RSA 2625-TB RANDOM SEMI-AUTOMATIC CASE SEALER

Table of Contents

Chapter Title Page

1

GENERAL INFORMATION ........................................................................................ 1-1

1.1

Revision Control....................................................................................................................... 1-1

1.2

Technical Support .................................................................................................................... 1-1

1.3

Replacement Parts .................................................................................................................. 1-1

1.4

Field Service Assistance.......................................................................................................... 1-2

1.5

Warranty .................................................................................................................................. 1-2

1.6

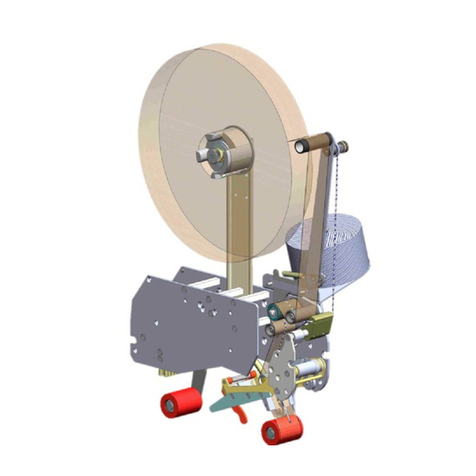

Description of RSA 2625-TB Random Semi-Automatic Case Sealer...................................... 1-4

2

IMPORTANT SAFEGUARDS..................................................................................... 2-1

2.1

Safety Label Descriptions ........................................................................................................ 2-1

2.2

Explanation of Signal Word Consequences ............................................................................ 2-4

2.3

Operator Skill Level Descriptions............................................................................................. 2-5

2.3.1

Skill “A” Machine Operator ................................................................................................... 2-5

2.3.2

Skill “B” Mechanical Maintenance Technician............................................................................. 2-5

2.3.3

Skill “C” Electrical Maintenance Technician ......................................................................... 2-5

2.3.4

Skill “D” Manufacturer’s Technician .............................................................................................. 2-5

3

SPECIFICATIONS...................................................................................................... 3-1

3.1

Machine Dimensions................................................................................................................ 3-1

3.2

Machine Operating Conditions ................................................................................................ 3-2

3.2.1

Power Requirements ............................................................................................................ 3-2

3.2.2

Operating Speed .................................................................................................................. 3-2

3.2.3

Tape Specifications .............................................................................................................. 3-2

3.2.4

Case Specifications .............................................................................................................. 3-2

4

SET-UP PROCEDURES ............................................................................................ 4-1

4.1

Receiving and Handling ........................................................................................................... 4-1

4.2

Table Leveling.......................................................................................................................... 4-2

4.3

Installation of External In-Feed and Exit Conveyors................................................................ 4-3

4.4

Control Box .............................................................................................................................. 4-3

4.5

Connecting Utilities .................................................................................................................. 4-4

4.5.1

Electrical Utilities................................................................................................................... 4-4

4.5.2

Air Connection ...................................................................................................................... 4-5

4.5.3

Pneumatic Adjustment.......................................................................................................... 4-5

4.6

Tape Loading ........................................................................................................................... 4-6

4.7

Tape Threading Preparation.................................................................................................... 4-7

4.8

Tape Threading........................................................................................................................................4-8