Interflex IF-800/W02 User manual

Interflex Datensysteme GmbH 1/7

1 IF-800/W02 Terminal (Slave)

Thank you for choosing an Interflex system. With this slave terminal, you

have purchased a reliable device for access control.

Scope of delivery:

The following is included in the package:

W02 housing cover

Reader housing with encapsulated RFID electronics and 5 m connecting

cable

I/O controller board with address switch

Mounting plate for fastening

Material for wall mounting

Please check the completeness and condition of the shipment upon

receipt.

2 Function

Slave terminals of series IF-800 W02 are used for:

1. controlling the access of people who identify themselves via an RFID credential before entering a

security zone.

2. controlling and monitoring locking devices that prevent uncontrolled (physical) access to security zones.

3. writing NetworkOnCard access rights. The data is used for identification at offline devices, e.g. PegaSys

terminals.

A higher-ranking device, such as a terminal controller or a master terminal, is required for operation.

95-10327_ V2016-10-20 IF800_W02

IF-800/W02

Interflex Datensysteme GmbH 2/7

3 Hardware Components

The slave terminal consists of the following components:

4 Shielded Cables

To guarantee trouble-free operation, we recommend the use of shielded cables.

Operation, however, is also possible with unshielded cables. Data transfer problems must be examined on a

case-by-case basis. Where necessary, a shielded cable must be used for the corresponding devices.

5 How to Proceed During Installation

The following installation procedure has been proven and tested:

1. Install the electric cables required for operation.

2. Install the power supply.

3. Fasten the reader housing and the I/O controller board.

4. Set the address.

5. Connect the electrical cables.

6. Check the functions.

7. Close the W02 housing cover.

Interflex Datensysteme GmbH 3/7

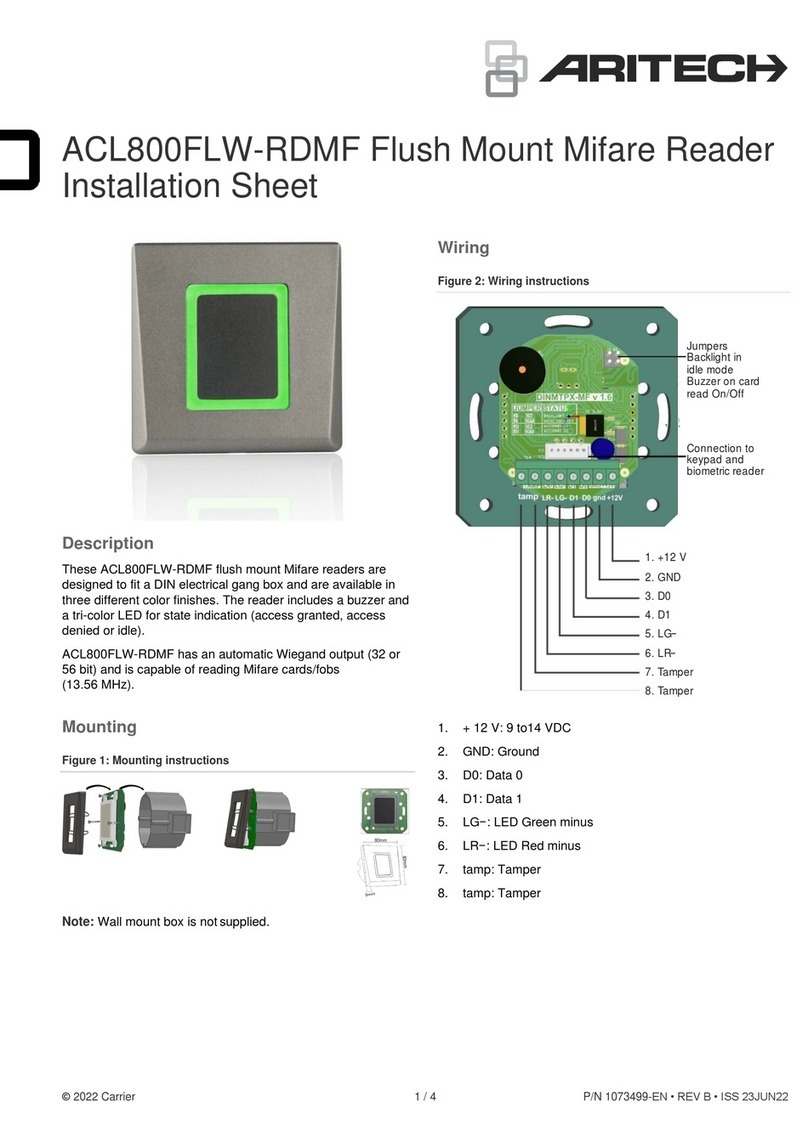

6 Electrical Connections

The figure below shows the electrical connections for door management and door monitoring. Installations

without door monitoring do not require sensors (13) or opening push-buttons (12) and the cables can be

omitted.

All cables must be laid to the I/O controller board.

The 5 m long reader cable (1) can be extended to 100 m.

For information on the connection, see: (Connections on the I/O Controller Board).

10 Housing for the installation of power packs and the I/O

board 12 Opening push-button or handle contact

11 Electric actuator up to 30 V, 2 A 13 Door sensor for monitoring the locking device

Figure Possible Connections and Electrical Wiring

Cable

No. Max. Length Cable Cores

1 Reader/ COM cable, preferably laid in empty conduit 100 m 4 x 2 x 0.6 mm²

2 Control line for electric actuator No

specifications 2 x 2 x 0.6 mm²

3 Cable to door sensor, handle contact or opening push-button 100 m 2 x 2 x 0.6 mm²

4 RS485 BUS cable to higher-ranking device 1200 m 2 x 2 x 0.6 mm²

4a RS485 spur line from BUS cable to installation site 100 m 2 x 2 x 0.6 mm²

5 Mains cable No

specifications NYM 3 x 1.5 mm²

Only use shielded connecting cables, e.g. cable type J-Y(ST)Y.

The above-specified cable lengths may not be exceeded. Excessive lengths can cause malfunctions.

The power supply must have a separate fuse protection.

The power supply of the access control element must be provided separately.

The recommended distance between cables and power lines is 10 cm.

If the locking device is monitored, a handle contact or door opening switch must be installed. The

switching of the contact allows for the locking device to be opened without setting off an alarm when

exiting the security zone.

Interflex Datensysteme GmbH 4/7

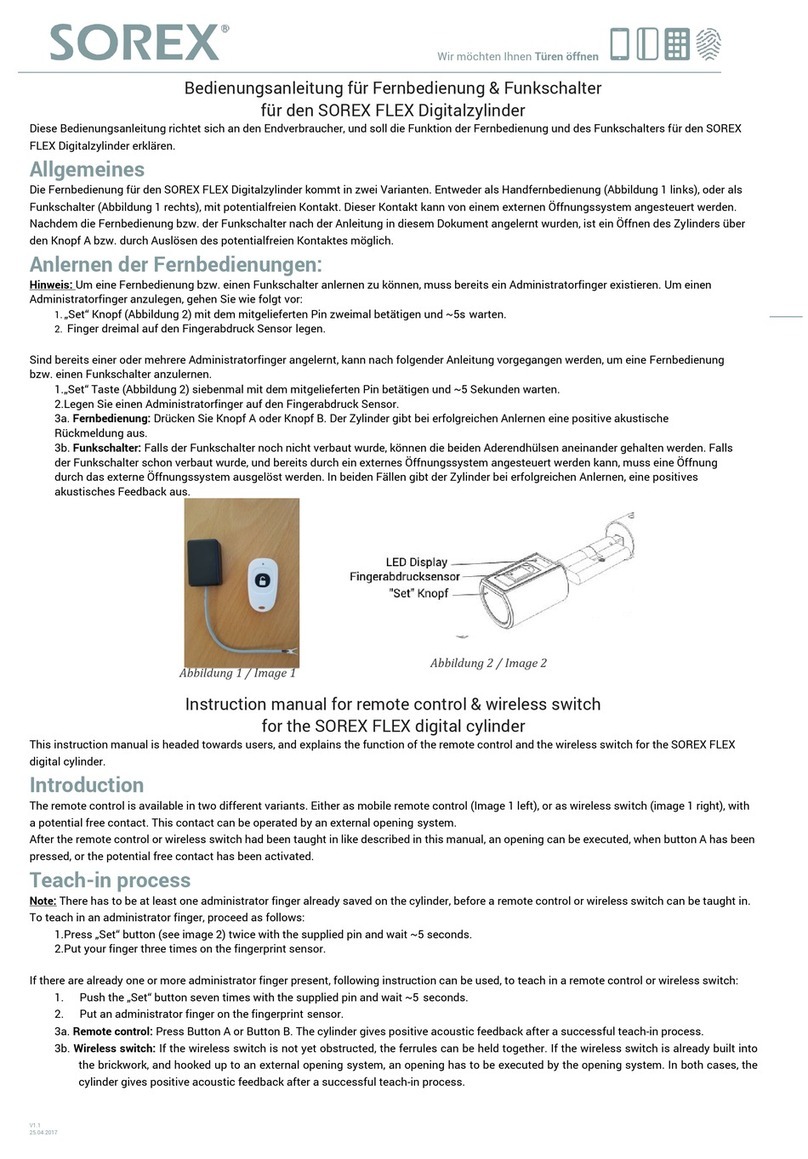

7 Installation

The reader (IP 65) can be installed on a flat wall or pillar, both indoors and outdoors.

The mounting plate (2) is used for fastening. The holes are designed for screw fastening to flat walls and

also to DIN appliance cases.

Snap-in elements (3a) in the housing cover (3) lock into place when the cover is pressed onto the mounting

plate (2) and thus, prevent the loosening of the cover.

The mounting plate must not get twisted out of shape when it is screwed down.

The countersunk screws must end up flush with the countersunk holes and not protrude.

There should be a distance of at least 20 cm from other devices with RFID readers.

When the device is mounted on a metal surface, the reading distance is reduced.

Close housing: The housing cover (3) is first placed over the reader electronics during initial operation. To

close the housing, the cover is positioned over the housing and pressed down until the snap-in elements lock

into place in the mounting plate.

1 Reader housing with reader electronics 3 Housing cover

1a 5 m reader cable for connection to I/O controller board 3a Snap-in elements in cover

2 Mounting plate 4 I/O controller board with address switches

2a Drilling for reader cable

7.1 Installation of the I/O Controller Board

The I/O controller board (4) can be installed in a distance of up to 100 m from the reader housing (1).

The I/O controller board must be installed in a secured area, e.g. in a DIN appliance

case or in a housing together with the power supply.

Interflex Datensysteme GmbH 5/7

8 Setting the Address

An address must be set for identification.

Address setting for the connection to a terminal controller or an access manager:

It is common practice to assign the first slave terminal on each RS485 BUS to address 1, the second to

address 2, and so on.

Address setting for the connection to a master terminal:

It is common practice to assign the first slave terminal to address 2, the second to address 3, and so on.

Before making the settings, check the BUS address section of the higher-ranking device, such as, e.g., a

master terminal. You can do so by using a remote program, e.g. Telnet, and entering the OC command "cfg".

Furthermore, please check if the address of the terminal already exists on this BUS. It is not allowed to

assign identical addresses to one RS485 BUS.

Switch off the power supply prior to changing an address.

Switch: 1 2 3 4

Address 1 (A) OFF OFF OFF OFF (not required if connected to a master terminal)

Address 2 (B) ON OFF OFF OFF

Address 3 (C) OFF ON OFF OFF (as shown in the figure above)

Address 4 (D) ON ON OFF OFF

Address 5 (E) OFF OFF ON OFF

Address 6 (F) ON OFF ON OFF

Address 7 (G) OFF ON ON OFF

Address 8 (H) ON ON ON OFF

Interflex Datensysteme GmbH 6/7

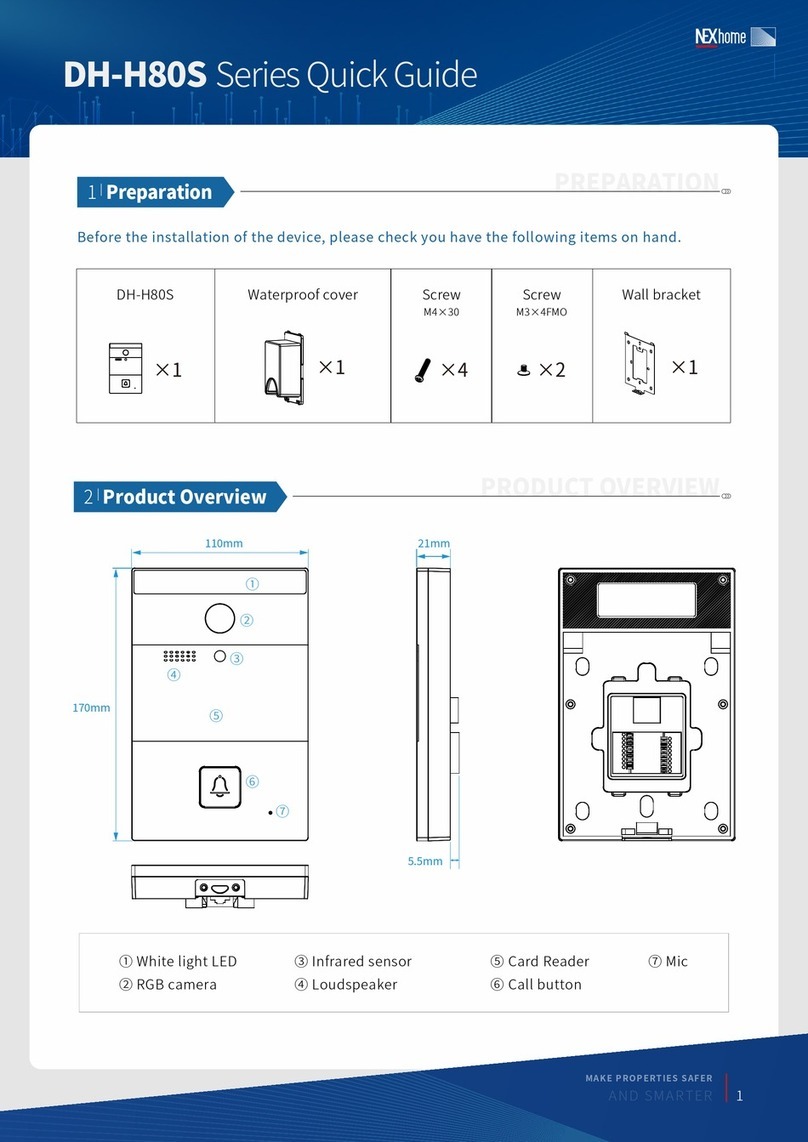

9 Connections on the I/O Controller Board

To maintain the required EMC values, the protective earth conductor and also the cable shields must be

connected as shown in the figure below.

For information on the connection of the RS485 data line to a terminal controller or master terminal, please

refer to the installation and wiring instructions included in the delivery of the respective device.

1 IF-800/W02 6 Example: Door monitoring connection

2 I/O controller board 7 Address switch

3 Power supply example Br1 Bridge is removed if the I/O controller board is to be used

as an expansion

4 Example: Connection of the RS485 data line Br2 Setting the relay output to normally open / normally closed

5 Example: Connection of an actuator Br3 Contact for monitoring the housing

Interflex Datensysteme GmbH 7/7

10 Technical Specifications

Power Supply

Low-voltage 12-24 VAC/DC

Power consumption Max. 4 VA

Protection Self-resetting fuse

Interface to parent devices RS485, 9600/ 19200 baud (automatic configuration)

RFID reader according to order Mifare, LEGIC or Proxif reading technology

Read range Up to 50 mm, depending on the size of the identification

medium used

Inputs for floating sensors 4 floating sensors (2 per each I/O controller board)

Output relays 2 relays with max. 30V 2A (1 per each I/O controller board)

Switching power Up to 30V, 2A

User information Buzzer; blue, red and green LEDs

Device Protection

Protection category III

Degree of protection Reader IP65, encapsulated electronics

I/O board IP 00

General Data

Ambient temperature -25°C to +55°C

Humidity Max. 95%, non-condensing

Product safety EN 60950-1

Compatibility (EMC) EN 300330-1/-2 EN 301489-1/-3

Dimensions (H x W x D) 119 x 77 x 23 mm (reader), 52 x 30 x 16 mm (I/O board)

Weight Approx. 0.4 kg

Installation type Surface-mounted

Color Anthracite or light gray

11 Disposal

Once its service life comes to an end, the device must be disposed of properly as

electronic waste. The owner can dispose of the device himself or return it to the

supplier.

Copyright © 2016 Version Date: October 31, 2016

Interflex Datensysteme GmbH

Zettachring 16, D-70567 Stuttgart, Germany Tel.: +49 (0711) 1322 0

Internet E-Mail: interflex.info@allegion.com Websites: www.interflex.de www.allegion.com

Table of contents

Other Interflex RFID System manuals

Popular RFID System manuals by other brands

Siemens

Siemens SIMATIC Ident CB Gate operating instructions

MegaPoints Controllers

MegaPoints Controllers System2 Starter Kit User reference

Intelleflex

Intelleflex CMR-6100 user manual

Elatec

Elatec MULTITECH 2 LEGIC M user manual

SILLA

SILLA PRISM SOLAR RFID Instructions for installation, use and maintenance manual

Balluff

Balluff BF-IDM07 operating guide