2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������3

3 Functions and features ����������������������������������������������������������������������������������������4

3�1 Applications ���������������������������������������������������������������������������������������������������4

4 Function���������������������������������������������������������������������������������������������������������������4

4�1 Processing of the measured signals��������������������������������������������������������������4

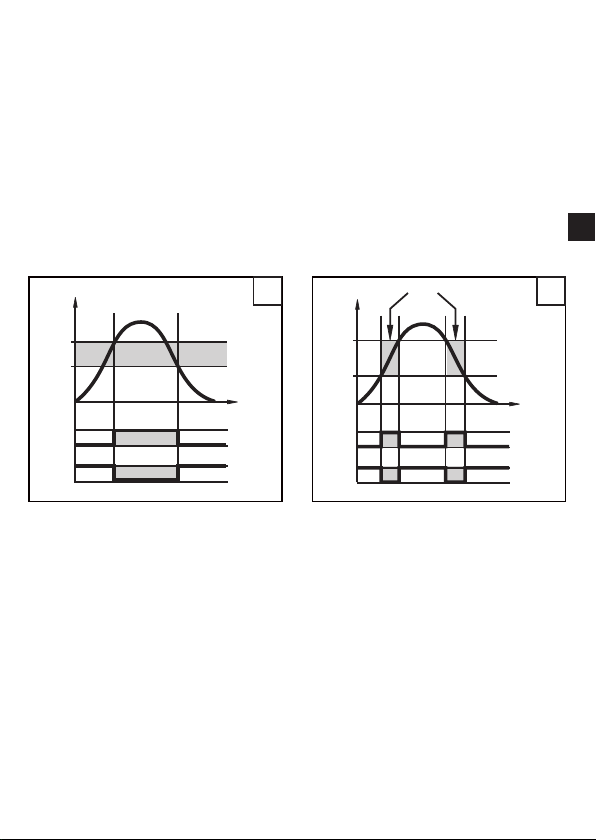

4�2 Pressure monitoring / switching function �������������������������������������������������������5

4�3 Pressure monitoring/ analogue function ��������������������������������������������������������5

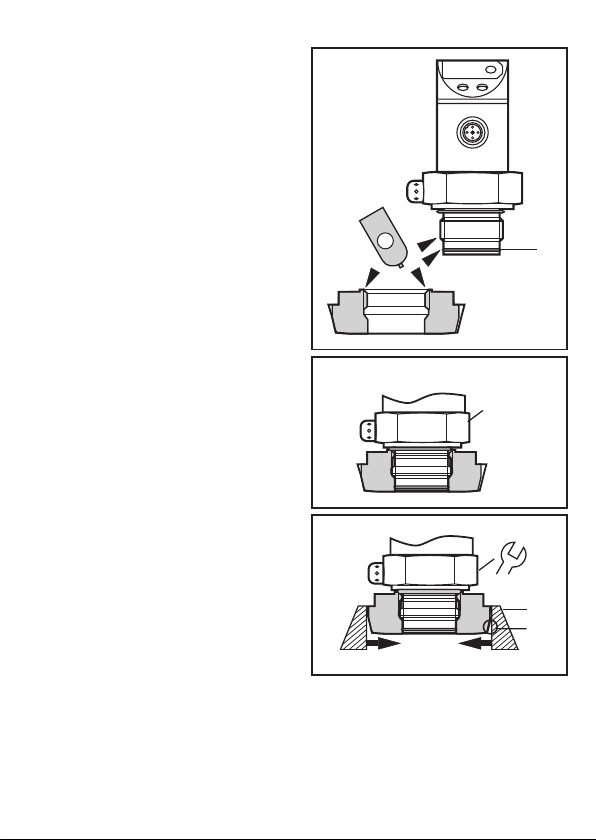

5 Installation������������������������������������������������������������������������������������������������������������7

6 Electrical connection��������������������������������������������������������������������������������������������9

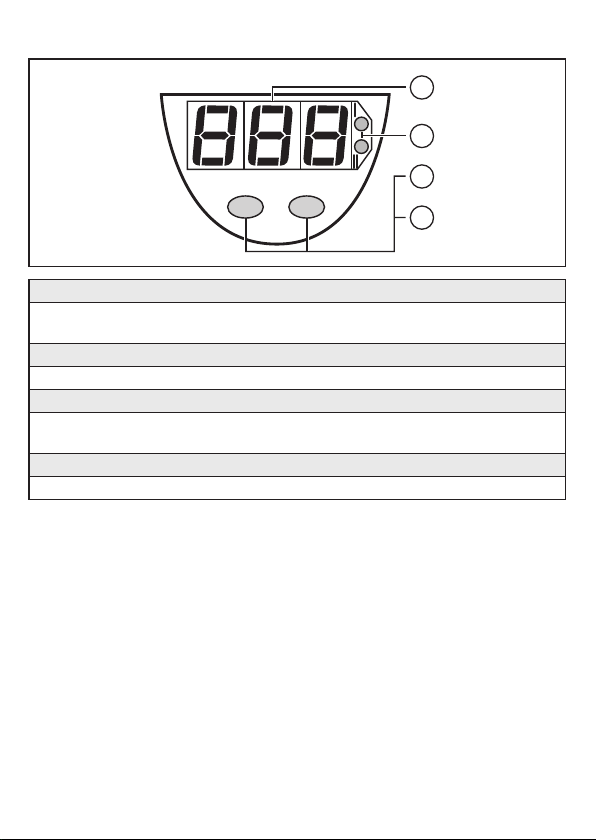

7 Operating and display elements ������������������������������������������������������������������������10

8 Menu������������������������������������������������������������������������������������������������������������������ 11

8�1 Menu structure��������������������������������������������������������������������������������������������� 11

8�2 Menu explanation ����������������������������������������������������������������������������������������12

9 Parameter setting ����������������������������������������������������������������������������������������������13

9�1 Parameter setting general ���������������������������������������������������������������������������13

9�2 Configuring the display (optional) ����������������������������������������������������������������14

9�3 Setting the output signal ������������������������������������������������������������������������������15

9�3�1 Setting the output function������������������������������������������������������������������15

9�3�2 Setting the switching limits �����������������������������������������������������������������15

9�3�3 Scaling the analogue value ����������������������������������������������������������������15

9�4 User settings (optional)��������������������������������������������������������������������������������15

9�4�1 Zero-point calibration��������������������������������������������������������������������������15

9�4�2 Calibration reset ���������������������������������������������������������������������������������15

9�4�3 Setting the delay time for the switching outputs ���������������������������������16

9�4�4 Setting the output polarity�������������������������������������������������������������������16

9�4�5 Setting the damping for the switching signal ��������������������������������������16

9�4�5 Setting the damping for the analogue signal ���������������������������������������16

9�5 Service functions �����������������������������������������������������������������������������������������16

9�5�1 Reading the min�/max� values for the system pressure����������������������16

10 Operation���������������������������������������������������������������������������������������������������������16