Interpack CE-12P User manual

Page 1 of 36

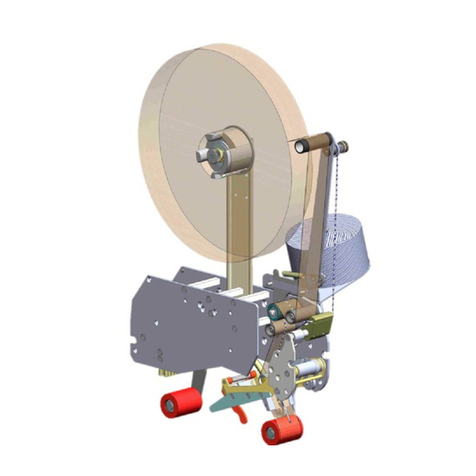

CE-12P

Automatic Case Erector

& Bottom Sealer

OPERATION MANUAL & PARTS LIST

This manual also available at www.itape.com.

Rapid Packaging, Inc.

763-404-8900 | [email protected]

www.RapidPackaging.com

Page 2 of 36

TABLE OF CONTENTS

GENERAL SAFETY RULES.................................................................................3

POWER SOURCE WIRING ..................................................................................3

CE-12P LAYOUT...................................................................................................4

MACHINE INSTALLATION ...................................................................................5

MANUAL FUNCTION LIST...................................................................................6

FAULT LIST...........................................................................................................6

OPERATION..........................................................................................................7

ABNORMAL REMEDY .......................................................................................10

ELECTRIC CIRCUIT ...........................................................................................12

AIR PRESSURE CIRCUIT ..................................................................................19

PNEUMATIC PART LIST ....................................................................................20

FRONT FLAP FOLDING ASSEMBLY ................................................................20

CASE DRAWING ASSEMBLY............................................................................21

LEFT & RIGHT FLAP FOLDING ASSEMBLY....................................................23

REAR FLAP FOLDING ASSEMBLY...................................................................24

SAFETY DOOR ASSEMBLY ..............................................................................26

HOPPER BASE...................................................................................................27

HOPPER TOP UNIT............................................................................................29

BOTTOM SEALING ASSEMBLY........................................................................31

TOP UNIT ADJUSTING ASSEMBLY..................................................................34

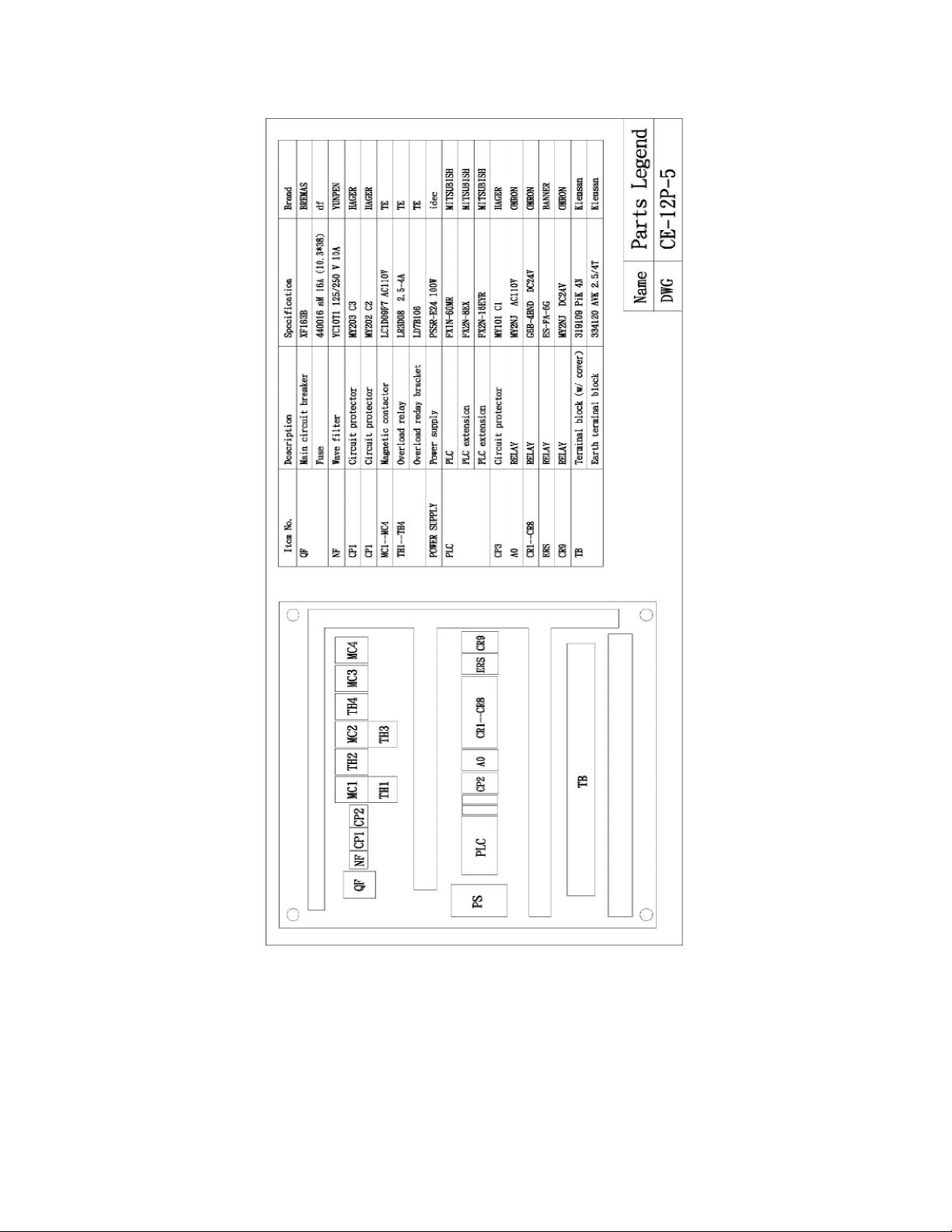

ELECTRIC CONTROL BOX ...............................................................................36

Page 3 of 36

GENERAL SAFETY RULES

1. Read and understand the entire instruction manual before operating the machine.

Know it’s limitations, as well as the specic potential hazards peculiar to it.

2. Make certain the machine is properly grounded.

3. Before operating the machine, remove ties, rings, watches other jewelry, and roll up

sleeves above the elbows. Remove all loose clothing and conne long hair. Do not

wear gloves.

4. Keep the oor around the machine clean.

5. Keep machine guards in place at all times when the machine is in use.

6. Do not overreach. Maintain a balanced stance at all times so that you do not fall or

lean against blades or other moving parts.

7. Make all machine adjustments or maintenance with the machine unplugged from the

power source.

8. Replace warning labels if they become obscured or removed.

9. Made sure the power source switch is in the OFF position before connecting the

machine to the power source

10.Make a habit of checking to see that the keys and adjusting wrenches are removed

before turning on the machine.

11. Keep belt guard and blade guards in place and in working order.

12.Failure to comply with all of these warnings could lead to serious injury.

POWER SOURCE WIRING

1. Before connecting, make sure the voltage is the same for both the machine and

the power source.The machine has been wired before shipment, and all electrical

information (such as voltage) indicated on the electrical instruction label.

2. Connect the power source wires to the “R.S.T.” connection points.The machine must

be properly grounded to prevent damage from electric shocks. (3 phase only)

3. After the power source wires have been connected, check to see if the wires are

connected to the correct points by the running direction of the left and right driving

belts. If the driving belts run in the correct direction, then the power source wires are

connected to the correct points. If the driving belts run in the opposite direction, cut

off the power source and change any two of the three power source wires to obtain

the correct running direction. (3 phase only)

Page 4 of 36

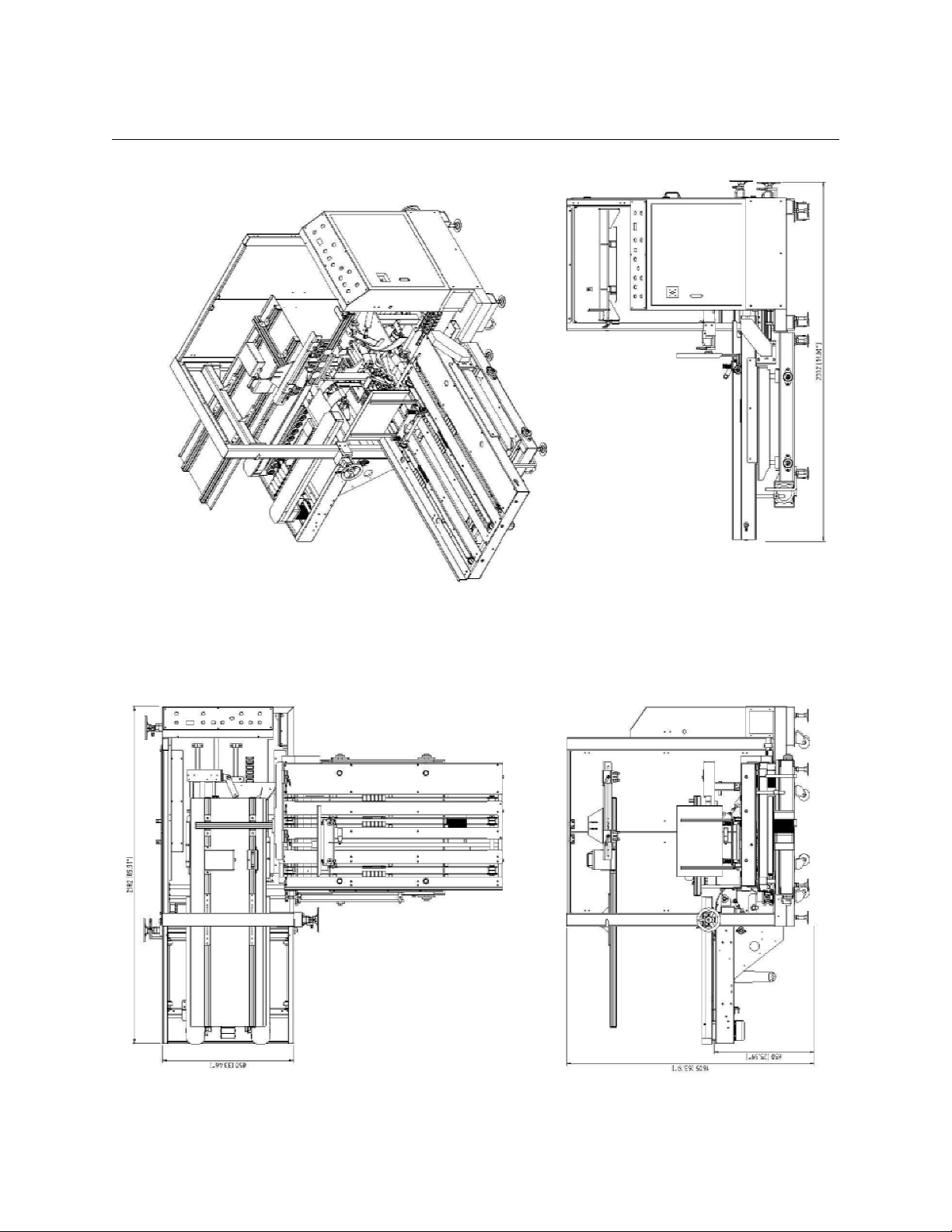

CE-12P LAYOUT

Page 5 of 36

MACHINE INSTALLATION

1. Please open the package and discharge the machine carefully for the installation.

Please check if appearance is food without any damage, otherwise, please advise

our company.

2. After installation, adjust the height of working table to parallel with the height of your

production line.

3. Remove the xed items inside the machine. (Ex: wooden block, plastic band)

4. Locate the machine, plus in the power source.

5. Connect pressure air source and adjust pressure to 5 kgs ~ 6kgs, then open manual

valve (VHS4000-03)

6. Machine testing: Switch on the Magnetic Breaker located inside the Control Box,

then press “Run Preparative”, turn Button (CS1) on Manual, start testing by Manual

Digital No. on Control Panel.

7. Side Belt On: Turn Manual No. to 01→press Manual On (Belt clockwise)→press

Manual Off (Belt stop).

a. Vacuum Activated: Turn Manual No. to 02→press Manual On (Vacuum cup suck

on)→press Manual Off (vacuum cup suck off)

b. Vacuum cup forward: Turn Manual No. to 03→press Manual On (Vacuum cup

forward)

c. Vacuum cup backward: Turn Manual No. to 04→press Manual On (Vacuum cup

forward)]

d. Guide Cylinder: Turn Manual No. to 05→press Manual On (Forming mechanism

effect) →press Manual Off (Forming mechanism return)

e. Front Minor Flap Forward Up: Turn Manual No. to 06→press Manual On (Front

Minor Folder upward up)

f. Rear Minor Flap Forward Up: Turn Manual No. to 07→press Manual On (Rear

minor ap forward up)

g. Left Major Flap Forward Up: Turn Manual No. to 08→press Manual On (Left

major ap forward up)

h. Right Major Flap Forward Up: Turn Manual No. to 09→press Manual On (Right

major ap forward up)

i. Vacuum release: Turn Manual No. to 10→press Manual On (Vacuum release)

j. Pushing Cylinder: Turn Manual No. to 11→press Manual On (Pushing cylinder

forward)

Page 6 of 36

MANUAL FUNCTION LIST

No. Description

01 Side Belt On

02 Vacuum Activated

03 Vacuum Cup Forward

04 Vacuum Cup Backward

05 Guide Cylinder

06 Front Minor Flap Folding Up

07 Rear Minor Flap Folding Up

08 Left Major Flap Folding Up

09 Right Major Flap Folding Up

10 Vacuum Released

11 Pushing Cylinder

FAULT LIST

No. Description

01 Low Air Pressure

02 Not in Initial Position

03 Vacuum Not Detected

04 Hopper Empty

05 Carton Withdraw Failure

06 Carton Jam

07 Tape Application Problem

08 Motor Problem

09 Safety Door Open

10 Emergency Stop Not Reset

11 Front Flap Folder Cylinder Not In Position

12 Rear Flap Folder Cylinder Not In Position

** When Alarm Sounds

1. Press “Alarm Reset” to stop alarm

2. Press and Hold Cycle Stop Button for 3 Seconds and Troubleshoot Fault

3. Press the button which is ashing to stop alarm and home-position

Page 7 of 36

OPERATION

1. Please make sure correct power source 110V, turn on Magnetic Breaker. Connect air

pressure at 5-6 kg/s.q.cm, switch on Manual Valve.

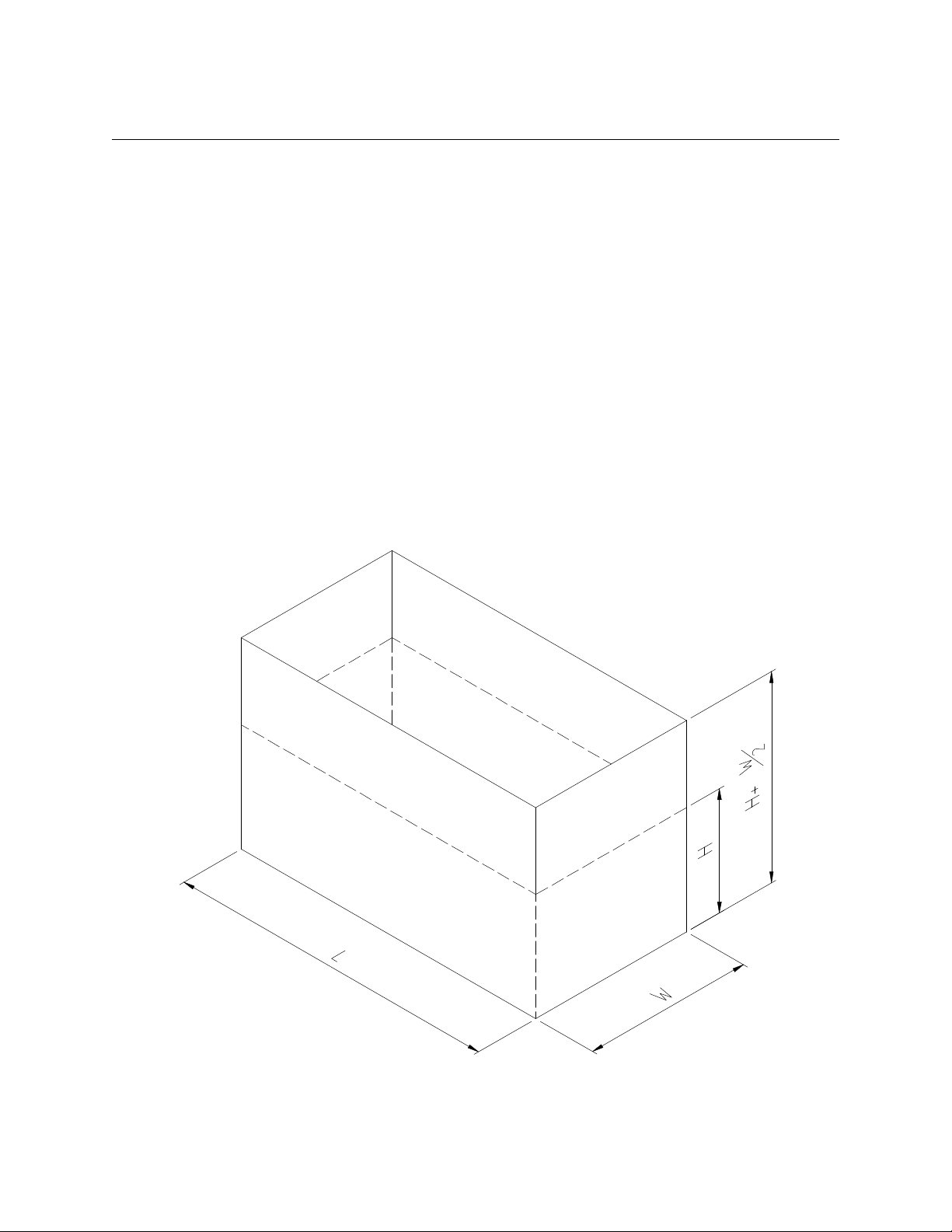

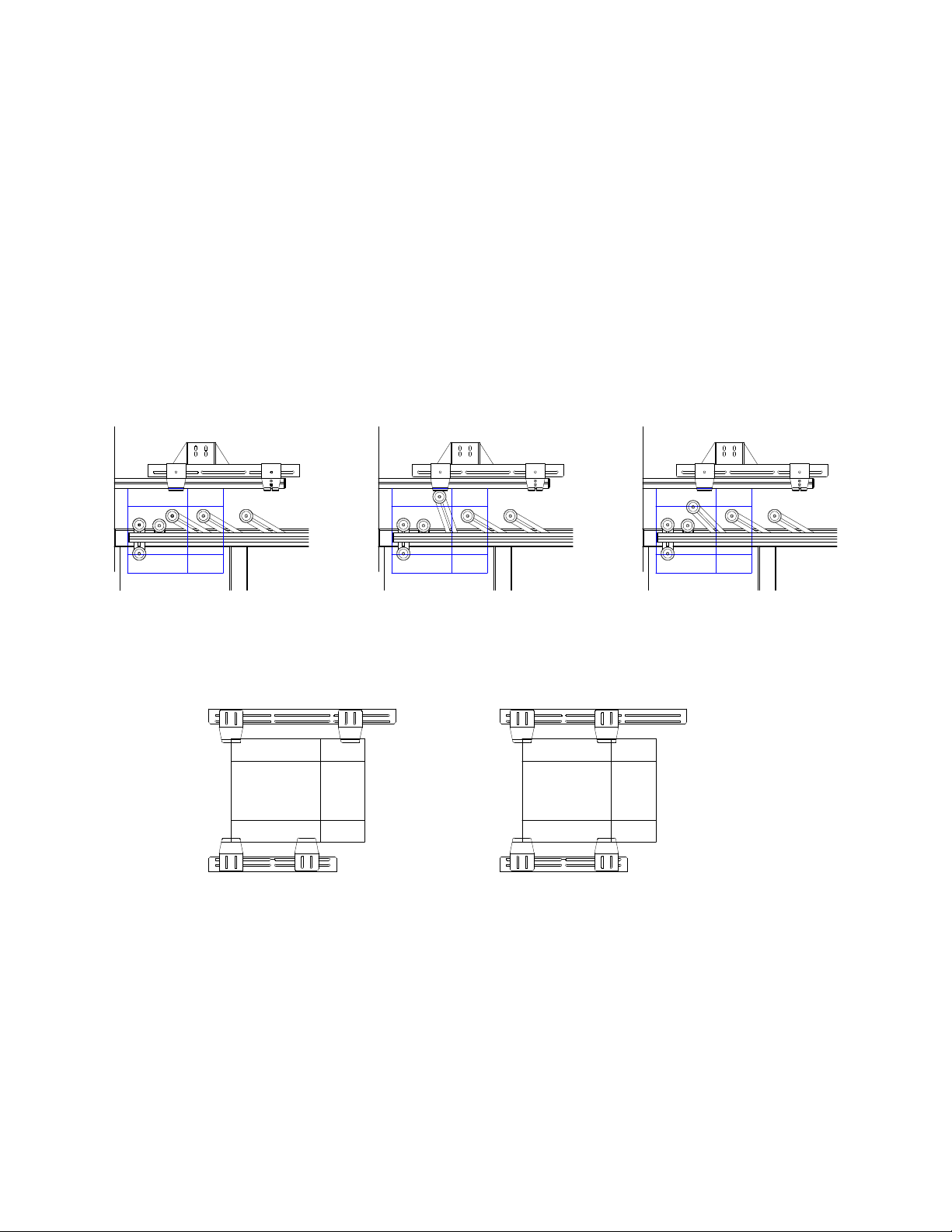

2. Adjust the location of Left//Right Belt (as Drawing 2) to t the wide of cartons (as

Drawing 1)

3. Adjust the location of Upper Working Table to t the height of carton plus half wide

(H+W/2). Notice: When the total is smaller than 300mm, adjust the location of

Sucking Plate rstly. Then adjust the location of Upper Working Table (as Drawing

2). Vacuum Cup can’t hit the stopper, Manual Valve of useless Vacuum Cup have to

be turn off.

4. Adjust the location of Magazine to the size of half wide (W/2).

5. Adjust the location of Carton Drawing Mechanism to the size of half wide (W/2).

6. Adjust the location of Carton Pushing Mechanism to length of carton (L).

Drawing 1

Page 8 of 36

L&R Belt

Upper working table

adjusting wheel

Drawing 2

Page 9 of 36

Notice:The machine is suitable for various wide range size of carton, so Vacuum Cup

and Stoppers are adjustable parts. If carton size is changed a lot for suitable position, all

adjustment might be necessary. So step G and H are not necessary.

7. G. The adjustment of Vacuum Cup can’t interfere other parts running. Please use

the Vacuum Cup as many as you could for proper function.

8. The folding line can’t be blocked by Up/Down Stopper.

9. Put Carton in the hopper, pre Power On, then turn on manual. Use Manual Mode to

complete a carton forming procedure. If carton sealing is not prefect, please conrm

the location of B,C,D,E,F. When carton sealing is perfect, turn on Auto and press

Continuous Cycle to start running.

Correct Incorrect

( ○) (╳) ( ╳)

Page 10 of 36

ABNORMAL REMEDY

1. Air Pressure is not enough,. Probable cause:

a. The air is not connected to pressure source or no compression air.

b. Air pressure is no enough.

c. Manual valve is not open.

2. Not reset: Motion don’t return to home position, just press ”Manual Reset”

3. Vacuum Cup effecting is not vacuum:

a. The inner lter of Vacuum Inspection need to clean.

b. The manual valve of useless sucker have not been turned off.

c. Vacuum Cup is sucking on the folding line.

4. Carton shortage indication:

a. No carton: Stop and supply carton.

b. Carton out of effort or black cartons used.

5. Carton drawing failure:

a. It’s failure to suck carton. So adjust Vacuum Cup and Up/down stopper to

adequate position. (As drawing as below)

b. The motion of front / rear / left / right ap folding is not precise.

6. Carton chocked: It’s too long for carton to stay at belt area. Probable causes:

a. Left / right belt is too wide or too narrow.

b. Upper working table is too low.

7. Taping trouble: caused by

a. No tape.

b. Taping Inspection is out of order.

8. Motor trouble: Motor has no power or motor is out of order.

9. Safety door doesn’t be closed: Active safety door have not been closed.

Page 11 of 36

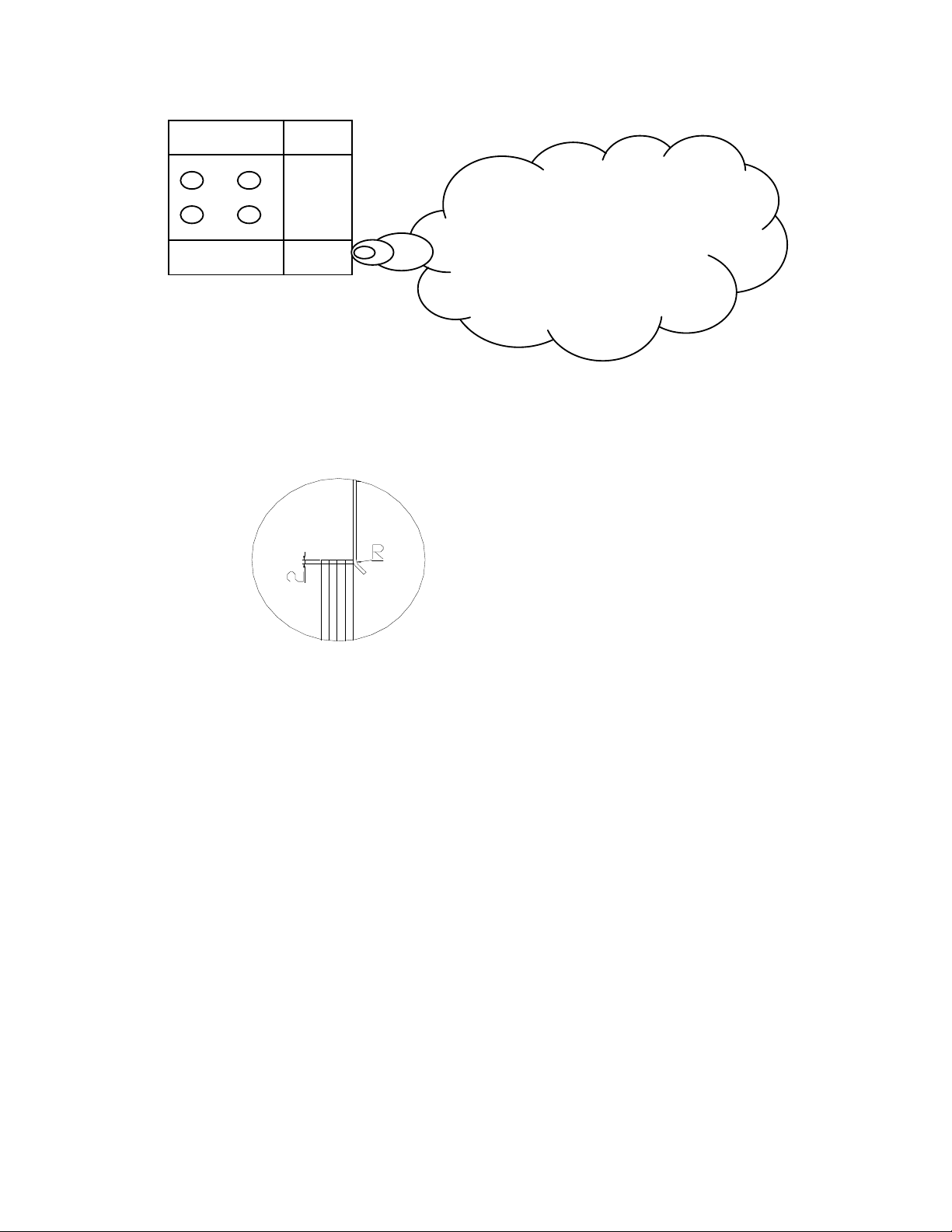

The vacuum cup can not

draw the case on the

folding line to prevent

from the air leaking.

a. After Up/Down stopper upward, the best distance is 2 mm between above

angle R and carton. If stopper is over high, carton. If stopper is over high, carton

will slip down or leap. If not, carton will not easy to be feed out due to strong

pressure.

b. Up/Down stopper position shouldn’t be against folding line.

c. The adjustment of Vacuum Cup can’t interfere other parts running.

d. The more Vacuum Cup to be used, better suction function. (As above drawing)

10.10. Trouble remedy: Press “ Alarm Reset” , solve trouble, then press “ Circle Motion”.

Page 12 of 36

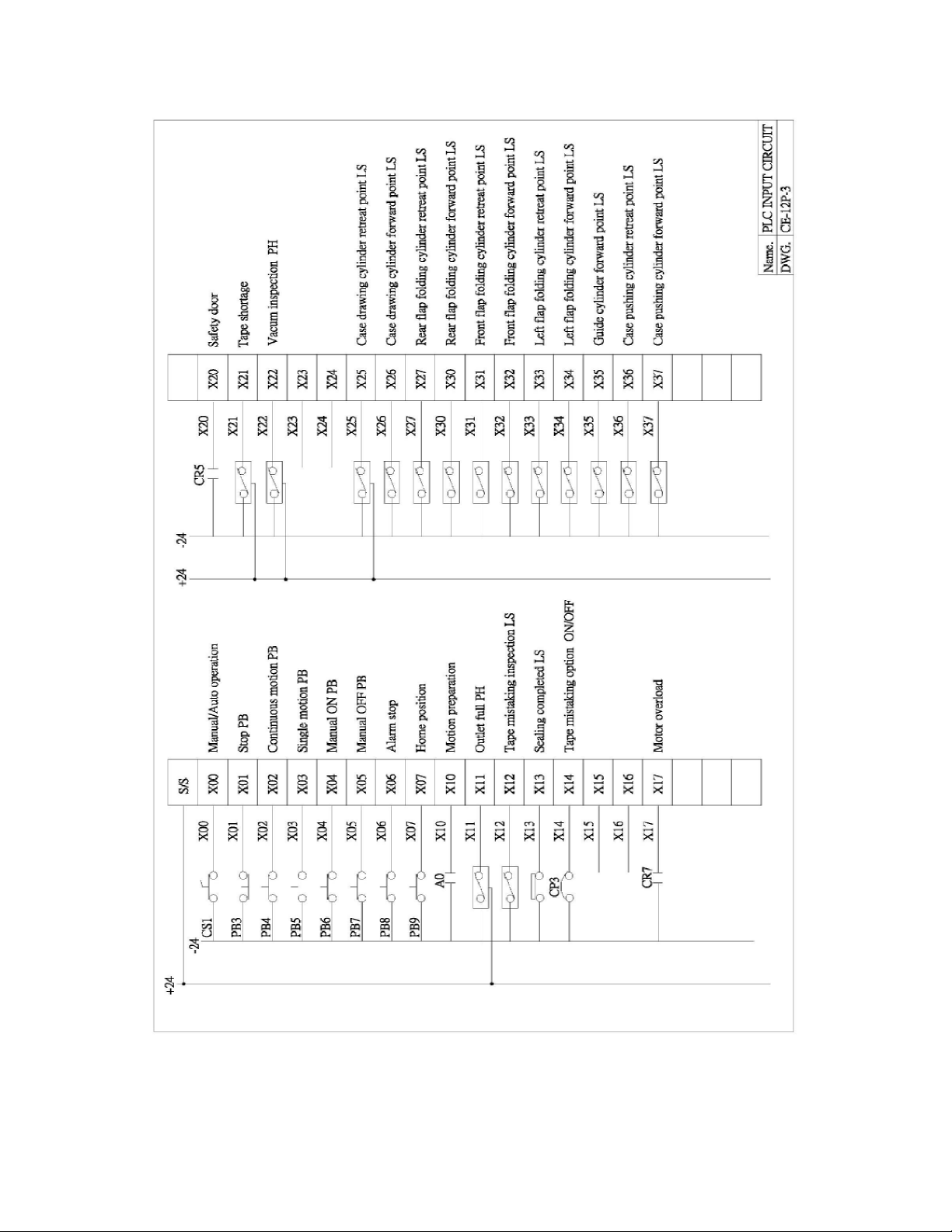

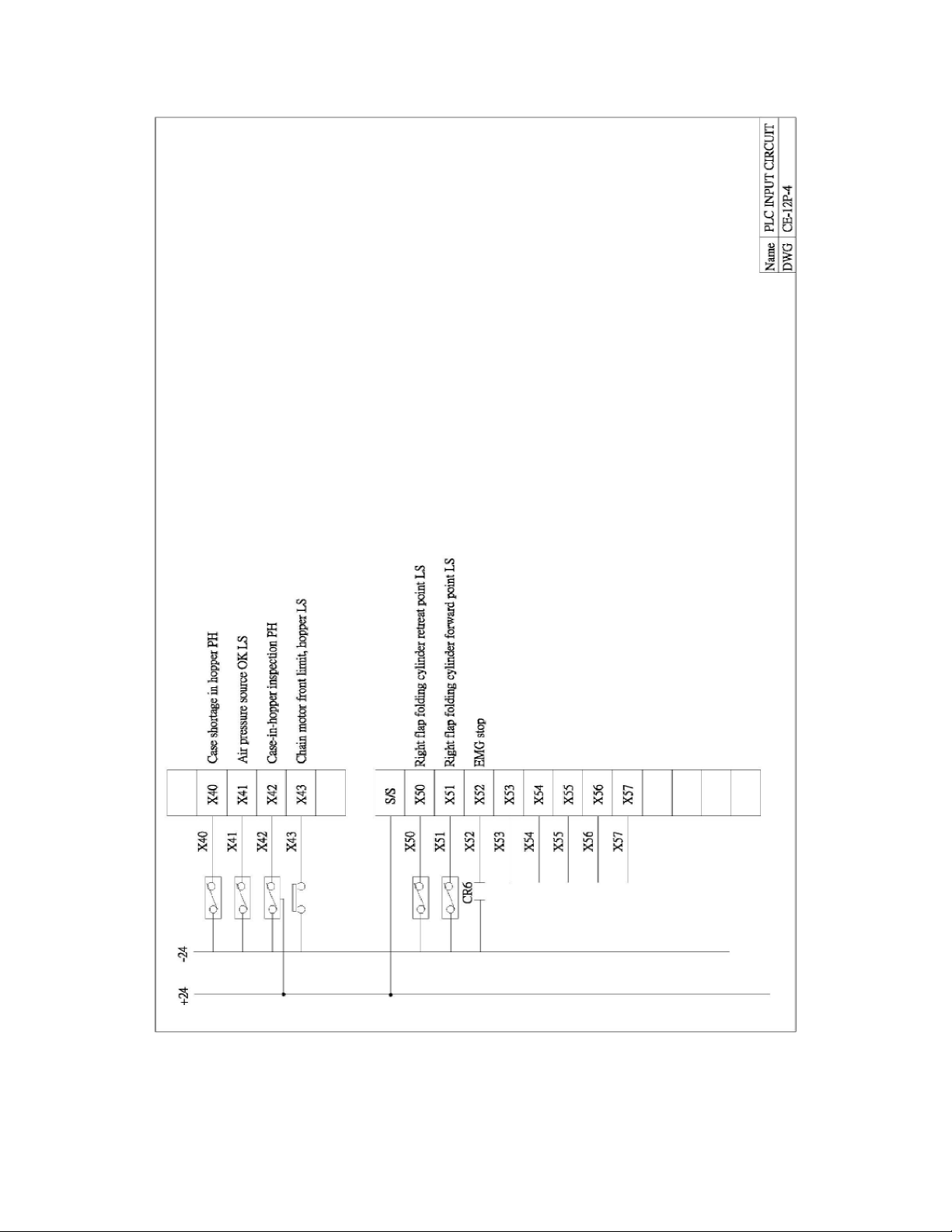

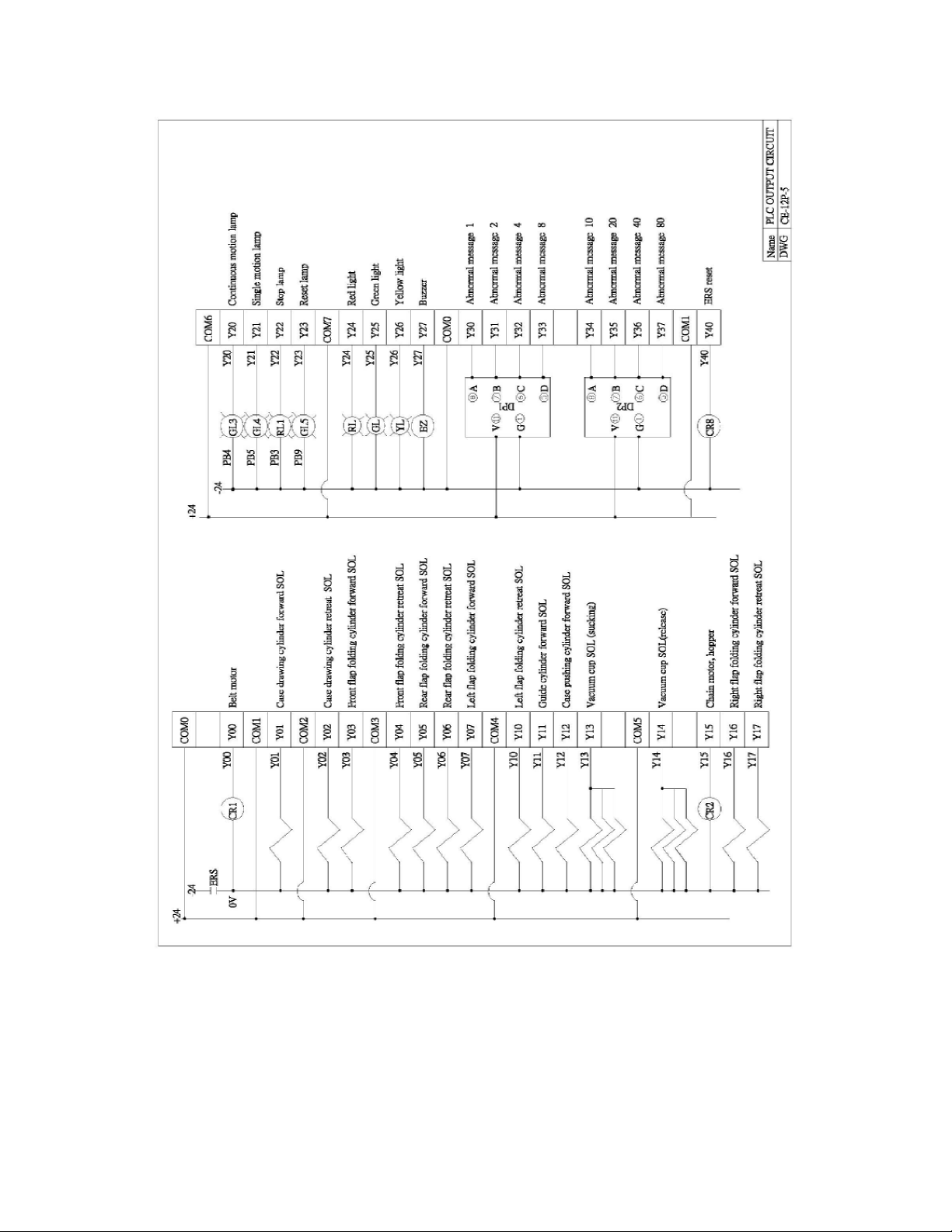

ELECTRIC CIRCUIT

Page 13 of 36

Page 14 of 36

Page 15 of 36

Page 16 of 36

Page 17 of 36

Page 18 of 36

Page 19 of 36

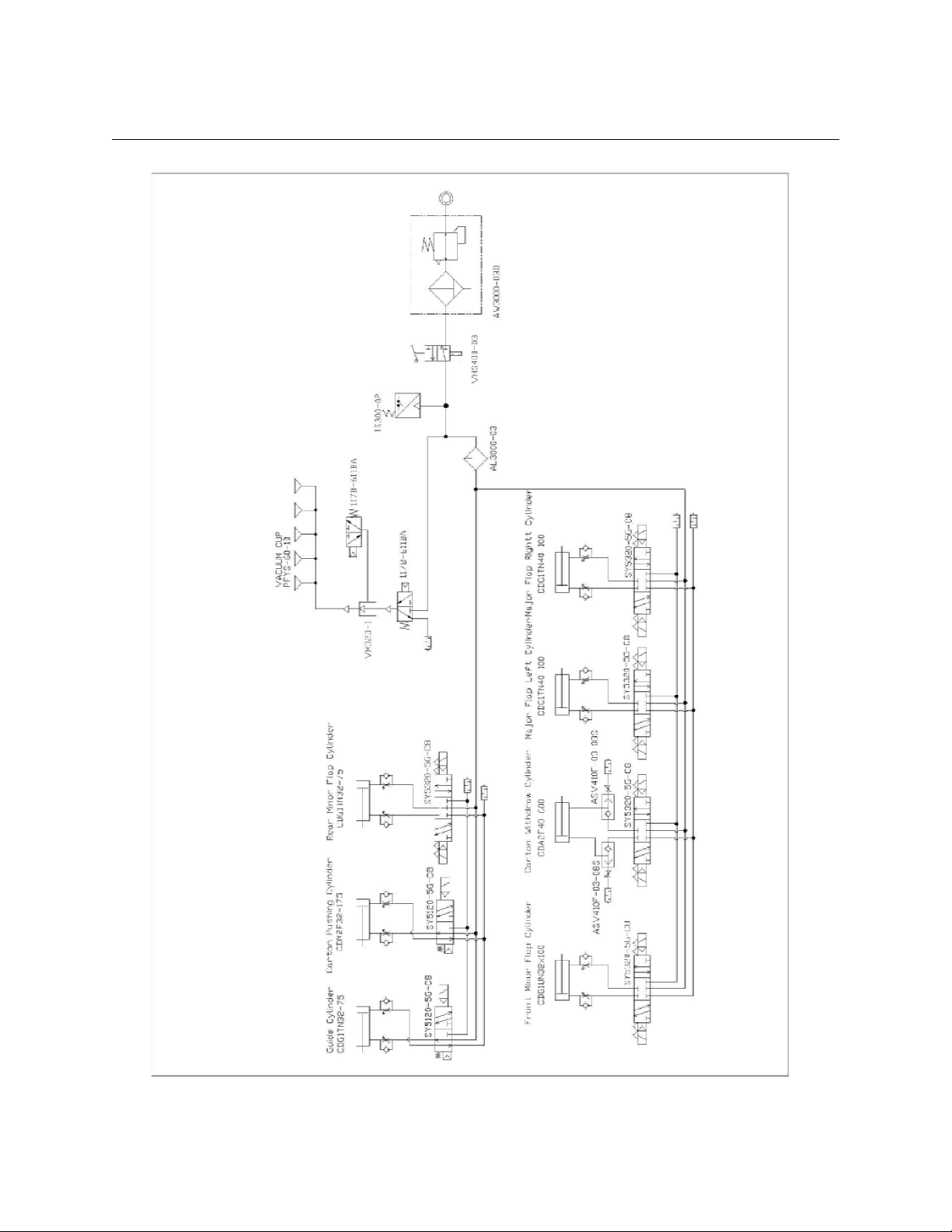

AIR PRESSURE CIRCUIT

Page 20 of 36

PNEUMATIC PART LIST

N9310-700

No. Part No. Description Q’ty

1. VM323-1 Vacuum pump 1

2. AW3000-03D Air lter 1

3. VHS400-03 Manual valve 1

4. IS300-02 Pressure inspecting switch 1

5. AL3000-03 Oil lter 1

6. SS5Y5-20-04 Solenoid valve w/ base 1

7. SS5Y5-20-03 Solenoid valve w/ base 1

8. SY5320-5G-C8 Solenoid valve 5

9. SY5120-5G-C8 Solenoid valve 2

10. 117B-611BA Solenoid valve 2

11. 101327601002 Pressure gauge 1

12. BVLC6-01 Closing valve 1

13. 33060806 Joint 1

14. 31260800 Adapt 1

15. 31260600 Adapt 2

FRONT FLAP FOLDING ASSEMBLY

M3303-20B

No. Part No. Description Q’ty

1. M3303-B01 Front ap folder 1

2. M3303-B02 Front ap folder mounting 1

3. M3303-B03 Bearing bushing 2

4. M3303-B04 Outfeed guide plate 1

5. Q1-201203 Washer 1

6. 81-3210 Cylinder 1

7. 81-3224 Cylinder 1

8. PHS10×1.25P Bearing 1

9. E00-2110 Ball bearing 2

Other manuals for CE-12P

1

Table of contents

Other Interpack Industrial Equipment manuals

Interpack

Interpack HSD2000 XS II Series User manual

Interpack

Interpack CE-12P User manual

Interpack

Interpack RSA 20-B User manual

Interpack

Interpack ETII+ LD User manual

Interpack

Interpack HSD2000 ET II RC User manual

Interpack

Interpack USA 2024-SB User manual

Interpack

Interpack USA 2024-SB DH User manual

Interpack

Interpack ipg RSA 2625-TB User manual