2

TABLE OF CONTENTS

1. IMPORTANT SAFETY INSTRUCTIONS .......................................................................................................................... 4

2. FEATURES....................................................................................................................................................................... 5

3. SPECIFICATION .............................................................................................................................................................. 7

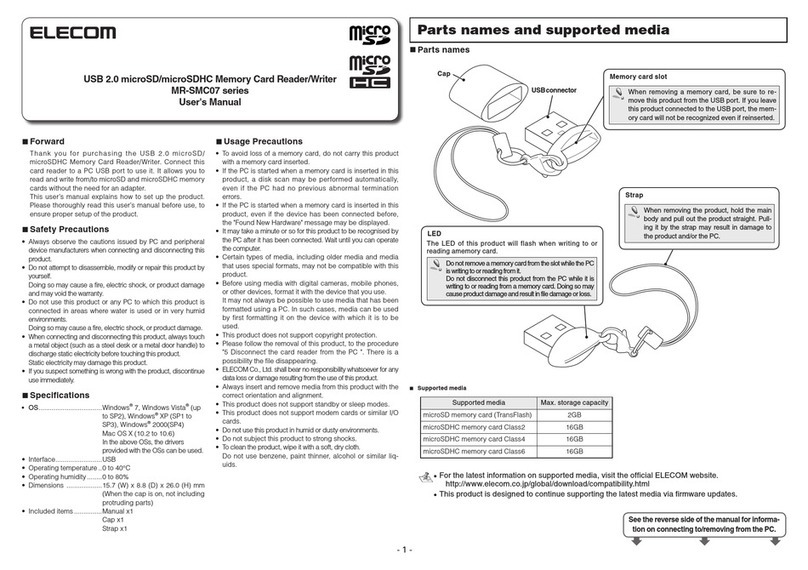

4. IDENTIFYNG SUPPLIED PARTS .................................................................................................................................... 9

5. PRODUCT EXPLANATION ............................................................................................................................................ 10

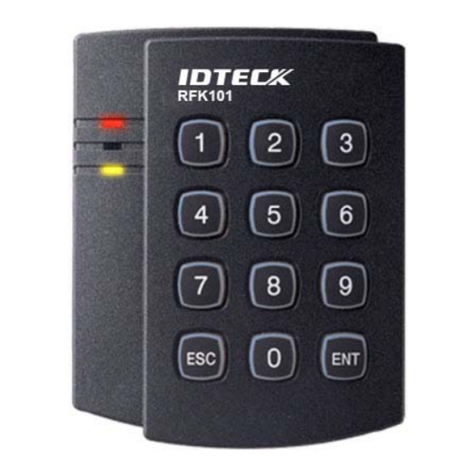

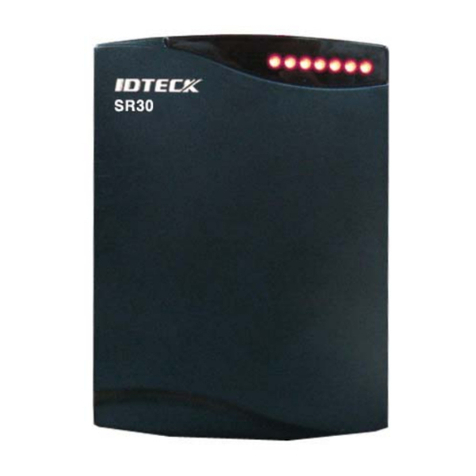

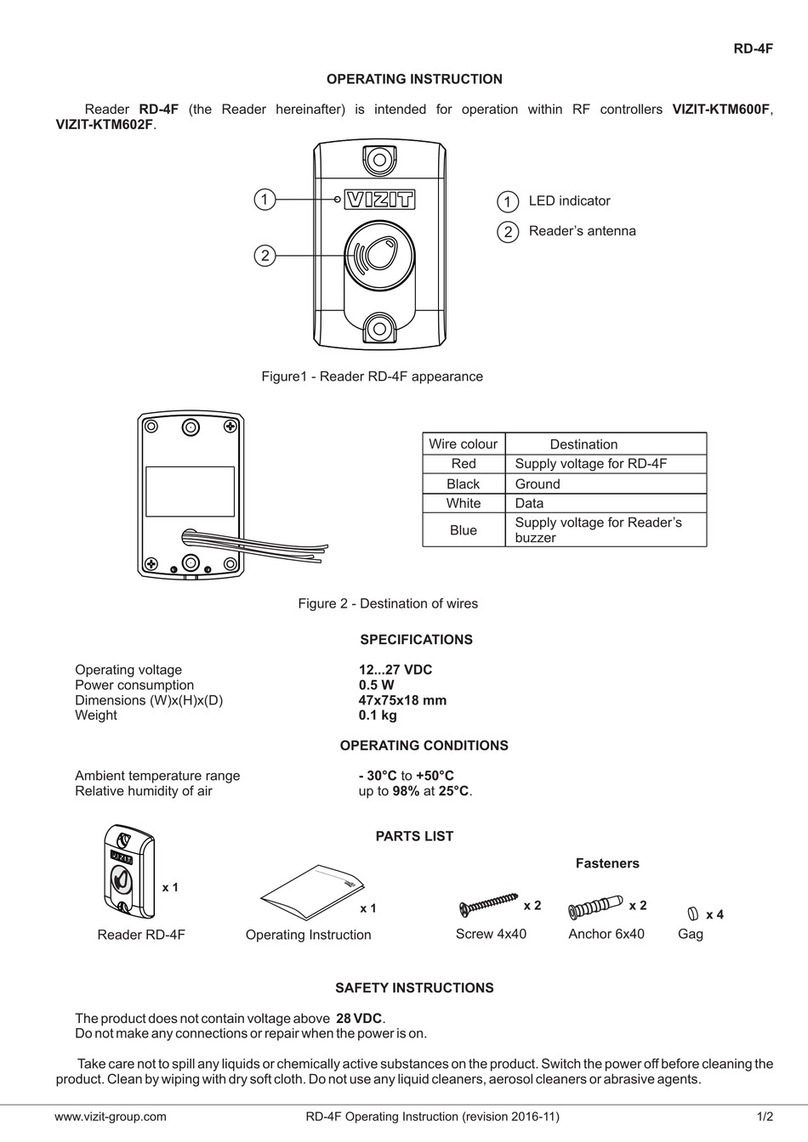

5.1 PANEL LAYOUT .................................................................................................................................................. 10

5.2 CONNECTION LAYOUT...................................................................................................................................... 10

5.3 COLOR CODED & WIRING TABLE .................................................................................................................... 11

6. INSTALLATION TIPS & CHECK POINTS ...................................................................................................................... 12

6.1 CHECK POINTS BEFORE INSTALLATION ........................................................................................................ 12

6.1.1 CABLE SELECTION ................................................................................................................................ 12

6.1.2 RECOMMENDED CABLE TYPE AND PERMISSIBLE LENGTH OF CABLE ......................................... 12

6.1.3 READER CONNECTION ......................................................................................................................... 12

6.2 CHECK POINTS DURING INSTALLATION......................................................................................................... 13

6.2.1 TERMINATION RESISTOR ..................................................................................................................... 13

6.2.2 HOW TO CONNECT TERMINATION RESISTORS................................................................................. 14

6.2.3 GROUNDING SYSTEM FOR COMMUNICATION CABLE...................................................................... 14

7. INSTALLATION OF THE PRODUCT.............................................................................................................................. 15

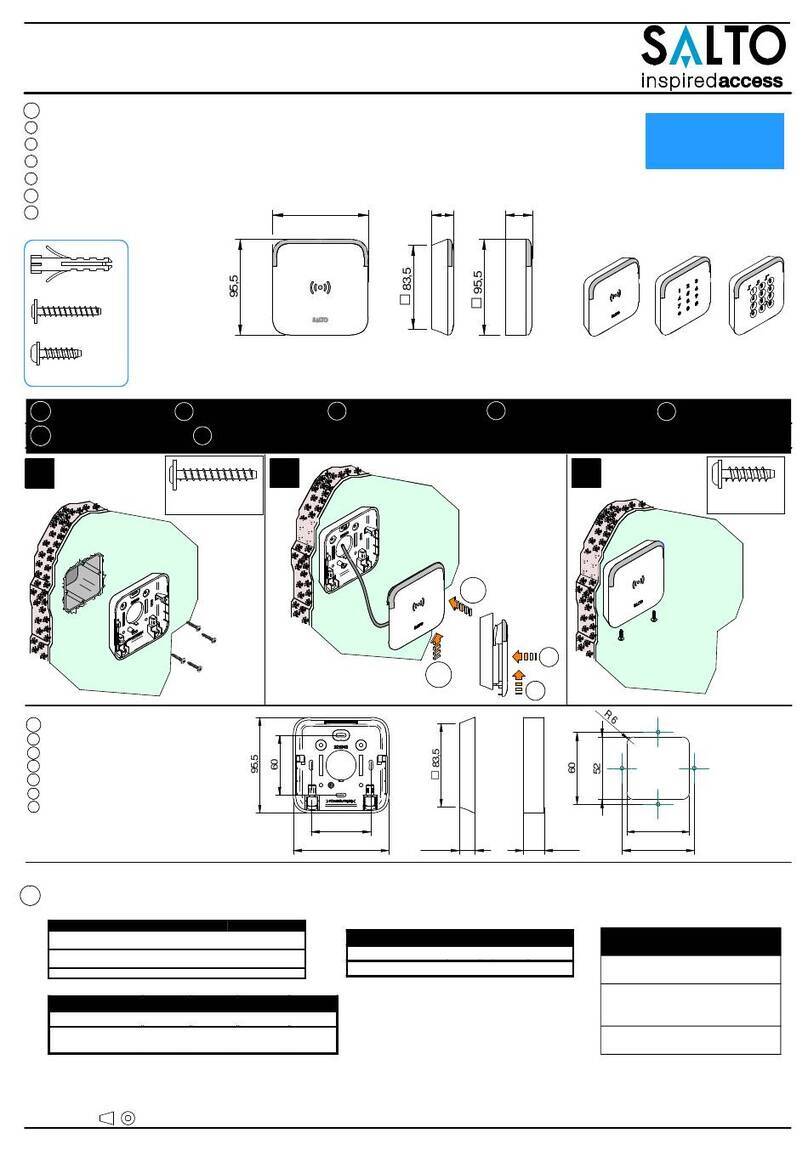

7.1 WALL MOUNT DRAWING................................................................................................................................... 15

7.2 INSTALLATION OF WALL MOUNT ..................................................................................................................... 15

7.3 SYSTEM INITIALIZATION ................................................................................................................................... 16

7.4 COMMUNICATION ID SETTING......................................................................................................................... 17

7.5 WIRING ............................................................................................................................................................... 18

7.5.1 WIRING LAYOUT..................................................................................................................................... 18

7.5.2 POWER WIRING ..................................................................................................................................... 18

7.5.3 INPUT WIRING ...................................................................................................................................... 19

7.5.4 OUTPUT CONNECTION ......................................................................................................................... 20

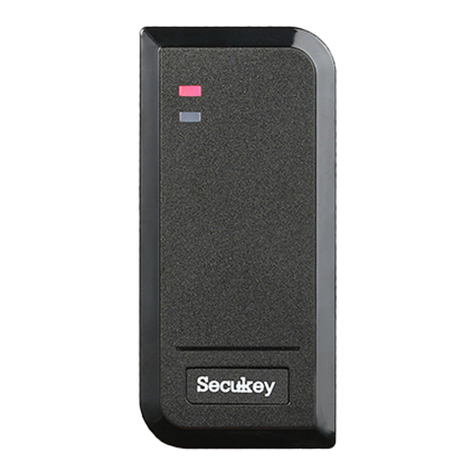

7.5.5 EXTERNAL READER CONNECTION ..................................................................................................... 21

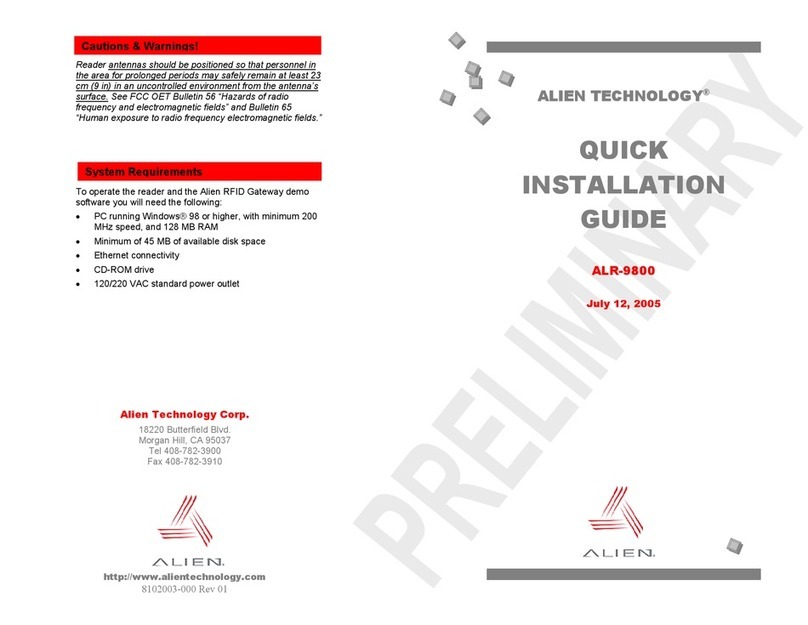

8. COMMUNICATION......................................................................................................................................................... 22

8.1 RS232 COMMUNICATION PORT CONNECTION...................

8.2. RS485 COMMUNICATION PORT CONNECTION............................................................................................. 22

8.2.1 RS485 COMMUNICATION PORT CONNECTION (SINGLE CONNECTION) ........................................ 22

8.2.2 RS485 COMMUNICATION PORT CONNECTION (MULTIPLE CONNECTION) .................................... 23

8.3 TCP/IP COMMUNICATION PORT CONNECTION ............................................................................................. 24

9. BASIC SETTING ............................................................................................................................................................ 25

............................................................................................. 22