Table 6 : Dashboard Icons

Name Icon Description

Remote

Control Remote control is enabled. This

can be Remote Start/Stop, COM

Control, Integral Sequencing or

Web Control.

Service

Required A service reminder is nearing or

has expired

(i.e.: an air or oil lter needs to be

changed).

Unloaded

or

Loaded

Compressor is in the unloaded

state.

Compressor is in the loaded state.

DASHBOARD STATUS MESSAGES

The dashboard also displays the current operating

state of the compressor. The following states can be

encountered during machine operation:

Ready to Start – The compressor currently has no trip

or start inhibit conditions present. The machine can be

started by pressing the start button at any time.

Starting – A start command has been given to

the compressor and the start sequence is being

performed. The time period for this state can vary

depending on the starter type of the machine.

Load Delay – The compressor is waiting for a small

period of time after starting before allowing the

machine to load. This ensures the machine is at

operating conditions before loading.

Running Loaded – The compressor is operating and

producing air. The inlet valve is open and the blow-o

valve is closed.

Running Unloaded – The compressor is operating,

but not producing air. The inlet valve is closed and the

blow-o valve is open.

Reload Delay – This is a brief period of time after the

compressor has unloaded before it is allowed to load

again. This gives the inlet and bypass valves time to

reach their proper positions.

Auto-Restart – The compressor has stopped due to

pressure rising above the oine or auto-stop setpoints

and auto-restart being enabled. The compressor will

automatically restart when pressure falls to the online

or target pressure setpoint.

Stopping – The compressor has received a stop

command and the stop sequence is being performed.

Blowdown – The compressor must wait for a brief

period of time after stopping its motor before it is

allowed to start again. The compressor will restart at

the end of the blowdown period if a start command is

recieved during blowdown.

Not Ready – The compressor has detected a condition

that will not allow the compressor to start. The

condition must be cleared before a start is allowed, but

does not need to be acknowledged.

Tripped – The compressor has detected an abnormal

operational condition that has stopped the machine. A

trip must be acknowledged by hitting the reset button

before the compressor can start.

Processor Init – The controller is being initialized.

•

•

•

•

•

•

•

•

•

•

•

•

FIXED SPEED COMPRESSOR

HOME FOLDER

Page 1: System Overview

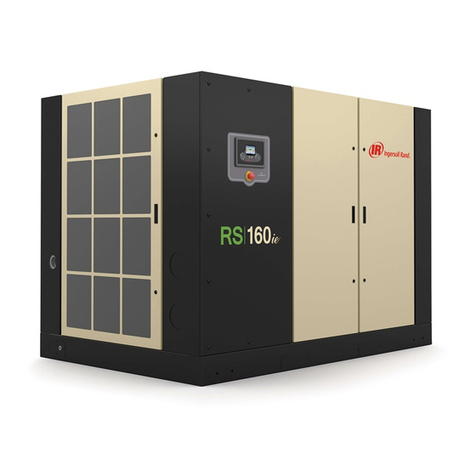

Figure 5 : Home Folder

This is the factory default display after powering up the

system.

Online Pressure Setpoint - indicated in the black box

and arrow, which is always left of center on the gauge.

The compressor will load when package discharge

pressure falls below this value.

Oine Pressure Setpoint - indicated in the black

box and arrow, which is always right of center on the

gauge. The compressor will unload when package

discharge pressure rises above this value.

Package Discharge Pressure - indicated by the large

numbers centered below the gauge and by the black

arrow below the gauge. This is the air pressure that the

compressor is supplying to the plant.

Pressure Unit of Measure - indicated below the

Package Discharge Pressure. This is selectable from the

GENERAL SETTINGS folder.

Airend Discharge Temperature - indicated by the

numbers in the lower right of the display. This is the

temperature of the air/oil mixture at the discharge of

the compression module.

Temperature Unit of Measure - indicated to the right

of the Airend Discharge Temperature. This is selectable

from the GENERAL SETTINGS folder.

Run Hours – indicated by the numbers in the

lower left of the display. The number of hours the

compressor motor has been running.