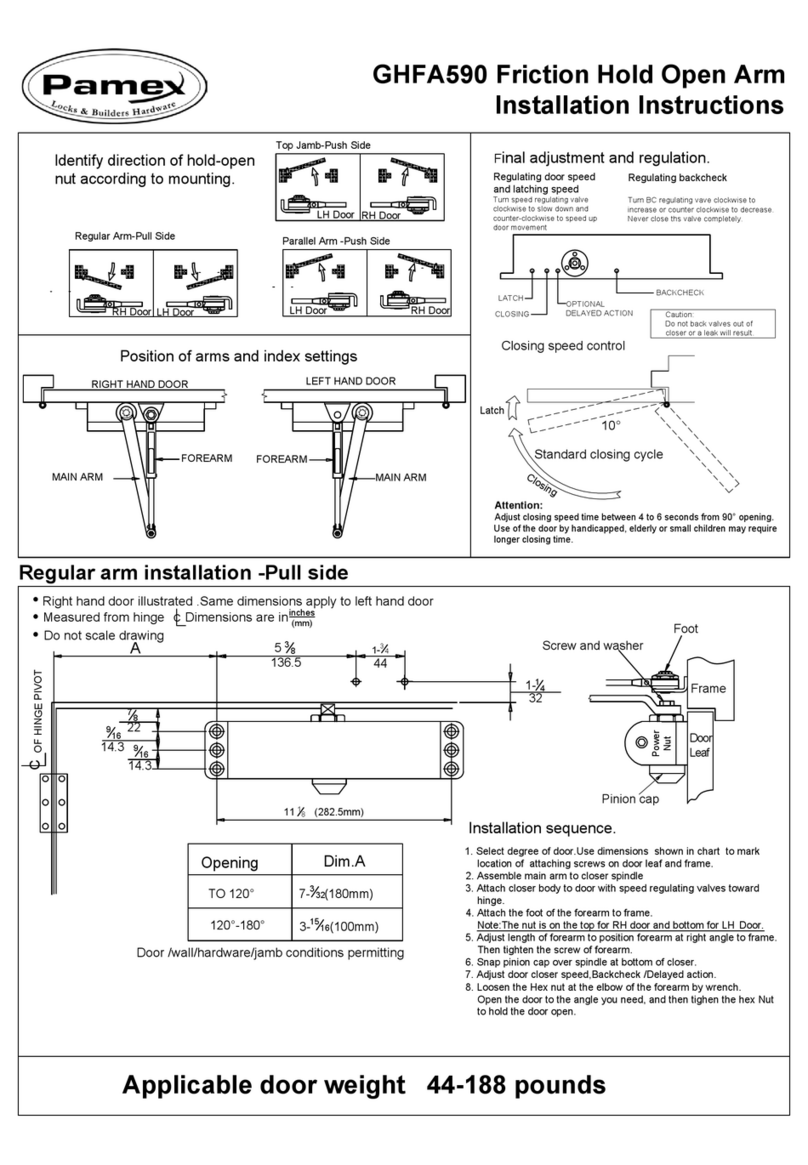

International Door Closers 44CI Series User manual

LEFT HAND RIGHT HAND

INSIDE

OUT SIDE

INSIDE

OUT SIDE

RIGHT HAND

REVERSE BEVEL

LEFT HAND

REVERSE BEVEL

DOOR HANDING

US STANDARDIZATION PROCEDURE

C.W. = CLOCKWISE

C.C. W = COUNTER CLOCKWISE

PLEASE NOTE: TURNS REQUIRED ARE APPROXIMATE BECAUSE OF

VARIOUS DOOR CONDITIONS AND LOCATIONS. YOU MAY HAVE TO

FURTHER ADJUST SPRING TENSION TO SUIT YOUR REQUIREMENTS.

CONTROL RANGE

DOOR HANDS DETERMINED

FROM OUTSIDE

West: 800-544-4422 • East: 800-225-6737

www.intldoorclosers.com

COPYRIGHT 2023 INTERNATIONAL DOOR CLOSERS, INC

International Door Closers, Inc.

44CI Series

INSTALLATION

INSTRUCTIONS

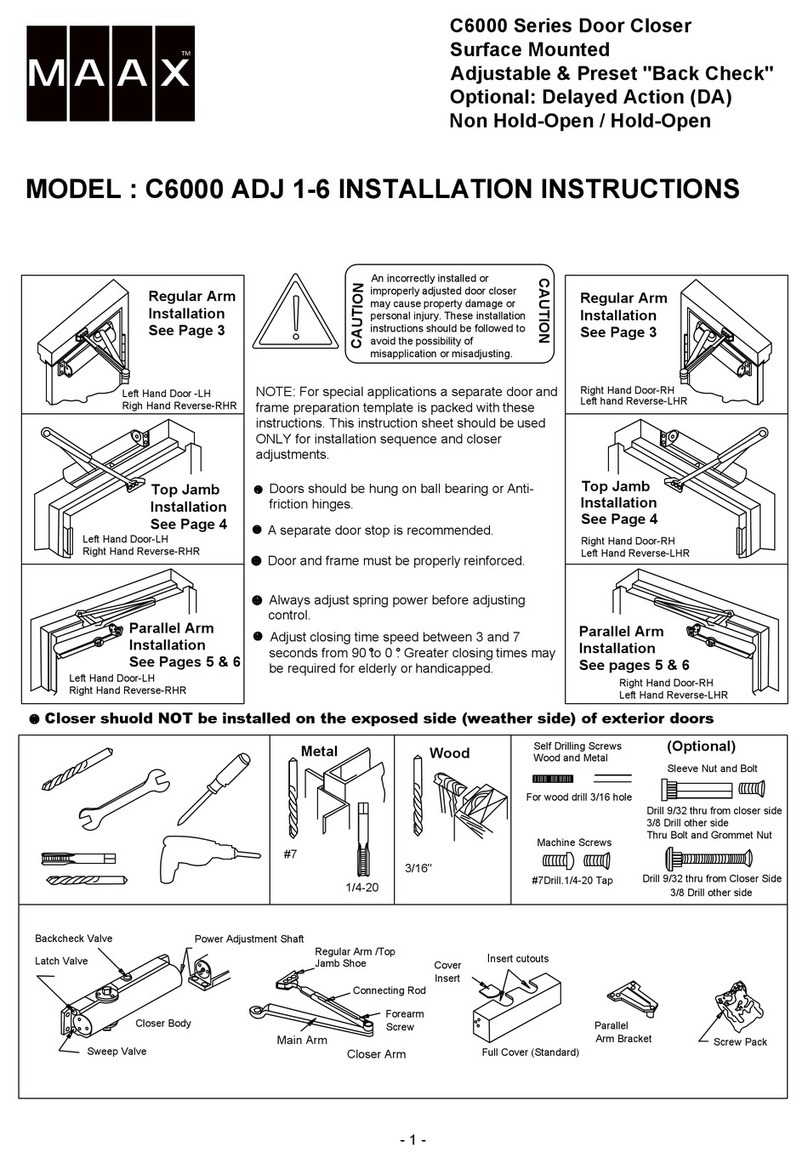

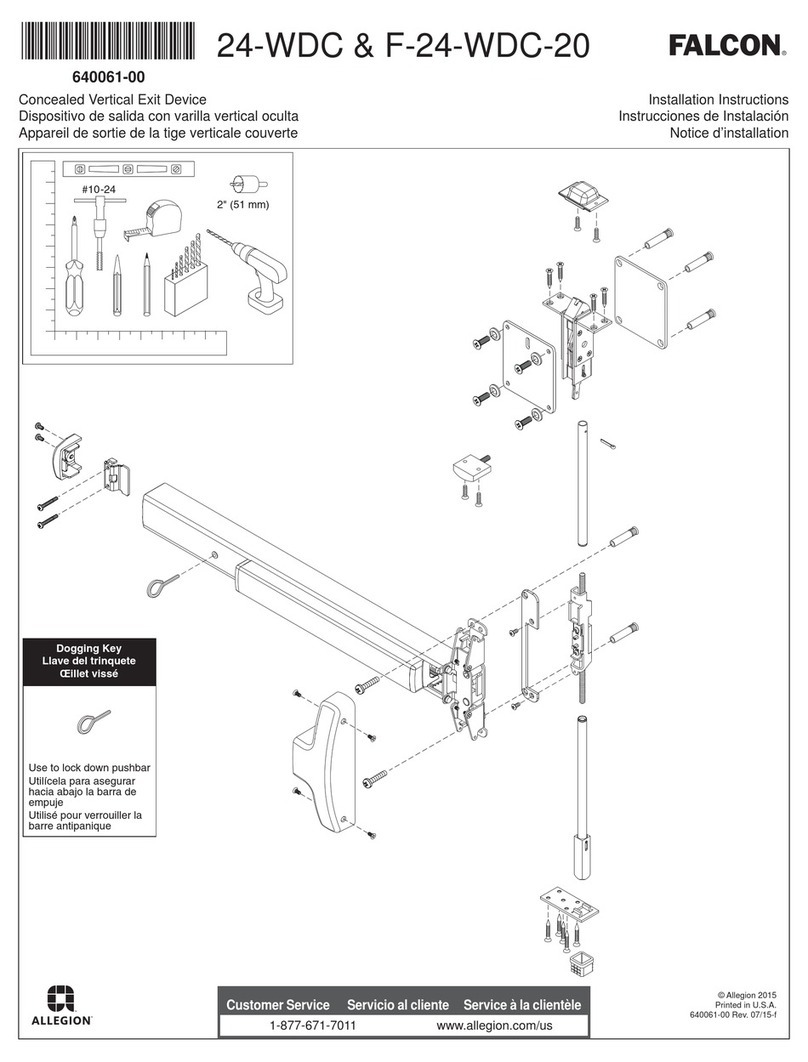

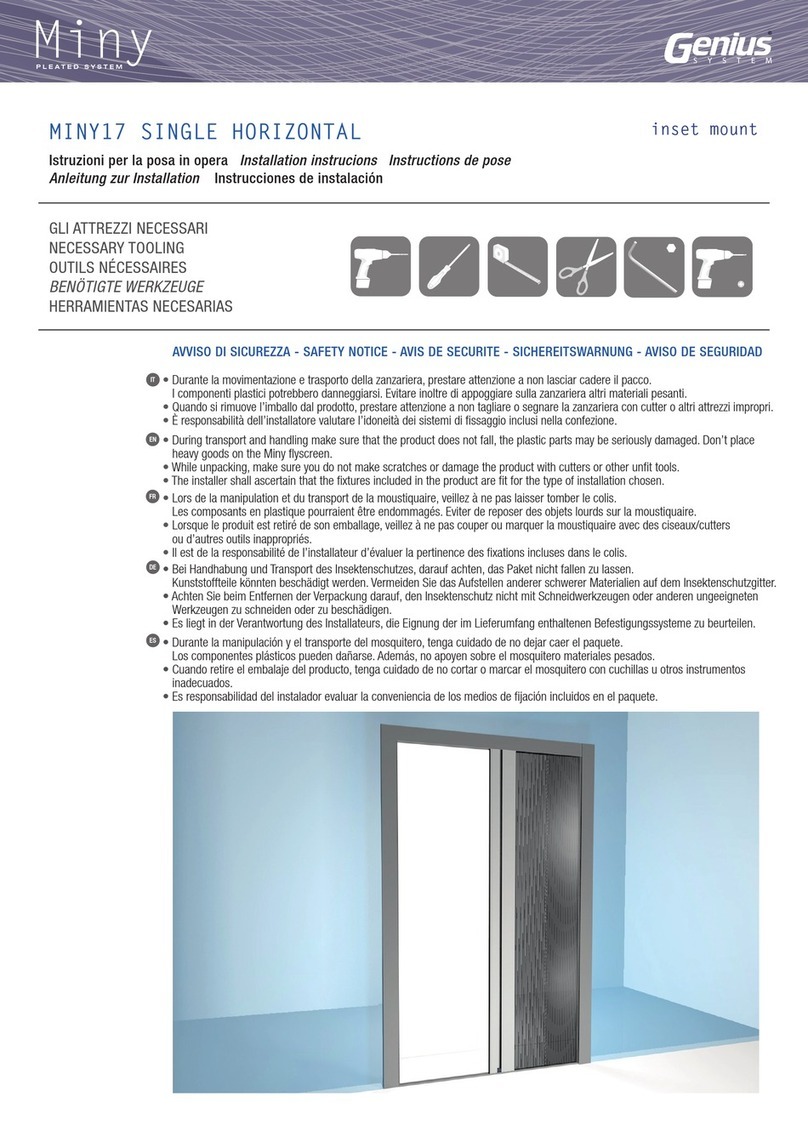

Standard Mount

(Pull Side)

Right Hand Door - RH

Left Hand Reverse - LHR

Right Hand Door - RH

Left Hand Reverse - LHR

Top Jamb Mount

(Push Side)

Right Hand Door - RH

Left Hand Reverse - LHR

Parallel Mount

(Push Side)

DOOR

CLOSER

SIZE

MAXIMUM DOOR WIDTH FULL TURNS OF POWER

ADJUSTMENT SCREW

EXTERIOR

(SWING OUT) lNTERIOR 44CI

1 28”(0.71m) 32”(0.81m) 7 C.C.W

2 32”(0.81m) 36”(0.91m) 4 C.C.W

3 36”(0.91m) 42”(1.07m) 0(PRESET)

4 42”(1.07m) 48”(1.22m) 5 C.W

5 48”(1.22m) 54”(1.22m) 10 C.W

6 54”(1.37m) 58”(1.47m) 15 C.W

IT IS IMPORTANT TO CAREFULLY FOLLOW ALL INSTALLATION AND

MOUNTING INSTRUCTIONS WHEN INSTALLING ANY DOOR CLOSER.

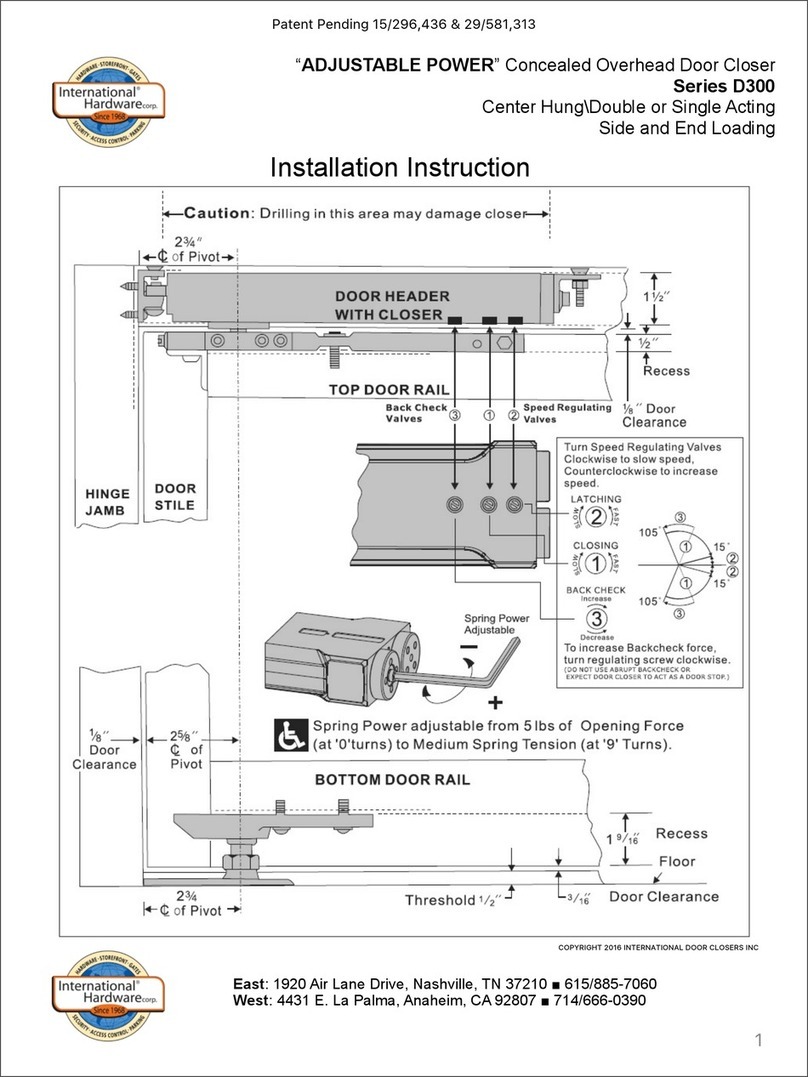

CLOSING SPEED

CONTROL SCREW

C.C.W

SPRING POWER

ADJUSTMENT SCREW

BACKCHECK

SCREW

LATCHING SPEED

CONTROL SCREW

C.W.

(Page 1 of 4)

Back Check

Closing

Slow

Fast

Latching

Slow

Fast

Increase

Decrease

1

2

3

West: 800-544-4422 • East: 800-225-6737

www.intldoorclosers.com

COPYRIGHT 2023 INTERNATIONAL DOOR CLOSERS, INC

International Door Closers, Inc.

44CI Series

Door Opening: 120°

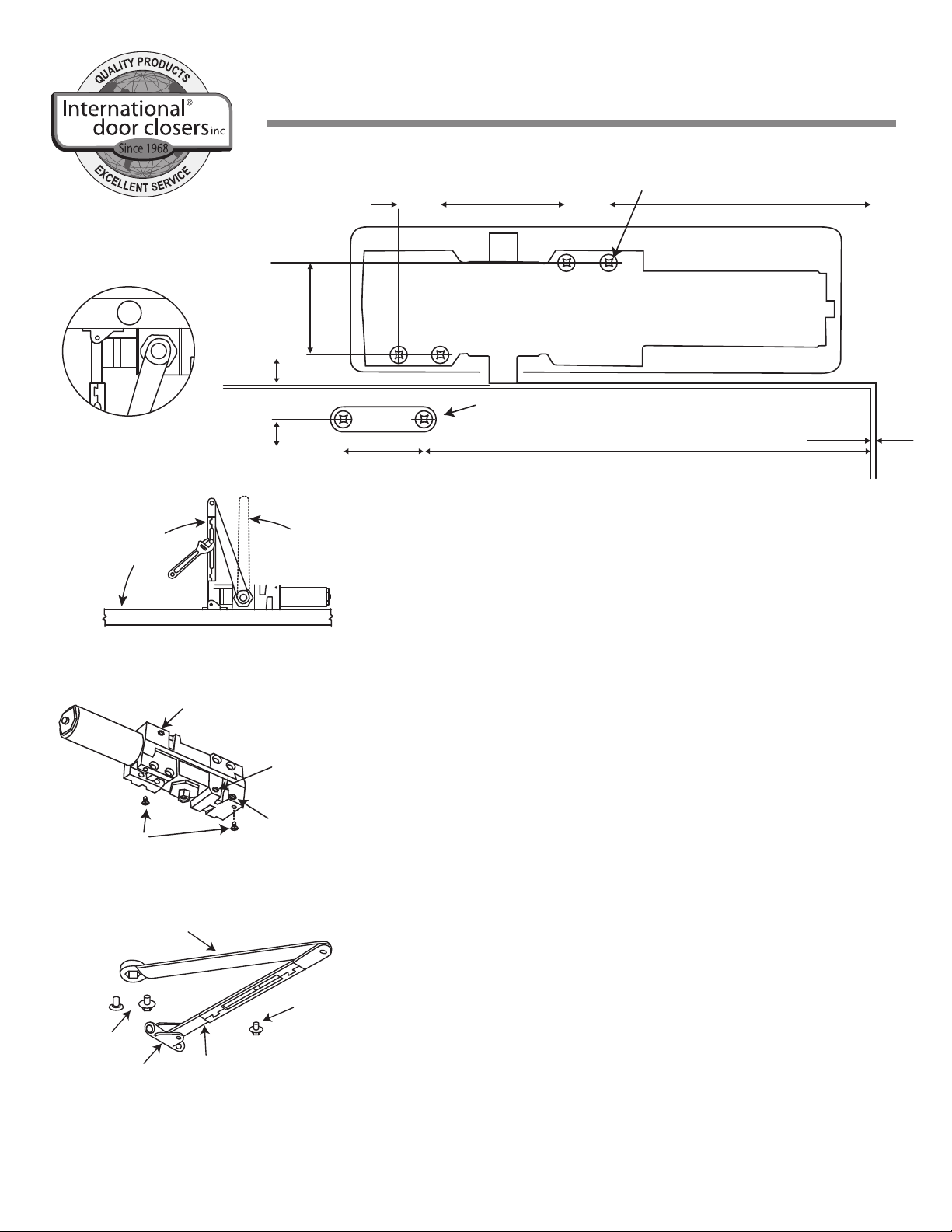

STANDARD INSTALLATION

CLOSER MOUNTED ON DOOR PULL SIDE

1” 3”

1 15/16” *10 13/16”

*1/8”

1”

2 Holes for #14

All-Purpose or 1/4-20

(M6x1.0) Machine Screws

4 Holes for #14

All-Purpose or 1/4-20

(M6x1.0) Machine Screws

(25.4mm) (76.2mm)

(49.2mm) (274.6mm)

(3mm)

(25.4mm)

*6 1/4”

(158.8mm)

2 1/4”

11/16”

(17.5.mm)

11/16”

(17.5.mm)

(57mm)

This drawing shown LEFT HAND DOOR. For RIGHT

HAND DOOR should be installed in symmetry.

4

PRELOAD TO

90°

LATCH SPEED

SCREW

CLOSING SPEED

SCREW

BACKCHECK

SCREW

COVER

SCREW

ROD

SHOE

ARM

SCREW

MAIN ARM

(Page 2 of 4)

1. Adjust spring power to match door width as indicated by chart on page 1.

2. Mount closer on door as dimensions shown. Tube end toward hinge.

If pivots are used, locate closer and shoe from CENTERLINE OF PIVOT.

(*For offset pivots, please increase the marked dimensions by 1/8”)

3. Place main arm on top of shaft, 100° to closer body, insert arm screw into top of

shaft and tighten.

4. Attach shoe to frame as shown. (If more latching power is required, shoe 180°)

5. Open door and insert rod in forearm.

6. With forearm at left angle to door (90°), insert forearm set screw and tighten.

(IF HOLD OPEN ARM IS USED, THE NUT IS ON THE TOP FOR RH DOOR AND

BOTTOM FOR LH DOOR)

REGULATION

A ‘Normal’ closing time from 90° open position to door stop position is 4-6 secs, evenly

divided between main swing speed and latch swing speed. Use socket key (furnished) to

adjust speed. To slow main speed of door, turn regulating screw nearest shaft clockwise.

To slow latch speed, turn regulating screw nearest latch clockwise.

BACK CHECK

To increase back-check force, turn regulating screw nearest hinge clockwise. DO NOT

USE ABRUPT BACKCHECK OR EXPECT DOOR CLOSER TO

ACT AS A DOOR STOP.

COVER

Place insert in proper cutout, then push cover against door. Tighten both

cover screw securely.

HOLD OPEN ADJUSTMENT (when hold open arm is used)

Loose adjusting nut, open door to desired hold open position and tighten nut.

Do not permit door to swing beyond hold open setting.

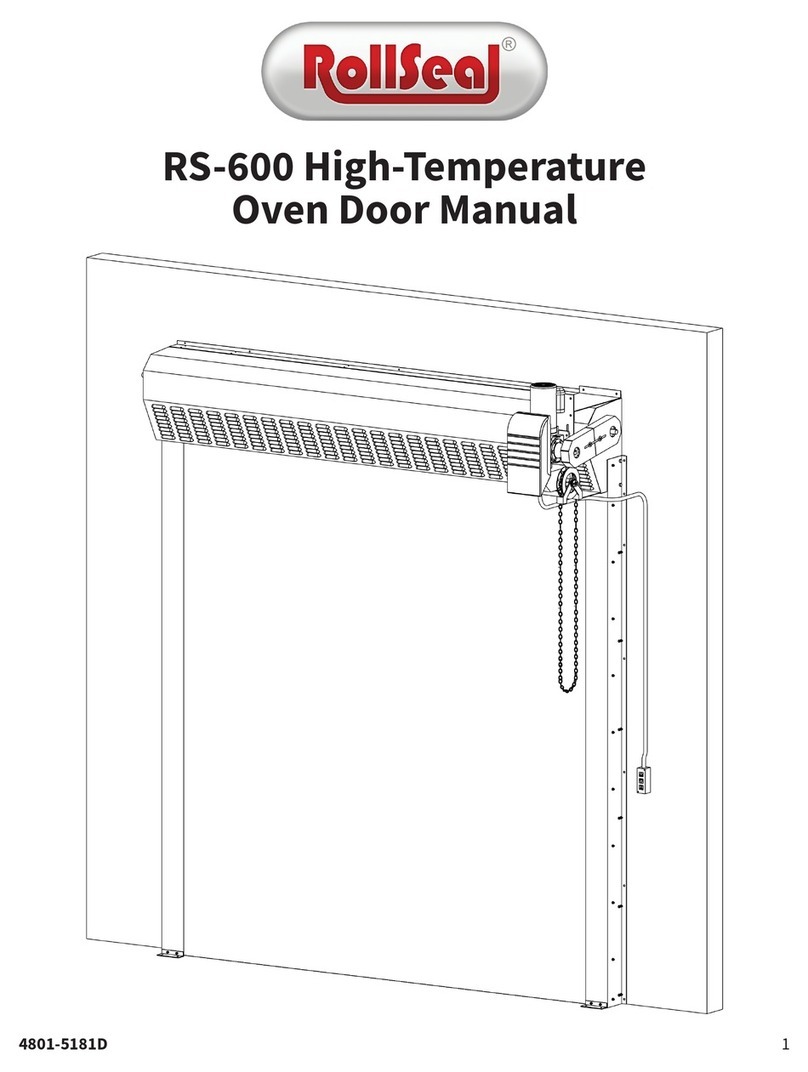

1” 3”

1 15/16” *10 3/4 ”

*1/8”

1”

2 Holes for #14

All-Purpose or 1/4-20

(M6x1.0) Machine Screws

4 Holes for #14

All-Purpose or 1/4-20

(M6x1.0) Machine Screws

(25.4mm) (76.2mm)

(49.2mm) (273mm)

(3mm)

(25.4mm)

*6 5/16”

(160 mm)

2 1/4”

11/16”

(17.5.mm)

11/16”

(17.5.mm)

(57mm)

West: 800-544-4422 • East: 800-225-6737

www.intldoorclosers.com

COPYRIGHT 2023 INTERNATIONAL DOOR CLOSERS, INC

International Door Closers, Inc.

44CI Series

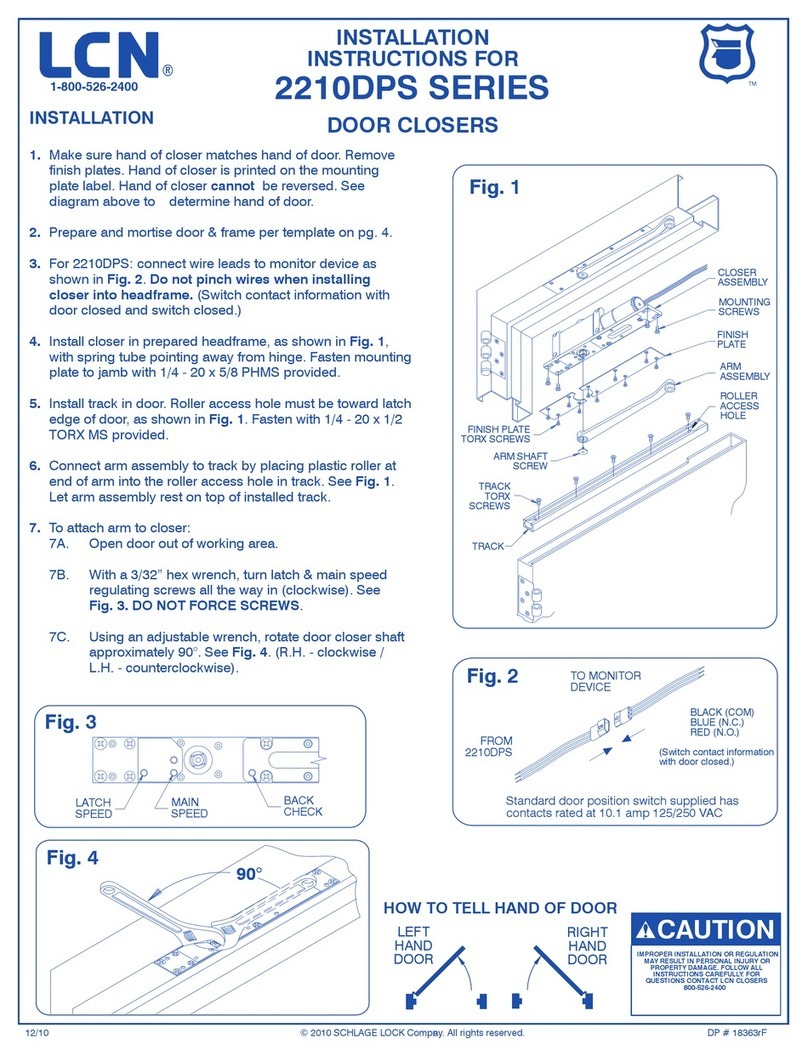

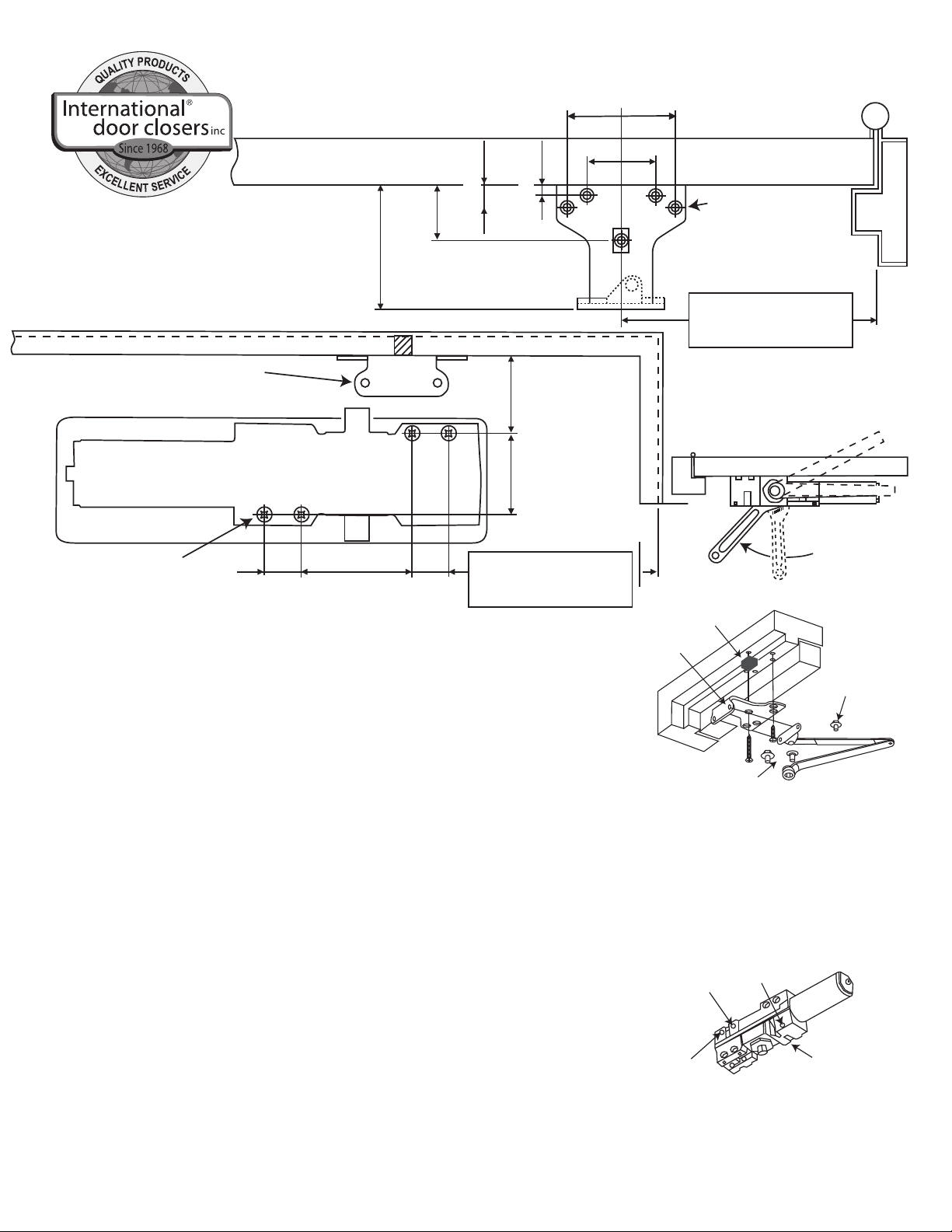

TOP JAMB INSTALLATION

CLOSER MOUNTED ON TOP JAMB

ON PUSH SIDE OF DOOR

This drawing shown RIGHT HAND DOOR. For LEFT

HAND DOOR should be installed in symmetry.

4

PRELOAD TO

90°

LATCH SPEED

SCREW

MAIN SPEED

SCREW

BACKCHECK

SCREW

COVER

SCREW

FOREARM

SCREW

ROD

SHOE

ARM

SCREW

MAIN ARM

or

1. Adjust spring power to match door width as indicated by chart on page 1.

2. Mount closer on door as dimensions shown. Tube end toward hinge.

If pivots are used, locate closer and shoe from CENTERLINE OF PIVOT.

(*For offset pivots, please increase the marked dimensions by 1/8”)

3. Place main arm on top of shaft, 100° to closer body, insert arm screw into top of

shaft and tighten.

4. Attach shoe to frame as shown. (If more latching power is required, shoe 180°)

5. Open door and insert rod in forearm.

6. With forearm at left angle to door (90°), insert forearm set screw and tighten.

(IF HOLD OPEN ARM IS USED, THE NUT IS ON THE TOP FOR RH DOOR AND

BOTTOM FOR LH DOOR)

REGULATION

A ‘Normal’ closing time from 90° open position to door stop position is 4-6 secs, evenly

divided between main swing speed and latch swing speed. Use socket key (furnished) to

adjust speed. To slow main speed of door, turn regulating screw nearest shaft clockwise.

To slow latch speed, tum regulating screw nearest latch clockwise.

BACK CHECK

To increase back-check force, tum regulating screw nearest hinge clockwise. DO NOT

USE ABRUPT BACKCHECK OR EXPECT DOOR CLOSER TO

ACT AS A DOOR STOP.

COVER

Place insert in proper cutout, then push cover against door.Tighten both

cover screw securely.

HOLD OPEN ADJUSTMENT (when hold open arm is used)

Loose adjusting nut, open door to desired hold open position and tighten nut.

Do not permit door to swing beyond hold open setting.

(Page 3 of 4)

Door Opening: 120°

West: 800-544-4422 • East: 800-225-6737

www.intldoorclosers.com

COPYRIGHT 2023 INTERNATIONAL DOOR CLOSERS, INC

International Door Closers, Inc.

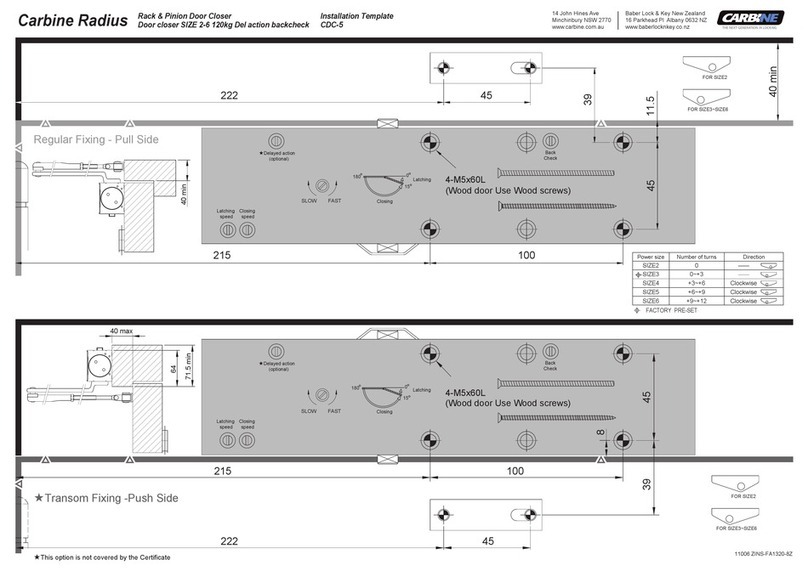

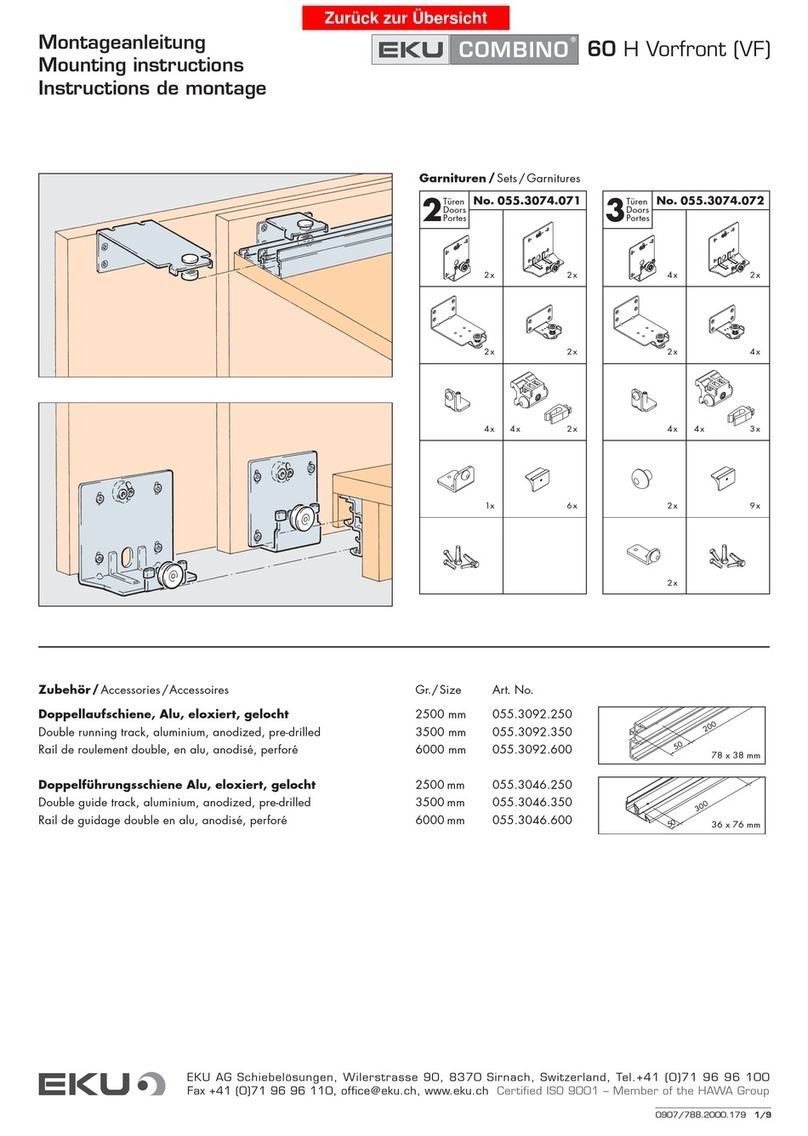

9 1/2” (241mm)=90° OPENING

8” (203mm)=120° OPENING

6 1/2” (165mm)=180° OPENING

2 Holes for #14

All-Purpose or 1/4-20

(M6x1.0) Machine Screws

4 Holes for #14

All-Purpose or 1/4-20

(M6x1.0) Machine Screws

1”

2 1/4”

(25.4mm)

3”

(76.2mm)

1”

(25.4mm)

(57mm)

11 1/2” (292mm)=90° OPENING

1O” (254mm)=120° OPENING

7 7/8” (200mm)=180° OPENING

5 Holes for #14

All-Purpose or 1/4-20

(M6x1.0) Machine Screws

1 11/16”

1 1/16”

5/16”(8mm)

1 1/16”(17.5mm)

1 3/4”(44.5mm)

4 ”(101.6mm)

1 1/16”

(27mm)(27mm)

1 11/16”

(43mm) (43mm)

44CI Series

Door Opening: 180°

PARALLEL ARM INSTALLATION

CLOSER MOUNTED ON DOOR ON PUSH SIDE

This drawing shown RIGHT HAND DOOR.

For LEFT HAND DOOR should be installed

in symmetry.

30°

PARALLEL

BRACKET

FOREARM

SCREW

ARM

SCREW

or

SPACER

BLOCKER

BACKCHECK

SCREW

MAIN SPEED

SCREW

LATCH

SPEED

SCREW

BACKCHECK

SELECTOR

SCREW

(Page 4 of 4)

1. Before installation, turn Back Check selector valve

(found on the opposite side of closer from back check screw side)

ALL THE WAY IN (CLOCKWISE).

2. Adjust spring power to match door width as indicated by chart on page 1.

3. Mount closer on door as dimensions shown. Tube end toward latch. If pivots are used,

locate closer and parallel bracket from CENTERLINE OF PIVOT.

4. Place open end wrench on bottom shaft and turn toward hinge jamb about 30°

and then place main arm on top shaft, insert arm screw into top of shaft and tighten.

5. Attach parallel bracket on frame as dimensions shown.

6. Attach rod and shoe to parallel bracket as shown.

7. Insert rod in forearm, and then insert main arm to closer parallel to door. Then insert forearm set screw and tighten.

(IF HOLD OPEN ARM IS USED, THE NUT IS ON THE TOP FOR RH DOOR AND BOTTOM FOR LH DOOR)

REGULATION

A ‘Normal’ closing time from 90° open position to door stop position is 4-6 secs, evenly divided between main swing speed and latch swing speed.

Use socket key (furnished) to adjust speed. To slow main speed of door, turn regulating screw nearest shaft clockwise. To slow latch speed, turn

regulating screw nearest latch clockwise.

BACK CHECK

To increase back-check force, turn regulating screw nearest hinge clockwise.

DO NOT USE ABRUPT BACKCHECK OR EXPECT DOOR CLOSER TO ACT AS A DOOR STOP.

COVER

Place insert in proper cutout, then push cover against door. Tighten both

cover screw securely.

HOLD OPEN ADJUSTMENT (when hold open arm is used)

Loose adjusting nut, open door to desired hold open position and tighten nut.

Do not permit door to swing beyond hold open setting.

Other International Door Closers Door Opening System manuals