Interpack RSA 20-B User manual

USER MANUAL

RSA 20-B

For Serial Numbers:

TM123 and TM623 XX X XXX

REV 3 06232022

2

Interpack RSA 2024-SB Rev 3

Rev 3 UM122TW

3

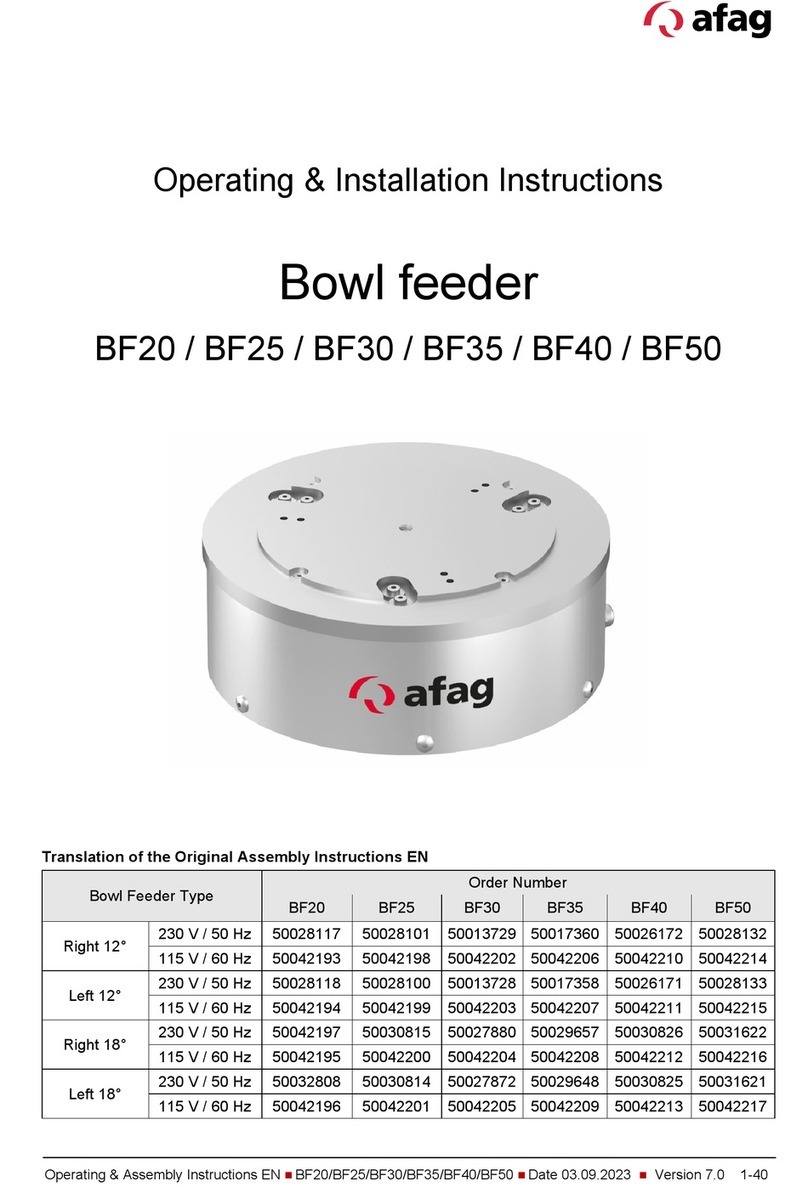

Replacement Parts 4

Explanation of Signal Word Consequences 14

Operator Skill Level Descriptions 15

Receiving and Handling 20

Set up 20

Optional Equipment: Caster Installation 21

Optional Equipment: In-feed/Out-feed Table Installation 22

Optional Equipment: Installation of External In-feed and Exit Conveyors 24

Preparing Cases to be Processed 34

The Machine is Turned on and Nothing Happens 39

Front Tape Leg Not Sticking 40

Rear Tape Leg Not Sticking 41

Case is Getting Crushed? 42

Tape Does Not Cut 43

Tape Jam 44

Wrinkles in the Tape 45

Tape Not Dispensed 46

Lubrication: 47

Cleaning: 47

Recommended Spare Parts: 47

Changing the Air Regulator Filter 48

Removing the Top Tape Head 49

Removing the Top Tape Head 50

Cleaning the Cutter Blade, Top Tape Head 51

Cleaning the Cutter Blade, Bottom Tape Head 52

Cutter Blade Maintenance 53

Cutter Blade Replacement 54

Drive Belt Replacement 55

Drive Belt Adjustment 56

4

Interpack RSA 2024-SB Rev 3

This is the Interpack Model Side-Belt Case Sealer you ordered. It has been set up and

tested in our factory with Intertape manufactured water activated tapes. If any problems occur when setting up or operating this

equipment, please contact the authorized distributor from where you purchased this item.

If contact with the authorized distributor is not possible, is available. Should the need to contact

arise, This information

can be found on the nameplate of the tape head as well as on the machine, both sets of information may be necessary to

assist. A section at the bottom of this page is available to writ this information down. is available during

normal business hours (M-F 8am-5pm) Eastern Time.

A breakdown of parts, including part numbers, can be found in the appendix of this manual. If you know the part number that

you require please contact your authorized distributor or IPG Customer Service 877-447-4832 Option 3

Please use this area to enter the detailed information on your Case Sealer and Tape Heads. This should be lled out at the

time of install. This information can be found on the nameplate of the machine, typically on the side the electrical box is on.

On pressure sensitive tape the nameplate is located on the same side the tape is loaded from. On the WAT Tape Heads serial

information can be found near the air intake of the head.

(if applicable)

Rev 3 UM122TW

5

Your Interpack Case Sealer and Tape Heads are designed to provide years of trouble free operation. This is not without proper

preventative maintenance, a recommended schedule can be located in the maintenance section of this manual, performed by

then end user of the equipment. If any problems arise with this machine during the normal course of operation, your properly

trained and qualied internal service personnel should be able to repair any issues after consulting the troubleshooting section

of this manual in conjunction with phone and/or email support from IPG Machinery Support.

Field Service Support is available from your IPG Authorized Distributor at additional cost if the problem cannot be remedied after

consulting the troubleshooting section of this manual.

IPG oers comprehensive programs that help keep your equipment up and running.

Proactive maintenance eorts help to prevent equipment failures and costly emergency repairs. Keeping your machine in

optimal working condition also enhances employee safety, reduces facility downtime and eciently allocates internal resources.

Please contact your IPG Representative to discuss the best options for your IPG equipment.

6

Interpack RSA 2024-SB Rev 3

EQUIPMENT WARRANTY AND LIMITED REMEDY: The following warranty is made in lieu of all other warranties, express

or implied, including, but not limited to, the implied warranty of merchantability, the implied warranty of tness for a particular

purpose, and any implied warranty arising out of a course of dealing, a custom or usage of trade:

Intertape sells its Interpack Tape Heads, Case Tapers and Case Erectors with the following warranties:

1. The HSD® 2000 Tape Heads’ knife blades, springs and wipe down rollers will be free from all defects for a period of

ninety (90) days.

2. All other HSD® 2000 Tape Head parts will be free from all defects for one (1) year after delivery.

3. Water Activated Tape Heads’ blades will be free from defects for ninety (90) days after delivery.

4. Drive Belts will be free from defects for ninety (90) days after delivery

5. The Gear Motors will be free from defects for one (1) year after delivery.

6. All other components for Case Tapers and Case Erectors will be free from defects for one (1) year after delivery.

If any part is proven defective within its warranty period, then the exclusive remedy and Intertape’ s and the seller’s sole

obligation shall be, at Intertape’ s option, to repair or replace the part, provided the defective part is returned immediately to

Intertape’ s factory or an authorized service station designated by Intertape.

A part will be presumed to have become defective after its warranty period unless the part is received or Intertape is notied of

the problem no later than ve (5) calendar days after the warranty period.

If Intertape is unable to repair or replace the part within a reasonable time, then Intertape, at its option, will replace the

equipment or refund the purchase price. Intertape shall have no obligation to install the repaired or replacement part.

Intertape shall have no obligation to provide or pay for the labor required to install the repaired or replacement part.

Intertape shall have no obligation to repair or replace (1) those parts failing due to: operator misuse, carelessness, or due to any

accidental cause other than equipment failure, or (2) parts

7. Failure or damage is due to misapplication, lack of proper maintenance, abuse, improper installation or abnormal

conditions such as temperature, moisture, dirt or corrosive matter, etc.

8. Failure due to inadequate cleaning, improper operating environment, improper utilities or operator error.

9. Failure due to operations above the rated capacities, or in any other improper manner, either intentional or otherwise.

10. Failure is due to equipment, which has been altered by anyone other than an authorized representative of Intertape

Polymer Group.

11. Failure is due to an attempt by the purchaser to correct alleged defective equipment. In this event the purchaser is

responsible for all expenses incurred.

LIMITATION OF LIABILITY: Intertape and seller shall not be liable for direct, indirect, special, incidental or consequential

damages based upon breach of warranty, breach of contract, negligence, strict liability or any other legal theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by written agreement

signed by authorized ocers of Intertape and seller.

Rev 3 UM122TW

7

This machine is designed to provide years of trouble free operation. If any problems arise with this machine during the normal

course of operation, your properly trained and qualied internal service personnel should be able to repair any issues after

consulting the Troubleshooting section of this manual.

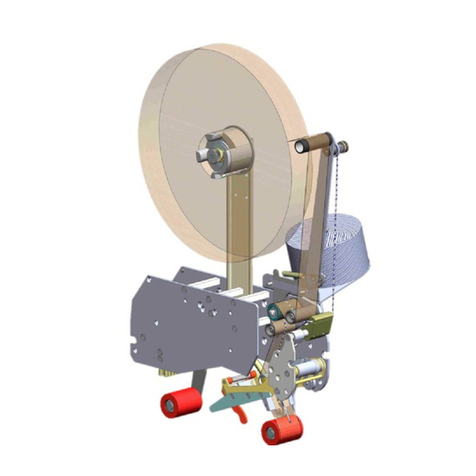

The Interpack RSA 20-B Case Sealing Machine with HSD®2000-ET II+ Tape Head is designed to apply Intertape brand

pressure sensitive case sealing tape to the bottom center seam of regular slotted corrugated cases. The RSA 20-B is auto

adjustable to a random variety of case sizes.

Common terms that will be used throughout this manual.

– This will refer to the HSD®2000-ET II+ Tape Head for the remainder of this manual

– Refers to IPG manufactured Case Sealers

– Refers to the fully assembled Case Sealer with the Tape Head(s) installed

– The individual who has been trained on the daily use of the Machine System

– The individual(s) who work for the end user of the Machine System who are responsible for

conducting general and preventative maintenance

8

Interpack RSA 2024-SB Rev 3

The RSA 20-B can be outtted with a variety of optional equipment. The below list is standard and should be discussed with

your distributor or authorized IPG representative if you would like them to be added to your machine.

It is recommended to keep a spare tape head in the event any failure or malfunction causes the machine to stop production.

This is to help reduce any possible downtime.

Feed Table 16” (.4M) UM894T 1

Feed Table 24” (.6M) UM998T 1

Feed Table 36” (.9M) UM898T 1

Casters UM841 1 set of 4 (36” Feed Table will require 2

additional casters)

Secondary Emergency Stop UM9003 1

4” Drive Bases UAM1079 (right) and UAM10798 (left) 1

Reverse Electrical Box UM085 1

Reverse Operator Control Pneumatic UM087 1

Low Tape No Tape Box UH1426 1

HSD® 2000-ET II+ 2” UH275TW

HSD® 2000-ET II+ 3” UH775TW

ET Extreme 2” UH230TW

ET Extreme 3” UH430TW

Casters

Infeed/Outfeed

Tables

ETX Tape

Head

Rev 3 UM122TW

9

There are a number of safety labels used on the RSA 20-B Case Sealer. These labels are placed at dierent locations on the

machine to warn operators and service personnel of possible dangers. Please read the labels on the machine and the following

safety precautions before using the machine.

Should any of the safety labels on the Case Sealer be damaged or destroyed, replacements can be ordered through your

distributor.

10

Interpack RSA 2024-SB Rev 3

Rev 3 UM122TW

11

The label shown is axed to the upper tape head

assembly on both sides of the machine.

It warns operators and service personnel of the presence

of the cutting blade that may not be visible. Caution

should be exercised when approaching this area.

The label shown is axed to the upper tape head

assembly on either side of the machine.

It warns operators and service personnel of the presence

of the cutting blade that may not be visible. Caution

should be exercised when approaching this area.

The label shown is located on the in-feed and exit ends of

the machine belt drives.

The label warns the operators and service personnel of

the pinch points at each end of the belt drives.

The label shown is axed to the electrical control box.

The label advises service personnel to connect the

machine to a properly grounded outlet.

The label shown is axed to the electrical control box.

The label advises service personnel to connect the

machine to a properly grounded outlet.

12

Interpack RSA 2024-SB Rev 3

The label shown is located on the side of the column.

This label provides convenient safety instructions for

the operator and service personnel in the operation of

the Intertape Case Sealing Equipment.

The label shown is located on the in-feed end

of the machine. The label advises personnel about

the dangers of the machine due to compressed

air used in the system. Be aware of warnings and

proper procedures when running and/or servicing

the machine.

Rev 3 UM122TW

13

The label shown is located on the gear side of

the machine.

The label warns the operators and service personnel

of the pinch points.

The label shown is located on the chain side of

the machine.

The label warns the operators and service personnel

of the pinch points.

The label shown is located on the side of the

outfeed table.

The label warns the operators and service personnel

to keep ngers clear of lower tape mandrel.

Should any of the safety labels on the Case Sealer be damaged or destroyed, replacements can be ordered through your

distributor.

14

Interpack RSA 2024-SB Rev 3

◦Read, understand, and follow all safety and operating instructions before operating or servicing the Case Sealer and/or Tape

Head

◦ Allow only properly trained and qualied personnel to operate and service this equipment

◦ Turn electrical supply o and disconnect before performing any adjustments, maintenance, or servicing the Case

Sealer or Tape Head

◦Do not leave the Case Sealer running while unattended

◦ Turn the Case Sealer o when not in use

◦Never attempt to work on any part of the Case Sealer, Tape Head, load tape, or remove jammed boxes from the

Case Sealer while the machine is running

◦ Position electrical cord away from foot trac and vehicle trac

◦Do not operate the Case Sealer with a damaged power cord

◦ Keep hand and ngers away from the tape cuto blades, the blades are very sharp

◦ Do not operate this equipment in potentially ammable and/or explosive environments

◦Use the appropriate rigging and material handling equipment when lifting or repositioning this equipment

◦Use proper body mechanics when removing or installing Tape Heads that are moderately heavy or may be

considered awkward to lift

◦ Allow only properly trained and qualied personnel to operate and service this equipment

◦ Keep hands clear of the upper head support assembly as boxes are transported through the Case Sealer

◦ Keep hands, hair, loose clothing, and jewelry away from box compression rollers, moving belts, and Tape Heads

◦Always feed boxes into the Case Sealer by pushing only from the end of the box

Rev 3 UM122TW

15

These descriptions and levels are uniform across all IPG Case Sealers

This operator is trained to use the Case Sealer with the machine controls, to feed cases into the machine, make adjustments for

dierent case sizes (USA series machines), to change tape, to start, stop, and restart production, and to clear jams and perform

basic troubleshooting.

Important: The end user area supervisor must ensure that the operator has been properly trained on all machine functions

before operating the machine.

Also referred to as the Maintenance Champion, this technician, is trained to use the Case Sealer as the Operator is able and

in addition is able to work with the safety protection disconnected to check and adjust mechanical components, to perform

maintenance operations and repair the Case Sealer. A skill “B” operator is not allowed to work on live electrical components.

This technician is trained to use the Case Sealer as the Operator is able and in addition is able to work with the safety protection

disconnected, to check and adjust mechanical components, to perform maintenance operations and repair the Case Sealer. A

skill “C” operator is allowed to work on live electrical panels, terminal blocks, and control equipment.

Skilled technician sent by the manufacturer or its agent (distributors) to perform complex repairs of modications, when agreed

with the customer.

Tape Roll Replacement Stopped by pressing the

Emergency Stop Button A 1

Blade Replacement Electrical Power Disconnected B 1

Ordinary Maintenance and

Preventative Maintenance Electrical Power Disconnected B 1

Extraordinary Mechanical

Maintenance

Running with Safety Protections

Disabled C 1

Extraordinary Electrical

Maintenance

Running with Safety Protections

Disabled D 1

Drive Belt Replacement Electrical Power Disconnected B 1

Machine Installation & Set-Up Running with Safety Protections

Disabled B & C 2

16

Interpack RSA 2024-SB Rev 3

Machine Weight: 650 lbs. (295 kg)

24" - 30"

44 3/4"

51"

48 1/2"

35 1/2"

41 1/2"

RSA 20-B

Rev 3 UM122TW

17

Main Air

Regulator

Electrical Box

Operator

Controls

Adjustable

Legs

Open/Close

Regulators

18

Interpack RSA 2024-SB Rev 3

Use in a dry, relatively clean environment at 40° to 105° F (5° to 40° C) with clean dry cartons.

Actual production rate is dependent on operator’s dexterity and the case size mix. Belt speed is v82 ft/min, boxes must be

separated by 14 in. (355.6mm).

Use only Pressure Sensitive Tape. The machine can accommodate tape widths of 2 – 3 in. (48 - 75mm)

depending on the tape heads supplied.

A maximum tape roll diameter of 16” (406m) on a 3” (76mm) core can be installed on the tape heads. This machine can

accommodate a variety of Intertape brand tape. Consult the factory if a specic tape is needed for your application.

The standard tape leg length of 2.25” (57.2mm) is factory set. The standard tape leg length may vary up to ¼” (6mm) based on

tape tension and line speed.

The standard tape leg length is adjustable +/- ¼” (6mm). Refer to the tape head manual for your tape heads for how to adjust

the tape leg length.

Electrical:

This machine comes standard with two gear motors, one on each drive base, an electrical box, and a control box.

The control box contains a switch, an switch, and a push button. A 12 ft (3657.6mm) standard,

three-conductor power cord with plug is provided for service. The receptacle providing this service be

properly grounded.

Compressed Air: 90 PSI 9CFM

This machine comes standard with one main regulator and four sub-regulators.

Air must be clean and dry. If moisture enters the system valves can begin to degrade and lines slowly clog. This can cause

reduced ow resulting in undesired machine behavior.

Rev 3 UM122TW

19

However, if the box length (in the direction of the seal) to box height ratio is 0.75 or less, several boxes should be test run to

assure proper machine performance. The formula is as follows:

• Regular Slotted Containers (RSC)

• Other styles may be processed. Consult factory.

• 125 to 175 PSI bursting test, single or double wall, B or

C utes

• Other styles may be processed. Consult factory.

• 0 to 85 lbs. Max (0 to 38.5 kg)

6” (152mm) 4” (101mm) 3.5” (88mm)

Innite 20” (508mm) Innite

Carton Length in direction of seal

Carton Height > 0.75

20

Interpack RSA 2024-SB Rev 3

The Interpack RSA 20-B is shipped to the customer in a box and xed to a pallet. The machine is enclosed with either

a corrugated sleeve and cap or an HSC corrugated box. The sequence below is step by step instructions to remove all

packing materials.

After unpacking the Case Sealer, look for any damage that may have occurred during shipping. Should the Case Sealer be

damaged, le a claim with the transport company and notify your IPG representative as soon as possible.

The Case Sealer must be installed on a near level ground. Use the adjustable legs to ensure the machine is level and rmly

planted on the ground (no rocking). Adjust the leg height with the four (4) telescopic adjustment legs to accommodate conveyor

heights from 24 to 30 inches. Consult with the factory for any other conveyor heights that may be required.

Customer supplied feed conveyor (if used) should provide straight and level entry into the Case Sealer. Customer supplied exit

conveyor (if used) should be straight and declined no more than 20mm/meter away from the Case Sealer to convey the sealed

cartons away from the machine.

To adjust the Case Sealer height, jack up the machine to

give ample room to extend the legs. Using a 19mm box

end wrench, loosen the eight (8) M12mm hex bolts. Adjust

the legs to the desired conveyor height and tighten the

bolts. Etched lines on the legs ease leveling.

1. Remove the strapping and staples at

the bottom of the box

2. Lift the box cover o of the machine,

use caution and team lift

3. Inspect the machine for any damage that

may have occurred during shipping

4. Remove the mounting bolts and nuts

that secure the machine to the pallet

5. Using a forklift or other lifting device, lift

the machine o the pallet

◦Install any optional casters at this

point as well as adjusting leg height

for desired conveyor height

6. Position the machine in its desired

location

7. Remove any remaining tie wraps and

shipping materials

8. Install any optionally ordered

equipment

Leg

Extension

Leg

Adjustment Screws

This manual suits for next models

2

Table of contents

Other Interpack Industrial Equipment manuals

Interpack

Interpack USA 2024-SB User manual

Interpack

Interpack ipg RSA 2625-TB User manual

Interpack

Interpack HSD2000 ET II RC User manual

Interpack

Interpack HSD2000 XS II Series User manual

Interpack

Interpack USA 2024-SB DH User manual

Interpack

Interpack ETII+ LD User manual

Interpack

Interpack CE-12P User manual

Interpack

Interpack CE-12P User manual