OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 3

Components #153-14 Graduated Cylinder, 50 mL × 1 mL

#154-10 Dual-Scale Thermometer with Dial, 5" Stem, 50°– 500°F

(0° – 260°C)

#170-00-1 Heating Jacket (115V) -OR-

#170-01-1 Heating Jacket (230V):

#130-10-52 JamNut,⅜"-24,StainlessSteel,Qty:2

#130-38-005 Strain Relief

#164-32 Male Connector for Power Cable (230V Only)

#170-05 Thermostat

#170-09 Insulation Board

#170-10 Thermostat Pilot Lot

#170-11 HeatingElement,115V,200W,Qty:2

#170-15 Base

#170-21 StandSupportRod,Qty:2

#170-25 Aluminum Well

#170-30 Stainless Steel Thermostat Cover

#170-30-001 Fish Paper

#170-44 ½"RubberFoot,Qty:4

#171-32 Midget Knob

#171-82 AC Power Cord (115V Only)

#170-06-1 Back Pressure Receiver, 15-mL Stainless Steel Tube for N2

#144-11 ⅛"90StreetEll

#144-15 PlateBrassBushing,¼"NPTMaleto⅛"NPTFemale

#170-07 O-ring

#170-28 Receiver Body

#170-32 NeedleValve,Male,⅛"×⅛"NPT

#171-23-1 Safety Pin with Lanyard

#170-19 Filter Paper, 2½" (6.35 cm), Specially Hardened for Filter Presses

#170-35 6" Adjustable Wrench

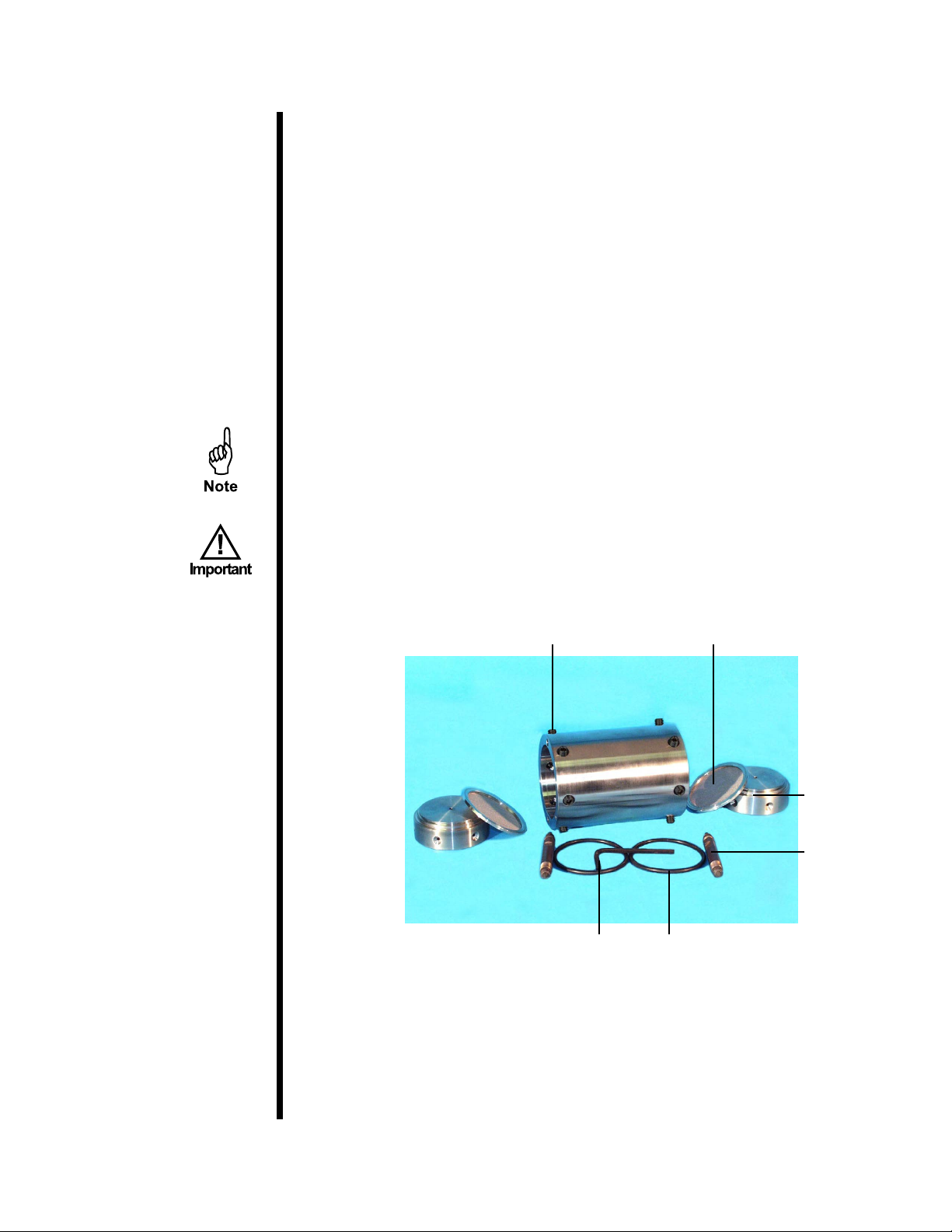

#170-45 Test Cell Assembly, Double-Capped for Cement Testing,

With Cement Screens, 2,000 PSI

#170-13-3 O-ring,Viton,Qty:4

#170-16 ValveStem,Qty:2

#170-17 ValveStemO-ring,Qty:4

#170-18 DetachableScreen,325-Meshwith60-MeshBackup,Qty:2

#170-24 2,000-PSIEndCap,Qty:2

#170-26-1 HardenedLockingScrew,Qty:12

#170-27 " Allen Wrench

#170-45-3 Cell Body

#171-24 1350 / 750 PSI (9,308 / 5,171 kPa) Nitrogen Manifold

#142-39 PipePlug,¼",Qty:2

#170-20 Manifold Block

#170-32 NeedleValve,Male,⅛"×⅛"NPT

#171-23-1 Safety Pin with Lanyard

#171-24-002 Regulator,Qty:2