3

9 Menu .............................................................................................................. 24

9.1 Menu overview........................................................................................ 24

9.2 Main menu and submenus...................................................................... 25

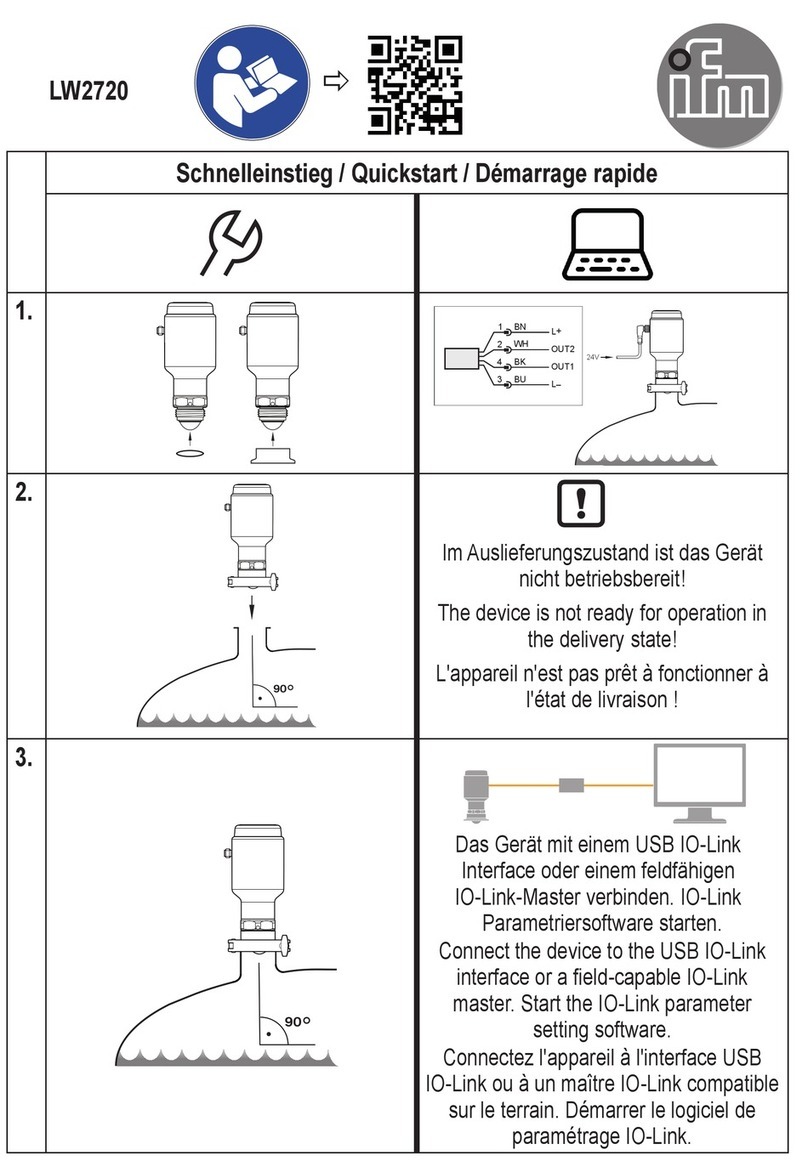

10 Set-up ............................................................................................................ 29

11 Parameter setting........................................................................................... 29

11.1 Parameter setting in general................................................................... 30

11.2 Presetting................................................................................................ 30

11.2.1 Process value for OUT2 ................................................................... 30

11.2.2 Operating mode ................................................................................ 30

11.2.3 Standard unit of measurement for flow............................................. 31

11.2.4 Internal pipe diameter ....................................................................... 31

11.2.5 Flow adjustment................................................................................ 31

11.2.6 Remote calibration............................................................................ 32

11.3 Setting the output functions .................................................................... 33

11.3.1 Limit monitoring OUTx/ hysteresis function ..................................... 33

11.3.2 Limit monitoring OUTx/ window function ......................................... 33

11.3.3 Frequency signal OUTx .................................................................... 33

11.3.4 Analogue signal OUT2...................................................................... 34

11.4 User settings (optional) ........................................................................... 34

11.4.1 Standard display ............................................................................... 34

11.4.2 Display colour setting........................................................................ 34

11.4.3 Output logic....................................................................................... 35

11.4.4 Measured value damping ................................................................. 35

11.4.5 Switch-on /switch-off delay ............................................................... 35

11.4.6 Error behaviour of the outputs .......................................................... 35

11.4.7 Calibration......................................................................................... 36

11.4.8 Lock / unlock..................................................................................... 36

11.4.9 Factory reset..................................................................................... 36

11.5 Diagnostic functions................................................................................ 37

11.5.1 Reading minimum values / maximum values ................................... 37

12 Operation ....................................................................................................... 37

12.1 Process value display ............................................................................. 37

12.2 Reading the parameter setting................................................................ 38

13 Technical data................................................................................................ 38

14 Troubleshooting ............................................................................................. 38

GB