Intelligent Charging Limited IC48V User manual

IC48V Battery Charger/Analyser

Operator Manual

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 1 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V

BATTERY CHARGER

AND CAPACITY TESTER

OPERATORS MANUAL

IC48V Battery Charger/Analyser

Operator Manual

Table of Contents

1 Manual Revision History............................................................................................................4

2 Equipment Description..............................................................................................................5

2.1 General.............................................................................................................................5

2.1.1 Charging Mo es..........................................................................................................5

2.1.2 Capacity Testing Mo es...............................................................................................6

2.2 Component Parts...............................................................................................................8

2.3 Installation........................................................................................................................8

2.4 Front Panel Controls An In icators....................................................................................9

2.5 Rear Panel Controls An In icators....................................................................................11

3 Cell Monitor Interface..............................................................................................................12

3.1 General............................................................................................................................12

3.2 Charging With The Cell Monitor.........................................................................................12

3.2.1 Constant current charge............................................................................................12

3.3 Discharging With The Cell Monitor.....................................................................................13

3.3.1 Capacity Testing To Target Or Time...........................................................................13

3.3.2 Automatic Cell Balance...............................................................................................13

3.4 Monitor Only Mo e...........................................................................................................13

3.5 Normal Charge or Capacity Test Mo e...............................................................................13

3.6 Cell Monitor Exten e Display Reference...........................................................................13

3.7 Printing Data When Using The Cell Monitor........................................................................14

3.8 Cell Number Reversal.......................................................................................................15

3.9 Cell Monitor Specifications................................................................................................15

4 Equipment Menu Operation.....................................................................................................16

4.1 Main Menu.......................................................................................................................16

4.2 Charging Menu.................................................................................................................17

4.3 Capacity Testing Menu......................................................................................................18

4.4 Library Menu....................................................................................................................19

4.5 Settings Menu..................................................................................................................20

4.6 Cell Monitor Menu............................................................................................................21

4.7 Process Operation Menu...................................................................................................22

5 Connecting A Battery...............................................................................................................23

6 Connecting The Flying Lea Cell Monitor..................................................................................25

7 Connecting The Crown............................................................................................................25

8 Battery Charge Operation........................................................................................................26

8.1 Constant Voltage Charge..................................................................................................26

8.2 Constant Current Charge..................................................................................................27

8.3 Multi-Step Constant Current Charge..................................................................................28

8.4 Constant Current Charge Using Cell Monitor.......................................................................29

8.5 Performing A Charge........................................................................................................30

8.5.1 CHARGE FROM A LIBRARY ENTRY..............................................................................30

8.5.2 CHARGE FROM MANUAL DATA...................................................................................30

8.5.3 CHARGE FROM PREVIOUS DATA................................................................................30

9 Battery Capacity Test or Discharge Operation...........................................................................31

9.1 Capacity Test To 100%....................................................................................................31

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 2 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

9.2 Capacity Test To Target Voltage........................................................................................32

9.3 Capacity test Using Cell Monitor........................................................................................33

9.4 Automatic Cell Balancing...................................................................................................34

9.5 Full Battery Discharge.......................................................................................................35

9.6 Performing A Capacity Test...............................................................................................36

9.6.1 Capacity Test or Discharge From A Library Entry.........................................................36

9.6.2 Capacity Test or Discharge From Manual Data.............................................................36

9.6.3 Capacity Test or Discharge From Previous Data...........................................................36

10 Creating Or Mo ifying Library Entries.....................................................................................37

10.1 Data Entry Proce ure......................................................................................................37

10.2 Entering Charge Data.....................................................................................................37

10.3 Entering Discharge Data.................................................................................................39

11 Process Mo e........................................................................................................................40

11.1 Overview Of Operation...................................................................................................40

11.2 Process Menu.................................................................................................................40

11.2.1 Renaming a process.................................................................................................41

11.2.2 View or E it A Process.............................................................................................41

11.3 Process Execution...........................................................................................................42

11.4 Process Termination.......................................................................................................42

12 Calibration............................................................................................................................44

12.1 Equipment Require .......................................................................................................44

12.2 Calibration Equipment Connection...................................................................................44

12.3 Check Proce ure............................................................................................................44

12.4 Making Calibration A justment........................................................................................45

12.5 Reviewing Calibration Date.............................................................................................46

13 Miscellaneous Unit Functions..................................................................................................47

13.1 Description Of Stop Co es...............................................................................................47

13.2 Print Or Display Previous Operation Results......................................................................49

13.3 Changing The Date Format An Date Time......................................................................49

13.4 Mo ifying Display Intensity.............................................................................................50

13.5 Printing battery serial number.........................................................................................50

14 Service An Maintenance.......................................................................................................51

14.1 Calibration.....................................................................................................................51

14.2 Cleaning........................................................................................................................51

14.3 Battery Backup...............................................................................................................51

14.4 Printer Care....................................................................................................................52

14.4.1 Door Latch..............................................................................................................52

14.4.2 Paper Fee Button...................................................................................................52

14.4.3 Paper Roll Replacement...........................................................................................53

14.4.4 Ribbon Cartri ge Replacement.................................................................................53

14.4.5 Consumables Available.............................................................................................54

15 Specifications........................................................................................................................55

16 Pro uct Disposal Instructions.................................................................................................57

17 Pro uct Warranty..................................................................................................................58

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 3 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

1 Manual Revision istory

Rev Date Description

1 17-09-2013 Written from an IC50A manual.

2 21-07-2015 Formatting changes..

3 21-04-2016 Corrected maximum charge current at 12V

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 4 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

2 Equipment Description

2.1 General

The Battery Charger Analyser is an electronically controlle combine universal battery

charging unit with built in battery analysing (capacity testing) capabilities. It is house

in a metal enclosure esigne for bench mounting. As it is supplie it is esigne to

work on a 240V supply. It can be operate on a 115V supply but it will excee the fuse

rating if use on high charge rates.

Equipment control is via an interactive 253 x 32 ot matrix isplay an ata entry is via

a 16-key keypa . Operating mo es an functions are selecte by the use of a simple

menu system. Access to charging an testing operations is performe by either entry of

eight igit battery library names, repeat of last charge or capacity test or new manual

parameters. During operation the isplay will show the instantaneous values of battery

voltage, current an time elapse through the selecte program.

Process mo es can be create where complete unatten e charging, capacity testing

an final charging can be performe . Up to 6 ifferent charge or capacity test steps can

be create an up to 4 process programs can be store in the unit. Each process step

has an optional elaye start for resting the battery an also each step can soun the

alarm with or without a pause in operation. The process is simply continue by pressing

a key on the keypa .

Battery ata is store internally in the units non-volatile memory. The operator can a

an mo ify this list by entering the etails of the battery to be inclu e on the isplay

an keyboar . Alphanumeric igits, up to a maximum of 8 igits, i entify Battery library

entries

Batteries are connecte to the front of the unit by means of two in ivi ual high current

connectors. Connection to the battery has to be ma e via the appropriate connectors

for that battery. The unit is supplie with M8 ring crimps that must have the

appropriate connector for the battery type being teste fitte .

The IC48V can: -

Charge 12V at 80.0A

Charge 24V batteries at 80.0A

Charge 48v batteries at 40.0A

Capacity Test 12V Batteries at 100.0A

Capacity test 24V batteries at 80.0A

Capacity test 48v batteries at 40.0A

The unit contains a high flow rate fan to extract the heat energy generate internally

when running in capacity test mo e.

2.1.1 Charging Modes

CONSTANT VOLTAGE CHARGE

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 5 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

Where the battery is charge at a re ucing current when the constant voltage

threshol is met. Parameters for this mo e are maximum charge time, optional

minimum current to stop charge an a current threshol , which can etect a

potentially faulty battery.

CONSTANT CURRENT CHARGE WITH TOP UP CHARGE

Where battery is charge at a constant current until a terminal voltage is met, at

this point it can be charge for an a itional time at a user set current. The

overcharge voltage is set in this mo e to prevent overcharging of the battery.

MULTIPLE STEP CONSTANT CURRENT CHARGE

Up to 4 constant current steps can be implemente for the charge cycle. this

mo e also has an overcharge voltage setting to prevent overcharging of the

battery. Charge current can be set to zero for “rest” perio s between charge

steps.

CONSTANT CURRENT USING CELL MONITOR

In this mo e the battery will be charge at constant current with the charge

switching to the top up charge (if require ) when all the cells reach the target

voltage specifie .

2.1.2 Capacity Testing Modes

CAPACITY TEST TO 100 PERCENT

This mo e will ischarge the battery connecte at the current specifie for the

test uration specifie thus reporting the battery capacity is 100% or more. The

capacity test will be stoppe if the target voltage is reache before the full test

time has elapse . During the capacity test an when it is terminate the isplay

will show the amount the capacity test is complete as a percentage.

CAPACITY TEST TO TARGET VOLTAGE

This mo e will ischarge the battery own to the terminal voltage specifie thus

reporting the actual percentage capacity. The capacity test will be stoppe if the

target threshol voltage is reache before the full test time has elapse . During

the capacity test an when it is terminate the isplay will show the amount the

capacity test is complete as a percentage.

CAPACITY TEST WITH CELL MONITOR

This mo e will ischarge the battery connecte at the current specifie for the

test uration specifie thus reporting the battery capacity is 100% or more. The

capacity test will be stoppe if any cell reache the cell target voltage before the

full test time has elapse . During the capacity test an when it is terminate the

isplay will show the amount the capacity test is complete as a percentage.

AUTOMATIC CELL BALANCE

This mo e is esigne to ischarge the battery own to zero volts, where when

any cell reache zero volts a balancing resistor will automatically be place

across it. When the battery total voltage reache near zero all the remaining

balancing resistors will be applie .

FULL DISCHARGE

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 6 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

This mo e will o a basic ischarge of the battery at the current specifie for the

time specifie .

The unit can be set so that a pre efine charge or capacity test can be sche ule to start at

up to 99.9h in the future. An if uring this time the power is lost to the unit, such as a power

outage, the unit will continue to count own when the power is restore . Note: If the power

outage resumes after the elapse time has been passe the pre efine charge or capacity test

will not be execute .

The unit contains the software that will allow it to be calibrate by the en user oing away

with the nee to sen the unit to a service centre for perio ic calibration. The re-calibration

process only takes a few minutes an this is one without the nee to access the internals of

the unit.

The printer when fitte allows the operator to print har copies of the charge an test results

upon completion of the test. This report can be use to complement the service sche ule by

provi ing full traceability.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 7 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

2.2 Component Parts

Upon receipt of your new battery charger analyser unpack an check that all items are

present in the containing box.

STANDARD ITEMS

One IC48V Battery Charger Analyser

One power cor

One Set (+ve & -ve) stan ar battery lea s.

One paper Copy Operators Manual

Certificate Of Conformity

Calibration Certificate

OPTIONAL ITEMS

Cell Monitor Interface

Cell Monitor Crown (to suit battery specifie ).

Battery specific connectors.

2.3 Installation

The Battery Charger Analyser shoul be mounte on a level surface such as a

workbench or stur y shelf above the batteries with a loa ing weight of at least 50Kg.

The unit shoul be site so that at least 10cm of airspace is available all roun the si es

an top of the unit to allow free movement of air require for cooling.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 8 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

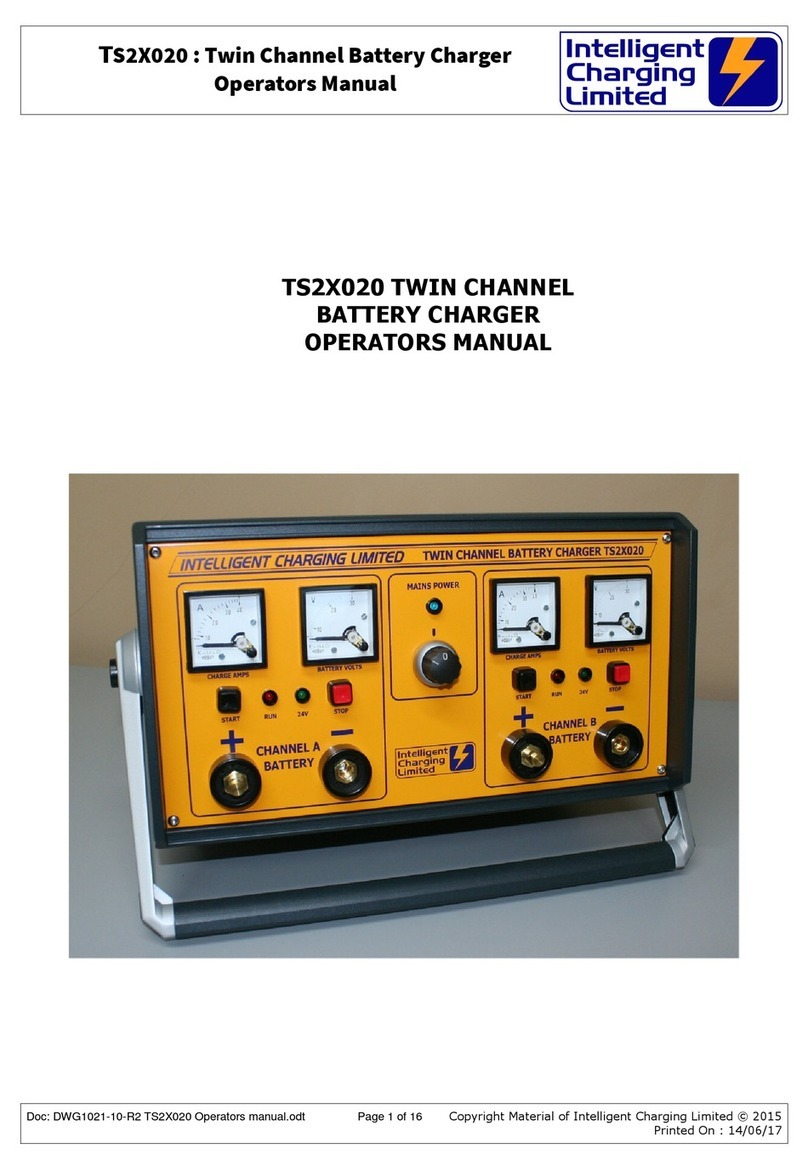

MEM

B63

ON

OFF

I

O

MEM

B63

ON

OFF

I

O

8

5

9 A

6 B

31 2

*

CLR 0#

ENT

C

.

4

7

MB73+ MAIN A CHARGE

7-05-2006 16:30:15 B TEST

C SETTINGS

100.0 mm 100.0 mm

100.0 mm

IC48V Battery Charger/Analyser

Operator Manual

2.4 Front Panel Controls And Indicators

(A) – DISPLAY

All battery charger in ications are ma e on this 256 x 32 ot matrix vacuum fluorescent

isplay.

(B) - BUILT IN PRINTER

If fitte the optional 24 column printer. On the non printer mo els this will be a

blanking plate.

(C) - MAINS POWER SWITCH

Pressing this switch activates mains power. It will illuminate to in icate power is being

applie to the unit.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 9 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

GFEDC

B

A

I

H

J

IC48V Battery Charger/Analyser

Operator Manual

(D) - AUXILLIARY CONNECTOR

This 6 pin connector is the RS232 an power connector for the cell monitoring unit. It

can also be use for remote control operation with PC base software.

(E) – KEYPAD

All battery charge an capacity test functions are activate via this 16 key keypa .

(F) - NEGATIVE BATTERY TERMINAL

Connection of the negative battery lea is ma e to this terminal.

(G) - POSITIVE BATTERY TERMINAL

Connection of the positive battery lea is ma e to this terminal.

(H) - HEAT EXCHANGER EXHAUST FAN

During use the unit absorbs electrical power, which it turns into heat, this fan exit is

where the heat is extracte from the unit. It is important that it is not obstructe .

(I) & (J) - CHARGE & CAPACITY TEST CIRCUIT BREAKERS

The circuit breakers are fitte to prevent high currents from being riven into the

battery or into the unit shoul a fault con ition occur. Always ensure that the circuit

breaker is in the ON position before starting a charge or capacity test.

WARNING

NEVER SWITC T E CIRCUIT BREAK TO ON W EN T E UNIT IS PERFORMING A

C ARGE OR CAPACITY TEST AS SEVERE DAMAGE MAY OCCUR TO T E BATTERY OR T E

EQUIPMENT

ALWAYS PRESS STOP FIRST

If the circuit breaker operates uring a charge imme iately press STOP an remove

power from the unit an isconnect the battery.

Operation of the circuit breaker is an in ication of a fault an the unit will nee to be

checke before using.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 10 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

2.5 Rear Panel Controls And Indicators

(K) - Mains Lea

This is the entry point for the power lea into the unit. Always check that the lea is not

amage before use.

(L) - Mains Fuse.

The mains fuse fitte to the IC48V is 16.0A Slow Blow 1¼”

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 11 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

MAINS 220V-240V 50Hz/60Hz 2.4KW

REPLACE ONLY WITH SAME TYPE FUSE 13A S/B

SERIAL No:

INTELLIGENT CHARGING

from

ControlledAccess Storage Cabinets Ltd

Ford House, Dewing Road,

RackheathInd. Est. Norwich,

Norfolk, NR13 6PS, ENGLAND.

TEL: +44-1603-722770

FAX: +44-1603-722771

MAIL: sales@casc-ltd.com

C ARGING

INTELLIGENT

FROM

K L

IC48V Battery Charger/Analyser

Operator Manual

3 Cell Monitor Interface

3.1 General

The IC48V battery charger analysers have built in support for the cell-monitoring

interface.

This allows the monitoring of NiC batteries of up to 20 cells. Contact us if cell

monitoring is require above 20 cells.

With the cell-monitoring interface connecte two a itional capacity test options

become available an one a itional charge option.

When the cell monitor is in use two a itional isplays can be selecte by pressing ‘B’

or ‘C’ keys on the keypa while the unit is running. Pressing ‘A’ key will return the

isplay back to the efault isplay.

‘A’ Default isplay.

This is the conventional isplay which all mo es of operation use.

‘B’ A textual list of cell voltages

This isplay will show all 20 cell voltages being measure as a simple list.

‘C’ A graphical bar graph.

This isplay will, show all 20 cell voltages being measure a graphical bar graph,

which will show the inter-relationship between each cell. Also isplaye is a line

representing the target voltage. The battery voltage an charge of capacity test

current highest cell voltage, lowest cell voltage an the "cell focus" voltage are

shown in text format. By using the left an right arrow keys on the keypa a

highlight marker can be move across each cell so that if one particular cell

voltage nee s to be monitore it will be isplaye by the right of the bar graph.

By pressing "0" an either "" or "" keys simultaneously will cause the 1.0V

isplay win ow to be shifte up or own the 2.0V range.

The cell monitor is supplie as an interface unit with 21 patch lea connection for

connecting to batteries via in ivi ual clamps. It has a connector fitte to it where

“crown” assembly can be plugge in. The “crown” arrangement is place onto the top

of the battery with contact to the cells ma e via stainless test pins. The “crown”

arrangement is manufacture to suite one style of battery. If many ifferent styles of

batteries are in use a “crown” will be require for each battery.

3.2 Charging With The Cell Monitor

3.2.1 Constant current charge.

In the constant current charge mo e using the cell monitor interface the charge will

take place at the pre efine constant current until all the cells have reache the target

set point typically 1.55V. At which time the charge rate will change to the a itional

time rate an the charge will continue until the a itional time has elapse . If at any

time uring the charge any cell voltage excee s the cell overcharge voltage typically

1.65V the charge will stop. If a printer is connecte to the unit the cell voltages can be

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 12 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

printe at pre efine time intervals or can be printe by simply pressing the ‘.’ key. If

a printe report is require at the en of the charge, the final cell voltages will be

inclu e .

3.3 Discharging With The Cell Monitor

3.3.1 Capacity Testing To Target Or Time

This capacity test mo e allows you to ischarge the battery at the require current for

your pre-selecte time until one cell goes below a pre efine target voltage typically

1.00V at which point the ischarge stops an the battery capacity can be seen. If a

printer is connecte to the unit the cell voltages can be printe at pre efine time

intervals or can be printe by simply pressing the ‘.’ key. If a printe report is require

at the en of the capacity test the final cell voltages will be inclu e .

3.3.2 Automatic Cell Balance

This mo e allows you to set a pre efine ischarge current to flatten the battery an to

perform an automatic cell balancing exercise. While uring the ischarge any cell

approaches 0.00V its balancing resistor will be switche in to re uce the reverse charge

effect. When the battery voltage falls below 3.0V an the ischarge current falls below

2.0A the cell-monitoring interface will automatically switch in all the balancing resistors

an will remain it that state until either the CLR key is presse or the Discharge Time

elapses.

3.4 Monitor Only Mode

A mo e of operation is available where the cell monitor interface can be scanne while

the unit is i le. This is obtaine through the SYSTEM menu. While in this mo e the ‘B’

& ‘C’ keys will isplay the textual cell voltages or the bar graph respectively. While this

mo e is active an the printer is installe a snapshot of the cell voltages can be printe

by pressing the ‘.’ key. When accessing the monitor mo e the option of applying the

cell balancing resistors is available, so manual cell balancing can be applie .

3.5 Normal Charge or Capacity Test Mode

When activating the normal charge an capacity test mo es if the unit etects that the

cell monitor is connecte it will ask the operator if cell monitoring is require uring the

operation. If this is selecte the cell monitor will scan the cells an report the voltages

but will take no actions on in ivi ual cell voltages etc.

3.6 Cell Monitor Extended Display Reference

When performing a charge or capacity test the isplay will always efault to showing

the main process con itions, but when the cell monitor is in use there are two

a itional isplays which give the operator a list of cell voltages at the instant in time or

a graphical bar isplay of the cell voltages. The alternative isplays are viewe by

pressing either of the ‘A’, ‘B’ or ‘C’ keys on the keypa .

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 13 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

IC48V Battery Charger/Analyser

Operator Manual

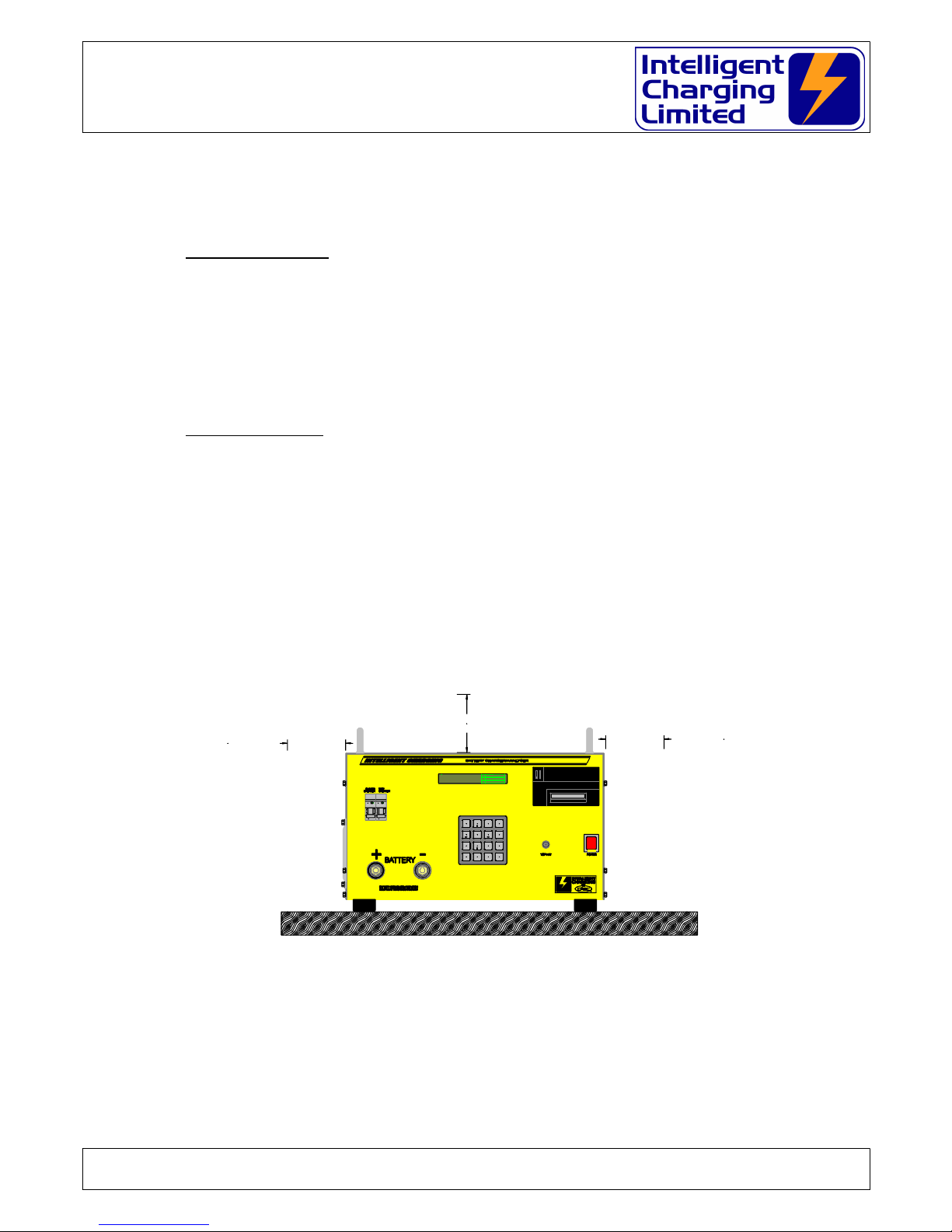

The ‘A’ key changes the isplay to the main process con itions as shown:

The ‘B’ key changes the isplay to the full 20-cell voltage list as shown:

The ‘C’ key changes the isplay to a bar graph of cell voltages as shown:

While the graphical isplay is viewe the range of the isplay can be ynamically

change from the efault 0.8 to 1.8V to a bottom limit of 0.0V to 1.0V or an upper limit

of 1.0 to 2.0V by pressing an hol ing the "0" key an pressing the "" or ""

respectively. Each step is an increment or ecrement of 0.1V.

3.7 Printing Data When Using The Cell Monitor

If the printer is fitte to the charger analyser an the cell monitor is in use there are

a itional printing facilities available. When performing a charge or capacity test the cell

voltages can be printe manually at a time to suit you by simply pressing the ‘.’ key or

a print interval can be specifie in minutes. When the cell monitor is in use the full list

of cell voltages will also be inclu e in the final print at the en of the operation. The

cell monitor printout is a similar format to the figure below:

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 14 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

STOP

*

CLR

1.. 5 1.35V 1.35V 1.35V 1.35V 1.35V

6..10 1.35V 1.35V 1.35V 1.35V 1.35V

11..15 1.35V 1.35V 1.35V 1.35V 1.35V

16..20 1.35V 1.35V 1.35V 1.35V 1.35V

STOP

*

CLR

1.80

1.20

0.08

26.9V 0.0A

HIGH = 1.36V

LOW = 1.32V

C 01 = 1.32V

T1.55V 1.0A + 1.0A 1.0H O1.65V F 5.0H

27.6V 0.5A 0h00m00

MANUAL 24.0V CELL MONITOR CC CHARGE

STOP

*

CLR

IC48V Battery Charger/Analyser

Operator Manual

3.8 Cell Number Reversal

The cell monitor accessory is marke with cell numbers starting with #1 through to #20

(The maximum number of calls that can be monitore ). Cell #1 is consi ere to be the

cell which is connecte to the negative (-ve) cell en of the battery whereas cell #20

(in a 20 cell battery) is consi ere to be the cell which is connecte to the positive

(+ve) en of the battery.

Many battery manufacturers use the reverse cell numbering where cell #1 is the

positive (+ve) en of the battery an in the case of a 20 cell battery the #20 cell is the

negative.

Because of this numbering technique the battery charger has an option in the cell,

monitor settings to “reverse” the cell numbering for isplay an printing purposes. The

cell isplays show which is +ve en of the battery an which is the negative so that if

the cell numbering is reverse it is shown which way roun the numbering takes.

3.9 Cell Monitor Specifications

Power +5.0V

Cell Voltage Range -2.5V to +2.5V

Max No. Cells 20

Full Scan Rate 5 secon s

Balance Switching current 2.0A

Balance continuous current 1.0A

Balance Resistance 1.0Ω ±1% 2W

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 15 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

------------------------

CELL VOLTAGES AT 1.5H

01 1.46V 02 1.46V

03 1.46V 04 1.46V

05 1.46V 06 1.46V

07 1.46V 08 1.46V

09 1.46V 10 1.45V Lo

11 1.46V Hi 12 1.46V

13 1.46V 14 1.46V

15 1.46V 16 1.46V

17 1.46V 18 1.46V

19 1.46V 20 1.46V

------------------------

IC48V Battery Charger/Analyser

Operator Manual

4 Equipment Menu Operation

The Battery Charger Analyser is operate by the use of a simple menu structure which is

accesse by simply pressing the A, B, C or ‘.’ keys. To get back to the main menu the CLR

key is presse repeate ly. The following flowcharts illustrate the menu structure.

4.1 Main Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 16 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

THE AIN ENU

SETTINGS ENU

PRINT

SET CLOCK

SYSTE

DISPLAY

A

B

C

DISCHARGE ENU

PREVIOUS

LIBRARY

ANUAL

PROCESS

A

B

C

CHARGE ENU

PREVIOUS

LIBRARY

ANUAL

PROCESS

A

B

C

26 Feb 2009 10:16 o C TP

B73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

A

B

C

NO DATA

ove

CLR-Abort

ENT-Select

1 NO DATA 2 NO DATA

5 NO DATA

7 NO DATA 8 NO DATA

6 NO DATA

3 NO DATA 4 NO DATA

CM SHOWN WHEN CELL MONITOR IS CONNECTED

TP IS SHOWN WHEN TEMPERATURE PROBE IS CONNECTED

IC48V Battery Charger/Analyser

Operator Manual

4.2 Charging Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 17 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

CHARGING IN PROGRESS

CHARGING OPERATIONS

A

ENT

CLR

ENT

CLR

ENT

CLR

ENT

CLR

C16..C20 1.35V 1.35V 1.35V 1.35V 1.35V

STOP

*

CLR

C 1..C 5 1.35V 1.35V 1.35V 1.35V 1.35V

C 6..C10 1.35V 1.35V 1.35V 1.35V 1.35V

C11..C15 1.35V 1.35V 1.35V 1.35V 1.35V

STOP

*

CLR

1.80

1.20

0.08

26.9V 0.0A

HIGH = 1 .36V

LOW = 1.32 V

C 01 = 1 .32V

USE A/B TO CHARGE ODE

CHARGE ODE

CONSTANT VOLTAGE CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

C

CHARGE ENU

PREVIOUS

LIBRARY

ANUAL

PROCESS

A

B

C

CHARGE ODE

CELL ONITOR CC CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

CHARGE ODE

CONSTANT CURRENT CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

USE A/B TO CHARGE ODE

CHARGE ODE

ULTI-STEP CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

26 Feb 2009 10:16 o C TP

B73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

A

B

C

NO DATA

éèêç ove

CLR-Abort

ENT-Select

1 NO DATA 2 NO DATA

5 NO DATA

7 NO DATA 8 NO DATA

6 NO DATA

3 NO DATA 4 NO DATA

Nominal Volts 12.0V Target Volts 13.8V

in 0.0A Rise 0.0A Target Fail 5.0H

HELP LINE APPEARS HERE

Charge Amps 1.0A Charge Time 1.0H

TgFail 24.0H Ochg 1.65V CP 0m

Extra T 1.0H Extra Amps 0.5A

LIBRARY

ANUAL

TI ED

A

B

C

Target 1.55V ax Amps 1.0A

CELL ONITOR CC CHARGE 12.0V

STARTExtra Amps 0.5A For 1.0H Targ Fail 24.0H

Number If Cells 20 Cell Target Volts 1.55V

HELP LINE APPEARS HERE

Charge Amps 1.0A Overcharge Volts 1.65V

Cell Print 0H

Extra Amps 0.5A For 1.0H Targ Fail 24.0H

Nominal Volts 12.0V Target Volts 13.8V

HELP LINE APPEARS HERE

Charge Amps 1.0A Overcharge Volts 15.0V

TgFail 24.0H Overcharge 15.0V

Extra T 1.0H Extra Amps 0.5A

LIBRARY

ANUAL

TI ED

A

B

C

Target 13.8V ax Amps 1.0A

CONSTANT CURRENT CHARGE 12.0V

START

Overcharge Volts 15.0V

3: 1.0A 1.0H 4: 1.0A 1.0H

LIBRARY

ANUAL

TI ED

A

B

C

1: 1.0A 1.0H 2: 1.0A 1.0H

ULTI-STEP CHARGE 12.0V

START

Fail Tm 0.0H Amps Rise 0.0A

Run Tm 1.0H in Amps 0.0A

LIBRARY

ANUAL

TI ED

A

B

C

Target 13.8V ax Amps 1.0A

CONSTANT VOLTAGE CHARGE 12.0V

START

T1.55V 1.0A + 1.0A 1.0H O1.65V F 5.0H

27.6V 0.5A 0h00m00

ANUAL 24.0V CELL ONITOR CC CHARGE STOP

*

CLR

ANUAL 24.0V ULTI-STEP CHARGE

27.6V 0.5A 0h00m00

Step #1 1.0A For 1.0H Overchrg 13.2V STOP

*

CLR

27.6V 0.5A 0h00m00

ANUAL 24.0V CONSTANT CURRENT CHARGE

T13.8V 1.0A + 1.0A 1.0H O13.2V F 5.0H STOP

*

CLR

27.6V 0.5A 0h00m00

ANUAL 24.0V CONSTANT VOLTAGE CHARGE

T 13.8V 1.0A 1.0H 0.0A R0.0AF 5.0H STOP

*

CLR

PRNT

#

ENT

27.6V 0.5A 0h00m00

ANUAL 24.0V STOPPED BY OPERATOR

T1.55V 1.0A + 1.0A 1.0H O1.65V F 5.0H

PRNT

#

ENT

ANUAL 24.0V STOPPED BY OPERATOR

27.6V 0.5A 0h00m00

Step #1 1.0A For 1.0H Overchrg 13.2V

PRNT

#

ENT

27.6V 0.5A 0h00m00

ANUAL 24.0V STOPPED BY OPERATOR

T13.8V 1.0A + 1.0A 1.0H O13.2V F 5.0H

PRNT

#

ENT

27.6V 0.5A 0h00m00

ANUAL 24.0V STOPPED BY OPERATOR

T 13.8V 1.0A 1.0H 0.0A R0.0AF 5.0H

Overcharge Volts 15.0V

Nominal Volts 12.0V Charge Step #4

HELP LINE APPEARS HERE

Charge Amps 1.0A Charge Time 1.0H

B

Delay Before C CC CHARGE : 0.0H

Enter Delayed Start In Hours

Delay Before S CHARGE : 0.0H

Enter Delayed Start In Hours

Delay Before CC CHARGE : 0.0H

Enter Delayed Start In Hours

Delay Before CV CHARGE : 0.0H

Enter Delayed Start In Hours

IC48V Battery Charger/Analyser

Operator Manual

4.3 Capacity Testing Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 18 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

CAPACITY TEST IN PROGRESS

CAPACITY TESTING OPERATIONS

A

B

C

27.6V 0.5A 0h 0m 0

ANUAL 24.0V FULL DISCHARGE

Alarm 3.0V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

27.6V 0.5A 0h 0m 0

ANUAL 24.0V AUTO ATIC CELL BALANCE

Balanced 0 Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

27.6V 0.5A 0h 0m 0

ANUAL 24.0V CAPACITY TEST CELL ON

Targ 1.00V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

27.6V 0.5A 0h 0m 0

ANUAL 24.0V CAPACITY TEST TO 100%

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

27.6V 0.5A 0h 0m 0

ANUAL 24.0V CAPACITY TEST TO TARGET

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

A

B

C

ENT

CLR

ENT

CLR

ENT

CLR

ENT

CLR

ENT

CLR

DISCHARGE ODE

FULL DISCHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

27.6V 0.5A 0h 0m 0

ANUAL 24.0V CAPACITY TEST TO 100%

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

27.6V 0.5A 0h 0m 0

ANUAL 24.0V CAPACITY TEST TO TARGET

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

STOP

*

CLR

1.80

1.20

0.08

26.9V 0.0 A

HIGH = 1. 36V

LOW = 1 .32V

C 01 = 1.32V

STOP

*

CLR

1.. 5 1.35V 1.35V 1.35V 1.35V 1.35V

6..10 1.35V 1.35V 1.35V 1.35V 1.35V

11..15 1.35V 1.35V 1.35V 1.35V 1.35V

16..20 1.35V 1.35V 1.35V 1.35V 1.35V

27.6V 0.5A 0h 0m 0

ANUAL 24.0V CAPACITY TEST CELL ON

Targ 1.00V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

STOP

*

CLR

1.80

1.20

0.08

26.9V 0 .0A

HIGH = 1.36V

LOW = 1.32V

C 01 = 1.32V

STOP

*

CLR

1.. 5 1.35V 1.35V 1.35V 1.35V 1.35V

6..10 1.35V 1.35V 1.35V 1.35V 1.35V

11..15 1.35V 1.35V 1.35V 1.35V 1.35V

16..20 1.35V 1.35V 1.35V 1.35V 1.35V

27.6V 0.5A 0h 0m 0

ANUAL 24.0V AUTO ATIC CELL BALANCE

Balanced 0 Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

27.6V 0.5A 0h 0m 0

ANUAL 24.0V FULL DISCHARGE

Alarm 3.0V Amp 1.0A Tim 1.0H > 0.98H STOP

*

CLR

Delay Before FULL DISCHRG : 0.0H

Enter Delayed Start In Hours

Delay Before CELL BALANCE : 0.0H

Enter Delayed Start In Hours

Delay Before CELL CAPTEST : 0.0H

Enter Delayed Start In Hours

Delay Before CAPTEST TARG : 0.0H

Enter Delayed Start In Hours

Delay Before CAPTEST 100% : 0.0H

Enter Delayed Start In Hours

Discharge Time 1.0H

Discharge Amps 1.0A

LIBRARY

ANUAL

TI ED

A

B

C

Alarm Volts 3.0V

FULL DISCHARGE 24.0V

START

LIBRARY

ANUAL

TI ED

A

B

C

AUTO ATIC CELL BALANCE 12.0V

START

Discharge Time 1.0H

Discharge Amps 1.0A

LIBRARY

ANUAL

TI ED

A

B

C

Cell Target Volts 1.00V

CAPACITY TEST CELL ON 12.0V

START

Discharge Time 1.0H CP 0

Discharge Amps 1.0A

LIBRARY

ANUAL

TI ED

A

B

C

Target Volts 10.0V

CAPACITY TEST TO TARGET 12.0V

START

Discharge Time 1.0H

Discharge Amps 1.0A

LIBRARY

ANUAL

TI ED

A

B

C

Target Volts 10.0V

CAPACITY TEST TO 100% 12.0V

START

Discharge Time 1.0H

Discharge Amps 1.0A

Nominal Volts 12.0V Alarm Volts 3.0V

HELP LINE APPEARS HERE

Discharge Amps 1.0A Test Time 1.0H

HELP LINE APPEARS HERE

Number Of Cells 20

Discharge Amps 1.0A Test Time 1.0H

Number Of Cells 20 Cell Target Volts 1.00V

HELP LINE APPEARS HERE

Cell Print Interval 0

Discharge Amps 1.0A Test Time 1.0H

Nominal Volts 12.0V Target Volts 10.0V

HELP LINE APPEARS HERE

Discharge Amps 1.0A Test Time 1.0H

HELP LINE APPEARS HERE

Nominal Volts 12.0V Target Volts 10.0V

Discharge Amps 1.0A Test Time 1.0H

NO DATA

éèêç ove

CLR-Abort

ENT-Select

1 NO DATA 2 NO DATA

5 NO DATA

7 NO DATA 8 NO DATA

6 NO DATA

3 NO DATA 4 NO DATA

DISCHARGE ENU

PREVIOUS

LIBRARY

ANUAL

PROCESS

A

B

C

DISCHARGE ODE

AUTO ATIC CELL BALANCE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

DISCHARGE ODE

CAPACITY TEST CELL ON

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

26 Feb 2009 10:16 o C TP

B73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

A

B

C

DISCHARGE ODE

CAPACITY TEST TO 100%

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

DISCHARGE ODE

CAPACITY TEST TO TARGET

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

IC48V Battery Charger/Analyser

Operator Manual

4.4 Library Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 19 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

LIBRARY MENU

USE A/B TO CHARGE ODE

CHARGE ODE

CONSTANT VOLTAGE CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

CHARGE ODE

CONSTANT CURRENT CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

USE A/B TO CHARGE ODE

CHARGE ODE

ULTI-STEP CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

CHARGE ODE

CELL ONITOR CC CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

Extra Amps 0.5A For 1.0H Targ Fail 24.0H

Number If Cells 20 Cell Target Volts 1.55V

HELP LINE APPEARS HERE

Charge Amps 1.0A Overcharge Volts 1.65V

Cell Print 0H

Overcharge Volts 15.0V

Nominal Volts 12.0V Charge Step #4

HELP LINE APPEARS HERE

Charge Amps 1.0A Charge Time 1.0H

Extra Amps 0.5A For 1.0H Targ Fail 24.0H

Nominal Volts 12.0V Target Volts 13.8V

HELP LINE APPEARS HERE

Charge Amps 1.0A Overcharge Volts 15.0V

Nominal Volts 12.0V Target Volts 13.8V

in 0.0A Rise 0.0A Target Fail 5.0H

HELP LINE APPEARS HERE

Charge Amps 1.0A Charge Time 1.0H

DISCHARGE ODE

CAPACITY TEST TO 100%

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

DISCHARGE ODE

CAPACITY TEST TO TARGET

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

DISCHARGE ODE

CAPACITY TEST CELL ON

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

DISCHARGE ODE

AUTO ATIC CELL BALANCE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

DISCHARGE ODE

FULL DISCHARGE

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

USE A/B TO CHARGE ODE

Nominal Volts 12.0V Alarm Volts 3.0V

HELP LINE APPEARS HERE

Discharge Amps 1.0A Test Time 1.0H

HELP LINE APPEARS HERE

Number Of Cells 20

Discharge Amps 1.0A Test Time 1.0H

Number Of Cells 20 Cell Target Volts 1.00V

HELP LINE APPEARS HERE

Cell Print Interval 0

Discharge Amps 1.0A Test Time 1.0H

Nominal Volts 12.0V Target Volts 10.0V

HELP LINE APPEARS HERE

Discharge Amps 1.0A Test Time 1.0H

HELP LINE APPEARS HERE

Nominal Volts 12.0V Target Volts 10.0V

Discharge Amps 1.0A Test Time 1.0H

26 Feb 2009 10:16 o C TP

B73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

A

B

C

NO DATA

ove

CLR-Abort

ENT-Select

1 NO DATA 2 NO DATA

5 NO DATA

7 NO DATA 8 NO DATA

6 NO DATA

3 NO DATA 4 NO DATA 1 NO DATA

SAFT 40912

SAFT 40912

CONSTANT VOLTAGE CHARGE

LIBRARY

ODIFY

PRINT

A

B

C

CAPACITY TEST TO 100%

ERASE

ENTER LIBRARY NA E "_ "

HELP LINE APPEARS HERE

PRESS ENT TO CONFIR

ERASING SAFT 40912 [+12.0V] FRO LIBRARY

CAPACITY TEST TO 100%

CONSTANT VOLTAGE CHARGE

IC48V Battery Charger/Analyser

Operator Manual

4.5 Settings Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 20 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/1

ACCESSING THE SETTINGS

26 Feb 2009 10:16 o C TP

B73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

A

B

C

SETTINGS ENU

PRINT

SET CLOCK

SYSTE

DISPLAY

A

B

C

SYSTE ENU

RESET

CALIBRATE

CONTROL

ORE...

A

B

C

DISPLAY ENU

BATTERY

PREVIOUS

SYSTE

PRINT

A

B

C

PRINT ENU

BATTERY

PREVIOUS

SYSTE

DISPLAY

A

B

C

USE A/B TO CHANG E FOR AT

DATE FOR AT

dd/mm/yyyy

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

dd/mm/yyyy hh:mm:ss

ENTER DATE & TOD

16/12/2009 10:09:00

CALIBRATE ENU

RESET DATE

ADJUST ENT A

B

C02C-_

ENTER THE UNIT 4-DIGIT SERIAL NU BER

02C-_

ENTER THE UNIT 4-DIGIT SERIAL NU BER

ENTER VOLTAGE READING ON VOLT ETER _0.00V

CONNECT A GOOD 12/24V +40AH BATTERY

ENTER A PS READING ON A P ETER _0.00A

SETTING UP CHARGE A PS

ENTER VOLTAGE READING ON VOLT ETER _0.0V

SETTING UP DISCHARGE ODE

*** UPDATED ***

*** UPDATED ***

ENTER A PS READING ON A P ETER _0.00A

T=FFF 18.53 |TR O/H NOR AL

1-ATST>OFF |3=TR1>OFF |5- UTED |D1=000

V=3CE 10.21 |CH=007 0.00 |CT=007 0.00

2=BTST>OFF |4=TR2>OFF |6=PARALL|D2=000

02C-_

RESETTING OF DEFAULTS

ENTER THE UNIT 4-DIGIT SERIAL NU BER

02C-_

CONTROL DISPLAY : FOR DIAGNOSTIC USE

ENTER THE UNIT 4-DIGIT SERIAL NU BER

AUTHORISED SERVICE PERSONNEL ONLY

UNIT NEEDS RE-CALIBRATION

DONE

*

CLR

DONE

*

CLR

27.6V 0.5A 0h00m00

ANUAL 24.0V CONSTANT CURRENT CHARGE

T13.8V 1.0A + 1.0A 1.0H O13.2V F 5.0H

DONE

*

CLR

Target Volts 10.0V

CAPACITY TEST TO 100% 12.0V

Discharge Time 1.0H

Discharge Amps 1.0A

Run Tm 1.0H in Amps 0.0A

DONE

*

CLR

Fail Tm 0.0H Amps Rise 0.0A

Target 13.8V ax Amps 1.0A

CONSTANT VOLTAGE CHARGE 12.0V

DONE

*

CLR

VSF 0.01049266 L SF 0.00000000 CSF 0.01466274 TSF 0. 01466274

Cell onitor Program SW309 Version 02

Cal 21/12/2009 ***** Serviceable *****

S/N 02C-6137 firmware 4.0 21-12-2009

SYSTE ENU

Batt S/N

CELL ONIT

A

B

C

USE A/B TO CHANGE F OR AT

Request SN ?

no

>> NEXT >>

<< PREV <<

ACCEPT

A

B

C

Table of contents

Other Intelligent Charging Limited Batteries Charger manuals