IDEC HR1S-ATE User manual

2

114

9999

35 35

11445

45

Type Package Quantity: 1

Type No. Terminal Style

HR1S-ATE5110 Integrated Terminal Block

HR1S-ATE5110P Removable Terminal Block

Dimensions

LED Indicator

HR1S-ATE Safety Relay Modules

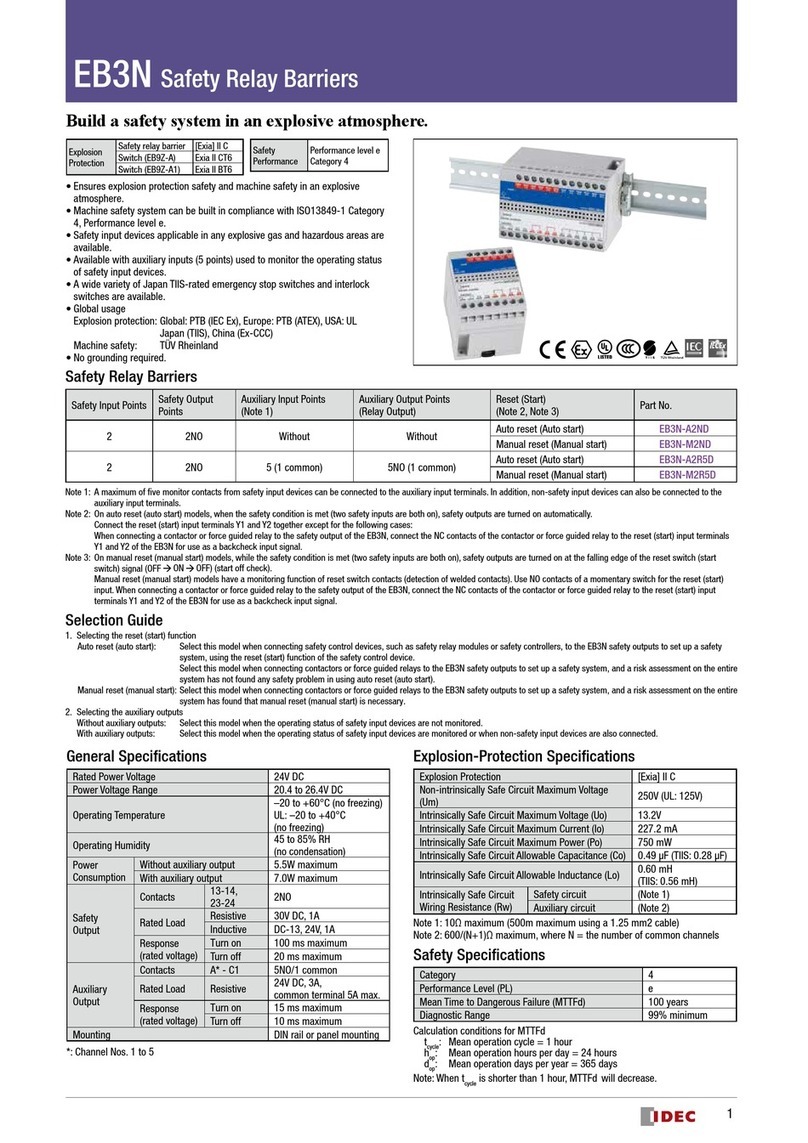

Specifications

Applicable Standards

EN 60204-1: 2007

EN 60947-1: 2007

EN 60947-5-1:2004

EN 61000-6-2: 2005

EN 61000-6-4: 2007

EN 62061: 2005

EN ISO 13849-1: 2008

EN ISO 13849-2: 2008

Applicable Standards

for Use

EN 60204-1: 2006

EN ISO 13850: 2008

Performance level (PL) e (EN ISO 13849-1)

Safety Category 4 (EN ISO 13849-1)

Safety Integrity Level (SIL) 3 (EN 62061)

Stop Category 0, 1 (EN 60204-1) (Note)

Operating Temperature –10 to +55ºC (no freezing)

Relative Humidity 30 to 85% RH (no condensation)

Impulse Withstand Voltage 4 kV (IEC 60947-5-1)

Shock Resistance 150 m/s2, 11m sec, 3 shocks in each 3 axes

Vibration Resistance 10 to 60 Hz, amplitude 0.35 mm

60 to 150 Hz, acceleration 50 m/s2

Degree of Protection Terminal: IP20 Enclosure: IP40

Rated Voltage 24V AC –20% +10%

24V DC –20% +20%

Power Consumption 24V AC: 8 VA max. 24V DC: 4W max.

Overcurrent Protection Built-in, electronic

Minimal Applicable Load 17V DC / 10 mA (initial value)

Response Time

ON→OFF: 20 ms max. (instantaneous output)

Overvoltage Category III

Pollution Degree 2

Rated Insulation Voltage 300V AC

No. of

Outputs

Safety Circuit 2NO

Time-delay Circuit 3NO

Auxiliary

Circuit

Contact None

Transistor 4

Output Contact

Ratings

Safety

Circuit

AC15 C300 (230V AC / Ie=0.75A)

DC13 24V DC / Ie=1A

Time-

delay

Circuit

AC15 C300 (230V AC/ Ie=0.75A)

DC13 24V DC / Ie=1A

Preset Time 0, 0.5, 1, 2, 4, 6, 8, 10, 15, 20, 25, 30 sec.

Auxiliary Circuit 24V DC / 20 mA (PNP)

Mechanical Durability 10,000,000 operations

Electrical Durability See page 4

Rated Current Total output: 8A max. 1 output 4A max.

HR1S-ATE5110 Integrated Terminal Type•

HR1S-ATE5110P Removable Terminal Type•

New compact safety relay modules. Size is reduced by 50% from conventional models.

Plug-in terminal structure enables simple wiring.

EN ISO 13849-1 performance level e, safety category 4•

compliant, and EN 62061 safety integrity level 3.

Integrated and removable teminal styles available.•

Compact design: 45 mm in width.•

Time delay outputs: 3NO•

Auxiliary output enables power supply monitoring, inputs•

(2 channels), and a time delay output.

Environmentally friendly, RoHs directive compliant.•

UL Listed, CSA certified,•

TÜV NORD approved.

Wire Size

HR1S-ATE5110 Single wire: 0.2 to 2.5 mm2max. (24~14 AWG)

Multiple wires: 0.14 to 0.75 mm2max.

HR1S-

ATE5110P

Single wire: 0.2 to 2.5 mm2max.(24~14 AWG)

Multiple wires: 0.2 to 1.5 mm2max.

Weight (approx.) 280g

Note: Safety output contact Stop category 0

Time-delay output contact Stop category 1

Use a 4A fuse (Type gG) for power protection.Use a 6A fuse (Type gG)•

for safety output protection. Use a 4A fuse (Type gG) for time-delay output

and auxiliary output protection.

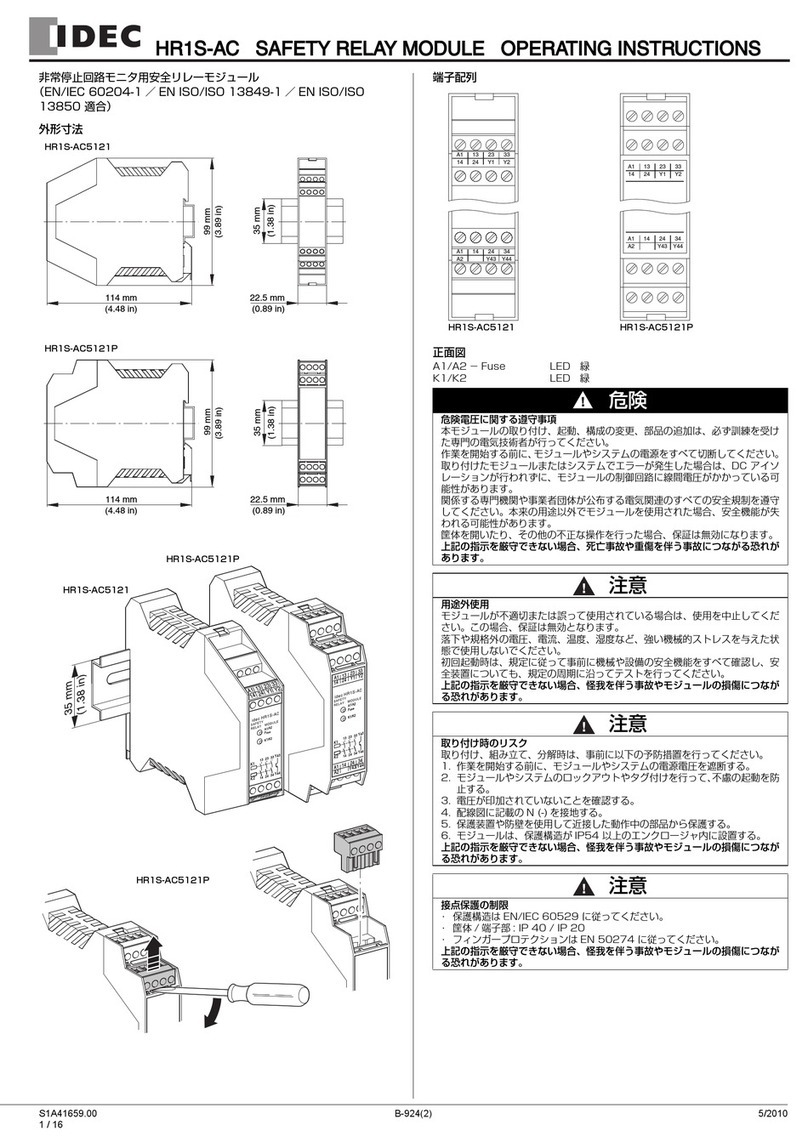

A1/A2

Fuse

Input A

S12

Input B

S22

Stop 1

A1/A2 Fuse: Turns on when power circuit is normal.•

Input A S12:Turns on when S11–S12 is closed.•

Input B S22:Turns on when S21–S22 is closed.•

Stop1: Turns on when the time-delay output•

circuits 57-58, 67-68, and 77-78 are

closed.

All dimensions in mm.

(100705)

3

HR1S-ATE Safety Relay Modules

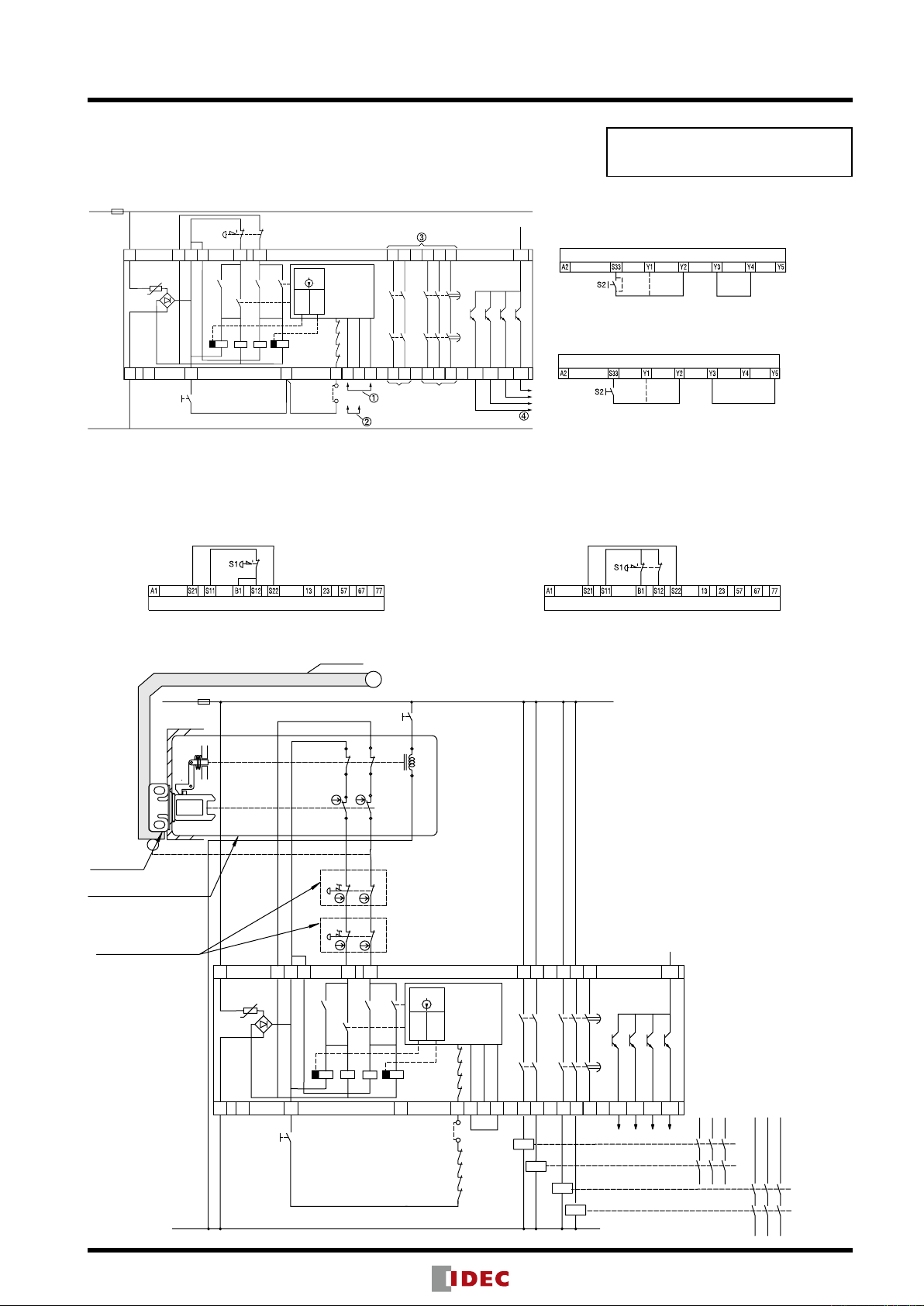

HR1S-ATE Wiring Diagram

Safety Category 4 (3) Circuit•

(using an emergency stop switch) (Note)

Safety•Category 3 Circuit (using multiple emergency stop switches)

Emergency stop switch - Input 2 channels•

When not detecting short-circuit

(B1-S12 short-circuit not detected)

Emergency stop switch - Input 1 channel•

When not detecting short-circuit (All failures such as short-

circuit of emergency stop switch wiring not detected)

When monitoring the start switch•

(Y3-Y5 short-circuited)

When not monitoring the start switch•

(Y3-Y4 short-circuited)

(automatic start when S33-Y2 is short-circuited)

S2

S1

S11S21

A1 13 57 67

A2

S33

Y1

Y2 Y3 Y4 Y5 14 24 6858

S22

B1

S12

23

F1

K2 K4

K1

K1

K3

L1 (+)

N(–)

K3

K4

K1

K2

Timer 1

Time (s)

Timer 2

T

ESC

K1

K2

K3

K4

HR1S-ATE

LOGIC

77

78 Y88 Y89 Y90 Y91

Y+

(A1/A2)

(S12)

(S22)

(Stop 1)

+24V

(max. 4A)

Stop

Category 0

Stop

Category 1

K2

HR1S-ATE

HR1S-ATE

HR1S-ATE

HR1S-ATE

When monitoring the start switch, starts when switched off (default setting/recommended)

When monitoring the start switch, starts when switched on

Outputs must be fused (see the instruction manual for maximum fuse size)

To PLC, etc.

Note: When using off-delay output, safety category becomes 3.

S1 = Emergency stop switch with 2 NC contacts (recommended)

S2 = Start switch

ESC = External start conditions

Y1 (S33)– Y2 = Feedback loop

S4

S11

S21

A1 13 57 67

A2

S33

Y1 Y2 Y3 Y4 Y5 14 24 6858

S22

B1

S12

23

K2 K4K1

K1

K3

N(–)

K3

K4

K1

K2

Timer 1

Time (s)

Timer 2

T

ESC

K1

K2

K3

K4

HR1S-ATE

LOGIC

77

78 Y88 Y89 Y90 Y91

Y+

(A1/A2)

(S12)

(S22)

(Stop1)

+24V

K2

L1 (+) F1

S3 21

22

11

12

S2 21

22

11

12

A2(+)

22

21

11

42

A1(–)

S1

2

1

1

2

S5

S6

52

41 51

12

Door Cover

K5

K6

K7

K8

K5

K6

K7

K8

External Output Circuit

S1:HS5E-D4001 Interlock Switch with Solenoid

S2, 3:XW1E-BV402 Emergency Stop Switch

S4:Start Switch (HW series momentary)

S5:Unlocking Enabling Switch

S6:Limit Switch, etc.

ESC:External Start Condition

K5 to 8:Contactor (forced guided type)

F1:Fuse 4A (gG)

Operations of Interlock Switch with Solenoid

(Stop)

Machine stops →Unlocking enabling switch ON →

Safety output OFF →Door cover released

(Start)

Door cover closed →Safety relay module start switch ON

→ Safety output ON →Machine starts

Operations of Emergency stop switch

(Stop)

Press emergency stop switch →Safety output OFF →

Machine stops

(Reboot)

Emergency stop switch reset →

Safety relay module start switch ON →Safety output ON

→Machine starts

Read instructions before configuring circuits.

HS5E-D4001

Interlock Switch with Solenoid

XW1E-BV402

Emergency stop switch

HS9Z-A51

Actuator

Safety category is achieved by an entire control

system. Take the connected safety equipment

and wiring into consideration.

(100705)

Power ON

With Start Switch

Output

Emergency Stop Switch (NC1)

➀

➀

When monitoring the start switch,

with Y3-Y5 jumpered

(default setting/recommended)

Operation

ON

Tv = 0 to 30 seconds

adjustable

OFF

➁

When monitoring the start switch,

with Y3-Y4 jumpered

➁

Emergency Stop Switch (NC2)

Output 13-14 (NO)

Output 23-24 (NO)

Output 57-58 (NO)

Output 67-68 (NO)

Output 77-78 (NO)

Start Switch

Start Switch

Start Switch

External Start Conditions

Transistor Output Y89 (S12)

Transistor Output Y89 (S12)

Transistor Output Y90 (S22)

Transistor Output Y90 (S22)

Transistor Output Y88 (A1/A2)

Transistor Output Y91 (Stop1)

Start

Emergency Stop

Not Operated

Emergency Stop

Operated

Without Start Switch

Emergency Stop Switch

(NC2 or NC1)

Emergency Stop Switch

(NC1 or NC2)

tmax.= 75ms∗

➂➂

Without start switch,

with Y3-Y4 and S33-Y1 jumpered

∗When using without start switch,

the input synchronization time

should be 75 ms max.

HR1S-ATE Operation Chart

HR1S-ATE Safety Relay Modules

Residual Risk (EN ISO/ISO12100-1)

The wiring diagrams on page 3 have been tested under actual

operating conditions. The HR1S-ATE safety relay module can be

used in a safety circuit by connecting to safety equipment compli-

ant to applicable standards. Consider residual risk in the following

circumstances:

a) When it is necessary to modify the recommended circuit and if

added/modified components are not properly integrated into the

control circuit.

b) When applicable standards of machine operation are not observed,

or when the machine is not adjusted or maintained properly

(adhere to a strict maintenance schedule).

c) When the contacts of relays and contactors for connected with

safety outputs are not forced guided (compliant with EN 50205).

Instructions

Only persons with technical expertise may install, startup, modify,•

or retrofit the HR1S-ATE safety relay module.

Turn the power off before installation, removal, wiring, mainte-•

nance, or inspection of the safety relay module. If an error occurs,

line voltage may be present at the control circuit in devices without

DC isolation.

Observe all electrical safety regulations issued by appropriate•

technical authorities or trade association. The safety function can

be lost if the device is not used for its intended purpose.

Do not open the housing or perform invalid operation, otherwise•

the warranty will become voided.

Negligence to observe the following instructions may cause ac-•

cidents that may result in death or serious injuries.

Connect the wires according to the wiring diagrams shown on⋅

page 3.

Connect the wires according to applicable standards.⋅

The contacts of relays and contactors to connected with safety⋅

outputs must be forced guided (compliant with EN 50205).

For external fusing, use an appropriate fuse size and connect ac-⋅

cording to the wiring diagram on page 3.

When maintaining or adjusting machines, observe the mainte-⋅

nance schedule.

If the recommended circuit is modified or if components are⋅

added/modified, make sure that they are properly integrated into

the control circuit.

Relays must have mechanically-linked contacts.⋅

Follow required standards applicable to the operation of the ma-⋅

chine. When maintaining or adjusting machines, observe a proper

maintenance schedule.

Do not use the module if it has been subjected to improper or•

incorrect use. In this case, the warranty will be voided.

Do not use the HR1S-ATE under stressful conditions such as ir-•

regular voltage, current, temperature, or humidity.

Before starting up your equipment for the first time, be sure to•

check all safety functions according to regulations and observe

the specified test cycles for safety equipment.

Perform the following precautionary steps prior to installation, as-•

sembly, or disassembly of the system.

1. Disconnect the supply voltage to the equipment / system prior to

starting work.

2. To prevent accidental activation of the module or system, per-

form lock-out or tag-out.

3. Make sure that no voltage is applied.

4. Ground N (–) as shown in the wiring diagram on page 3.

5. Protect against adjacent operating components using guards or

barriers.

6. The devices must be installed in a cabinet with a protection class

of at least IP54.

Contact Protection•

Type of protection according to EN/IEC 60529

Housing / Teminals: IP40 / IP20

Finger-safe protection according to EN 50274

Connect external fuse according to the wiring diagram on page 3.•

Output Contact Electrical Life

(Safety Circuit, Time-delay Circuit, Auxiliary Circuit)

Operating Current × 0.1A

Operations

AC15:

230V

AC1:

230V

DC1: 24V

DC13: 24V

(<0,1Hz)

7-31, Nishi-Miyahara 1-Chome, Yodogawa-ku, Osaka 532-8550, Japan

Tel: +81-6-6398-2571, Fax: +81-6-6392-9731

E-mail: [email protected]

Specifications and other descriptions in this catalog are subject to change without notice.

Cat. No. EP1318-0-2 JULY 2010 PDF

IDEC ELECTRONICS LIMITED

IDEC ELEKTROTECHNIK GmbH

IDEC (SHANGHAI) CORPORATION

IDEC (BEIJING) CORPORATION

Tel: +86-10-6581-6131

IDEC (SHENZHEN) CORPORATION

Tel: +86-755-8356-2977

IDEC IZUMI (H.K.) CO., LTD.

IDEC TAIWAN CORPORATION

Tel: +886-2-2698-3929 E-mail: service@tw.idec.com

IDEC IZUMI ASIA PTE. LTD.

www.idec.com

IDEC CORPORATION (USA)

Tel: +1-408-747-0550 / (800) 262-IDEC (4332)

E-mail: [email protected]

IDEC CANADA LIMITED

Tel: +1-905-890-8561, Toll Free: (888) 317-4332

E-mail: [email protected]

IDEC AUSTRALIA PTY. LTD.

Tel: +61-3-9763-3244, Toll Free: 1800-68-4332

E-mail: [email protected]

Other manuals for HR1S-ATE

2

This manual suits for next models

2

Other IDEC Relay manuals

IDEC

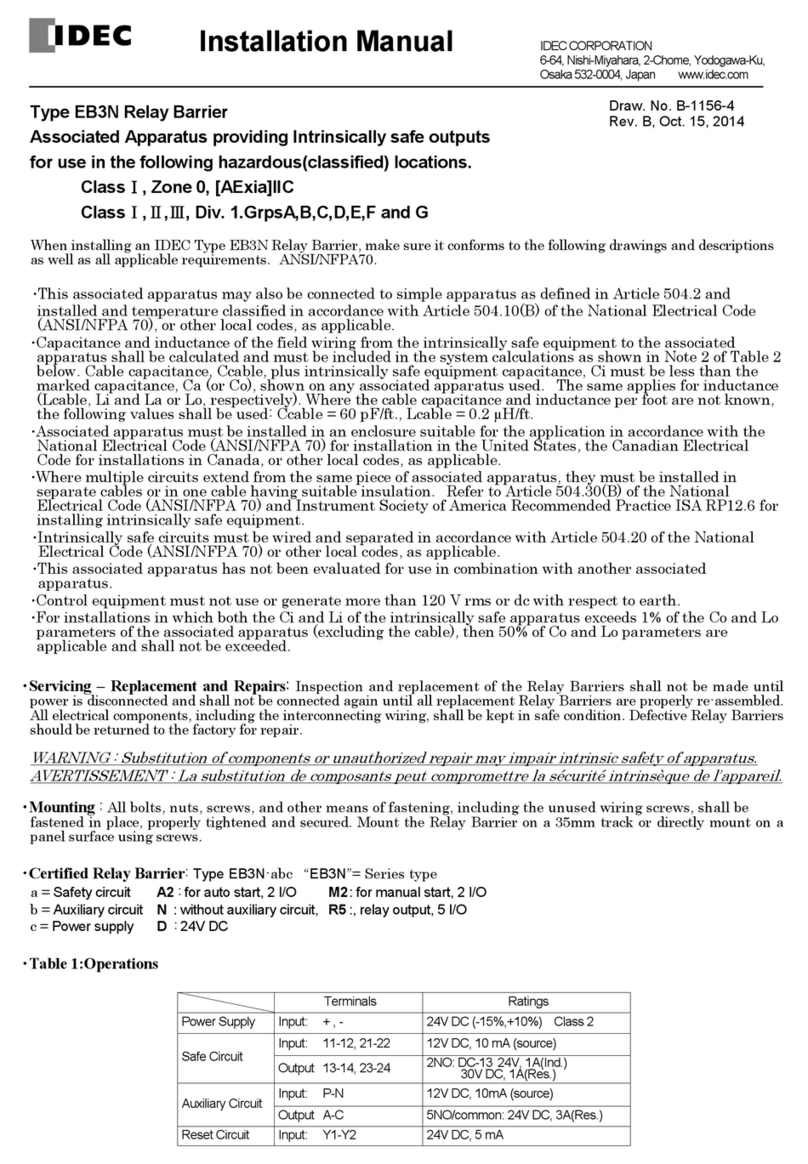

IDEC EB3N User manual

IDEC

IDEC HR1S-AC User manual

IDEC

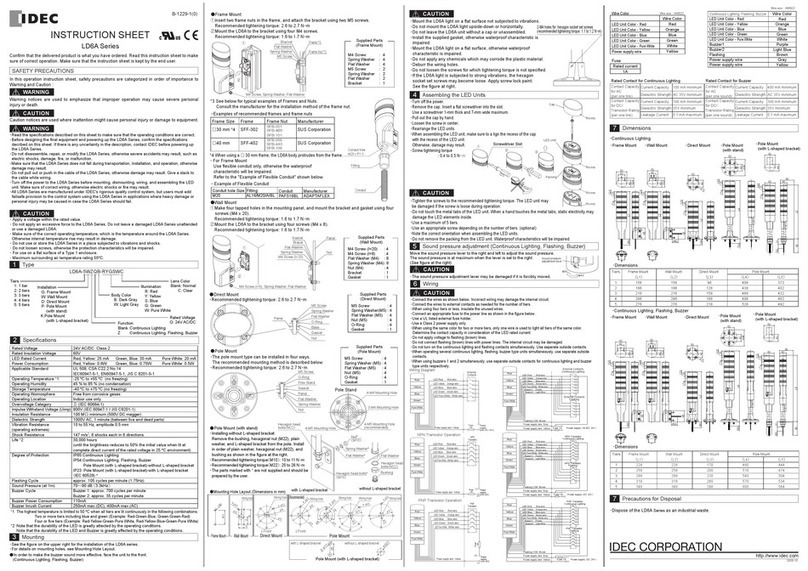

IDEC LD6A Series User manual

IDEC

IDEC HR1S-ATE User manual

IDEC

IDEC HR1S-AF 5130B/PB User manual

IDEC

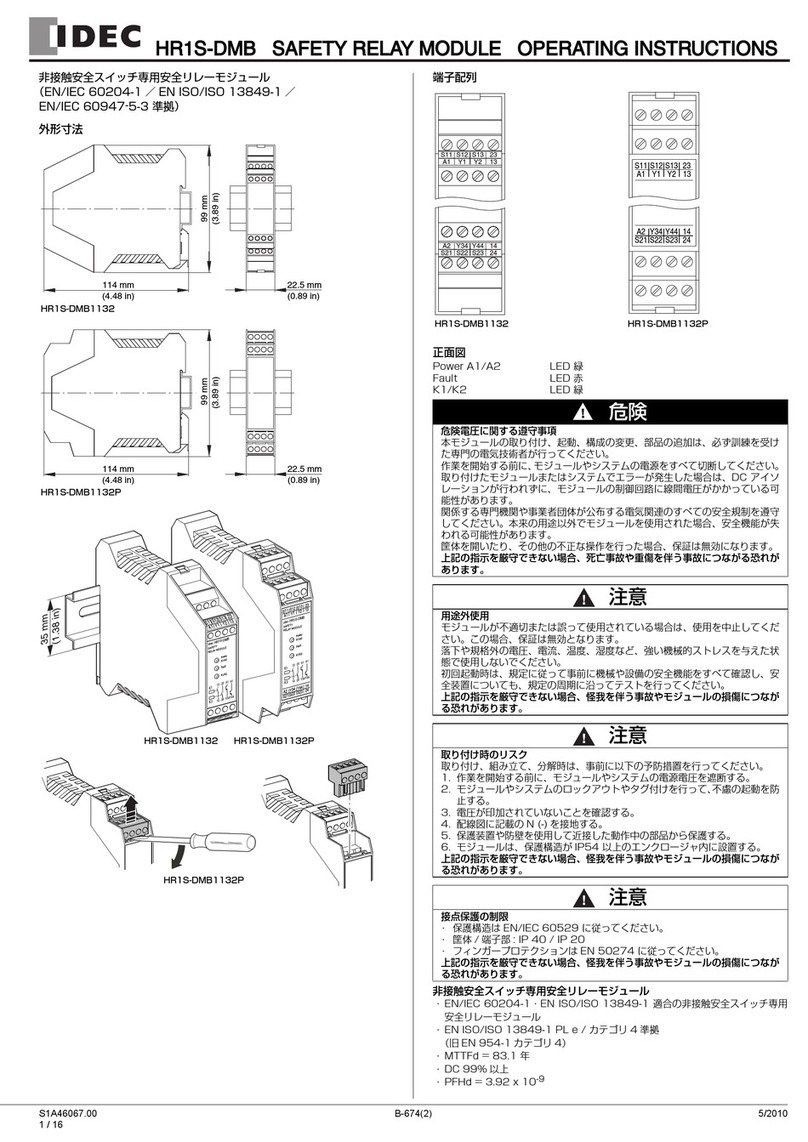

IDEC HR1S-DMB Series User manual

IDEC

IDEC EB3N User manual

IDEC

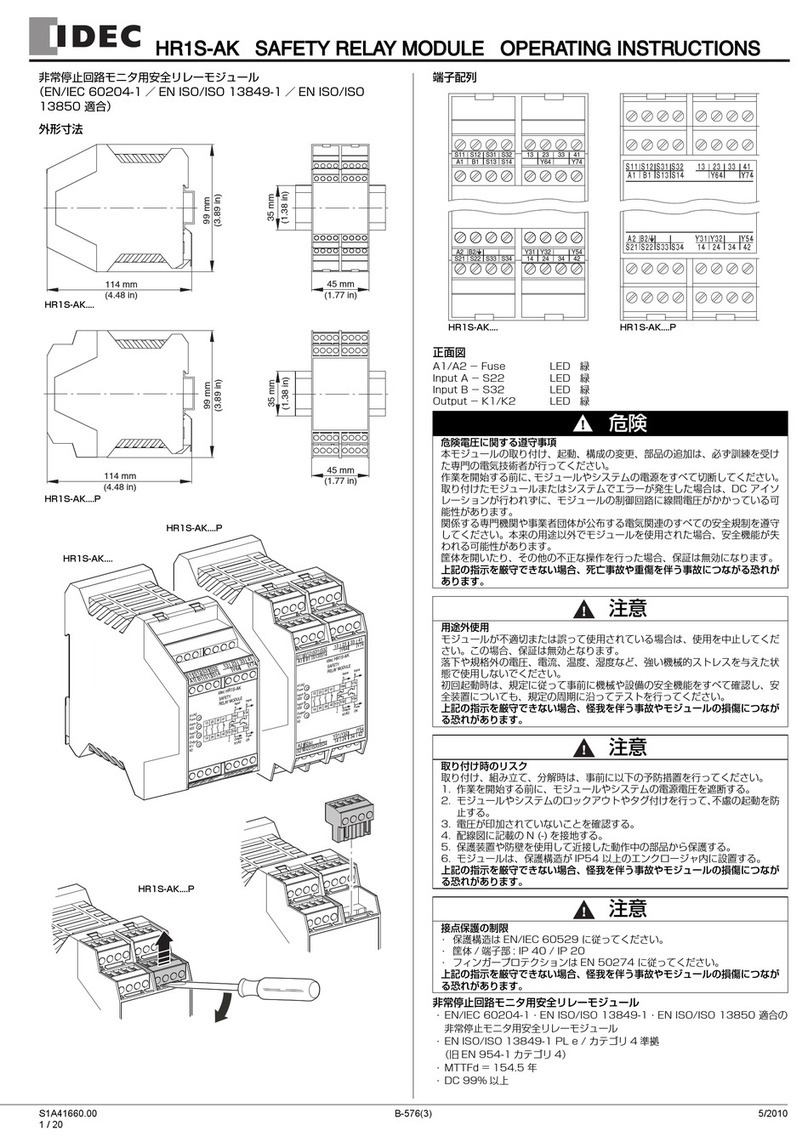

IDEC HR1S-AK User manual

IDEC

IDEC SmartAXIS FT9Z-1A01 User manual

IDEC

IDEC SmartRelay FL1A-H12RCE User manual