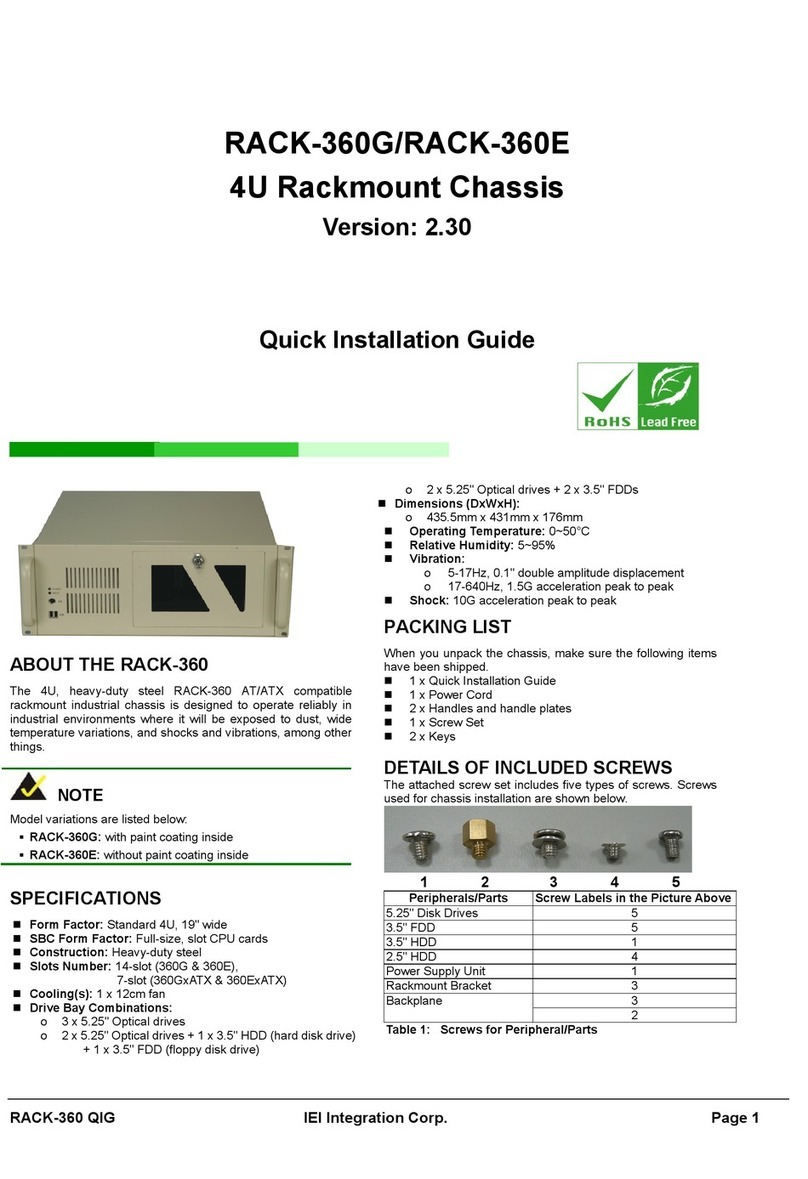

RACK-360GQIG IEIIntegrationCorp. Page7

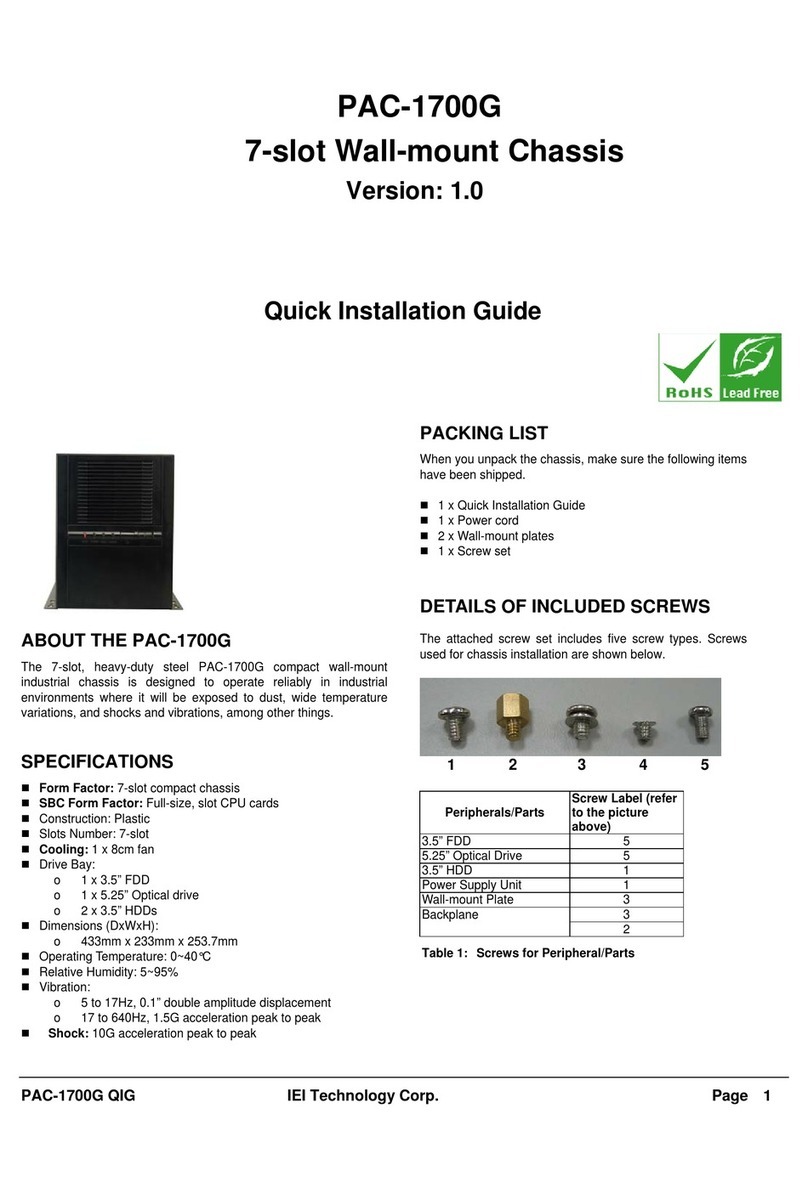

Figure 15: Install a 3.5” Disk Drive into the Adapter Bracket

Step 4: Reinsert the 3.5” drive tray, with the installed 3.5” HDD into

the main drive bracket. Make sure that the 4-pin HDD

power connector and the IDE/SATA drive interface

connector are facing the rear and the drive is at the top of

the drive bracket.

Step 5: Reinsert the four previously removed 3.5” drive tray

retention screws.Step 0:

If you want to install a 3.5” FDD drive into the main drive bracket,

follow the steps below:

Step 1: Remove the 3.5” drive tray from the top drive bay in the

main drive bracket. To do this, remove the four retention

screws that secure the 3.5” drive tray to the main drive

bracket and then slide the 3.5” drive tray out of the main

drive bracket.

Step 2: The front of the 3.5” drive tray is covered with a detachable

metal cover. Use your fingers to push the detachable cover

inwards until the cover snaps off the 3.5” drive tray.

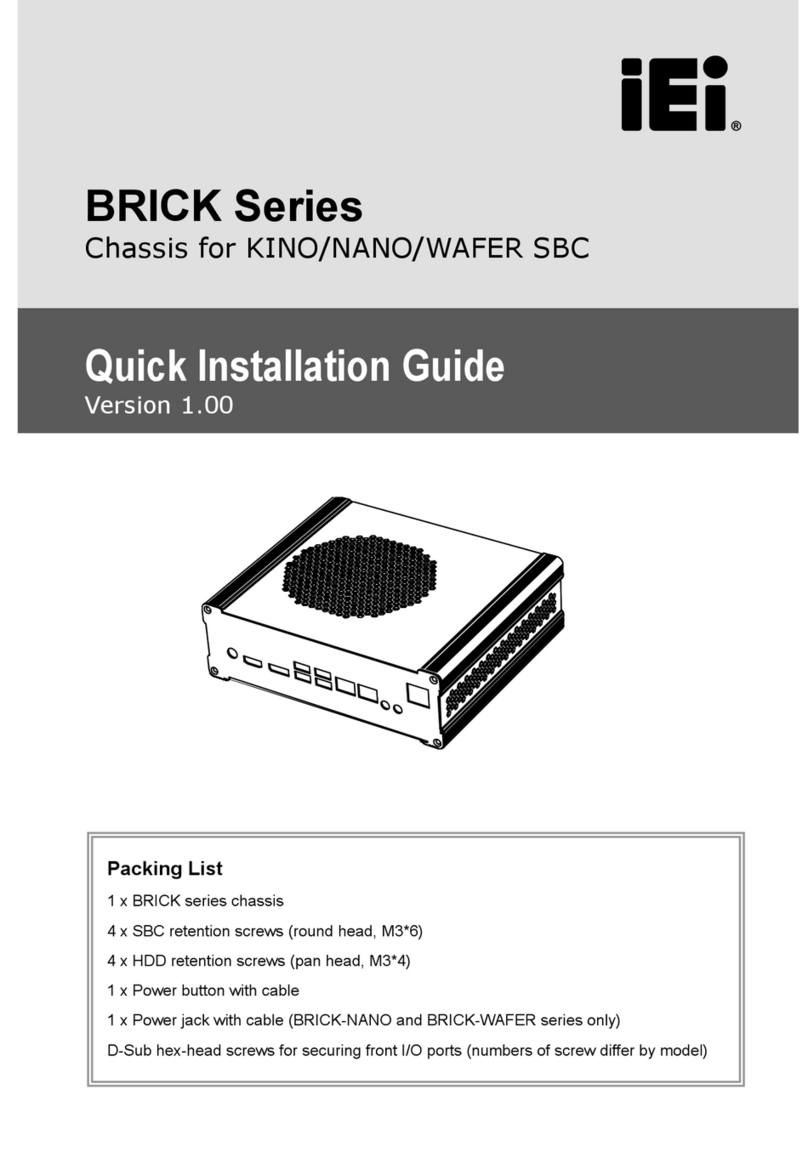

Figure 16: Bend off the front cover of the 3.5"drive bracket

Step 3: Place a 3.5” FDD drive into the bracket. Make sure the

FDD is upright and both the 4-pin FDD power connector

and the IDE/SATA drive interface connector are facing the

rear of the bracket.

Step 4: Make sure the PCB on the 3.5” FDD is placed directly on

the bottom surface of the drive bracket and the 4-pin FDD

power connector and the IDE/SATA drive interface

connector are facing the rear.

Step 5: Secure the FDD to the drive bracket by inserting four

retention screws (two on each side) through the sides of

the drive bracket and into the HDD.

Step 6: Reinsert the 3.5” drive tray, with the installed 3.5” FDD into

the main drive bracket. Make sure that the 4-pin FDD

power connector and the IDE/SATA drive interface

connector are facing the rear of the chassis and the FDD is

at the top of the drive bracket.

Step 7: Reinsert the four previously removed 3.5” drive tray

retention screws.Step 0:

STEP 8.5: REINSTALL THE DRIVE BRACKETS

Once all the drives have been installed into the drive brackets,

reinstall the drive brackets into the chassis. To reinstall the drive

brackets into the chassis, please follow the steps below:

Step 1: Place the main drive bracket into the chassis making sure

that the front of the 5.25” optical drives are facing out of the

chassis and the 4-pin drive power connectors and

IDE/SATA interface connectors are all facing the rear of the

chassis.

Step 2: Reinsert the four, previously removed, main drive bracket

retention screws.

Step 3: Correctly mount the side drive bracket onto the main drive

bracket making sure the 4-pin FDD power connector and

IDE/SATA interface connector both face the rear of the

chassis.

Step 4: Reinsert the two, previously removed, side bracket

retention screws into the top of the side bracket. Step 0:

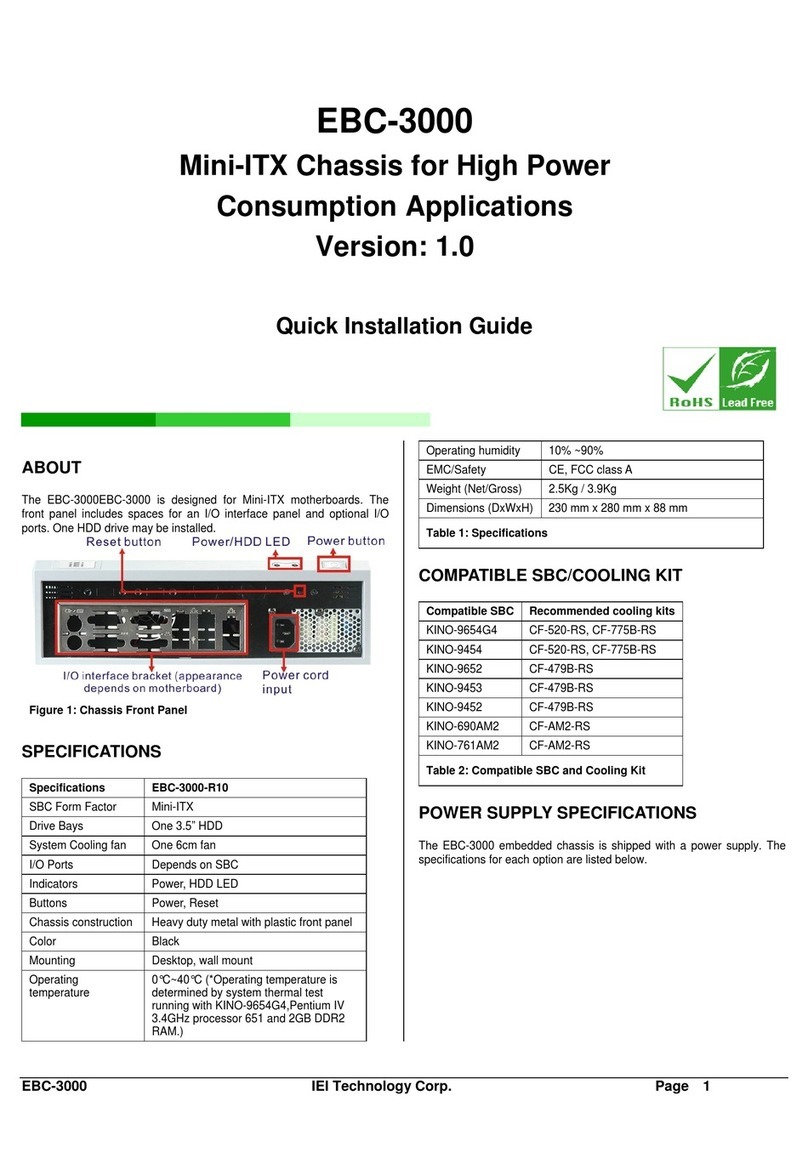

STEP 9: FRONT PANEL CABLES

The RACK-360G has the following components accessible at the

front:

o 1 x Power LED

o 1 x HDD activity LED

o 1 x Power switch

o 1 x Reset button

o 2 x USB ports

o 1 x PS/2 keyboard/mouse

These components are all connected to the CPU card with cables. To

correctly connect these cables, please refer to the technical

documentation that came with your CPU card. The connectors that

are provided with the chassis are listed below:

No. Name

2

USB cable

1

KB cable

1

Power LED cable

1

Reset Switch cable

1

HDD LED cable