Interpack HSD2000 XS II Series User manual

HSD2000 XS II 2”/ 3”

TAPE HEAD

UH088 / UH588

OPERATION MANUAL

&

PARTS LISTS

UDH10002 Rev. 0

This Manual Covers Tape Heads With Serial Numbers Starting

With H 088 or H 588

For All Other Serial Numbers, Contact Customer @800-474-8273

UDH10002 HSD 2000 XSII 2” / 3” Manual 2

UH088-UH588

OPERATION MANUAL

TABLE OF CONTENTS

OPERATION MANUAL ............................................................................... 2

TABLE OF CONTENTS ............................................................................................. 2

SERVICE INSTRUCTIONS ....................................................................................... 3

Service .................................................................................................................................... 3

Replacement Parts .................................................................................................................. 3

WARRANTY................................................................................................................. 4

DESCRIPTION OF TAPE HEADS............................................................................ 5

SAFETY ISSUES.......................................................................................................... 7

Safety Rules............................................................................................................................ 7

Safety Decal Location............................................................................................................. 8

SPECIFICATIONS....................................................................................................... 9

Dimensions ............................................................................................................................. 9

Tape Head Weight .................................................................................................................. 9

Operating Conditions.............................................................................................................. 9

Tape Requirements ............................................................................................................... 10

SET-UP PROCEDURES............................................................................................ 11

Receiving and Handling ....................................................................................................... 11

Tape Head Installation.......................................................................................................... 11

Tape Loading........................................................................................................................ 11

Tape Threading..................................................................................................................... 11

Tape Centering...................................................................................................................... 13

Tape Tension Adjustment..................................................................................................... 14

Clutch Roller Tension Adjustment ....................................................................................... 15

Front Leg Length Adjustment............................................................................................... 16

Rear Leg Length Adjustment................................................................................................ 17

Front Arm Compression Spring Tension Adjustment .......................................................... 18

Blade Replacement ............................................................................................................... 19

TROUBLESHOOTING ............................................................................................. 20

RECOMMENDED SPARE PARTS ......................................................................... 21

2” Model:.............................................................................................................................. 21

3” Model:.............................................................................................................................. 21

PARTS LIST ................................................................................................ 23

UDH10002 HSD 2000 XSII 2” / 3” Manual 3

UH088-UH588

SERVICE INSTRUCTIONS

Service

This is the manual for the Intertape HSD2000 XS II series Tape Head. It has been set up

and tested in our factory with Intertape brand tapes. If any problems occur when

operating this equipment and you desire a service call or phone consultation, call

Intertape Customer Service at 1-800-972-4675.

Please provide the customer service representative with the Tape Head model number

and serial number. If you have a technical question that does not require an immediate

response, you may fax it to 1-813-621-9680.

Replacement Parts

Order parts by item number, part name and quantity required. Replacement parts are

available from your Authorized Interpack Distributor. Should you require assistance

selecting the correct part, you may call:

Intertape Polymer Group

Interpack Machinery Division

9940 Currie Davis Drive, Suite 23B

Tampa, FL, 33619

Tel: 1-800-972-4675

Fax: 1-813-621-9680

MODEL:

SERIAL NUMBER:

DATE OF PURCHASE:

UDH10002 HSD 2000 XSII 2” / 3” Manual 4

UH088-UH588

WARRANTY

EQUIPMENT WARRANTY AND LIMITED REMEDY: The following warranty is made in lieu

of all other warranties, express or implied, including, but not limited to, the implied

warranty of merchantability, the implied warranty of fitness for a particular purpose, and

any implied warranty arising out of a course of dealing, a custom or usage of trade:

Intertape sells its HSD2000 XS II series Tape Heads with the following warranties:

1. The knife blades, springs and wipe down rollers will be free from all defects for a

period of ninety (90) days. A lifetime warranty is available after delivery with an

Annual Tape Agreement and completed Pioneering Protection Warranty form.

Contact your Intertape representative for further details.

2. All other HSD2000 XS II Tape Head parts will be free from all defects for one (1)

year after delivery.

If any part is proven defective within its warranty period, then the exclusive remedy and

Intertape's and the seller's sole obligation shall be, at Intertape's option, to repair or

replace the part, provided the defective part is returned immediately to Intertape's factory

or an authorized service station designated by Intertape.

A part will be presumed to have become defective after its warranty period unless the

part is received or Intertape is notified of the problem no later than five (5) calendar days

after the warranty period.

If Intertape is unable to repair or replace the part within a reasonable time, then Intertape,

at its option, will replace the equipment or refund the purchase price. Intertape shall have

no obligation to install the repaired or replacement part.

Intertape shall have no obligation to provide or pay for the labor required to install the

repaired or replacement part. Intertape shall have no obligation to repair or replace (1)

those parts failing due to operator misuse, carelessness, or due to any accidental cause

other than equipment failure, or (2) parts failing due to inadequate cleaning, improper

operating environment, improper utilities or operator error.

LIMITATION OF LIABILITY: Intertape and seller shall not be liable for direct, indirect,

special, incidental or consequential damages based upon breach of warranty, breach of

contract, negligence, strict liability or any other legal theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may

be changed only by written agreement signed by authorized officers of Intertape and

seller.

UDH10002 HSD 2000 XSII 2” / 3” Manual 5

UH088-UH588

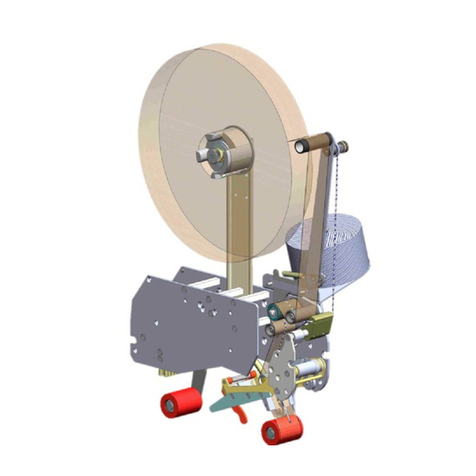

DESCRIPTION OF TAPE HEADS

Figure 1

The HSD2000 XS II Tape Head (figure1) is designed to apply Intertape brand pressure

sensitive carton sealing tape to the top and bottom center seam of regular slotted

corrugated cartons. It is easy to set-up and to operate. The model shown in this manual is

a standard 2” Tape Head. Also available are the mirror models 2” or 3” wide.

MIRROR MODEL

STANDARD MODEL

UDH10002 HSD 2000 XSII 2” / 3” Manual 6

UH088-UH588

How the Tape Head Works

MANDREL

PEEL OFF ARM

MANDREL ARM

AUXILIARY ARM

REAR ARM

FRONT ARM

KNIFE ARM

CLUTCH

Figure 2

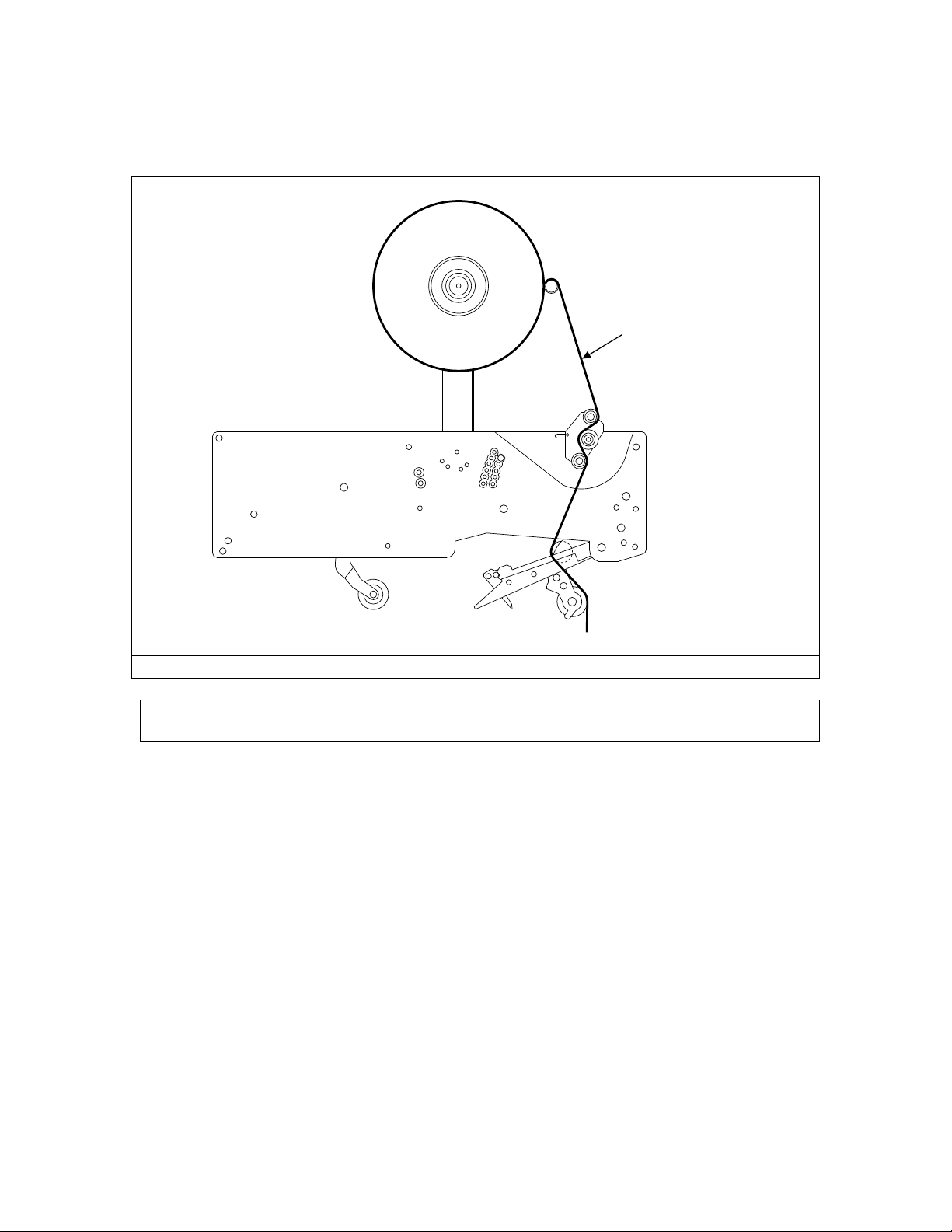

When the operator installs a new tape roll on the mandrel, the Tape Head is ready to

operate. The tape leg catches the front side of the incoming carton. The tape is then

applied to the top or bottom of the carton with pressure provided by the front arm. When

the carton’s rear edge advances passed the front arm and knife arms, both arms are

snapped back into place and the knife cuts the tape. As the carton exits the tape head the

rear arm snaps back into place wiping down the rear leg of the tape.

UDH10002 HSD 2000 XSII 2” / 3” Manual 7

UH088-UH588

SAFETY ISSUES

Safety Rules

The Tape Head has been designed to be extremely safe for operators and bystanders.

Nevertheless, accidents can happen. Therefore, it is important to follow safe work

practices. The operator must read and follow these safety rules when working on or near

the device.

•Read this manual and its safety instructions thoroughly before operating.

•Only trained personnel are to operate, adjust or service the equipment.

•Shut off machine in case of emergency.

•Never wear loose clothing, jewelry or tie when operating machine.

•Wear safety glasses.

•All covers and guards must be in place before operating.

•Stay clear of moving parts which may shear and cut.

•Never operate the Tape Head with the knife flipper guard removed.

•Do not modify the equipment in any way. Unauthorized modification may impair

the function and/or safety and could affect the life of the equipment.

•Carefully read all safety decals on the Tape Head. If they are damaged and

become illegible, replace them immediately. (See section 2.2, figure 4 for safety

decal location).

•Use caution when handling knife. Knife blade is very sharp. Do not touch blade

with bear hand.

Figure 3

CAUTION!

Very Sharp!

UDH10002 HSD 2000 XSII 2” / 3” Manual 8

UH088-UH588

Safety Decal Location

The figure below shows where the safety decal is located on the equipment. Replace

decal if it is absent or becomes illegible. Replacement decals can be found in the Parts

section of this manual.

WARNING

Sharp

Cutting

WARNING

Sharp

Cutting

Blade

Figure 4

UDH10002 HSD 2000 XSII 2” / 3” Manual 9

UH088-UH588

SPECIFICATIONS

Dimensions

19,0

22,560

24,250

1,114

1,00

7,273,4

8,48

20,35

10,42

3" version

5,358 2" v.

4,358

Figure 5

Tape Head Weight

Tape Head weight when shipped:

2” model: 29 lbs (13 Kg)

3” model: 32 lbs (14.5 Kg)

Operating Conditions

Use in a dry, relatively clean environment at 40º to 105º F (5º to 40º C) with clean dry

cartons.

Note: The Tape Head should never be washed down or subjected to conditions causing

condensation on components.

UDH10002 HSD 2000 XSII 2” / 3” Manual 10

UH088-UH588

Tape Requirements

1. Type:

Intertape brand Pressure Sensitive Carton Sealing Tape.

2. Tape Width:

1!to 2 inch wide tape maximum for the 2” model.

2!to 3 inch wide tape maximum for the 3” model.

3. Tape roll diameter:

Maximum of 16 inches.

4. Tape Application Leg Length:

From 2 3/8” to 2 "”.

UDH10002 HSD 2000 XSII 2” / 3” Manual 11

UH088-UH588

SET-UP PROCEDURES

Receiving and Handling

All contents must be verified upon reception. The following items must be in the box:

HSD2000 XS II Tape Head with mandrel arm dismounted, this brochure, 4 mounting

adaptors with M6 socket head cap screws, one extra blade flip-guard torsion spring, two

knife arm extension springs, two compression springs and two extension springs for the

rear arm.

Note: After unpacking the Tape Head, look for any damage that may have occurred

during shipping. Should the Tape Head be damaged, file a claim with the

transport company and notify your Intertape representative.

Tape Head Installation

The tape heads require the installation of adapters to mount into the machines. Different

length adapters are supplied with the 2 inch and 3 inch versions of the tape head and

other lengths are available. For non-standard mounting adaptors consult technical

support.

Tape Loading

WARNING! TURN OFF ELECTRICAL POWER SUPPLY AND DISCONNECT THE POWER

CORD FROM THE ELECTRICAL SUPPLY BEFORE BEGINNING TO WORK ON

THE TAPE HEADS OR TO LOAD TAPE. IF POWER CORDS ARE NOT

DISCONNECTED,SEVERE INJURY TO PERSONNEL COULD RESULT.

Push the roll of tape onto the mandrel with the adhesive side up (refer to Threading

Diagram under Tape Threading in this manual) until the core seats against the mandrel

flange. This ensures the tape will be aligned when feeding into the tape head.

Tape Threading

WARNING!THE KNIFE CONTAINED IN THE TAPE HEAD IS EXTREMELY SHARP. USE

CAUTION WHEN REMOVING THE BLADE GUARD AND THREADING THE TAPE

TO AVOID PERSONNEL INJURY.

UDH10002 HSD 2000 XSII 2” / 3” Manual 12

UH088-UH588

Figure 6 shows how the tape must be threaded. You can also refer to the diagram on the

Tape Head plate for threading instructions. Use a knife to cut tape leg.

ADHESIVE SIDE

Figure 6

Note: Plastic blade guard must be removed before operating tape head.

UDH10002 HSD 2000 XSII 2” / 3” Manual 13

UH088-UH588

Tape Centering

Should the tape require centering, the tape mandrel can be adjusted in and out. First

loosen the 1” hex jam nut, then adjust the shaft in or out as required using a flat-head

screwdriver. When the tape is centered, tighten the jam nut.

Figure 7

UDH10002 HSD 2000 XSII 2” / 3” Manual 14

UH088-UH588

Tape Tension Adjustment

The roll of tape should turn with slight resistance provided by the mandrel. Mandrel

tension may be adjusted by turning the mandrel nut (As shown in Figure 8). Turn

clockwise for more tension or counter clockwise to loosen the tension.

Figure 8

Loosen

Mandrel

Nut

UDH10002 HSD 2000 XSII 2” / 3” Manual 15

UH088-UH588

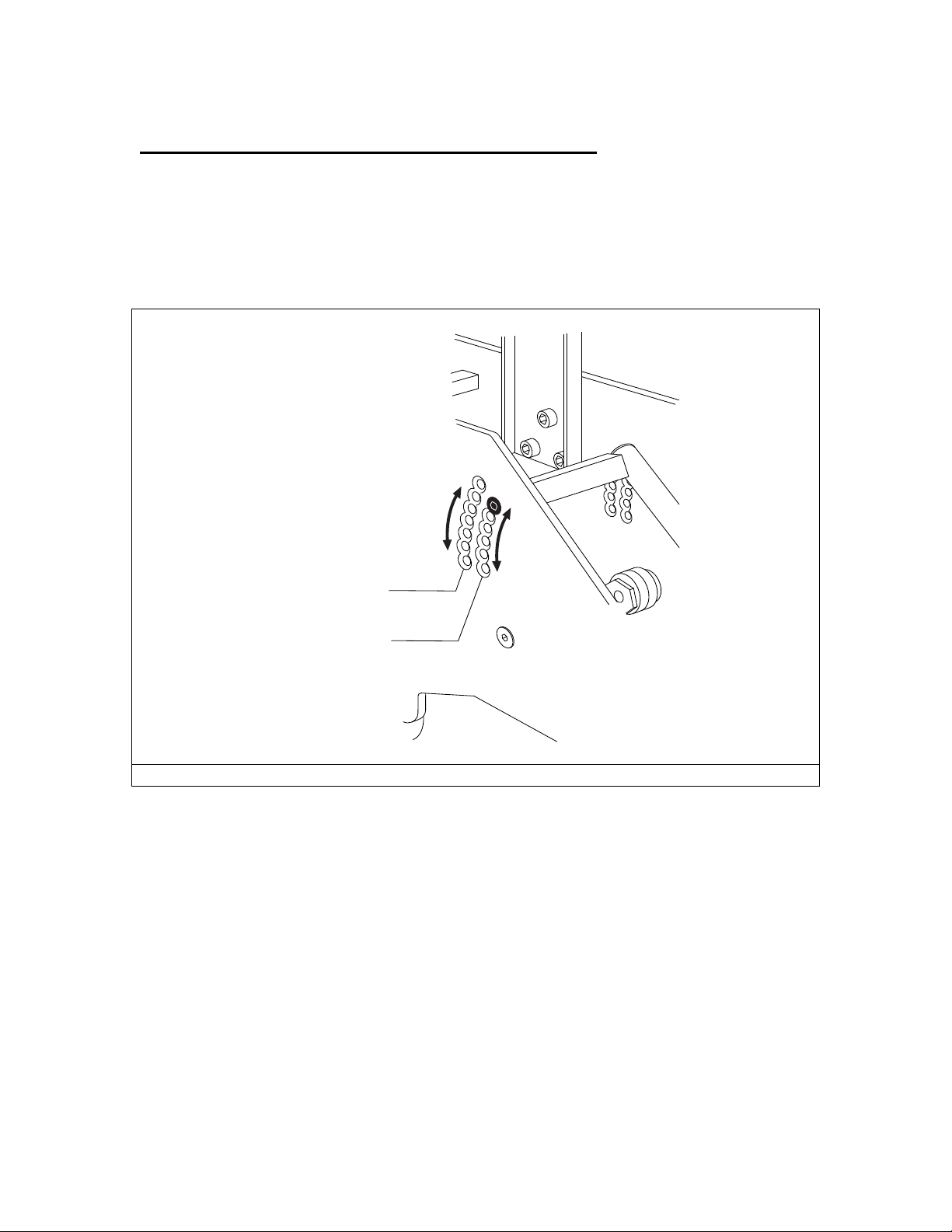

Clutch Roller Tension Adjustment

The clutch roller should be adjusted for very little tension. Use lock-nut to adjust tension

as shown in figure 9.

Figure 9

UDH10002 HSD 2000 XSII 2” / 3” Manual 16

UH088-UH588

Front Leg Length Adjustment

To adjust the length of the front leg, slide the clutch forward or backward until leg

length is satisfactory. To move the clutch, first loosen the two adjustment screws as

shown below. Retighten screws once clutch is adjusted.

ADJUSTMENT

SCREWS

SHORTER FRONT LEG

LONGER FRONT LEG

Figure 10

UDH10002 HSD 2000 XSII 2” / 3” Manual 17

UH088-UH588

Rear Leg Length Adjustment

To adjust the length of the rear tape leg, remove the four (4) knife arm screws and adjust

length by moving the knife arm forward or backward, as shown in figure 11.

REMOVE SCREWS

TO SLIDE KNIFE ARM

LONGER

REAR LEG

SHORTER

REAR LEG

Figure 11

UDH10002 HSD 2000 XSII 2” / 3” Manual 18

UH088-UH588

Front Arm Compression Spring Tension Adjustment

This adjustment is done to insure gradual reduction in force as the roller travels up on the

end of the carton panel to eliminate carton crushing and dog earring as the front arm’s

roller turns around the corner onto the center seam. There are two sets of adjustment

holes, one for less pressure and one for more pressure. The pressure (or force) can also be

adjusted by moving the adjustment screw up or down as shown in figure 12.

+

-

+

-

LESS PRESSURE

SETTINGS

MORE PRESSURE

SETTINGS

LESS

PRESSURE

MORE

PRESSURE

Figure 12

UDH10002 HSD 2000 XSII 2” / 3” Manual 19

UH088-UH588

Blade Replacement

WARNING!THE BLADE CONTAINED IN THE TAPE HEAD IS EXTREMELY SHARP. USE

CAUTION WHEN OPENING THE BLADE GUARD AND REPLACING THE BLADE

TO AVOID PERSONAL INJURY.

To replace the blade:

1. Open the blade flipper guard

2. Remove the two (2) button head screws

3. Remove and replace the blade. Make sure the flat part of the blade is facing the

back plate

4. Ascertain that the blade flipper guard returns to cover the knife blade.

BLADE

SCREWS

BLADE

GUARD

Figure 13

UDH10002 HSD 2000 XSII 2” / 3” Manual 20

UH088-UH588

TROUBLESHOOTING

The Tape Head requires minimum maintenance. Simply replace the blade regularly to

provide clean tape leg cuts.

PROBLEM POSSIBLE CAUSE AND SOLUTION

Rear leg stretched or not cut Blade does not cut. Replace blade.

The tape is overstretched by having too

much friction on the mandrel or front arm

roller.

Rear leg is not properly wiped down

Dirt on rear arm causing friction. Clean or

replace roller.

Dog ears on carton

Lower pressure by adjusting tension on the

front arm compression springs (pivot

assembly) as shown in Figure 12.

Table of contents

Other Interpack Industrial Equipment manuals

Interpack

Interpack CE-12P User manual

Interpack

Interpack USA 2024-SB User manual

Interpack

Interpack RSA 20-B User manual

Interpack

Interpack USA 2024-SB DH User manual

Interpack

Interpack CE-12P User manual

Interpack

Interpack ipg RSA 2625-TB User manual

Interpack

Interpack HSD2000 ET II RC User manual

Interpack

Interpack ETII+ LD User manual