4.2 General notes

• The iLOQ cylinders are successfully tested according the EN 1634-1 (EUFI29-19003368) for 120

minutes in a hinged single leaf steel door.

• Where the D5S cylinder is manufactured in more than one size, make sure that you select the correct

size.

• Make sure that any seals or weather-stripping fitted to the complete door assembly, does not inhibit

the correct operation of then D5S lock cylinder.

• Make sure that no projection of the D5S cylinder and associated parts can prevent the door from

swinging freely.

• Fit all components necessary for the specific installation in order to ensure compliance with EN15684

standard.

• The cylinder must protrude less than 1 mm on outside of the door to ensure proper operation.

• Before fitting D5S cylinder to a fire/smoke resisting door, examine the fire certification to ensure

conformity. Consult an iLOQ sales representative for the correct configuration.

• To extend the cylinder length, only use the associated D5 cylinder extensions (AD5.Exx).

• The incorrect type of cylinder can block or hinder the panic mechanism of the panic mortise

locks. Make sure that the anti-panic cylinder (D5S.7xx) is installed. Do not use other cylinder

types (D5S.1xx/2xx/3xxx etc.) unless you have made sure the lock type does not need a specific

cam position and the cam cannot block the panic functionality. Confirm the information from the

declaration of conformity provided by the mortice lock manufacturer.

• After installation, make sure that all parts of the lock are in an operational condition. When the D5S

lock cylinder is used in combination with panic locks, make sure the panic function of the mortise lock

is operational and cannot be hindered.

• The long neck versions have specially been developed for doors that do not have a Euro-profile cut

out inside the door frame resp. escutcheon/cylinder ring but only has a round hole.

• Use as a spare part only the article “A5.001”, and it is mandatory to mount the provided IP cover.

• Disposal of an RTC (Real Time Clock) into fire or a hot oven, or mechanically crushing or cutting of an

RTC can result in an explosion.

• Leaving an RTC in an extremely high temperature surrounding environment can result in an explosion

or the leakage of flammable liquid or gas.

• An RTC subjected to extremely low air pressure may result in an explosion or the leakage of

flammable liquid or gas.

• To meet the German VdS (VdS Schadenverhütung GmbH) requirements class BZ+ on burglary

threatened doors use a D5S.XX0A.SB high security cylinder installed with a VdS approved security lock

furniture of class B or C. Such security lock furniture corresponds to DIN 18 257 class ES 2 and ES 3.

• To meet the Dutch SKG*** requirements use a D5S.XXXA.SB high security cylinder. Consult an iLOQ

sales representative for correct configuration.

• Especially in industrial areas or near the sea, impurities can cause deposits in the form of rust and

attacked the material. This equipment should be cleaned and maintained frequently.

• For security reasons, the cylinder will lock itself after 10-12 seconds. The key can then be removed.

Turn the key back to the 12 o’clock position (either clockwise or anti-clockwise) and pull it out.

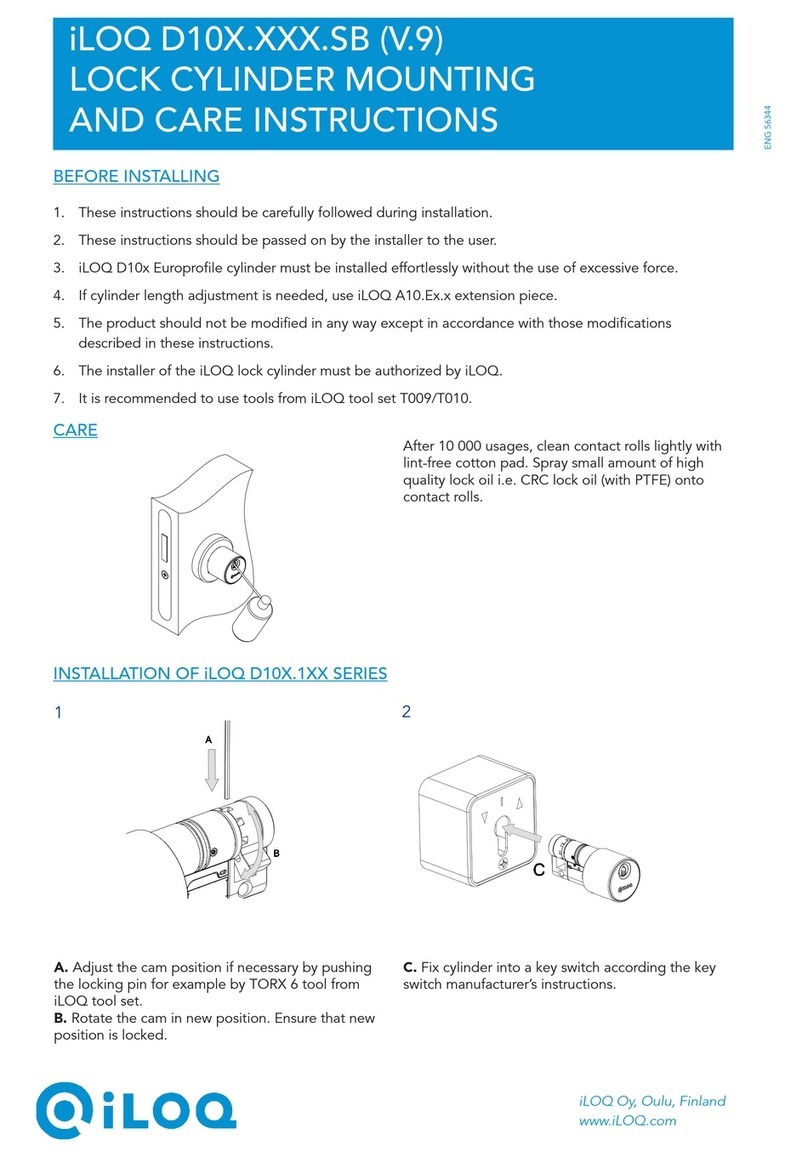

• After 5-10,000 usages, clean the contact rolls lightly with a lint-free cotton pad. Spray a small amount

of high-quality lock oil i.e. CRC lock oil (with PTFE) onto the contact rolls.

• If the cylinder is not functioning properly, clean the cylinder with e.g. compressed air spray or similar.

4

Document ID - 300598

iLOQ 5 Series (iLOQ D5S.XXX(A).SB, D5S.XXX.(L).SB)