-KL2 (5m/16.4 ft. long) cannot be used for

the MICRO3C. Cables used for connecting to the loader port on the MICRO3Ccannot be used for the

MICRO3. If a wrong cable is used, machine damage may result.

When connecting and disconnecting the

loader cable, be sure to hold the connec-

tor. Since the connector has a latch, the

cable cannot be removed holding the

cable.

Make sure of correct direction of the

cable as indicated on the direction labels

attached near the connectors on the cable.

Loader Cable 3C

FC2A-KL3C (2m/6.56 ft. long)

The loader cable 3C has an

RS232C/RS485 converter in

the middle.

Slide the cover to the right

Loader Cable Connection Port

onlinecomponents.com

1: GENERAL INFORMATION

1-4 USER’SMANUAL

Connecting Program Loader to the Data Link Terminals

A program loader can also be connected to the data link terminals on the MICRO3Cwhen the protocol selector switch is set

to 2, 3, or 4 to select loader protocol for the data link terminals. This capability is particularly useful to monitor the com-

munication data transmitted through the loader port while user communication or modem communication is performed

with the protocol selector switch set to 3.

Connecting the Cable

The program loader has a cover on the top to select the loader cable

connection port or AC adapter jack. Slide the cover to the right to

open the loader cable connection port.

Connect the connector of the loader cable to the loader cable con-

nection port on the program loader and the three spade terminals on

the other end of the cable to the data link terminals on the MICRO3C

as indicated on the marker tubes.

Connecting an AC Adapter

Connect an AC adapter to the power supply box in the middle of the

loader cable 4C to supply power to the program loader. Applicable

output plug of the AC adapter is shown on the right.

Loader Cable 4C

FC2A-KL4C (2m/6.56 ft. long)

The loader cable 4C has a power

supply box in the middle.

AC Adapter (Output: 5V DC)

The loader cable 4C is not supplied with

an AC adapter, which must be prepared

by the user.

Note: AC adapters for IDEC’s FA series

PLCs cannot be used.

(RS485)

(RS485)

Slide the cover to the right

Loader Cable Connection Port

9.5 ø2.1

ø5.5

Polarity

+–

Dimensions in mm.

Caution When a program loader or computer running CUBIQ is connected to the data link terminals and a

communication device is connected to the loader port at the same time to perform communications

shown below, multi-stage comparison instruction HSC1 cannot be used.

Data link terminals: Used for loader protocol communication

Loader port: Used for loader protocol communication at 19,200 bps

onlinecomponents.com

1: GENERAL INFORMATION

USER’SMANUAL 1-5

Computer Link through Loader Port

To set up a 1:1 computer link system, connect an IBM PC or compatible to the MICRO3Cusing the computer link cable 4C

(FC2A-KC4C). Set the protocol selector switch to 0, 2, or 4 to select loader protocol for the loader port.

Computer Link through Data Link Terminals

A 1:1 computer link system can also be set up through the data link terminals on the MICRO3Cusing the computer link

cable 6C (FC2A-KC6C). Set the protocol selector switch to 2, 3, or 4 to select loader protocol for the data link terminals.

Computer Link Cable 4C

FC2A-KC4C

3m (9.84 ft.) long

To RS232C Port

To Loader Port

(RS232C) D-sub 9-pin

Female Connector

Cable Connector Pinouts

Pin Description

1DCD Data Carrier Detect

2RXD Receive Data

3TXD Transmit Data

4DTR Data Terminal Ready

5GND Signal Ground

6DSR Data Set Ready

7——

8CTS Clear to Send

9——

Computer Link Cable 6C

FC2A-KC6C

2m (6.56 ft.) long To RS232C Port

RS232C/RS485

Converter

D-sub 9-pin

Female Connector

Cable Connector Pinouts

Pin Description

1——

2RXD Receive Data

3TXD Transmit Data

4——

5GND Signal Ground

6——

7RTS Request to Send

8CTS Clear to Send

9——

Connect the three spade ter-

minals on the computer link

cable 6C to data link termi-

nals A, B, and SG as indi-

cated on the maker tubes.

A

B

SG

AC Adapter

Output: 5V DC

Connect an AC adapter to the RS232C/RS485 converter in the

middle of the computer link cable 6C.

The computer link cable 6C is not supplied with an AC adapter,

which must be prepared by the user.

For applicable output plug of the AC adapter, see page 1-4.

Note: AC adapters for IDEC’s FA series PLCs cannot be used.

(RS485)

ABSG

onlinecomponents.com

1: GENERAL INFORMATION

1-6 USER’SMANUAL

Connecting Modem through Loader Port

To connect a modem to the loader port on the MICRO3C, use the modem cable 1C (FC2A-KM1C). Set the protocol selector

switch to 1 or 3 to select user protocol for the loader port.

Connecting RS232C Equipment through Loader Port

To connect equipment with an RS232C communication port to the loader port on the MICRO3C, use the user communica-

tion cable 1C (FC2A-KP1C). One end of the user communication cable 1C is not provided with a connector, and it can be

terminated with a proper connector to plug in to communicate with the RS232C port.

When the protocol selector switch is set to 1 or 3, MICRO3Ccan communicate with RS232C equipment through the loader

port using the user protocol. When the protocol selector switch is set to 0, 2, or 4, MICRO3Ccan communicate through the

loader port using the loader protocol.

Modem Cable 1C

FC2A-KM1C

3m (9.84 ft.) long

To RS232C Port

To Loader Port

(RS232C) D-sub 25-pin

Male Connector

Cable Connector Pinouts

Pin Description

1FG Frame Ground

2TXD Transmit Data

3RXD Receive Data

4RTS Request to Send

5——

6——

7SG Signal Ground

8DCD Data Carrier Detect

20 DTR Data Terminal Ready

Modem

User Communication Cable 1C

FC2A-KP1C

2.4m (7.87 ft.) long To RS232C Port

To Loader Port

(RS232C) Attach a proper connector to the

open end referring to the cable

connector pinouts shown below.

Cable Connector Pinouts

Pin Description AWG# Color

1RTS Request to Send 28 Twisted Black

2DTR Data Terminal Ready 28 Yellow

3TXD Transmit Data 28 Blue

4RXD Receive Data 28 Green

5DSR Data Set Ready 28 Brown

6SG Signal Ground 28 Gray

7SG Signal Ground 26 Twisted Red

8NC No Connection 26 White

Cover — Shield — —

RS232C Equipment

Signal Direction

onlinecomponents.com

1: GENERAL INFORMATION

USER’SMANUAL 1-7

Link Systems

MICRO3Chas three link functions; expansion link, data link, and computer link. When using a link function, the function

selector switch and protocol selector switch have to be set and the FUN settings may be required. For details of these set-

tings, see Expansion Link Function and Data Link Function in the MICRO3User’s Manual and Computer Link 1:N Com-

munication on page 7-1 in this manual. The expansion link cannot be used in the data link system.

Expansion Link System

The expansion link system consists of two MICRO3Cor MICRO3base units connected through the data link terminals using

the optional expansion cable FC2A-KE1 (250 mm/9.84" long) or a shielded twisted pair cable as shown below. The cable

for the expansion link system can be extended up to 200 meters (656 feet). Every MICRO3Cor MICRO3base unit can be

used as an expansion station.

Data Link System

The data link system consists of one master station connected to a maximum of six slave stations to communicate control

data for distributed control. Every MICRO3Cor MICRO3base unit can be used as a master or slave station. When a slave sta-

tion performs communication at 19,200 bps through the loader port, multi-stage comparison instruction HSC1 cannot be

used at the slave station.

Computer Link System

In the computer link system, a personal computer is connected to one or a maximum of 32 MICRO3Cbase units to control

the operation of all MICRO3Cbase units. The 1:1 computer link system requires the computer link cable 4C (FC2A-KC4C)

or computer link cable 6C (FC2A-KC6C). The 1:N computer link system using MICRO3Cbase units requires RS232C/

RS485 converter FC2A-MD1 and cables; computer link interface unit FC2A-LC1 is not required.

Base Station

Function selector switch: 0

Protocol selector switch: 0 or 1

Expansion Station

Function selector switch: 7

Protocol selector switch: 0 or 1

The RUN indicator on the expan-

sion station remains off whether the

base station is running or stopped.

Master Station

Function selector switch: 0

Protocol selector switch: 0 or 1

Slave Station 6

Function selector switch: 6

Protocol selector switch: 0 or 1

Slave Station 2

Function selector switch: 2

Protocol selector switch: 0 or 1

Slave Station 1

Function selector switch: 1

Protocol selector switch: 0 or 1

RS232C/RS485

Converter

FC2A-MD1

1st Unit

Function selector switch: 0

Protocol selector switch: 2, 3, or4

FUN9: 0

2nd Unit

Function selector switch: 0

Protocol selector switch: 2, 3, or 4

FUN9: 1

Nth Unit (N ≤32)

Function selector switch: 0

Protocol selector switch: 2, 3, or 4

FUN9: N–1

The figure above illustrates a 1:N computer link system for MICRO3C.

onlinecomponents.com

1: GENERAL INFORMATION

1-8 USER’SMANUAL

Communication Specifications

This section describes the MICRO3Ccommunication specifications. For general specifications, function specifications, I/O

specifications, and program loader specifications, see the MICRO3User’s Manual.

Loader Port Communication Specifications

User Communication Mode Specifications

When the protocol selector switch is set to 1 or 3 to select user protocol for the loader port, the MICRO3Ccan communicate

through the loader port with external equipment which has an RS232C port, such as a computer, modem, printer, or bar-

code reader.

Using transmit and receive instructions for user communication, user programs can be created to match the communica-

tion protocol of the equipment to communicate with. Determine the possibility of communication referring to the user

communication mode specifications described below:

Standards EIA RS232C

Maximum Cable Length 15m (49.2 ft.)

Communication

Parameters

Baud Rate 1200, 2400, 4800, 9600, 19200 bps

Data Bits 7 or 8 bits

Parity Odd, Even, None

Stop Bits 1 or 2 bits

Receive Timeout

10 to 2550 msec

(In the user communication, receive timeout is disabled when 2550 msec is

selected.)

Connection to Program Loader Using optional loader cable 3C (FC2A-KL3C)

Connection to RS232C Equipment Using optional user communication cable 1C (FC2A-KP1C) or other cables

Standards EIA RS232C

Control Signal TXD, RXD, DTR, RTS, DSR

Baud Rate 1200, 2400, 4800, 9600, 19200 bps

Data Bits 7 or 8 bits

Parity Odd, Even, None

Stop Bits 1 or 2 bits

Receive Timeout 10 to 2550 msec (10-msec increments) or none

(Receive timeout is disabled when 2550 msec is selected.)

Communication Method Start-stop synchronization system half-duplex

Maximum Transmit Data 200 bytes

Maximum Receive Data 200 bytes

onlinecomponents.com

1: GENERAL INFORMATION

USER’SMANUAL 1-9

Data Link Terminal Communication Specifications

Data Link Terminal Communication with Program Loader

When the protocol selector switch is set to 2, 3, or 4 to select loader protocol for the data link terminals, the MICRO3Ccan

communicate through the data link terminals with the program loader or computer to monitor the MICRO3Coperation,

transfer user programs, and perform other communications. The communication parameters using the loader protocol for

the data link terminals are fixed to the same values as the FUN8 (loader port communication mode setting) default shown

below and cannot be selected unlike the communication through the loader port.

Data Link Terminal Communication Parameters (Loader Protocol)

When the protocol selector switch is set to 2 or 4, the MICRO3Ccan perform loader communication through both the loader

port and data link terminals at the same time. If data write operation (write N bytes or write 1 bit) is attempted to the same

operand through both the loader port and data link terminals at the same time, the command through the data link termi-

nals has priority although communication error does not occur at both ports.

1. While a user program is written through either the loader port or data link terminals, a user program cannot be written

through the other port.

The prior write user program operation is executed normally, but the subsequent write user program operation results

in a protect error.

2. While a user program is written through either the loader port or data link terminals, a user program cannot be read

through the other port.

The prior write user program operation is executed normally, but the subsequent read user program operation results in

a protect error.

3. A user program cannot be read through either the loader port or data link terminals if a user program is written through

the other port before the read user program operation is completed.

The subsequent write user program operation is executed normally, but the prior read user program operation may fail

to read the complete user program and result in a CRC error.

Standards EIA RS485 (termination resistor is not required)

Recommended Cable ø0.9 mm shielded twisted cable

Conductor Resistance 85 Ω/km maximum

Shield Resistance 12 Ω/km maximum

Maximum Cable Length 200m (656 ft.)

Isolation Between data link terminals of multiple MICRO3C units: Not isolated

Baud Rate Expansion or data link communication: 19200 bps (fixed)

Loader protocol communication: 9600 bps (fixed)

Communication Delay

Expansion link: Master station normal scan time + approx. 9 to 10 msec

Data link: Master station normal scan time + approx. 12.5 to 13 msec + Slave

station scan time

Connection to Program Loader Using optional loader cable 4C (FC2A-KL4C)

Baud Rate 9600 bps

Terminator Code 0D (CR)

Data Bits 7 bits

Parity Even

Stop Bit 1 bit

Receive Timeout 500 msec

Caution Some of the program transfer operation cannot be performed as described below:

onlinecomponents.com

1: GENERAL INFORMATION

1-10 USER’SMANUAL

Dimensions

85 mm (3.346")

16-I/O Type: 135 mm (5.315")

24-I/O Type: 165 mm (6.496")

60 mm (2.362")

95 mm (3.740")

30 mm

(1.181")

185 mm (7.283")

80 mm (3.150") 25 mm

(0.984")

16-I/O Type: 116 mm (4.567")

24-I/O Type: 146 mm (5.748")

M4 tapped holes or

ø4.5 (0.177" dia.) drilled holes

77 mm

Minimum center to center

Minimum

29 mm (1.142")

(3.031")

center to center

58 mm (2.283")

Mounting Hole Layout

MICRO3C Base Unit Program Loader

onlinecomponents.com

USER’SMANUAL 2-1

2: ALLOCATION NUMBERS

Introduction

This chapter describes allocation numbers available only for the MICRO3C. For details about allocation numbers shared

with the MICRO3, see the MICRO3User’s Manual.

Expanded functions in the MICRO3Cinclude:

MICRO3Chas 500 data registers D0 through D499 while MICRO3has 100 data registers D0 through D99. D499 is used to

enable or disable expansion control data registers D484 through D498 and cannot be used as an ordinary data register to

store data.

Special internal relay M307 has different functions when used as a base or expansion station in the expansion link system

or when used as a master station or slave station in the data link system.

Allocation Numbers

Available I/O numbers depend on the type and combination of the MICRO3Cbase units used in the expansion link system.

For details of available I/O numbers in the expansion link system, see the next page.

Notes: Input and output allocation numbers for the expansion station start with I20 and Q20. For the I/O allocation num-

bers in the expansion link system, see the next page.

The maximum points shown in ( ) are values for the high-speed processing mode.

The same number cannot be used for a counter and a timer in a user program.

Internal relays M260 through M287 have special functions in the modem mode. See page 4-2.

Data register D499 is reserved to enable or disable expansion control data registers D484 through D498 and cannot be

used as an ordinary data register to store data. For details, see page 2-4.

Operand Processing Mode Allocation Number Maximum Points

Input

Standard and

High-speed I0 - I7 I10 - I15 14 points (Base)

+

14 points (Expansion)

Standard only I20 - I27 I30 - I35

Output

Standard and

High-speed Q0 - Q7 Q10 - Q11 10 points (Base)

+

10 points (Expansion)

Standard only Q20 - Q27 Q30 - Q31

Internal Relay

Standard and

High-speed

M0 - M7 M10 - M17 M20 - M27

M30 - M37 M40 - M47

232 points

(40 points)

Standard only

M50 - M57 M60 - M67 M70 - M77

M80 - M87 M90 - M97 M100 - M107

M110 - M117 M120 - M127 M130 - M137

M140 - M147 M150 - M157 M160 - M167

M170 - M177 M180 - M187 M190 - M197

M200 - M207 M210 - M217 M220 - M227

M230 - M237 M240 - M247 M250 - M257

M260 - M267 M270 - M277 M280 - M287

Catch Input Relay Standard and

High-speed M290 - M297 8 points

(8 points)

Special Internal

Relay

Standard and

High-speed M300 - M307 M310 - M317 16 points

(16 points)

Timer

Standard and

High-speed T0 - T15

32 points total

(16 points total)

Standard only T16 - T31

Counter

Standard and

High-speed C0 - C15

Standard only C16 - C31

Shift Register

Standard and

High-speed R0 - R31 64 points

(32 points)

Standard only R32 - R63

Data Register

Standard and

High-speed D0 - D31 500 points

(32 points)

Standard only D32 - D499

onlinecomponents.com

2: ALLOCATION NUMBERS

2-2 USER’SMANUAL

I/O Allocation Numbers for Expansion Link System

Input and output allocation numbers do not continue from the base station to the expansion station. At the expansion sta-

tion, inputs start at I20 and outputs start at Q20. Inputs and outputs are allocated depending on the MICRO3Cbase units

used in the expansion link system as shown below:

I/O Points MICRO3C Base Station

I/O Allocation Numbers

MICRO3C Expansion Station

I/O Allocation Numbers

Total IN/OUT

16 9/7

16-I/O Type

———

I0 - I7

I10 Q0 - Q6

24 14/10

24-I/O Type

———

I0 - I7

I10 - I15

Q0 - Q7

Q10 - Q11

32 18/14

16-I/O Type 16-I/O Type

I0 - I7

I10 Q0 - Q6 I20 - I27

I30 Q20 - Q26

40 23/17

16-I/O Type 24-I/O Type

I0 - I7

I10 Q0 - Q6 I20 - I27

I30 - I35

Q20 - Q27

Q30 - Q31

24-I/O Type 16-I/O Type

I0 - I7

I10 - I15

Q0 - Q7

Q10 - Q11

I20 - I27

I30 Q20 - Q26

48 28/20

24-I/O Type 24-I/O Type

I0 - I7

I10 - I15

Q0 - Q7

Q10 - Q11

I20 - I27

I30 - I35

Q20 - Q27

Q30 - Q31

onlinecomponents.com

2: ALLOCATION NUMBERS

USER’SMANUAL 2-3

Special Internal Relays

Internal relays M290 through M317 are special internal relays with the following functions:

Note: M290 through M297 and M301 are used only for reading in the user program, but can be directly set or reset using

the program loader or optional software CUBIQ on a computer.

M307 Link Communication Initialize Flag (Master Station)/Link Communication Stop Flag (Slave Station)

Special internal relay M307 has different functions when used as a base or expansion station in the expansion link system

or when used as a master station or slave station in the data link system.

Base or master station: Link communication initialize flag

When M307 at the base or master station is turned on during operation, the link configuration is checked to initialize the

expansion or data link system. When an expansion station or slave station is powered up after the base or master station,

turn M307 on to initialize the link system. After an expansion link or data link setup is changed, M307 must also be turned

on to ensure correct communication.

Slave station: Link communication stop flag

When a slave station does not receive communication data from the master station for 800 msec or more in the data link

system, M307 turns on. When the slave station receives correct communication data, M307 turns off.

In the expansion station, M307 has no effect and cannot be monitored using the program loader.

Allocation Number Description CPU Stopped Power OFF

M290

Catch Input Status Set

(See Note below)

Input I0 Operating Cleared

M291 Input I1 Operating Cleared

M292 Input I2 Operating Cleared

M293 Input I3 Operating Cleared

M294 Input I4 Operating Cleared

M295 Input I5 Operating Cleared

M296 Input I6 Operating Cleared

M297 Input I7 Operating Cleared

M300 Start Control Maintained Maintained

M301 Initialize Pulse (See Note below) Cleared Cleared

M302 All Outputs OFF Cleared Cleared

M303 Carry (Cy) or Borrow (Bw) Cleared Cleared

M304 User Program Execution Error Cleared Cleared

M305 Link Communication Error

(Expansion mode and data link mode) Maintained Cleared

M306 Link Communication Prohibit Flag

(Expansion mode and data link mode) Maintained Maintained

M307

Link Communication Initialize Flag (Master Station)

(Expansion mode and data link mode) Cleared Cleared

Link Communication Stop Flag (Slave Station)

(Data link mode)

M310 1-sec Clock Reset Cleared Cleared

M311 1-sec Clock Operating Cleared

M312 100-msec Clock Operating Cleared

M313 10-msec Clock Operating Cleared

M314 Timer/Counter Preset Value Changed Maintained Maintained

M315 High-speed Counter Soft Reset Maintained Cleared

M316 High-speed Counter (HSC3) Overflow Cleared Cleared

M317 In-operation Output Cleared Cleared

onlinecomponents.com

2: ALLOCATION NUMBERS

2-4 USER’SMANUAL

Data Register Allocation Numbers

Available data registers are limited in the high-speed processing mode or in the data link system configuration. Some data

registers are allocated to special functions in the data link system as shown below. For the data link function, see the

MICRO3User’s Manual. D100 through D209, D492, and D493 have special functions in the modem mode. See page 4-2.

Note: When FUN10 is set to enable control data registers, selected data registers D90 through D99 work as control data

registers; others can be used as ordinary data registers. For details of the data link function, see the MICRO3User’s Manual.

Expansion Control Data Registers

Data registers D484 through D499 are allocated as expansion control data registers. D499 is used to enable or disable

expansion control data register service for D484 through D498 divided into group 0 through 3. Data registers in the group

disabled for expansion control data registers can be used as ordinary data registers.

D499 cannot be used as an ordinary data register and must not be programmed to store data of operation results.

Data Register

Number

Standard Processing Mode High-speed

Processing Mode

Other than Data Link Data Link

(Master Station)

Data Link

(Slave Station)

D0 to D31

Available

Available Available

Available

D32 to D59

Not available

D60 to D84 For data link

D85 to D89 For data link

D90 to D99 Can be designated as control data registers using FUN10. (Note)

D100 to D483 Available

D484 to D485 When expansion control data register service is enabled for each group of these

data registers using D499, the selected data registers work as expansion con-

trol data registers; others can be used as ordinary data registers.

When expansion control data register service is disabled using D499, these

data registers can be used as ordinary data registers.

D486 to D491

D492 to D495

D496 to D498

D499 Reserved to enable or disable expansion control data register service.

Group Expansion Control DR Description

—D499 Expansion control data register service selection

0

D498 Day (Calendar)

D497 Month (Calendar)

D496 Year (Calendar)

1

D495 Modem mode selection

D494 Reserved

D493 Modem mode status

D492 Protocol selection in modem mode

2

D491 Control signal status

D490 DSR control signal option

Available only for communication through

the loader port using user protocol

(protocol selector switch set to 1 or 3)

D489 DTR control signal option

D488 RTS control signal option

D487 Reserved

D486 RTS control signal ON/OFF timer

3

D485 (Lower byte) Protocol selector switch value

D485 (Upper byte) For maintenance

D484 (Lower byte) Function selector switch value

D484 (Upper byte) For maintenance

onlinecomponents.com

2: ALLOCATION NUMBERS

USER’SMANUAL 2-5

D499 Expansion Control Data Register Service Selection

D499 is used to enable or disable expansion control data register service for D484 through D498 divided into group 0

through 3.

Store a value in D499 to enable or disable expansion control data service for group 0 through 3 as described below:

The D499 value marked with indicates that the data registers in the corresponding group are enabled for expansion con-

trol data register service. The enable/disable of expansion control data register service is determined by the lower 4 bits in

D499. Although a value over 15 can be entered to D499, upper 12 bits do not take effect.

Group 0

D498 Day (Calendar)

D497 Month (Calendar)

D496 Year (Calendar)

When group 0 is enabled as expansion control data registers, the calendar data are stored to D496 through D498. The year

is indicated with the lower 2 digits.

Group 1

D495 Modem mode selection

When group 1 is enabled as expansion control data registers and “1” is set to D495, the modem mode is enabled. When

“0” is set to D495, the modem mode is disabled. For the modem mode, see page 4-1.

D494 Reserved

D493 Modem mode status

When the modem mode is enabled (see above), D493 stores a modem mode status.

D492 Protocol selection in modem mode

When the modem mode is enabled (see above), the protocol at the loader port is switched from the user protocol depend-

ing on the value in D492 after the telephone line is connected.

D492 = 1: User protocol is continued at the loader port

D492 = 0: Loader protocol is enabled at the loader port

Group D499 Value

0123456789101112131415

0 (D496-D498)

1 (D492-D495)

2 (D486-D491)

3 (D484-D485)

D493 Value Description Remarks

30h AT command completed normally AT command (start IR) is completed normally.

31h Issuing AT command

32h AT command execution error See the result code stored in data registers D104 through D119.

Check the modem power, modem cable, and the remote modem.

33h Two or more start IRs are on Correct the program so that only one start IR goes on at a time.

34h Modem mode enabled

35h Start IR program error Correct the program so that only the disconnect command is issued

while the line is connected.

36h (Reserved)

37h (Reserved)

38h Retrying AT command

39h AT command program error Correct the program to include 0Dh in the AT command.

Warning

D499 cannot be used as an ordinary data register and must not be programmed to store data of oper-

ation results. If an unexpected value is set to D499, the modem mode may be enabled or disabled

during operation.

Table of contents

Other IDEC Controllers manuals

IDEC

IDEC SmartAXIS Touch FT1A Series User manual

IDEC

IDEC microsmart pentra Owner's manual

IDEC

IDEC MICRO3 User manual

IDEC

IDEC OpenNet series User manual

IDEC

IDEC SmartAXIS Touch FT1A Series User manual

IDEC

IDEC FS1A-C11S User manual

IDEC

IDEC MICROSmart FC4A Series Operating and safety instructions

IDEC

IDEC MICROSmart FC5A Series User manual

IDEC

IDEC SE9Z-HC User manual

IDEC

IDEC MICROSmart FC6A Series Owner's manual