SI0558 SI0564 Flow monitor

2

Contents

1 Preliminary note ............................................................. 3

1.1 Symbols used.......................................................... 3

1.2 Warnings used ......................................................... 3

2 Safety instructions............................................................ 4

3 Intended use................................................................ 5

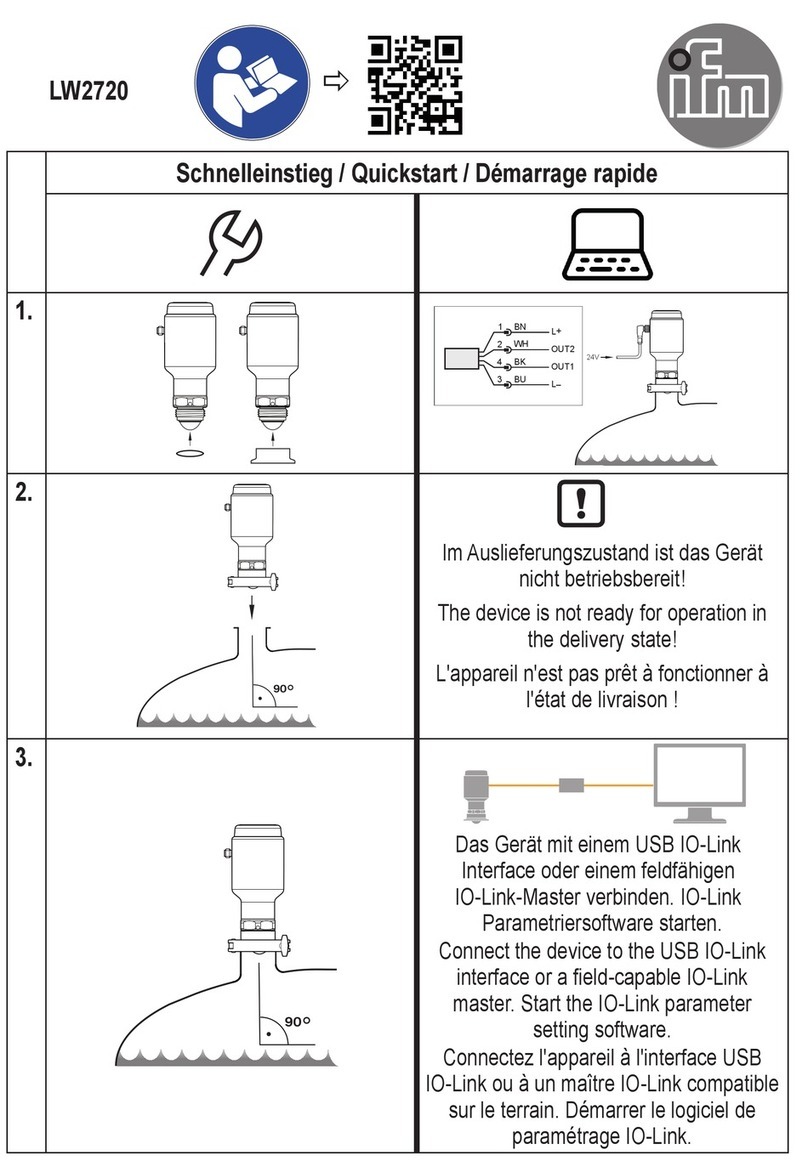

4 Installation.................................................................. 6

4.1 Installation position...................................................... 6

4.1.1 Immersion depth.................................................... 6

4.1.2 Recommended mounting position....................................... 6

4.1.3 Conditionally possible installation position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1.4 Impermissible installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Interference............................................................ 7

4.3 Process connection...................................................... 7

5 Electrical connection.......................................................... 9

6 Operating and display elements................................................. 10

7 Set-up..................................................................... 11

8 Settings.................................................................... 12

8.1 Switch point setting...................................................... 12

8.2 Teaching the switch point................................................. 12

8.3 Restoring factory settings (reset)............................................ 12

8.4 Lock / unlock........................................................... 12

9 Operation .................................................................. 14

10 Troubleshooting ............................................................. 15

11 Maintenance, repair and disposal................................................ 16