LR7009 Electronic level sensor

2

Contents

1 Preliminary note ............................................................. 4

1.1 Symbols used.......................................................... 4

2 Safety instructions............................................................ 5

3 Intended use................................................................ 6

3.1 Accessories............................................................ 6

3.2 Operation with single probe................................................ 7

3.3 Operation with coaxial probe............................................... 7

3.4 Application area ........................................................ 7

3.4.1 Restriction of the application area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Function ................................................................... 9

4.1 Measuring principle...................................................... 9

4.2 Display functions........................................................ 9

4.3 Switching function....................................................... 9

4.4 Offset for indicating the real level in the tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Probes for different tank heights............................................ 10

4.6 Safe state............................................................. 10

5 Installation.................................................................. 11

5.1 Device with single probe.................................................. 11

5.2 Device with coaxial probe................................................. 13

5.3 Installation of the probe................................................... 13

5.3.1 Installation of the rod................................................. 13

5.3.2 Installation of the coaxial pipe.......................................... 14

5.4 Shortening of the probe................................................... 14

5.4.1 Shortening of the rod and determination of its length L . . . . . . . . . . . . . . . . . . . . . . . 14

5.4.2 Shortening of the coaxial pipe.......................................... 14

5.4.3 Determination of the probe length L when coaxial probes are used . . . . . . . . . . . . . 15

5.5 Installation of the device with single probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5.1 Installation in closed metal tanks (without flange plate) . . . . . . . . . . . . . . . . . . . . . . . 15

5.5.2 Installation in closed metal tanks (with flange plate) . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5.3 Installation in open tanks.............................................. 17

5.5.4 Installation in plastic tanks............................................. 17

5.6 Installation of the device with coaxial probe in the tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7 Alignment of the sensor housing............................................ 18

6 Electrical connection.......................................................... 19

7 Operating elements and display elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Menu...................................................................... 21

8.1 Menu structure ......................................................... 21

8.2 Explanation of the menu.................................................. 21

9 Parameter setting............................................................ 23

9.1 IO-Link ............................................................... 23

9.2 Parameter setting in general............................................... 23

9.3 Basic settings (on delivery)................................................ 25

9.3.1 Entering the probe length ............................................. 25

9.3.2 Setting to the medium................................................ 26

9.3.3 Entering the type of probe used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.4 Setting ranges.......................................................... 26

9.5 Configuring the display................................................... 27

9.6 Offset setting........................................................... 27

9.7 Setting the output signals................................................. 27

9.7.1 Setting the output function............................................. 27

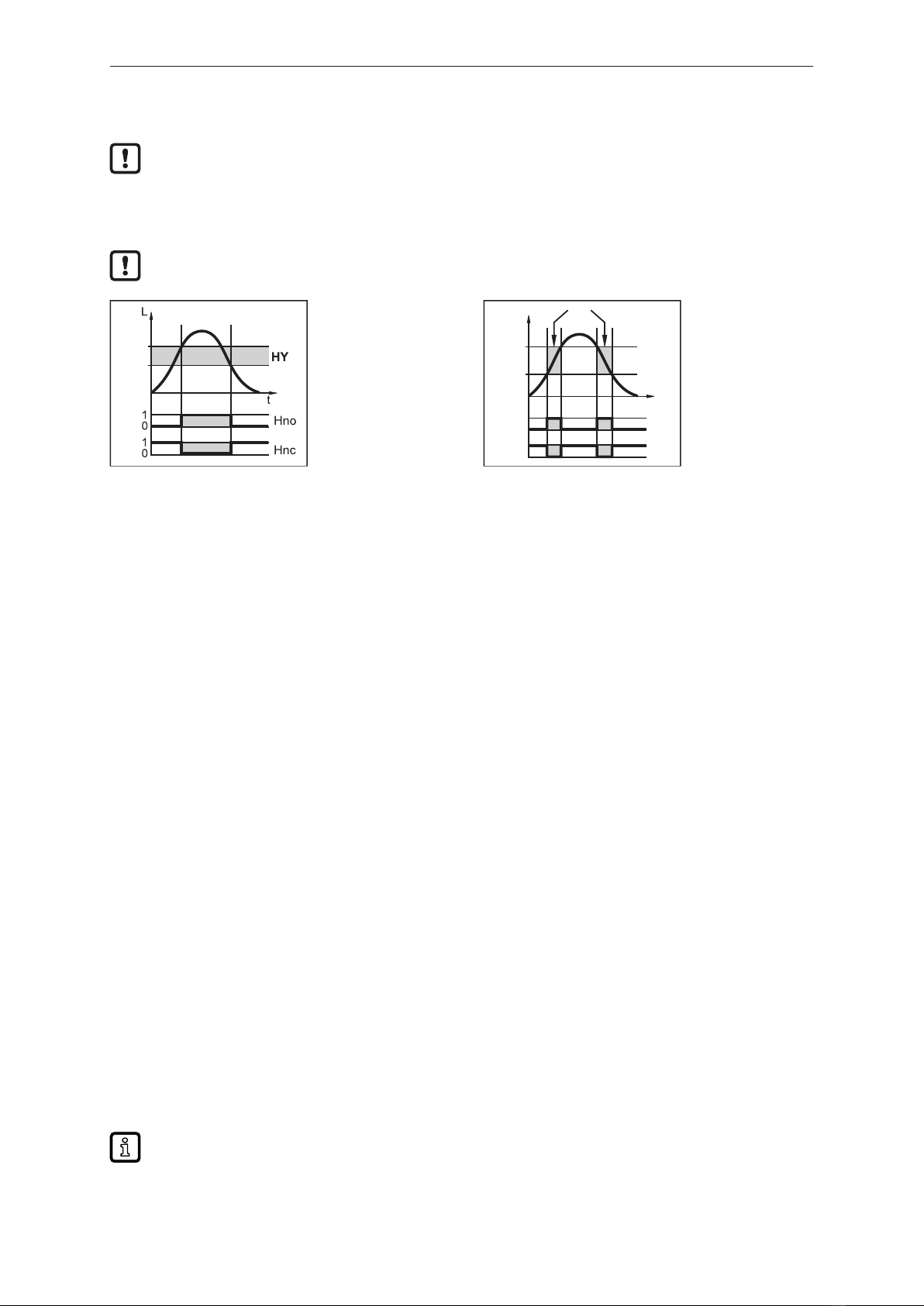

9.7.2 Setting the switching limits (hysteresis function) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.7.3 Setting the switching limits (window function) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.7.4 Setting the switch-off delay............................................ 27

9.7.5 Setting the switching logic for the outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.7.6 Setting response of the outputs in case of a fault . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.7.7 Setting the delay time after signal loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28