OY51 Measuring light grids (10mm beam spacing)

2

Contents

1 Preliminary notes............................................................. 3

1.1 Symbols used........................................................... 3

1.2 Warnings used.......................................................... 3

2 Safety instructions............................................................ 4

3 Intended use ................................................................ 5

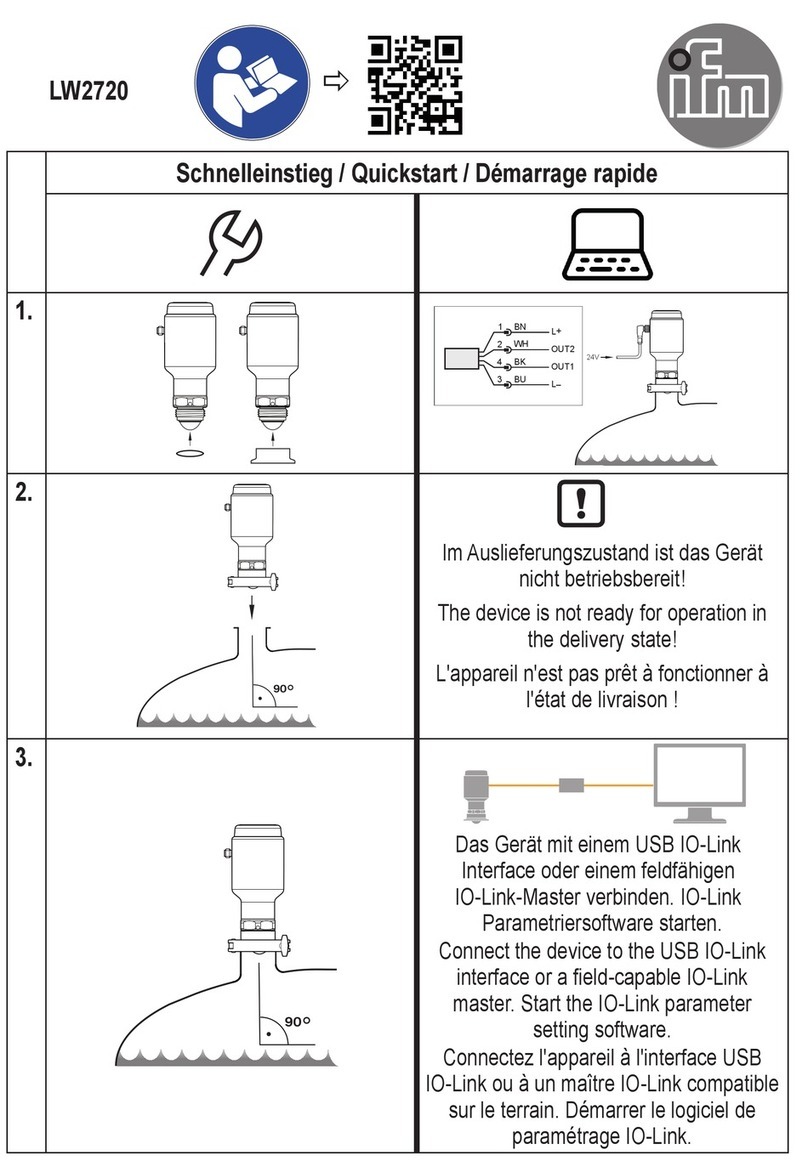

4 Getting started............................................................... 6

5 Function.................................................................... 7

5.1 IO-Link................................................................ 7

6 Installation .................................................................. 8

6.1 Installation instructions.................................................... 8

6.1.1 Fastening .......................................................... 8

6.1.2 Optical alignment..................................................... 9

6.2 Multiple systems......................................................... 9

7 Electrical connection .......................................................... 11

7.1 Transmitter wiring diagram................................................. 11

7.2 Receiver wiring diagram................................................... 11

7.3 Synchronisation of transmitter and receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.3.1 Synchronisation via ifm Y cable (EY5053 and EY5054) . . . . . . . . . . . . . . . . . . . . . . . 11

7.3.2 Synchronisation via standard sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.3.3 Optical synchronisation................................................ 12

8 Operating and display elements.................................................. 14

8.1 Transmitter LED states................................................... 14

8.2 Receiver LED states...................................................... 14

9 Operation................................................................... 15

9.1 Switching mode (SIO mode) ............................................... 15

9.2 Operation with IO-Link master.............................................. 15

9.3 Process values.......................................................... 15

9.3.1 FBO – first beam occupied ............................................. 15

9.3.2 LBO – last beam occupied ............................................. 16

9.3.3 CBO – central beam occupied........................................... 16

9.3.4 NBO – number of beams occupied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.3.5 NCBO – number of consecutive beams occupied . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.3.6 Tolerance .......................................................... 17

10 Technical data............................................................... 18

10.1 Light grid with 10 mm beam spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11 Troubleshooting.............................................................. 19

11.1 Transmitter fault diagnostics ............................................... 19

11.2 Fault diagnosis receiver................................................... 19

12 Maintenance, repair and disposal ................................................ 20