14 tina48e1-c (2017-10) MPG400-401.om

As long as the cold cathode measuring circuit has not yet ignited, the measured

value of the Pirani is output as measuring signal. The identification output (pin 6,

low) indicates the Pirani-only mode.

If the gauge is activated at a pressure p < 3×10-9, the gauge cannot

recognize whether the cold cathode system has ignited.

Once flanged on, permanently leave the gauge in the operating mode

irrespective of the pressure range. Like this, the ignition delay of the cold

cathode measuring circuit is always negligible (<1 s), and thermal

stabilizing effects are minimized.

Gauge failures due to contamination, as well as expendable parts

(filament), are not covered by the warranty.

Gauge contamination is influenced by the process media used as well as by any

present or new contaminants and their respective partial pressures. Continuous

operation in the range of 10-4 mbar … 10-2 mbar can cause severe contamination

as well as reduced up-time and maintenance cycles. With constantly low pressures

(p <1×10-6 mbar), the gauge can be operated for more than one year without

cleaning (cleaning the gauge →18, 21).

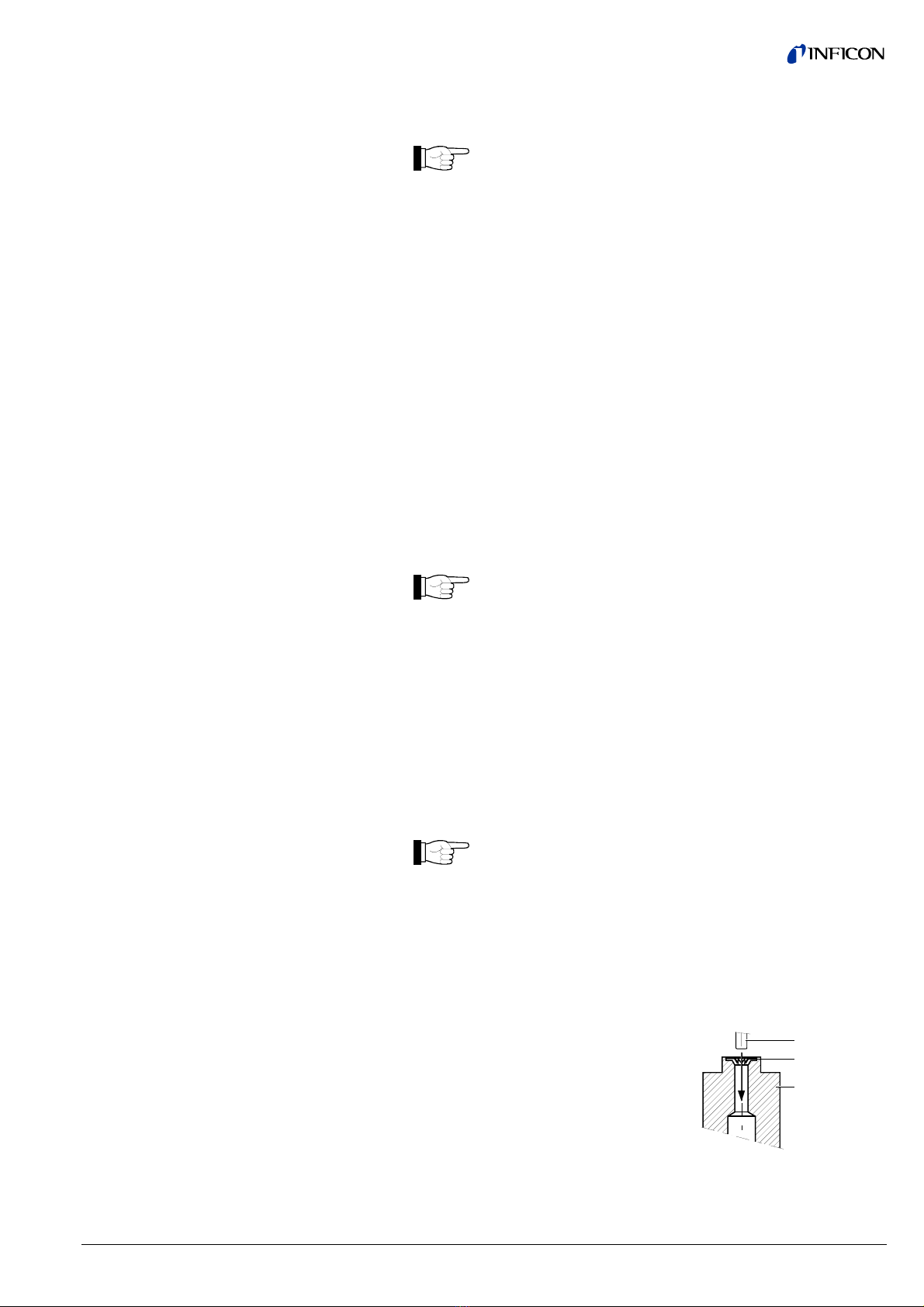

Contamination of the gauge generally causes a deviation of the measured values:

•In the high pressure range (1×10-3 mbar … 0.1 mbar), the pressure reading is

too high (contamination of the Pirani element). Readjustment of the Pirani

measuring system →16.

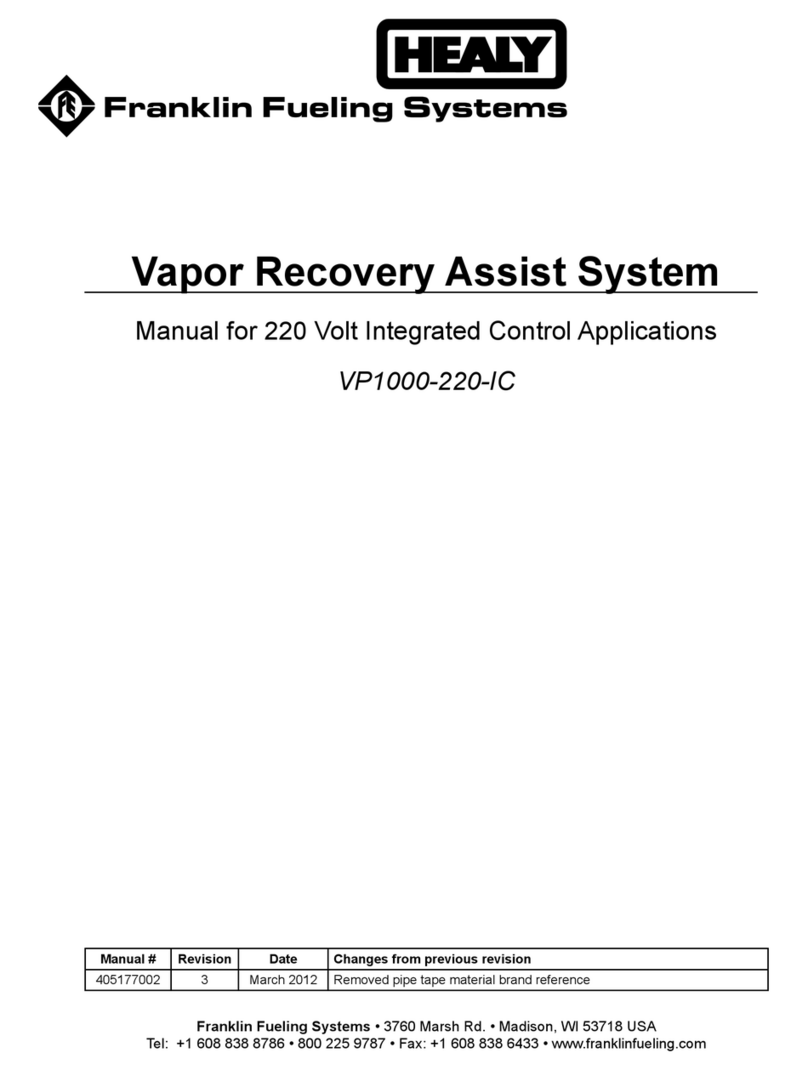

•In the low pressure range (p < 1×10-3 mbar), the pressure reading is usually too

low (contamination of the cold cathode system). In case of severe contami-

nation, instabilities can occur (layers of the measuring chamber peel off).

Contamination due to insulation layers can even lead to a complete failure of

the discharge ("Underrange" is displayed).

Contamination can to a certain extent be reduced by:

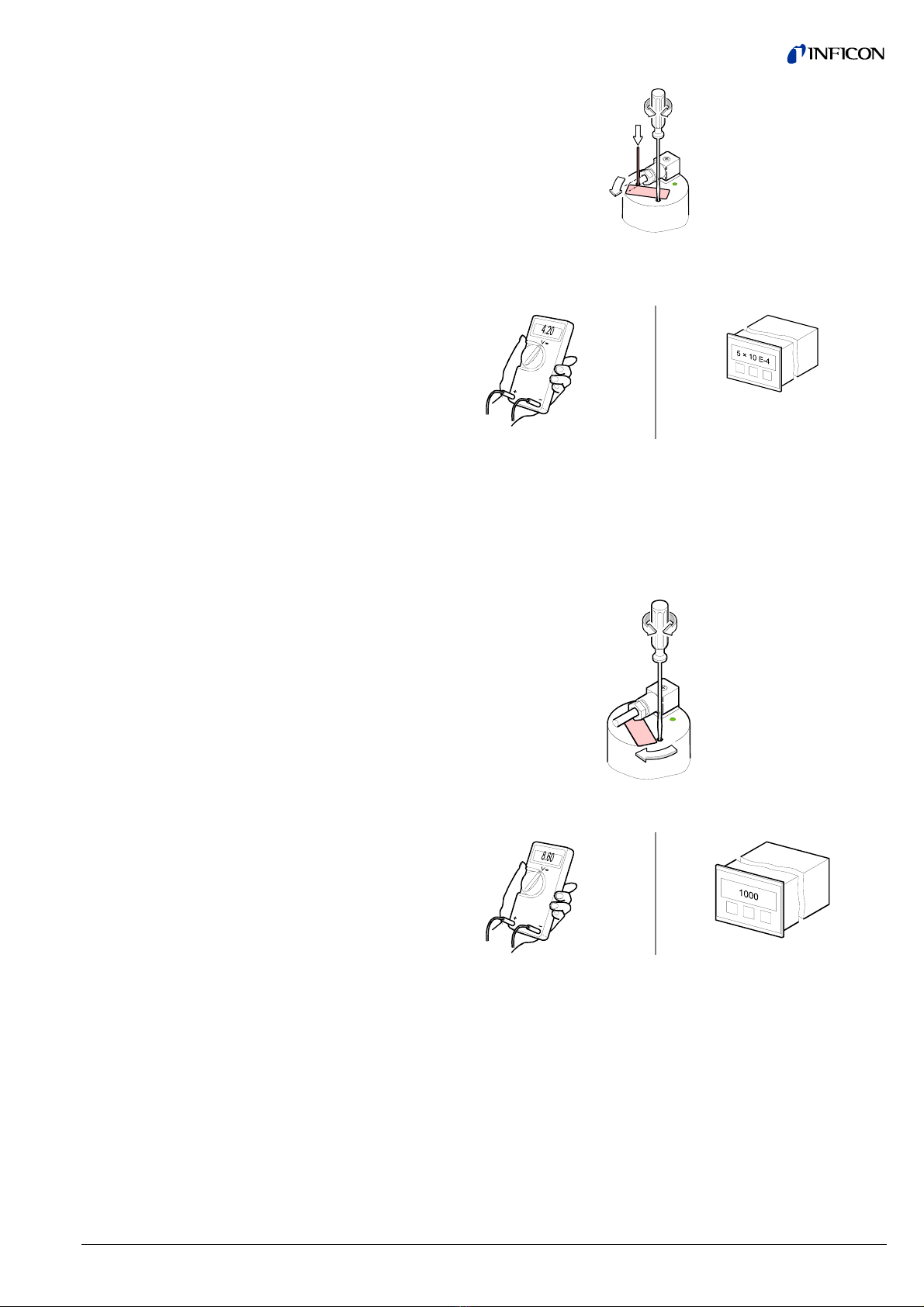

•geometric protection measures (e.g. screenings, elbows) for particles that

spread rectilinearly

•mounting the flange of the gauge at a place where the partial pressure of the

pollutants is particularly low.

Special precautions are required for vapors deposited under plasma (of the cold

cathode measuring system). It may even be necessary to temporarily switch of the

gauge while such vapors occur.

Contamination